WO2014208642A1 - パンツ型着用物品及びその製造方法 - Google Patents

パンツ型着用物品及びその製造方法 Download PDFInfo

- Publication number

- WO2014208642A1 WO2014208642A1 PCT/JP2014/066927 JP2014066927W WO2014208642A1 WO 2014208642 A1 WO2014208642 A1 WO 2014208642A1 JP 2014066927 W JP2014066927 W JP 2014066927W WO 2014208642 A1 WO2014208642 A1 WO 2014208642A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- exterior body

- wearing article

- type wearing

- pants

- side seal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15707—Mechanical treatment, e.g. notching, twisting, compressing, shaping

- A61F13/15739—Sealing, e.g. involving cutting

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15585—Apparatus or processes for manufacturing of babies' napkins, e.g. diapers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/496—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies in the form of pants or briefs

- A61F13/4963—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies in the form of pants or briefs characterized by the seam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1629—Laser beams characterised by the way of heating the interface

- B29C65/1648—Laser beams characterised by the way of heating the interface radiating the edges of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1629—Laser beams characterised by the way of heating the interface

- B29C65/1654—Laser beams characterised by the way of heating the interface scanning at least one of the parts to be joined

- B29C65/1661—Laser beams characterised by the way of heating the interface scanning at least one of the parts to be joined scanning repeatedly, e.g. quasi-simultaneous laser welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1696—Laser beams making use of masks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/74—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by welding and severing, or by joining and severing, the severing being performed in the area to be joined, next to the area to be joined, in the joint area or next to the joint area

- B29C65/747—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by welding and severing, or by joining and severing, the severing being performed in the area to be joined, next to the area to be joined, in the joint area or next to the joint area using other than mechanical means

- B29C65/7473—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by welding and severing, or by joining and severing, the severing being performed in the area to be joined, next to the area to be joined, in the joint area or next to the joint area using other than mechanical means using radiation, e.g. laser, for simultaneously welding and severing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

- B29C66/1122—Single lap to lap joints, i.e. overlap joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/43—Joining a relatively small portion of the surface of said articles

- B29C66/431—Joining the articles to themselves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/723—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined being multi-layered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/729—Textile or other fibrous material made from plastics

- B29C66/7294—Non woven mats, e.g. felt

- B29C66/72941—Non woven mats, e.g. felt coated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/834—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools moving with the parts to be joined

- B29C66/8341—Roller, cylinder or drum types; Band or belt types; Ball types

- B29C66/83431—Roller, cylinder or drum types; Band or belt types; Ball types rollers, cylinders or drums cooperating with bands or belts

- B29C66/83433—Roller, cylinder or drum types; Band or belt types; Ball types rollers, cylinders or drums cooperating with bands or belts the contact angle between said rollers, cylinders or drums and said bands or belts being a non-zero angle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/834—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools moving with the parts to be joined

- B29C66/8341—Roller, cylinder or drum types; Band or belt types; Ball types

- B29C66/83431—Roller, cylinder or drum types; Band or belt types; Ball types rollers, cylinders or drums cooperating with bands or belts

- B29C66/83435—Roller, cylinder or drum types; Band or belt types; Ball types rollers, cylinders or drums cooperating with bands or belts said rollers, cylinders or drums being hollow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/14—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using wave energy, i.e. electromagnetic radiation, or particle radiation

- B29C65/16—Laser beams

- B29C65/1603—Laser beams characterised by the type of electromagnetic radiation

- B29C65/1612—Infrared [IR] radiation, e.g. by infrared lasers

- B29C65/1619—Mid infrared radiation [MIR], e.g. by CO or CO2 lasers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/13—Single flanged joints; Fin-type joints; Single hem joints; Edge joints; Interpenetrating fingered joints; Other specific particular designs of joint cross-sections not provided for in groups B29C66/11 - B29C66/12

- B29C66/137—Beaded-edge joints or bead seals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/73—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/739—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of the parts to be joined being a thermoplastic or a thermoset

- B29C66/7392—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of at least one of the parts being a thermoplastic

- B29C66/73921—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the intensive physical properties of the material of the parts to be joined, by the optical properties of the material of the parts to be joined, by the extensive physical properties of the parts to be joined, by the state of the material of the parts to be joined or by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of the parts to be joined being a thermoplastic or a thermoset characterised by the material of at least one of the parts being a thermoplastic characterised by the materials of both parts being thermoplastics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/48—Wearing apparel

- B29L2031/4871—Underwear

- B29L2031/4878—Diapers, napkins

Definitions

- the present invention relates to a pants-type wearing article having a side seal portion.

- a conventional pant-type wearing article includes an absorbent main body and an exterior body that forms the outer surface of the wearing article, and both side edges of the exterior body in the front body and both side edges of the exterior body in the back body are joined together.

- a pants-type disposable diaper in which a side seal portion is formed is known.

- Patent Document 1 discloses a three-stage joint to the side seal part from the viewpoint of sufficient joint strength that does not come off while wearing a diaper and improvement in tearability. It is described that the strengths coexist.

- a heat roll device has been widely used for joining stacked sheets.

- the side seal portion is heated as described later. It is formed using a roll device.

- a method of welding using laser light is also known.

- Patent Document 2 a sheet laminate in which a plurality of sheets are stacked is deformed into a shape along the peripheral surface of a rotary roll having a laser light transmitting portion on the peripheral surface, and the sheet is conveyed. A method of irradiating the laminated body with laser light from the inside of the rotary roll to fuse the sheets in the laminated sheet is described.

- ⁇ Pants-type disposable diapers are usually manufactured through the following processes. That is, a diaper continuous body in which a plurality of diapers are arranged in one direction (conveying direction) is manufactured, and the front body side exterior body and the back body side of the diaper continuous body are overlapped with each other at a site where the side seal portion is to be formed. After the exterior body is joined by a joining means such as a heat roll device, the joint part is cut by a cutting means such as a cutter, thereby being divided into individual diapers.

- the side seal part of the conventional pants-type disposable diaper manufactured in this way is formed by overlapping the side edge part of the front body and the side edge part of the back body in the shape of a palm, and the top of the palm-shaped portion is Since it protrudes outward from the diaper than the part, it can be easily recognized visually.

- the palm-shaped side seal part obtained through the above-described manufacturing process is likely to be relatively hard due to the wide joining width between the exterior bodies and the exterior bodies being strongly pressed during joining. There is room for improvement in terms of wearing feeling and touch of the outer surface. Also, if there is a difference in the number of stacked sheets at the site forming the side seal part, due to the difference, a difference in unintentional bonding strength occurs in the side seal part, for example, the bonding strength on the waist opening side is Since it becomes too high, it becomes difficult to tear the side seal part from the waist opening side after use of the diaper.

- the present invention includes an exterior body that forms the outer surface of a worn article, and a pair of side seal portions, a waist opening, and both side edges of the exterior body in the front body and both side edges of the exterior body in the back body are joined together

- the present invention relates to a pants-type wearing article in which a pair of leg openings are formed.

- the side seal portion includes a seal edge portion in which the edge portion of the exterior body in the front body and the edge portion of the exterior body in the back body are joined by a continuous linear fusion portion extending in the longitudinal direction of the side seal portion. Formed.

- the seal edge is formed over a plurality of portions where the total number of stacked sheets of the sheet constituting the outer body on the front body side and the sheet constituting the outer body on the rear body side is different from each other, and the seal edge Are equal in fusion strength at the plurality of portions.

- the present invention includes an exterior body that forms the outer surface of the wearing article, and a pair of side seal portions and a waist opening are formed by joining both side edges of the exterior body in the front body and both side edges of the exterior body in the back body A pair of leg openings, and the side seal portion is a continuous line in which the edge of the exterior body in the front body and the edge of the exterior body in the back body extend in the longitudinal direction of the side seal portion.

- the method for producing a pants-type wearing article of the present invention includes a polymerization pressurizing step of applying pressure to a portion where a side seal portion is to be formed in a belt-shaped exterior body in a state where the front body side and the back body side are overlapped, By dividing the exterior body by irradiating a laser beam through a light passage portion extending in a direction intersecting the transport direction of the exterior body, to the formation planned site of the side seal portion in a pressure state, A side seal portion forming step of forming the seal edge portion by fusing the cut edge portions of the laminated exterior body produced by the division, and further comprising any one of the following (1) to (3) Is provided.

- the laser beam is applied to a plurality of portions where the total number of stacked sheets of the sheet constituting the outer body on the front body side and the sheet constituting the outer body on the rear body side are different from each other. The irradiation is performed with different output or scanning speed for each part, and the difference in the fusion strength of the seal edge formed in each part is reduced.

- the laser beam is applied to a plurality of portions where the total number of stacked sheets of the sheet constituting the front body side exterior body and the rear body side exterior body is different from each other. Irradiation is performed through light passing portions having different widths for each portion, and the difference in the fusion strength of the seal edge portion formed in each portion is reduced.

- a front body side exterior body is configured by having a projecting portion projecting toward the exterior body side in the vicinity of the light passage portion on the outer surface in contact with the belt-shaped exterior body.

- a support member having a different protruding height or width of the protruding portion is used. Irradiation is performed to reduce the difference in fusion strength between the seal edges formed at the respective portions.

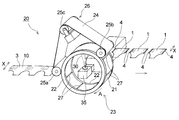

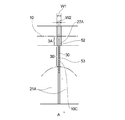

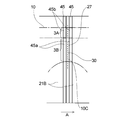

- FIG. 1 is a schematic perspective view which shows an example of the manufacturing method of the underpants type disposable diaper using the laser type

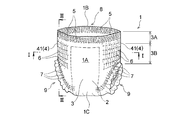

- FIG. 2 is a perspective view schematically showing a pants-type disposable diaper according to the first embodiment of the present invention.

- FIG. 3 is a cross-sectional view schematically showing a cross section taken along line II of FIG.

- FIG. 4 is a plan view schematically showing a developed and extended state of the diaper shown in FIG.

- FIG. 5 is a perspective view schematically showing a manufacturing process of the diaper continuous body shown in FIG. 1.

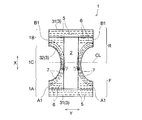

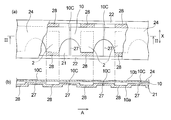

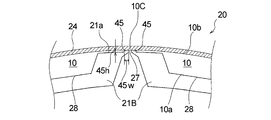

- FIGS. 7 (a) and 7 (c) are diagrams schematically showing a state where the diaper continuous body is introduced into the laser-type bonding apparatus shown in FIG. 1 in a plane

- FIG. FIG. 6B is a cross-sectional view taken along the line II-II of FIG. 6A.

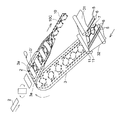

- FIGS. 7 (a) to 7 (c) show the side seal portion (seal edge) at the same time that the continuous diaper (strip-shaped exterior body) is cut using the laser type bonding apparatus shown in FIG. It is explanatory drawing explaining a mode that it forms.

- FIG. 8 is a view corresponding to FIG. 7C of another example of a method for manufacturing a pants-type disposable diaper using the laser-type bonding apparatus shown in FIG.

- FIG. 9 (a) and 9 (b) are respectively a side seal portion (seal edge portion) on one side and the vicinity thereof in FIG. 3 in a state where the waist opening of the diaper shown in FIG. 3 is expanded.

- . 10 is a cross-sectional view schematically showing a cross section taken along line III-III in FIG.

- FIG. 11 is a view corresponding to a partially enlarged view of FIG. 6A in the first embodiment of the manufacturing method of the present invention.

- FIG. 12 is a view corresponding to a partially enlarged view of FIG. 6A in the second embodiment of the manufacturing method of the present invention.

- FIG. 13: is a schematic cross section which shows the light passage part and its vicinity of the laser beam in the laser type joining apparatus used for the 3rd embodiment of the manufacturing method of this invention.

- FIG. 14 is a view showing a state in which the light passing portion of the laser beam and the vicinity thereof in the laser type apparatus shown in FIG. 13 are viewed from the outer surface side of the cylindrical roll on which the diaper continuous body (band-shaped exterior body) is arranged. is there. 15 (a) to 15 (c) are cross-sectional views showing other embodiments of the pant-type wearing article of the present invention, each corresponding to FIG.

- the present invention relates to a pants-type wearing article that has a side seal portion that is excellent in flexibility or touch and is also excellent in tearing of the side seal portion, and a method for manufacturing the same.

- One of the main features of the present invention includes an exterior body that forms an outer surface of a worn article, and a pair of side seals in which both side edges of the exterior body in the front body and both side edges of the exterior body in the back body are joined.

- a pant-type wearing article in which a waist opening and a pair of leg openings are formed, the side seal part is the edge of the exterior body in the front body and the edge of the exterior body in the back body is the side seal

- the number of sheets stacked in the part where the seal edge is formed is the seal edge.

- the difference is that a difference in bonding strength caused by the difference does not occur (hereinafter also referred to as a means for equalizing fusion strength).

- the use of this means for uniformizing the fusion strength is, for example, irradiating a predetermined portion of the belt-shaped exterior body in a state where the front body side and the back body side are overlapped with each other in the manufacturing process of the pant-type wearing article, for example. Then, at the same time as dividing the exterior body into lengths for individual wearing articles, the cut edges of the laminated exterior body produced by the separation are fused together to form a pair of side seal portions. It is particularly useful in cases.

- FIG. 1 shows an outline of a manufacturing method of a pants-type disposable diaper using a laser-type joining device, which can be applied to the manufacturing method of a pants-type disposable diaper that is the first embodiment of the manufacturing method of the present invention.

- the pants-type disposable diaper 1 (hereinafter also referred to as “diaper 1”) of the first embodiment of the pants-type wearing article can be manufactured using this laser-type joining device or a part of which is improved.

- the diaper 1 of 1st Embodiment is provided with the absorptive main body 2 and the exterior body 3 which forms the outer surface of a wearing article as shown in FIGS.

- the exterior in front body F (abdominal side part 1A)

- the left and right side edges A1, A1 along the vertical direction X of the body 3 and the left and right side edges B1, B1 along the vertical direction X of the exterior body 3 in the back body R (back side part 1B) are joined together to form a pair of sides.

- a pants-type disposable diaper in which seal portions 4 and 4, a waist opening 8 and a pair of leg openings 9 and 9 are formed.

- the exterior body 3 is positioned on the non-skin contact surface side of the absorbent main body 2 and fixes the absorbent main body 2.

- the pair of side seal portions 4, 4 in the diaper 1 extends in the longitudinal direction of the side seal portion 4, with the edge of the exterior body 3 in the front body F and the edge of the exterior body 3 in the back body R, respectively.

- the sealing edge part 41 couple

- the diaper 1 has a longitudinal direction X corresponding to the wearer's front-rear direction and a lateral direction Y orthogonal to the wearer's front-rear direction in a developed and extended plan view as shown in FIG.

- the diaper 1 can be divided into a crotch part 1C arranged at the crotch part at the time of wearing, and an abdominal side part 1A and a back side part 1B located in the longitudinal direction X.

- the exterior body 3 in the crotch part 1 ⁇ / b> C is formed with recesses for forming leg openings 9, 9 at the left and right side edges along the vertical direction X.

- the diaper 1 can be divided into a front body F and a back body R with a virtual center line CL that bisects the diaper 1 in the vertical direction X as a boundary.

- a skin contact surface is a surface directed to a wearer's skin side at the time of wearing in a pants type wearing article or its constituent member (for example, an absorptive main part), and a non-skin contact surface is In the pants-type wearing article or its constituent members, it is a surface directed to the side opposite to the wearer's skin side (clothing side) when worn.

- the vertical direction X corresponds to the direction (longitudinal direction) along the long side of the absorbent main body 2 which is a disposable diaper or its constituent member

- the horizontal direction Y is the absorbent which is a disposable diaper or its constituent member. It coincides with the width direction of the main body 2.

- the absorbent main body 2 has a vertically long shape in one direction (longitudinal direction X), and a surface sheet (not shown) that forms a skin contact surface; A back sheet (not shown) that forms a non-skin contact surface, and a liquid-retaining absorbent (not shown) interposed between the two sheets. And has a long shape in the same direction.

- the absorbent main body 2 is joined to a central portion of the outer package 3 by a known joining means (adhesive or the like) so that the longitudinal direction thereof coincides with the longitudinal direction X of the diaper 1 in the unfolded and extended state.

- the expanded and extended state means that the side seal portion is peeled off, the diaper is set in the expanded state, the elastic member of each part is expanded in the expanded diaper, and the design dimensions (the influence of the elastic member is eliminated at all). In this state, it is expanded until it becomes the same size as when expanded in a flat shape.

- the outer package 3 is arranged on the outer layer sheet 31 that forms the outer surface of the diaper 1 (non-skin contact surface of the outer package 3), and on the inner surface side of the outer layer sheet 31.

- An inner layer sheet 32 that forms the inner surface of 1 (skin contact surface of the exterior body 3), and a plurality of thread-like or belt-like elastic members 5, 6, and 7 fixed between the sheets 31 and 32 with an adhesive. It is configured to include.

- the two sheets 31 and 32 are joined to each other at a predetermined site by an adhesive or heat seal (not shown).

- the exterior body 3 (the outer layer sheet 31 and the inner layer sheet 32) includes a resin material and is formed using the resin material as a main component.

- the resin material includes a heat-sealable synthetic resin such as polyethylene, polyethylene terephthalate, and polypropylene.

- the nonwoven fabric include air-through nonwoven fabric, heat roll nonwoven fabric, spunlace nonwoven fabric, spunbond nonwoven fabric, and melt blown nonwoven fabric.

- the manufacturing method of the diaper 1 which is the 1st embodiment of the manufacturing method of this invention makes the formation plan site

- a laser beam By irradiating a laser beam through a light passing portion 27 extending in a direction intersecting the transport direction A of the outer package 3 to the formation pressure site of the polymerization pressure step and the side seal portion in a pressurized state And a side seal part forming step of forming the side seal part 4 by fusing the cut edges of the laminated outer case produced by the division, and cutting the outer package 3.

- the main body fixing process which fixes the absorptive main body 2 to the strip

- the belt-shaped outer package 3 (outer layer sheet 31, inner layer sheet 32) is folded in the width direction.

- the front body side and the back body side of the strip-shaped exterior body 3 to which the absorbent main body 2 is fixed are overlapped with each other, whereby “a precursor of a pants-type disposable diaper in which a side seal portion is not formed is unidirectional.

- a continuous diaper 10 is produced.

- sticker part formation process as shown in FIG. 1, the strip

- the pants comprising the exterior body 3 having a pair of side seal portions 4 and 4 by fusing the cut edges of the plurality of exterior bodies 3 (the outer layer sheet 31 and the inner layer sheet 32) in a laminated state generated by The mold disposable diaper 1 is continuously manufactured.

- the waist elastic member 5 forming the waist gather, the waist elastic member 6 forming the waist gather, and the leg elastic member 7 forming the leg gather have a predetermined elongation rate.

- a plurality of each are arranged in the stretched state.

- the leg elastic member 7 is arranged while forming a predetermined leg-circumferential pattern via a known swing guide (not shown) that reciprocates perpendicular to the sheet flow direction.

- an adhesive coating machine (see FIG. (Not shown) to apply hot melt adhesive.

- the elastic members such as the waist elastic member 5 and the waistline elastic member 6 are divided by the laser light irradiation in the sheets 31 and 32 (the portion where the side seal portion 4 is to be formed, FIG. 6A). And when it is arranged in an extended state so as to straddle the part to be divided indicated by reference numeral 10C in FIG. 6 (b), avoids inconveniences such as significant shrinkage of the elastic member and disconnection of the elastic member after the division. Therefore, it is preferable to apply an adhesive to the portion and the vicinity thereof.

- a hot melt adhesive is intermittently applied to the waist elastic member 5 and the waist elastic member 6 by an adhesive application machine (not shown) before being arranged between the sheets 31 and 32. May be.

- a plurality of joint portions for joining the belt-like outer layer sheet 31 and the belt-like inner layer sheet 32 between the two adjacent waistline elastic members 6 and 6, It is also preferable to use a convex roll and a corresponding joining means (not shown) such as an anvil roll. Thereafter, if necessary, a plurality of waistline elastic members 6 and a plurality of leg portion elasticities are made by using elastic member precut means (not shown) so as to correspond to positions where the absorbent main body 2 described later is disposed. The member 7 is pressed and divided into a plurality of pieces so that the contraction function is not expressed. Examples of the elastic member precut means include an elastic member dividing portion used in the method for manufacturing a composite elastic member described in JP-A-2002-253605.

- an adhesive such as a hot melt adhesive is applied in advance to the absorbent main body 2 manufactured in a separate process (not shown), and the absorbent main body 2 is rotated by 90 degrees. Then, it is intermittently supplied and fixed on the inner layer sheet 32 constituting the strip-shaped outer package 3.

- the adhesive for fixing the absorbent main body may be preliminarily applied not to the absorbent main body 2 but to the position where the absorbent main body 2 is arranged in the inner layer sheet 32.

- leg hole LO ' is formed inside the annular part enclosed by the leg part elastic member 7 in the strip

- This leg hole forming step can be carried out by using a technique similar to that in a conventional method for manufacturing this type of article, such as a rotary cutter and a laser cutter.

- the leg hole is formed after the absorbent main body 2 is arranged on the belt-shaped outer package 3, but the leg hole may be formed before the absorbent main body 2 is arranged.

- the strip-shaped exterior body 3 is folded in the width direction (a direction perpendicular to the conveying direction of the exterior body 3). More specifically, as shown in FIG. 5, both side portions 3 a, 3 a along the transport direction of the strip-shaped exterior body 3 are folded back so as to cover both ends in the longitudinal direction of the absorbent main body 2. After fixing both ends in the longitudinal direction, the outer package 3 is folded in the width direction together with the absorbent main body 2 (polymerization step in the polymerization pressure step). In this way, the diaper continuous body 10 is obtained.

- the diaper continuous body 10 thus manufactured is irradiated with laser light using a laser bonding apparatus 20 to form a pair of side seal portions 4 and 4 (side seal portion).

- a pants-type disposable diaper 1 having an exterior body 3 having a pair of side seal portions 4 is continuously manufactured.

- the laser type bonding apparatus 20 will be described.

- the laser type bonding apparatus 20 is arranged in a hollow cylindrical roll 23 that is rotationally driven in the direction of arrow A and a hollow portion of the cylindrical roll 23 as shown in FIG.

- a belt-type pressure device 26 including an irradiation head 35 that irradiates a laser beam 30 toward a cylindrical (annular) support member 21 that forms a peripheral surface portion 23, and an endless pressure belt 24 (pressing member).

- the laser-type joining device 20 includes a tension adjusting mechanism (not shown) that can adjust the tension of the pressure belt 24 wound around the outer peripheral surface of the annular support member 21 (the peripheral surface portion of the cylindrical roll 23). By adjustment, the pressure applied to the diaper continuous body 10 (sheet laminated body) can be appropriately adjusted by the support member 21 and the pressure belt 24.

- the support member 21 forms a peripheral surface portion (contact portion with the workpiece) of the cylindrical roll 23, and is between a pair of annular frames 22, 22 that form both ends of the cylindrical roll 23 in the rotation axis direction. It is pinched and fixed.

- the support member 21 is made of a metal material such as iron, aluminum, stainless steel, or copper, or a material having heat resistance such as ceramics.

- the support member 21 has a light passage portion 27 through which laser light can pass. As shown in FIG. 1, FIG. 6A and FIG. 6B, the support member 21 has a slit-like opening 27 that penetrates the support member 21 in the thickness direction as a light passage portion. .

- the opening 27 has a rectangular shape in plan view, and the longitudinal direction of the opening 27 intersects with the conveyance direction A of the diaper continuous body 10 (band-shaped exterior body 3).

- a plurality of cylinders are formed at predetermined intervals in the circumferential direction of the cylindrical support member 21 so as to coincide with the direction parallel to the axial length direction of the rotation shaft (the direction indicated by the symbol X in FIG. 6A).

- the support member 21 allows the laser light to pass through the opening 27, but does not allow the laser light to pass (transmit) at portions other than the opening 27.

- a method of forming the opening 27 in the support member 21 1) etching, punching, laser processing, or the like at a predetermined position of the support member 21 made of a single annular member having the same length as the circumferential length of the annular frame 22. 2)

- the support member 21 is replaced with a single annular member, and a plurality of curved rectangular members are used as the support member 21, and the plurality of members are connected between the pair of frames 22, 22.

- a method of arranging the frame body 22 at a predetermined interval in the circumferential direction may be mentioned.

- the interval between two adjacent members forms a slit-shaped opening 27.

- the method 2) is used.

- each of these members is the cylindrical shape of the cylindrical roll 23. It is rotationally moved in a curved state corresponding to the peripheral surface portion.

- a light passage portion through which laser light can pass is a support member.

- the parting portion 10C that overlaps with the opening 27 itself is not sandwiched between the members 21 and 24, but the vicinity thereof, that is, the portion that overlaps with the vicinity of the opening 27 (opening edge) in the diaper continuous body 10. Is sandwiched between the two members 21 and 24, and therefore does not move before and after the irradiation of the laser beam, and therefore, the cutting edge portion generated by the division of the diaper continuous body 10 by the irradiation of the laser beam does not move. That is, the parting planned portion 10C of the diaper continuous body 10 (portion overlapping the opening 27 in the sheet laminate) is a portion restrained by the pressing force between the members 21 and 24, and the pressing force is practically the same. It is an affected part.

- the support member 21 has a recess 28 on its outer surface (contact surface with the workpiece).

- a plurality of recesses 28 are formed at predetermined intervals in the circumferential direction of the cylindrical support member 21, and a slit-shaped opening 27 is formed in a region (convex part) located between two adjacent recesses 28, 28. Is formed.

- the opening 27 is formed in the center in the circumferential direction of the cylindrical support member 21 in the convex portion.

- the relative thickness of the diaper continuous body 10 is relatively small. It is possible to introduce the diaper continuous body 10 onto the outer surface of the support member 21 so that a large portion (for example, an arrangement region of the absorbent main body 2) is accommodated in the recess 28. Then, when the diaper continuous body 10 is introduced onto the support member 21 in such a manner, as shown in FIG. 6B, the contact surface (the other surface) of the diaper continuous body 10 with the pressure belt 24 (pressing member).

- the belt-type pressure device 26 includes an endless pressure belt 24 (pressing member) and three rolls 25a, 25b, and 25c that rotate while the pressure belt 24 is stretched.

- the rolls 25a, 25b, and 25c may be drive rolls or driven rolls that rotate with the pressure belt 24.

- the pressure belt 24 moves at the same speed as the cylindrical roll 23 (supporting member 21) by using any one or more of the rolls 25a, 25b, and 25c as a driving roll or rotating with the cylindrical roll 23.

- the support member 21 and the pressure belt 24 are preferably maintained in a predetermined temperature range by air cooling, water cooling, or the like.

- a metal or resin belt having heat resistance capable of withstanding the heat generated during processing can be used, for example, a metal material such as iron, aluminum, stainless steel, or the like. Can be used.

- a belt that does not transmit the laser beam irradiated to the workpiece strip-shaped outer package 3 is usually used. You can also.

- an irradiation head 35 that irradiates a laser beam 30 toward a support member 21 that forms a peripheral surface portion of the cylindrical roll 23 is provided in the hollow portion of the hollow cylindrical roll 23.

- the irradiation head 35 is a galvano scanner (device having a mirror on the motor shaft) that freely scans the laser light 30, and the laser light 30 is in a direction parallel to the rotation axis of the cylindrical roll 23 (reference numeral in FIG. 6A).

- a mechanism for making the spot diameter of the laser beam 30 constant is provided.

- the laser irradiation mechanism has such a configuration, so that the irradiation point of the laser light 30 is the circumferential direction of the cylindrical roll 23 and a direction orthogonal to the circumferential direction (a direction indicated by a symbol X in FIG. 6A). It can be arbitrarily moved in both directions of a direction parallel to the rotation axis of the roll 23).

- the diaper continuous body 10 includes a support member 21 that forms a peripheral surface portion of a cylindrical roll 23 that is rotationally driven in the direction of arrow A in a state where a predetermined tension is applied by a guide roll (not shown). After being transported by a predetermined distance in the circumferential direction by rotation of the cylindrical roll 23 so as to be wound around the support member 21, it is separated from the support member 21 by an unillustrated lead roll, nip roll or the like. . As described above, the diaper continuous body 10 is wound around the support member 21 forming the peripheral surface portion of the cylindrical roll 23 with a predetermined tension and is conveyed so as to be in pressure contact with the pressure belt 24.

- the portion sandwiched between the support member 21 and the pressure belt 24 and the vicinity thereof are in a state of being pressurized (compressed) in the thickness direction from before being divided by the laser light irradiation.

- the diaper continuous body 10 contains a nonwoven fabric, the diaper continuous body 10 can be more efficiently compressed, and as a result, the diaper continuous body 10 being compressed is irradiated with laser light.

- this it becomes possible to fuse the cut edges of the plurality of sheets (exterior body 3) constituting the divided portion more reliably, and the side seal portion 4 can be fused. The strength is improved.

- the rotation angle of the support member 21 (cylindrical roll 23) from when the diaper continuous body 10 is introduced onto the support member 21 to when the diaper continuous body 10 leaves the diaper continuous body 10 can be, for example, 90 degrees or more and 270 degrees or less. Is 120 degrees or more and 270 degrees or less.

- the range of the angle (pressure contact angle) at which the diaper continuous body 10 is pressed against the support member 21 by the pressure belt 24 (pressing member) is the entire circumference of the cylindrical support member 21 (cylindrical roll 23). When the pressure contact is 360 degrees, it is preferably 90 degrees or more and 270 degrees or less, and more preferably 120 degrees or more and 270 degrees or less.

- one surface 10a forms the peripheral surface portion of the cylindrical roll 23 and laser light.

- a continuous diaper brought into contact with the outer surface of the support member 21 having a slit-like opening 27 (light passage portion) through which 30 can pass and brought into a pressurized state by the support member 21 and the pressure belt 24 (pressing member).

- the body 10 part where the side seal portion 4 is to be formed

- the diaper continuous body 10 is divided at the same time.

- the cut edges of the plurality of sheets (exterior body 3) in the pressurized state are fused together to form the side seal portion 4 (side seal portion forming step).

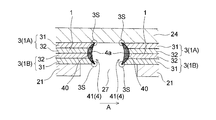

- FIG. 7 is a diagram for explaining how the side seal portion 4 (seal edge) is formed at the same time as the diaper continuous body 10 (band-shaped sheet laminate) is divided using the laser bonding apparatus 20.

- 7 (a) schematically shows a portion 10C (part where the side seal portion 4 is to be formed) scheduled to be divided by the laser beam 30 of the diaper continuous body 10 and its vicinity.

- the diaper continuous body 10C in the present embodiment has a center portion in the longitudinal direction (conveying direction A) in the region where the absorbent main body 2 of the diaper continuous body 10 is not disposed. It is.

- the outer package 3 in the diaper 1 of the present embodiment has an eight-layer structure portion in which eight sheets are stacked on the opening end portion of the waist opening portion 8 and the vicinity thereof (the total number of stacked layers is the largest).

- the highly laminated portion (3A) and the other portions are the four-layer structure portion (low laminated portion with the smallest total number of laminated layers) 3B in which four sheets are stacked.

- the 8-layer structure portion 3A is composed of an outer layer sheet 31 and an inner layer sheet 32 that constitute an outer body on the front body F side, and are folded back at the opening end of the waist opening 8 to form four layers.

- the layer structure portion and the outer layer sheet 31 and the inner layer sheet 32 constituting the outer body on the rear body R side are formed of a four-layer structure portion that is folded at the opening end portion of the waist opening portion 8 to form four layers.

- the four-layer structure portion 3B includes a two-layer structure portion composed of an outer layer sheet 31 and an inner layer sheet 32 constituting the outer body on the front body F side, and an outer layer sheet 31 and inner layer sheet constituting the outer body on the rear body R side. It consists of a two-layer structure consisting of 32.

- the eight-layer structure portion 3A in the central portion in the width direction of the diaper 1 is folded back so that both side portions 3a and 3a of the strip-shaped outer package 3 cover both longitudinal ends of the absorbent main body 2 when the diaper continuous body 10 is manufactured. (See FIGS. 4 and 5).

- a diaper continuous body 10 (a strip shape in which the front body side and the back body side of the diaper continuous body are stacked)

- an eight-layer structure portion 3A in which eight sheets are stacked and a four-layer structure portion 3B in which four sheets are stacked are formed.

- the waist elastic member 5 and the waistline portion are disposed between the sheets 31 and 32 that overlap each other.

- the elastic member present in the parting planned portion 10C may be cut before the side seal portion forming step by means such as pre-cutting, or may be cut by laser light irradiation in the side seal portion forming step.

- the 4-layer structure portion will be mainly described, but unless otherwise specified, the 8-layer structure portion is configured in the same manner as the 4-layer structure portion, and the side seal portion 4 is formed.

- the sheets (inner layer sheet 32) absorb the laser beam 30 and generate heat.

- all of the four sheets 31 and 32 constituting the parting planned portion 10 ⁇ / b> C are sheets (nonwoven fabrics) that absorb the laser beam 30 and generate heat.

- the two sheets of the outer layer sheet 31 and the inner layer sheet 32 that overlap each other in the vicinity of the portion 10C to be divided may be joined by an adhesive or the like before the irradiation with the laser beam 30, or may be joined at all. It is not necessary.

- the diaper continuous body 10 has one surface 10 a abutting against the support member 21, and a parting planned portion 10 ⁇ / b> C (part where the side seal portion 4 is to be formed) is on the slit-shaped opening 27.

- the pressure belt 24 pressing member

- the pressure belt 24 is pressed against the other surface 10b so that it is conveyed in the direction of the arrow A while being introduced onto the support member 21 that rotates in the direction of the arrow A so as to be positioned in the direction of the thickness A.

- Pressure compression

- the laser beam 30 is irradiated through the opening part 27 from the supporting member 21 side with respect to the parting part 10C to be divided in such a conveyance and pressurization state.

- the irradiation point of the laser beam 30 is configured to be arbitrarily movable in the circumferential direction of the cylindrical roll 23, and is set to scan following the movement of the opening 27 along the circumferential direction. Therefore, the laser beam 30 is continuously irradiated for a certain period of time to the parting planned portion 10C located on the opening 27 during the conveyance.

- the forming materials (fibers, etc.) of the sheets 31 and 32 existing in the parting portion 10C are vaporized by the heat generated by the direct irradiation of the laser light 30 and disappear.

- the forming material existing in the vicinity of the parting portion 10 ⁇ / b> C is indirectly heated by the laser beam 30 and melted.

- the parting plan part 10C of a four-layer structure is melted, and in a form in which a single sheet sheet laminate (diaper precursor) is cut from the diaper continuous body 10,

- the cut edges of the four sheets 31 and 32 in the sheet laminate of the single sheets produced by the division, and the diaper continuous 10 are fused together.

- Each of these cut edges is pressed (compressed) by being sandwiched between the support member 21 and the pressure belt 24 from before the formation (before the diaper continuous body 10 is divided by irradiation with the laser beam 30). ).

- the strip-shaped exterior body 3 is divided by the single laser light irradiation, and the exterior body 3 in the two pressurized states generated by the division is thus obtained.

- the fusion and separation are the same with approximately half the laser output compared to the method of fusing the two fusion places with two laser irradiations. It can be carried out in a process, and the diaper 1 can be manufactured efficiently.

- the cut edges of the sheets 31 and 32 are heated and melted during the irradiation of the laser beam 30 and immediately after the end of the irradiation, but are separated from the diaper continuous body 10 by the irradiation of the laser beam 30.

- Each of the leaf diaper precursor and the diaper continuum 10 is maintained in the pressurized state by the support member 21 and the pressure belt 24, and after the irradiation is completed, the air is applied to the outside air, the support member 21 and the pressure belt 24.

- the material is quickly cooled and solidified by heat transfer to form the fused portion 40 in which the forming material (fibers, etc.) of the cut edge is fused and integrated.

- the fused part 40 one of the pair of side seal parts 4, 4 in one diaper 1 is formed.

- the cutting edge portions of the sheets 31 and 32 may be forcibly cooled by using known cooling means such as a suction device and an exhaust device to promote the formation of the fused portion 40.

- the laser beam 30 seems to hit another opening 27 adjacent to the irradiation direction in the direction opposite to the conveyance direction A. And is irradiated to another parting planned portion 10C located thereabove through the other opening 27.

- another part 10C to be divided is divided and fused in the same manner as described above, and the other side seal part 4 (fused part 40) that forms a pair with the previously formed side seal part 4 is formed.

- the pants-type disposable diaper 1 including the exterior body 3 having the pair of side seal portions 4 and 4 is continuously manufactured.

- the diaper is larger than the width W of the slit-shaped opening 27 irradiated with the laser beam 30 (see FIG. 7B.

- the portion 27 may be located at a portion sandwiched between a pair of opening edges along a direction orthogonal to the conveyance direction A. That is, in the diaper continuous body 10, even in a portion that is not sandwiched between the support member 21 and the pressure belt 24 (pressing member), in the vicinity of the opening 27 (opening edge), that is, as described above, The fused part 40 can be formed if the pressure applied by the clamping between the members 21 and 24 is practically affected.

- the side seal portion 4 includes an edge portion 3F of the outer body 3 in the front body F and an edge portion 3R of the outer body 3 in the rear body R.

- the sealing edge part 41 couple

- the seal edge 41 has an outer edge 4a composed of the fused portion 40 in the cross section orthogonal to the direction in which the side seal portion 4 extends when worn. It has a shape recessed toward the inside.

- the fused portion 40 in the seal edge portion 41 has a narrow width W4 that appears on the outer surface of the diaper in the same cross section, and the width W4 is preferably 5 mm or less, more preferably 3 mm or less, and even more preferably 2 mm or less. It is.

- bond part 40 of the seal edge part 41 in this invention has the constant width W4 which appears on the outer surface of a pants

- the width W4 appearing on the outer surface of the pants-type wearing article is constant over the entire length in the longitudinal direction of the side seal part 4 and the maximum value of the width W4 in the entire range in the longitudinal direction of the side seal part 4 It means that the difference from the minimum value of the width W4 is less than 50% of the maximum value.

- the fusion strength can be provided substantially constant while maintaining the flexibility W, the touch, etc., with the width W4 being substantially constant.

- the width W4 is narrow as described above. Considering the size of the entire product, even if the width W4 of the side seal portion 4 is swung by 50%, the width W4 is substantially narrow and has the above-described fusion strength and appearance. .

- the direction where the side seal part 4 is extended is extended.

- the side seal part 4 (seal edge part 41) generated by the above-mentioned division in the cross section in the direction perpendicular to the horizontal direction (the same direction as the lateral direction Y of the diaper 1) is the outer edge 4a formed by the outer edge of the fused part 40.

- a fusion arcuate portion 40 of the four sheets 31 and 32 constituting the outer package 3 is formed on the inner side of the diaper 1 including the outer edge 4a and more on the inner side of the diaper 1 than the outer arc 4a.

- the fusion part 40 is formed, and the center part in the thickness direction of the exterior body 3 (the vertical direction in FIG. 7C or FIG. 8) is wider than the both end parts (upper end part and lower end part). . More specifically, the fusion part 40 has a width of the fusion part 40 toward the center part in the thickness direction in a cross-sectional view along the lateral direction Y of the diaper 1 (direction orthogonal to the dividing direction by the laser beam). It gradually becomes wider and is formed in a so-called crescent or half-moon shape (the fused portion 40 shown in FIG. 7 (c) has a crescent shape). It is preferable that the seal edge part 41 has such a shape even in a worn state.

- the side seal portion 4 is harder and softer than other parts of the diaper 1 due to the presence of the fused portion 40 formed by melting and solidifying the sheet forming material, and causes the feeling of wearing the diaper 1 to be reduced.

- the fusion part 40 is formed in a crescent shape or a half moon shape in a cross-sectional view in the width direction of the diaper 1 as described above, the fusion part in the conventional side seal part (for example, in Patent Document 1) Compared to the case where it is formed in a rectangular shape in the same sectional view as shown in FIG. 1 (part indicated by reference numeral 9), the corner 3S of the side edge portion of the exterior body 3 constituting the side seal portion 4 is formed.

- the wearing feeling of the diaper is improved as compared with the conventional product.

- the central portion in the thickness direction of the side edge of the exterior body 3 (the corner 3S on the one surface side of the exterior body 3 and the 3S on the other surface side, which is a part that greatly affects the fusion strength of the side seal portion 4) Since a sufficient amount of the fused portion 40 exists in the center portion between the side portions), the side seal portion 4 has a practically sufficient fusion strength, and the side seal portion 4 is worn while the diaper 1 is worn. Inconveniences such as tearing of the seal 4 hardly occur.

- the side seal part 4 (fusion

- 9A and 9B show the side seal portion 4 (fused portion 40) in a state where the waist opening 8 is expanded when the diaper 1 is worn. In the state where the waist opening 8 is expanded, the side seal portion 4 is normally in a state where the fused portion 40 is exposed as shown in FIG. 9A, but the outer edge 4a of the side seal portion 4 is the exterior. It is difficult to visually recognize from the outside due to the convex arc shape toward the inside of the body 3 and the fact that the fused portion 40 is smaller than the conventional side seal portion (fused portion).

- the outer edge 4a of the side seal portion 4 has a convex arc shape toward the inner side of the exterior body 3, so that depending on the forming material of the sheets 31, 32, as shown in FIG.

- the corner 3S of the side edge of the exterior body 3 on the abdominal side 1A side and the corner of the side edge of the exterior body 3 on the back side 1B side The portion 3S may approach and the separation distance between the corner portions 3S and 3S may be reduced. Therefore, the fusion part 40 located between the two corners 3S and 3S is difficult to touch by the hand and is located on the outer side of the diaper 1 closer to the diaper 1 than the fusion part 40. Therefore, not only the feeling of wearing the diaper 1 but also the appearance is improved.

- the laser beam irradiated to the diaper continuous body 10 is absorbed by the sheets (the outer layer sheet 31 and the inner layer sheet 32) constituting the outer package 3 to generate heat.

- a laser beam having a wavelength is used.

- the “sheet constituting the exterior body” is not limited to the sheet (for example, the outer layer sheet 31 in the above-described embodiment) constituting one surface of the exterior body (the contact surface with the support member 21). Any sheet may be used as long as the sheet is configured. Whether or not the laser light applied to the exterior body has an oscillation wavelength that is absorbed by the sheet and generates heat for the individual sheets constituting the exterior body depends on the material of the sheet and the laser light to be used.

- the laser beam may be CO 2 laser, YAG It is preferable to use a laser, an LD laser (semiconductor laser), a YVO4 laser, a fiber laser, or the like.

- the oscillation wavelength that can be absorbed by the sheet and cause the sheet to generate heat is, for example, 8.0 ⁇ m or more and 15 It is preferable to use 0.0 ⁇ m or less, and it is particularly preferable to use an oscillation wavelength of 9.0 ⁇ m or more and 11.0 ⁇ m or less of a CO 2 laser in which a high-power laser device exists.

- the spot diameter of laser light, laser output, and the like can be appropriately selected in consideration of the material and thickness of the sheet constituting the exterior body.

- the diaper 1 having a pair of side seal portions 4 and 4 obtained through the process of dividing and welding the exterior body 3 at the same time is excellent in flexibility and touch of the side seal portion 4 and has a good wearing feeling. It is.

- the diaper continuous body 10 has a portion where the number of laminated sheets is different, such as the 8-layer structure portion and the 4-layer structure portion, the number of the laminated sheets is formed on the seal edge portion constituting the side seal portion. A difference in fusion strength due to the difference is likely to occur. Therefore, in the first embodiment of the manufacturing method of the present invention, the difference in fusion strength due to the difference in the number of laminated side seal portions is reduced by the method described below.

- a slit-like opening (light passing) Part) 27 is irradiated with a laser beam 30 to divide the strip-shaped outer package in the diaper continuous body 10, and the cut edges of the laminated outer package produced by the division are fused to form a seal edge.

- the laser beam 30 is linearly scanned in one direction along the longitudinal direction of the light passage portion 27, and the output or scanning speed of the irradiated laser beam is determined by the above-described eight-layer structure portion. (Highly laminated portion) 3A is different from that when the above-described four-layer structure portion (low laminated portion) 3B is irradiated.

- the portion 10C to be formed of the side seal portion of the diaper continuous body 10 (band-shaped outer package 3) has eight layers due to the difference in thickness.

- the structure portion 3A is more easily pressed than the four-layer structure portion 3B. Then, in the state where the 8-layer structure portion 3A is pressed more strongly than the 4-layer structure portion 3B, the laser beam is not changed in spot diameter and laser output, and the central portion of the slit-shaped opening 27 (light passage portion).

- the fusion strength 41 is higher than the fusion strength generated in the four-layer structure portion (low lamination portion) 3B.

- laser light is irradiated to the formation site of the side seal portion by linearly scanning along the longitudinal direction of the slit-shaped opening (light passage portion).

- the output value of the laser beam while irradiating the laser beam to the 8 layer structure portion (high lamination portion having the largest total number of laminations) 3A is changed to the four layer structure portion (low lamination portion having the smallest total lamination number).

- Reduced compared to the output value during irradiation of 3B, or scanned linearly along the longitudinal direction of the slit-shaped opening (light passage part) and laser light is applied to the site where the side seal part is to be formed.

- the scanning speed of the laser beam while the laser beam is radiated to the 8-layer structure portion (high stack portion where the total number of stacked layers is the largest) 3A is low.

- (Laminated part) 3B irradiated And faster than the scanning speed between that.

- the first embodiment of the pant-type wearing article of the present invention forms the sealing edge 41 having the same fusion strength between the 8-layer structure portion 3A and the 4-layer structure portion 3B by such a method.

- the seal edge portion 41 formed on the side seal portion 4 is formed from the 8-layer structure portion 3A to the 4-layer structure portion 3B, and has a fusion strength of 4 in the 8-layer structure portion 3A.

- the fusion strength in the layer structure portion 3B is equal.

- the fusion strength is the maximum when the fusion strength is measured by the following method for each of a plurality of portions where the total number of stacked sheets in the side seal portion 4 is different from each other. It means that the fusion strength value (maximum value) of the part and the fusion strength value (minimum value) of the part having the smallest fusion strength are within the average fusion strength value ⁇ 30%, respectively. .

- the average fusion strength is an average value of the fusion strength measured over the entire side seal including at least one point for each of the portions where the total number of laminated sheets is different.

- the side seal part 4 is located in the center in the longitudinal direction, and has a width having a part of the outer body 3 on the front body F side and a part of the outer body 3 on the rear body R side on both sides thereof.

- a 10 mm strip-shaped test piece is cut out, and the test piece is fixed between chucks of a tensile tester (for example, Tensilon “RTC series” manufactured by A & D). Then, the test piece is pulled at an extension speed of the interval between chucks of 300 mm / min until the outer body 3 on the front body F side and the outer body 3 on the rear body R side are completely divided in the longitudinal direction. .

- the maximum value of the tensile stress at that time is defined as the fusion strength.

- the side seal part 41 is formed by forming the seal edge part 41 connected in step S4, so that the side seal part 4 is excellent in flexibility and touch. Further, the seal edge portion 41 has a fusion strength in the 8-layer structure portion 3A formed in the vicinity of the opening end portion on the waist opening portion 8 side in the 4-layer structure portion 3B formed on the leg opening portion 9 side.

- the fusion strength formed on the 8-layer structure portion 3A can be kept lower than when the 8-layer structure portion 3A and the 4-layer structure portion 3B are irradiated with laser light under the same conditions. Therefore, when removing the diaper (wearing article), it is easy to tear the side seal portion 4 from the waist opening 8 side, and the diaper (wearing article) removal operation can be performed smoothly.

- the sealing edge is a “sheet” such as the 8-layer structure portion 3A and the 4-layer structure portion 3B.

- the fusion strength measured by the measurement method described above is preferably 18 N / 10 mm or less, more preferably 15 N / 10 mm or less, and preferably 1.5 N / 10 mm or more, more preferably 2 N / 10 mm or more.

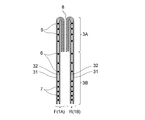

- an opening 27A (light passage portion) is provided.

- the irradiation of the laser beam through the slit-shaped opening 27 (light passage portion) is performed by using the laser beam 30 at the center of the slit-shaped opening 27 (light passage portion) without changing the spot diameter and the laser output.

- the scanning is performed at a constant speed in one direction. Except these, the diaper 1 of 1st Embodiment is manufactured similarly to a 1st embodiment.

- the diaper continuous body 10 (band-shaped exterior body 3) in a state where the front body side and the back body side are overlapped is introduced into a cylindrical roll 23 having a peripheral surface portion made of a support member 21A.

- the opening 27A is formed with respect to the formation planned portion 10C of the side seal portion of the diaper continuous body 10 (band-shaped outer package 3) while applying pressure between the pressure belt 24 and the support member 21A.

- the laser beam 30 is irradiated. As shown in FIG.

- the opening 27 ⁇ / b> A (light passage portion) in the support member 21 ⁇ / b> A is an eight-layer structure portion (total) of the planned portion 10 ⁇ / b> C of the side seal portion of the diaper continuous body 10 (band-shaped exterior body 3).

- a high lamination portion with the largest number of layers a wide portion 52 in a portion overlapping with 3A, and a width narrower than the wide portion 52 in a portion overlapping with a four-layer structure portion (low lamination portion with the smallest total number of laminations) 3B It has a narrow portion 53.

- the 8-layer structure portion 3A of the side seal portion formation planned portion 10C is pressed by both side portions sandwiching the narrow portion 53 in the support member 27A.

- the light 30 is irradiated, and the four-layer structure portion 3B is irradiated with the laser light 30 while being pressed by both side portions of the support member 27A across the wide portion 52. Therefore, even if there is a thickness difference due to the number of stacked sheets between the 8-layer structure portion 3A and the 4-layer structure portion 3B, the front body F to be fused between the 8-layer structure portion 3A and the 4-layer structure portion 3B.

- the close contact state between the side exterior body and the back body R side exterior body can be made the same.