WO2014092059A1 - Sensor element and composite sensor - Google Patents

Sensor element and composite sensor Download PDFInfo

- Publication number

- WO2014092059A1 WO2014092059A1 PCT/JP2013/083020 JP2013083020W WO2014092059A1 WO 2014092059 A1 WO2014092059 A1 WO 2014092059A1 JP 2013083020 W JP2013083020 W JP 2013083020W WO 2014092059 A1 WO2014092059 A1 WO 2014092059A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fixed

- movable

- capacitance

- detection base

- acceleration

- Prior art date

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01C—MEASURING DISTANCES, LEVELS OR BEARINGS; SURVEYING; NAVIGATION; GYROSCOPIC INSTRUMENTS; PHOTOGRAMMETRY OR VIDEOGRAMMETRY

- G01C19/00—Gyroscopes; Turn-sensitive devices using vibrating masses; Turn-sensitive devices without moving masses; Measuring angular rate using gyroscopic effects

- G01C19/56—Turn-sensitive devices using vibrating masses, e.g. vibratory angular rate sensors based on Coriolis forces

- G01C19/5719—Turn-sensitive devices using vibrating masses, e.g. vibratory angular rate sensors based on Coriolis forces using planar vibrating masses driven in a translation vibration along an axis

- G01C19/5726—Signal processing

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01C—MEASURING DISTANCES, LEVELS OR BEARINGS; SURVEYING; NAVIGATION; GYROSCOPIC INSTRUMENTS; PHOTOGRAMMETRY OR VIDEOGRAMMETRY

- G01C19/00—Gyroscopes; Turn-sensitive devices using vibrating masses; Turn-sensitive devices without moving masses; Measuring angular rate using gyroscopic effects

- G01C19/56—Turn-sensitive devices using vibrating masses, e.g. vibratory angular rate sensors based on Coriolis forces

- G01C19/5719—Turn-sensitive devices using vibrating masses, e.g. vibratory angular rate sensors based on Coriolis forces using planar vibrating masses driven in a translation vibration along an axis

- G01C19/5733—Structural details or topology

- G01C19/574—Structural details or topology the devices having two sensing masses in anti-phase motion

- G01C19/5747—Structural details or topology the devices having two sensing masses in anti-phase motion each sensing mass being connected to a driving mass, e.g. driving frames

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01P—MEASURING LINEAR OR ANGULAR SPEED, ACCELERATION, DECELERATION, OR SHOCK; INDICATING PRESENCE, ABSENCE, OR DIRECTION, OF MOVEMENT

- G01P15/00—Measuring acceleration; Measuring deceleration; Measuring shock, i.e. sudden change of acceleration

- G01P15/02—Measuring acceleration; Measuring deceleration; Measuring shock, i.e. sudden change of acceleration by making use of inertia forces using solid seismic masses

- G01P15/08—Measuring acceleration; Measuring deceleration; Measuring shock, i.e. sudden change of acceleration by making use of inertia forces using solid seismic masses with conversion into electric or magnetic values

- G01P15/125—Measuring acceleration; Measuring deceleration; Measuring shock, i.e. sudden change of acceleration by making use of inertia forces using solid seismic masses with conversion into electric or magnetic values by capacitive pick-up

Definitions

- the present invention relates to a sensor element that detects angular velocity and acceleration, and a composite sensor including the sensor element.

- the sensor element of the composite sensor described in Patent Document 1 includes a mass portion supported by a support beam so as to have a gap with respect to the substrate.

- the mass portion is supported so as to be displaceable in two axial directions (for example, the X-axis direction and the Y-axis direction) that are parallel to the substrate surface and orthogonal to each other.

- This composite sensor detects the angular velocity in a state where the mass part is vibrated in the X-axis direction. In this state, when an angular velocity around the Z axis orthogonal to the X axis and the Y axis acts on the mass portion, a Coriolis force in the Y axis direction is generated. By detecting the Coriolis force electrically, the angular velocity around the Z axis is detected.

- this composite sensor includes an acceleration detection unit that detects an acceleration in the Y-axis direction using an electric signal in a region different from the mass unit that detects the angular velocity.

- FIG. 22 is an enlarged plan view of a part of the acceleration detection unit of the conventional composite sensor.

- FIG. 22A shows a case where the displacement ⁇ x of the movable part in the X-axis direction due to vibration is zero.

- FIG. 22B shows a case where the displacement ⁇ x of the movable part in the X-axis direction due to vibration is + x1.

- the movable-side acceleration detector detection base 240P1 is disposed between the fixed-side acceleration detector detection bases 220P1 and 220P2 arranged along the Y-axis direction.

- the detection bases 240P1, 220P1, and 220P2 have a long shape extending in the X-axis direction.

- a protrusion 241P1 protruding in the Y-axis direction is formed on the side surface of the movable detection base 240P1 on the fixed detection base 220P1 side.

- a protrusion 242P1 protruding in the Y-axis direction is formed on the side of the movable detection base 240P1 on the fixed detection base 220P2 side.

- the protrusion 241P1 and the protrusion 242P1 have a shape with a length of 2W along the X axis.

- the positions of the protrusion 241P1 and the protrusion 242P1 along the X-axis direction are shifted by W.

- a protrusion 221P1 is formed on the side of the movable detection base 240P1 side of the fixed detection base 220P1.

- the protruding portion 221P1 has a shape with a length of 2W along the X axis.

- the position of the protrusion 221P1 in the X-axis direction is the same as the position of the protrusion 242P1.

- the fixed-side protrusion 221P1 and the movable-side protrusion 241P1 face each other with a length of W in the X-axis direction.

- the fixed-side protrusion 221P2 and the movable-side protrusion 241P1 face each other at an interval of D12 in the Y-axis direction.

- a protrusion 221P2 is formed on the movable detection base 240P1 side of the fixed detection base 220P2.

- the protrusion 221P2 has a shape with a length of 2W along the X axis.

- the position of the protrusion 221P2 in the X-axis direction is the same as the position of the protrusion 241P1.

- the fixed-side protrusion 221P2 and the movable-side protrusion 242P1 face each other with a length of W in the X-axis direction.

- the fixed-side protrusion 221P1 and the movable-side protrusion 242P1 face each other at an interval of D12 in the Y-axis direction.

- the acceleration detecting unit includes a capacitance C1P1 determined by a facing area S1P1 (dependent on W) and a facing distance D12 between the fixed-side protrusion 221P1 and the movable-side protrusion 241P1, and the fixed-side protrusion 221P2 and the movable side.

- the acceleration is detected from the change of the capacitance C2P1 determined by the facing area S2P1 (depending on W) and the facing distance D12 with respect to the protrusion 242P1.

- the movable-side detection base 240P1 moves away from the fixed-side detection base 220P1 and close to the fixed-side detection base 220P2. To do.

- the facing distance D12 between the protrusion 221P1 on the fixed side and the protrusion 241P1 on the movable side increases, and the capacitance C1P1 decreases.

- the facing distance D12 between the fixed-side protrusion 221P2 and the movable-side protrusion 242P1 decreases, and the capacitance C2P1 increases.

- the capacitances C1P1 and C2P1 are determined by the reciprocal of the facing interval.

- the combined capacitance of the capacitance C1P1 and the capacitance C2P1 decreases according to the reciprocal of the opposing distance change, and the acceleration can be detected from this decrease amount.

- the movable-side detection base 240P1 and the protrusions 241P1 and 242P1 vibrate in the X-axis direction in order to detect the angular velocity described above. Therefore, the facing area between the movable-side protrusion 241P1 and the fixed-side protrusion 221P1 changes, and the facing area between the movable-side protrusion 242P1 and the fixed-side protrusion 221P2 also changes. For example, as shown in FIG. 21B, when moving in the positive direction of the X-axis, the facing area S1P2 between the movable protrusion 241P1 and the fixed protrusion 221P1 increases as W ′ increases.

- the amount reduced to S2P2 is the same. Therefore, the amount of change in capacitance between the movable-side protrusion 241P1 and the fixed-side protrusion 221P1 and the amount of change in capacitance between the movable-side protrusion 242P1 and the fixed-side protrusion 221P2 are offset. To do. Therefore, the combined capacitance of the capacitances C1P2 and C2P2 is the same as the combined capacitance of the capacitances C1P1 and C2P1.

- the opposing shape of the protrusion of the movable part and the fixed part is as described above, so that the X-axis direction vibration for detecting the angular velocity has an influence on the acceleration detection capacitance. It does not occur.

- the acceleration detection accuracy may decrease in the following state.

- FIG. 23 is an enlarged plan view of a part of the acceleration detection unit for explaining the problem of the conventional composite sensor.

- FIG. 24 is a waveform diagram for explaining the problem of the conventional composite sensor.

- FIG. 24A shows the capacitance C1P between the movable projection 241P1 and the fixed projection 221P1

- FIG. 24B shows the capacitance between the movable projection 242P1 and the fixed projection 221P2.

- C2P is shown.

- FIG. 24C shows a combined capacitance of the capacitances C1P and C2P.

- the displacement in the X-axis direction becomes large, and the following problem occurs when the movable-side protrusion 242P1 and the fixed-side protrusion 221P2 do not face each other.

- the capacitance generated between the movable side and the fixed side is only the capacitance C1P3 due to the length Wex (opposing area S1P3) between the movable side protrusion 241P1 and the fixed side protrusion 221P1.

- the opposing length Wex is smaller than the length 2W at which the movable-side protrusion 241P1 and the fixed-side protrusion 221P1 are opposed to each other longest. Therefore, the capacitance C1P3 is smaller than the capacitance C1Pm when the movable side protrusion 241P1 and the fixed side protrusion 221P1 face each other with a length of 2W. In this case, no capacitance is generated between the movable protrusion 242P1 and the fixed protrusion 221P2.

- the combined capacitance generated between the movable portion and the fixed portion is more rapidly reduced than the change due to the displacement of the combined capacitance when the movable portion is opposed to the fixed portion at both ends in the Y-axis direction.

- the linearity is broken.

- the primary combined capacitance (C1P + C2P) cancels out the primary components C1P and C2P. 0.

- the secondary combined capacitance (C1P + C2P) is doubled by adding the secondary components C1P and C2P together. Such a secondary component becomes noise when measuring acceleration, and deteriorates the detection performance of acceleration.

- the present invention provides a sensor that can detect acceleration with high accuracy even when the angular velocity detection unit and the acceleration detection unit are formed using a single movable unit. It is to provide an element and a composite sensor.

- the present invention includes a substrate, a fixed portion fixed to one surface of the substrate, a movable portion that is supported by the substrate in a state capable of vibrating in a first direction parallel to the one surface of the substrate, and faces the fixed portion, And has the following characteristics.

- the movable part includes a movable side detection base, a movable first protrusion, and a movable second protrusion.

- the movable side detection base portion extends along the first direction, and has a first surface and a second surface on both sides of the second direction parallel to one surface of the substrate and orthogonal to the first direction.

- the movable first protrusion protrudes in one direction in the second direction from the first surface of the movable detection base.

- the movable second protrusion protrudes in the other direction of the second direction from the second surface of the movable detection base.

- the fixed portion has a first fixed side detection base, a second fixed side detection base, a fixed side first protrusion, and a fixed side second protrusion.

- the first fixed side detection base and the second fixed side detection base are respectively disposed on both sides of the movable side detection base in the second direction, and extend along the first direction.

- the fixed first protrusion protrudes from the first fixed detection base to the movable first protrusion side.

- the fixed-side second protrusion protrudes from the second fixed-side detection base toward the movable-side second protrusion.

- the sensor element includes a first capacitance between the movable first projection and the fixed first projection, and a second capacitance between the movable second projection and the fixed second projection.

- An acceleration detection signal is output from the change in the combined electrostatic capacity.

- a third capacitance between the movable portion and the fixed portion is generated at an end portion in the first direction of any of the movable side detection base, the first fixed side detection base, and the second fixed side detection base.

- a capacitance forming portion is disposed.

- the vibration becomes a predetermined value or more, and the movable side first protrusion and the fixed side first protrusion do not face each other, or the movable side second protrusion and the fixed side second protrusion face each other. If the combined capacitance of the first capacitance and the second capacitance decreases and the third capacitance increases. As a result, the decrease in the combined capacitance of the first capacitance and the second capacitance can be compensated by the increase in the third capacitance. Therefore, it is possible to substantially eliminate the change in capacitance due to vibration.

- the movable part includes a movable side detection base, a movable first protrusion, and a movable second protrusion.

- the movable side detection base portion extends along the first direction, and has a first surface and a second surface on both sides of the second direction parallel to one surface of the substrate and orthogonal to the first direction.

- the movable first protrusion protrudes in one direction in the second direction from the first surface of the movable detection base.

- the movable second protrusion protrudes in the other direction of the second direction from the second surface of the movable detection base.

- the fixed portion includes a first fixed-side detection base, a second fixed-side detection base, a fixed-side first protrusion, and a fixed-side second protrusion.

- the first fixed side detection base and the second fixed side detection base are respectively disposed on both sides of the movable side detection base in the second direction, and extend along the first direction.

- the fixed first protrusion protrudes from the first fixed detection base to the movable first protrusion side.

- the fixed-side second protrusion protrudes from the second fixed-side detection base toward the movable-side second protrusion.

- the sensor element includes a first capacitance between the movable first projection and the fixed first projection, and a second capacitance between the movable second projection and the fixed second projection.

- An acceleration detection signal is output from the change in the combined electrostatic capacity.

- a capacitance forming portion is disposed at an end portion in the first direction in any of the movable side detection base, the first fixed side detection base, and the second fixed side detection base.

- the width along the second direction of the capacitance forming portion is the same as the width of the movable side detection base, the first fixed side detection base, and the second fixed side detection base in which the capacitance formation portion is arranged. Larger than the width along two directions.

- the capacitance of the capacitance forming portion can be increased, and the change in capacitance due to vibration can be suppressed and almost eliminated.

- each of the movable part and the fixed part may be provided with a capacitance forming part.

- the movable part has a movable side holding part extending along the second direction at one end of the movable side detection base in the first direction.

- the fixed portion has a fixed-side holding portion extending along the second direction at the other end in the first direction of the first fixed-side detection base and the second fixed-side detection base.

- the movable side detection base, the first fixed side detection base, and the second fixed side detection base are disposed between the movable side holding part and the fixed side holding part in the first direction.

- the capacitance forming part is disposed at the other end in the first direction of the movable side detection base.

- This configuration shows a specific structure of the capacitance forming portion in the movable portion.

- the sensor element of the present invention preferably has the following configuration.

- the movable part has a movable side holding part extending in the second direction at one end in the first direction of the movable side detection base.

- the fixed portion has a fixed-side holding portion extending along the second direction at the other end in the first direction of the first fixed-side detection base and the second fixed-side detection base.

- the movable side detection base, the first fixed side detection base, and the second fixed side detection base are arranged between the movable side holding part and the fixed side holding part in the first direction.

- the capacitance forming part is disposed at one end of the first fixed side detection base and the second fixed side detection base in the first direction.

- This configuration shows a specific structure of the capacitance forming portion in the fixed portion.

- the sensor element of the present invention preferably has the following configuration.

- the movable side detection bases are formed on both sides of the movable side holding portion in the first direction.

- the capacitance forming part is arranged symmetrically about the second direction on both sides of the movable side holding part.

- the sensor element of the present invention preferably has the following configuration.

- the sensor element includes a first mass unit and a second mass unit arranged in the second direction with a gap with respect to the substrate, and the first mass unit and the second mass unit along the first direction. And a supporting beam that supports the vibration so that the vibration is in the opposite phase.

- the first mass unit has a fixed part and a movable part, and outputs a first acceleration detection signal.

- the second mass unit has a fixed part and a movable part, and outputs a second acceleration detection signal.

- acceleration can be detected more reliably.

- the sensor element of the present invention preferably has the following configuration.

- the first mass unit outputs a first angular velocity detection signal based on an angular velocity around a third direction orthogonal to the first direction and the second direction.

- the second mass unit outputs a second angular velocity detection signal based on an angular velocity around the third direction.

- the sensor element is configured to output so that the phase relationship between the first angular velocity detection signal and the second angular velocity detection signal is opposite to the phase relationship between the first acceleration detection signal and the second acceleration detection signal.

- angular velocity detection can be detected simultaneously with the acceleration detector.

- a sensor element that can detect acceleration and angular velocity can be realized in a small size.

- the composite sensor according to the present invention includes a sensor element that detects the acceleration and the angular velocity, a first detection signal including a first angular velocity detection signal and a first acceleration detection signal, a second angular velocity detection signal, and a second acceleration detection signal. And an addition unit that adds the second detection signal, and a subtraction unit that subtracts the first detection signal and the second detection signal.

- This configuration shows a specific configuration of the composite sensor using the above-described sensor element. And by setting it as this structure, the composite sensor which can detect an acceleration and an angular velocity separately is realizable small.

- the acceleration can be accurately determined without being affected by the magnitude of vibration for angular velocity detection. Can be detected.

- FIG. 1 It is a block diagram which shows the structure of the composite sensor which concerns on embodiment of this invention. It is a figure which shows the behavior when angular velocity (omega) is applied to the sensor element which concerns on embodiment of this invention. It is a figure which shows the behavior when the acceleration a is applied to the sensor element which concerns on embodiment of this invention. It is a wave form chart of each signal when only angular velocity omega is impressed to sensor element 1 concerning an embodiment of the present invention. It is a wave form chart of each signal when only acceleration a is impressed to sensor element 1 concerning an embodiment of the present invention. It is a wave form chart of each signal when acceleration a and angular velocity omega are impressed to sensor element 1 concerning an embodiment of the present invention. FIG.

- FIG. 5 is a partial plan view showing a more specific structure of a movable acceleration detector and a fixed acceleration detector. It is an enlarged view of the both ends of the X-axis direction of a movable-side acceleration detector (when displacement amount (DELTA) x is 0). It is an enlarged view of the both ends of the X-axis direction of the movable-side acceleration detector (when the displacement amount ⁇ x is + W).

- FIG. 4 is an enlarged view of both ends of a movable-side acceleration sensor in the X-axis direction (when the displacement amount ⁇ x is ⁇ W). It is a graph which shows the change with respect to the amount of displacement of synthetic capacity.

- FIG. 12 is a partial plan view showing another more specific second structure of a movable-side acceleration detector and a fixed-side acceleration detector. It is the top view which expanded a part of acceleration detection part of the conventional composite sensor. It is the top view which expanded a part of acceleration detection part for demonstrating the subject of the conventional composite sensor. It is a wave form diagram for demonstrating the subject of the conventional composite sensor.

- FIG. 1 is a plan view showing a configuration of a sensor element according to an embodiment of the present invention.

- the sensor element is sealed by a housing (not shown).

- the atmosphere in the housing in which the sensor element is arranged is maintained, for example, in a reduced pressure atmosphere.

- the sensor element 1 includes a rectangular substrate 2.

- the substrate 2 is formed of an insulating semiconductor such as silicon.

- the short direction of the rectangular substrate 2 is defined as the X-axis direction (corresponding to the “first direction” of the present invention), and the longitudinal direction is defined as the Y-axis direction (the “second direction” of the present invention). Will be described.

- the sensor element 1 includes a first mass unit 10, a second mass unit 20, a third mass unit 300, and a fourth mass unit 400. These mass parts are made of a conductive semiconductor such as low-resistance silicon. Further, the parts other than the substrate 2 constituting the sensor element 1 are made of a conductive semiconductor such as low-resistance silicon, for example, in the same manner as each mass part.

- the first mass unit 10, the second mass unit 20, the third mass unit 300, and the fourth mass unit 400 are arranged in the Y-axis direction at intervals. As a more specific arrangement order, the first mass unit 10 and the second mass unit 20 are arranged at the center along the arrangement direction (Y-axis direction).

- the third mass unit 300 is disposed on the opposite side of the first mass unit 10 from the second mass unit 20 side.

- the fourth mass unit 400 is disposed on the opposite side of the second mass unit 20 from the first mass unit 10 side.

- the first mass unit 10, the second mass unit 20, the third mass unit 300, and the fourth mass unit 400 are supported by the support beams 4A and 4B with a gap from the substrate 2.

- the support beams 4A and 4B have a long shape extending along the Y-axis direction.

- the width (length in the X-axis direction) of the support beams 4A and 4B is set so as to be strong enough to be bent while being partially displaced in the X-axis direction due to vibration described later.

- the support beam 4A is disposed on one end side in the X-axis direction with respect to the region where the first mass unit 10, the second mass unit 20, the third mass unit 300, and the fourth mass unit 400 are arranged.

- the support beam 4B is disposed on the other end side in the X-axis direction with respect to the region where the first mass unit 10, the second mass unit 20, the third mass unit 300, and the fourth mass unit 400 are arranged. That is, the support beams 4A and 4B are arranged so as to sandwich the first mass unit 10, the second mass unit 20, the third mass unit 300, and the fourth mass unit 400 along the X-axis direction.

- the first mass part 10 and the support beam 4A are connected by a connecting part 5A.

- the second mass part 20 and the support beam 4A are connected by a connecting part 5B.

- the third mass part 300 and the support beam 4A are connected by a connecting part 5C.

- the fourth mass part 400 and the support beam 4A are connected by a connecting part 5D.

- the first mass part 10 and the support beam 4B are connected by a connecting part 5E.

- the 2nd mass part 20 and support beam 4B are connected by connecting part 5F.

- the third mass unit 300 and the support beam 4B are coupled by a coupling unit 5G.

- the fourth mass part 400 and the support beam 4B are connected by a connecting part 5H.

- the connecting part 5A and the connecting part 5E pass through the center of gravity G of the arranged first mass part 10, the second mass part 20, the third mass part 300, and the fourth mass part 400, and are symmetrical about an axis parallel to the Y-axis direction. As an axis, they are arranged in line-symmetric positions.

- the connecting part 5B and the connecting part 5F are arranged at positions symmetrical with respect to the symmetry axis.

- the connecting portion 5C and the connecting portion 5G are arranged at positions symmetrical with respect to the symmetry axis.

- the connecting part 5D and the connecting part 5H are arranged at positions symmetrical with respect to the symmetry axis.

- the support beam 4A is connected to the fixing portions 3A, 3B, 3C.

- the support beam 4B is connected to the fixing portions 3D, 3E, and 3F.

- the positions where the fixing portions 3A to 3F are connected to the support beams 4A and 4B are points (nodes) where the displacement of the support beams 4A and 4B in the X-axis direction does not occur when each mass portion vibrates in the X-axis direction. .

- the first mass unit 10 includes an inner frame portion 101A and an outer frame portion 102A.

- the inner frame portion 101A is a rectangle having a long side in the X-axis direction and a short side in the Y-axis direction.

- the outer frame portion 102A is a rectangle having a long side in the X-axis direction and a short side in the Y-axis direction.

- the outer frame portion 102A has a shape surrounding the inner frame portion 101A.

- the outer frame portion 102A is connected to the support beams 4A and 4B by connecting portions 5A and 5E.

- the inner frame portion 101A is connected to the outer frame portion 102A in the vicinity of the axis along the Y-axis direction passing through the center of gravity G. More specifically, a long connecting member 103A is formed on the side on the center of gravity G side of the inner frame portion 101A.

- the connecting member 103A has a shape extending along the X-axis direction, and is connected to the inner frame portion 101A at both ends in the X-axis direction.

- a connecting member 104A is formed at the center of the connecting member 103A.

- the connecting member 104A has a short shape in the Y-axis direction, one end in the Y-axis direction is connected to the outer frame portion 102A, and the other end in the Y-axis direction is connected to the connecting member 103A.

- the connecting member 104A has a shape in which the length in the X-axis direction is longer than the length in the Y-axis direction and is sufficiently shorter than the length in the longitudinal direction (X-axis direction) of the connecting member 103A.

- a long connecting member 103B is formed on the side opposite to the center of gravity G side of the inner frame portion 101A.

- the connecting member 103B has a shape extending along the X-axis direction, and is connected to the inner frame portion 101A at both ends in the X-axis direction.

- a connecting member 104B is formed at the center of the connecting member 103B in the longitudinal direction.

- the connecting member 104B has a short shape in the Y-axis direction, one end in the Y-axis direction is connected to the outer frame portion 102A, and the other end in the Y-axis direction is connected to the connecting member 103B.

- the connecting member 104B has a shape in which the length in the X-axis direction is longer than the length in the Y-axis direction and is sufficiently shorter than the length in the longitudinal direction (X-axis direction) of the connecting member 103B.

- the inner frame portion 101A includes a central axis 101C.

- the central axis 101C has a shape extending in the Y-axis direction and has a predetermined width in the X-axis direction.

- the central axis 101C is disposed at the center in the X-axis direction of the inner frame 101A. In other words, the central axis 101C is arranged at a position where the extending axis substantially coincides with the Y axis.

- the inner space of the inner frame portion 101A is divided into two regions in the X-axis direction by the central axis 101C. The two regions are generally line symmetric with respect to the Y axis except for the arrangement order of the conductor portions described later.

- a fixed portion 111, an acceleration detection portion 112, and an angular velocity detection portion 113 are formed inside one of the inner frame portions 101A.

- the fixed part 111 has substantially the same length in both the X-axis direction and the Y-axis direction.

- the fixed portion 111 has a shape having a relatively large plane area in the sensor element 1 when viewed in plan.

- the fixing part 111 is fixed to the substrate 2.

- the acceleration detection unit 112 and the angular velocity detection unit 113 include a conductor part connected to the fixed part 111 and a conductor part connected to the inner frame part 101A.

- the conductor part has shown the part of the electroconductive semiconductor which generate

- the first detection unit 11 is configured by the fixing unit 111, the first mass unit 10, and the conductor units that constitute the acceleration detection unit 112 and the angular velocity detection unit 113.

- a fixed part 121, an acceleration detection part 122, and an angular velocity detection part 123 are formed on the other inner side of the inner frame part 101A.

- the fixed part 121 has substantially the same length in both the X-axis direction and the Y-axis direction.

- the fixed part 121 has a shape having a relatively large plane area in the sensor element 1 when viewed in plan.

- the fixing part 121 is fixed to the substrate 2.

- the fixed part 121 has a shape symmetrical with the fixed part 111 with respect to the Y axis.

- the acceleration detection unit 122 and the angular velocity detection unit 123 include a conductor part connected to the fixed part 121 and a conductor part connected to the inner frame part 101A.

- the acceleration detection unit 122 is generally symmetrical with the acceleration detection unit 112 with respect to the Y axis, but a conductor connected to the inner frame 101A for acceleration detection and a conductor connected to the fixed unit 121.

- the arrangement order with respect to the parts is not line symmetric but the same order along the X-axis direction.

- the angular velocity detection unit 123 is symmetrical with respect to the angular velocity detection unit 113 in the extending direction of the conductor with respect to the Y axis, but the arrangement order of the conductors is different from that of the angular velocity detection unit 113.

- the second detection unit 12 is configured by the fixing unit 121, the first mass unit 10, and the conductor units that constitute the acceleration detection unit 122 and the angular velocity detection unit 123.

- the second mass unit 20 includes an inner frame portion 101B and an outer frame portion 102B.

- the inner frame portion 101B is a rectangle having a long side in the X-axis direction and a short side in the Y-axis direction.

- the outer frame portion 102B is a rectangle having a long side in the X-axis direction and a short side in the Y-axis direction.

- the outer frame portion 102B has a shape surrounding the inner frame portion 101B.

- the outer frame portion 102B is connected to the support beams 4A and 4B by connecting portions 5B and 5F.

- the inner frame portion 101B is arranged in a line-symmetrical position with respect to the inner frame portion 101A of the first mass unit 10 with respect to the X axis passing through the center of gravity G, and has a line-symmetric shape.

- the outer frame portion 102B is arranged at a line-symmetrical position with respect to the outer frame portion 102A of the first mass unit 10 with respect to the X axis passing through the center of gravity G, and has a line-symmetric shape.

- the inner frame portion 101B is connected to the outer frame portion 102B in the vicinity of the axis along the Y-axis direction passing through the center of gravity G. More specifically, a long connecting member 103C is formed on the side of the inner frame portion 101B on the center of gravity G side.

- the connecting member 103C has a shape extending along the X-axis direction, and is connected to the inner frame portion 101B at both ends in the X-axis direction.

- a connecting member 104C is formed at the center of the connecting member 103C.

- the connecting member 104C has a short shape in the Y-axis direction, one end in the Y-axis direction is connected to the outer frame portion 102B, and the other end in the Y-axis direction is connected to the connecting member 103C.

- the connecting member 104C has a shape in which the length in the X-axis direction is longer than the length in the Y-axis direction and is sufficiently shorter than the length in the longitudinal direction (X-axis direction) of the connecting member 103C.

- the connecting member 103C and the connecting member 104C are symmetrical with the connecting member 103A and the connecting member 104A, respectively, with respect to the X axis.

- a long connecting member 103D is formed on the side opposite to the center of gravity G side of the inner frame portion 101B.

- the connecting member 103D has a shape extending along the X-axis direction, and is connected to the inner frame portion 101B at both ends in the X-axis direction.

- a connecting member 104D is formed at the center of the connecting member 103D in the longitudinal direction.

- the connecting member 104D has a short shape in the Y-axis direction, one end in the Y-axis direction is connected to the outer frame portion 102B, and the other end in the Y-axis direction is connected to the connecting member 103D.

- the connecting member 104D has a shape in which the length in the X-axis direction is longer than the length in the Y-axis direction and is sufficiently shorter than the length in the long direction (X-axis direction) of the connecting member 103D.

- the connecting member 103D and the connecting member 104D are symmetrical with the connecting member 103B and the connecting member 104B, respectively, with respect to the X axis.

- the inner frame portion 101B includes a central axis 101D.

- the central axis 101D has a shape extending in the Y-axis direction and has a predetermined width in the X-axis direction.

- the center axis 101D is disposed at the center of the inner frame 101B in the X-axis direction. In other words, the central axis 101D is disposed at a position where the extending axis substantially coincides with the Y axis.

- the inner space of the inner frame portion 101B is divided into two regions in the X-axis direction by the central axis 101D. The two regions are generally line symmetric with respect to the Y axis except for the arrangement order of the conductor portions.

- the central axis 101D has a shape symmetrical with the central axis 101C with respect to the X axis.

- the fixed part 131, the acceleration detection part 132, and the angular velocity detection part 133 are formed inside one side of the inner frame part 101B.

- the fixed part 131 has substantially the same length in both the X-axis direction and the Y-axis direction.

- the fixed portion 131 has a shape having a relatively large plane area in the sensor element 1 when viewed in plan.

- the fixing part 131 is fixed to the substrate 2.

- the acceleration detection unit 132 and the angular velocity detection unit 133 include a conductor portion connected to the fixed portion 131 and a conductor portion connected to the inner frame portion 101B.

- the fixed unit 131, the acceleration detection unit 132, and the angular velocity detection unit 133 are symmetrical with the fixed unit 111, the acceleration detection unit 112, and the angular velocity detection unit 113, respectively, with respect to the X axis.

- the third detection unit 13 is configured by the fixing unit 131, the second mass unit 20, and the conductors that form the acceleration detection unit 132 and the angular velocity detection unit 133.

- a fixed portion 141, an acceleration detection portion 142, and an angular velocity detection portion 143 are formed on the other inner side of the inner frame portion 101B.

- the fixed portion 141 has substantially the same length in both the X-axis direction and the Y-axis direction.

- the fixed portion 141 has a shape having a relatively large plane area in the sensor element 1 when viewed in plan.

- the fixing part 141 is fixed to the substrate 2.

- the fixed portion 141 has a shape symmetrical with the fixed portion 131 with respect to the Y axis, and has a shape symmetrical with the fixed portion 121 with respect to the X axis.

- the acceleration detection unit 142 and the angular velocity detection unit 143 include a conductor part connected to the fixed part 141 and a conductor part connected to the inner frame part 101B.

- the acceleration detection unit 142 is generally symmetrical with the acceleration detection unit 132 with respect to the Y axis, but the conductor connected to the acceleration detection inner frame 101B and the conductor connected to the fixed unit 141.

- the arrangement order with respect to the parts is not line symmetric but the same order along the X-axis direction.

- the angular velocity detector 143 has a conductor line extending in a line-symmetric shape with respect to the angular velocity detector 133 with respect to the Y axis, but the arrangement order of the conductors is different from that of the angular velocity detector 133.

- 4th detection part 14 is constituted by fixed part 141, 2nd mass part 20, and a conductor part which constitutes acceleration detection part 142 and angular velocity detection part 143.

- the third mass unit 300 is disposed away from the first mass unit 10.

- the third mass unit 300 has a rectangular shape extending in the X-axis direction.

- One end of the third mass part 300 in the longitudinal direction is connected to the support beam 4A by a connecting part 5C.

- the other end in the longitudinal direction of the third mass unit 300 is connected to the support beam 4B by a connecting part 5G.

- the fixing unit 31 is disposed between the third mass unit 300 and the first mass unit 10.

- the fixing part 31 has a shape having a predetermined area, like the fixing parts 111, 121, 131, 141, and is fixed to the substrate 2.

- the fixed portion 31 is disposed at the center position in the X-axis direction.

- the support member 32 has a substantially rectangular shape extending along the X-axis direction with the fixed portion 31 as the center.

- a plurality of comb teeth 33 ⁇ / b> A are formed on the outer frame 102 ⁇ / b> A side of the first mass unit 10 in the support member 32.

- a plurality of comb tooth portions 34A are formed on the support member 32 side of the outer frame portion 102A.

- the comb tooth portion 33A and the comb tooth portion 34A are arranged so as to mesh with each other.

- a plurality of comb teeth portions 33B are formed on the third mass portion 300 side of the support member 32.

- a plurality of comb teeth 34 ⁇ / b> B are formed on the support member 32 side of the third mass unit 300.

- the comb tooth portion 33B and the comb tooth portion 34B are arranged so as to mesh with each other.

- the first drive unit 30 is configured by the comb tooth portion 33A and the comb tooth portion 34A, and the comb tooth portion 33B and the comb tooth portion 34B.

- the fixed part 500 is arranged on the opposite side of the third mass part 300 from the first mass part 10.

- the fixing unit 500 is disposed away from the third mass unit 300.

- the fixed part 500 has a rectangular shape extending in the X-axis direction. One end in the extending direction of the fixing portion 500 is connected to the substrate 2. As a result, the fixing unit 500 is fixed to the substrate 2 in the same manner as the fixing units 111, 121, 131, 141, and 31.

- a plurality of comb-tooth portions 51 are formed on the fixed portion 500 side of the third mass portion 300.

- a plurality of comb teeth portions 52 are formed on the third mass portion 300 side of the fixed portion 500.

- the comb-tooth part 51 and the comb-tooth part 52 are arrange

- the first monitor unit 50 is configured by the comb-tooth portion 51 and the comb-tooth portion 52.

- the fourth mass unit 400 is disposed away from the second mass unit 20.

- the fourth mass unit 400 has a rectangular shape extending in the X-axis direction.

- One end of the fourth mass part 400 in the longitudinal direction is connected to the support beam 4A by a connecting part 5D.

- the other end in the longitudinal direction of the fourth mass part 400 is connected to the support beam 4B by the connecting part 5H.

- the fixed part 41 is disposed between the fourth mass part 400 and the second mass part 20.

- the fixing portion 41 has a shape having a predetermined area, like the fixing portion 31, and is fixed to the substrate 2.

- the fixed portion 41 is disposed at the center position in the X-axis direction.

- the support member 42 has a substantially rectangular shape extending along the X-axis direction with the fixed portion 41 as the center.

- a plurality of comb-tooth portions 43A are formed on the support member 42 on the outer frame portion 102B side of the second mass portion 20.

- a plurality of comb teeth 44A are formed on the support member 42 side of the outer frame portion 102B.

- the plurality of comb-tooth portions 44A are connected to the outer frame portion 102B.

- the comb tooth portion 43A and the comb tooth portion 44A are arranged so as to mesh with each other.

- a plurality of comb teeth 43B are formed on the support member 42 on the fourth mass portion 400 side.

- a plurality of comb teeth portions 44B are formed on the support member 42 side of the fourth mass portion 400.

- the comb tooth portion 43B and the comb tooth portion 44B are disposed so as to mesh with each other.

- the second drive unit 40 is configured by the comb tooth portion 43A and the comb tooth portion 44A, and the comb tooth portion 43B and the comb tooth portion 44B.

- the fixed part 600 is arranged on the opposite side of the fourth mass part 400 from the second mass part 20.

- the fixed part 600 is disposed away from the fourth mass part 400.

- One end in the extending direction of the fixing portion 600 is connected to the substrate 2.

- the fixed part 600 has a rectangular shape extending in the X-axis direction.

- the fixing part 600 is fixed to the substrate 2 in the same manner as the fixing part 500.

- a plurality of comb-tooth portions 61 are formed on the fourth mass portion 400 side of the fixing portion 600.

- a plurality of comb teeth 62 are formed on the fixed part 600 side of the fourth mass part 400.

- the comb-tooth part 61 and the comb-tooth part 62 are arrange

- the comb monitor 61 and the comb 62 constitute a second monitor 60.

- FIG. 2 is an enlarged plan view showing the configuration of the first detection unit according to the embodiment of the present invention.

- FIG. 3 is an enlarged plan view showing configurations of the acceleration detection unit and the angular velocity detection unit of the first detection unit according to the embodiment of the present invention.

- the fixed portion 111 is disposed in one internal space divided by the central axis 101C in the internal space of the inner frame portion 101A.

- the length of the fixed portion 111 in the X-axis direction is shorter than the length of the internal space in the X-axis direction.

- the fixed portion 111 is located near the second mass portion 20 side (the connecting members 103A and 104A), and is shifted from the center of the internal space along the Y-axis direction so as to be separated from the third mass portion 300 side. Is arranged.

- predetermined spaces are formed on the support beam 4A side, the central axis 101C side, and the third mass unit 300 side (the coupling portions 103B and 104B side) of the fixed portion 111.

- Acceleration detectors 202A1, 202B1, 202C1, 202D1, 202E1, 202F1, 202G1, 202H1, 202I1, 202J1, 202K1, 202L1, 202M1, 202N1 and acceleration detectors 204A1, 204B1, 204C1, 204D1, 204E1, 204F1, 204G1, 204H1 , 204I1 and 204J1 are arranged in a space on the third mass unit 300 side of the fixed part 111 including the vicinity of the end of the fixed part 111 on the third mass unit 300 side.

- the fixing unit 111 includes long detector holding parts 201A1 and 201B1 (corresponding to the “fixing side holding part” of the present invention) protruding toward the third mass part 300 side.

- the detector holding part 201A1 is disposed at a corner where the end of the fixed part 111 on the support beam 4A side and the end of the third mass part 300 intersect.

- the detector holding part 201B1 is disposed at a corner where the end of the fixed part 111 on the central axis 101C side and the end of the third mass part 300 intersect.

- the side of the inner frame portion 101A on the third mass portion 300 side includes a long detector holding portion 2051 (corresponding to the “movable side holding portion” of the present invention) protruding toward the fixed portion 111 side.

- the detector holding unit 2051 is arranged at an intermediate position between the detector holding units 201A1 and 201B1 along the X-axis direction.

- the acceleration detectors 202A1, 202B1, 202C1, 202D1 are connected to the support beam 4A side of the detector holding portion 201A1 and have a shape protruding to the support beam 4A side.

- the acceleration detector 202A1 includes a detection base 220A1 and a plurality of protrusions 222A1.

- the detection base 220A1 has a long shape extending in the X-axis direction, and one end thereof is connected to the detector holding portion 201A1.

- the plurality of protrusions 222A1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 222A1 are arranged on the side of the base 220A1 on the second mass unit 20 side at a predetermined interval along the direction in which the base 220A1 extends (X-axis direction).

- the acceleration detector 202B1 includes a detection base 220B1, a plurality of protrusions 221B1, and a plurality of protrusions 222B1.

- the detection base 220B1 has a long shape extending in the X-axis direction, and one end thereof is connected to the detector holder 201A1.

- the plurality of protrusions 221B1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 221B1 are arranged at predetermined intervals along the direction (X axis direction) in which the detection base 220B1 extends on the side of the detection base 220B1 on the third mass unit 300 side.

- the plurality of protrusions 222B1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 222B1 are arranged at predetermined intervals along the direction (X-axis direction) in which the detection base 220B1 extends on the side of the detection base 220B1 on the second mass unit 20 side.

- the acceleration detector 202C1 includes a detection base 220C1, a plurality of protrusions 221C1, and a plurality of protrusions 222C1.

- the detection base 220C1 has a long shape extending in the X-axis direction, and one end thereof is connected to the detector holding portion 201A1.

- the plurality of protrusions 221C1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 221C1 are arranged on the side of the detection base 220C1 on the third mass unit 300 side at a predetermined interval along the direction in which the detection base 220C1 extends (X-axis direction).

- the plurality of protrusions 222C1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 222C1 are arranged at predetermined intervals along the direction in which the detection base 220C1 extends (X-axis direction) on the side of the detection base 220C1 on the second mass unit 20 side.

- the acceleration detector 202D1 includes a detection base 220D1 and a plurality of protrusions 221D1.

- the detection base 220D1 has a long shape extending in the X-axis direction, and one end thereof is connected to the detector holding portion 201A1.

- the plurality of protrusions 221D1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 221D1 are arranged at predetermined intervals along the direction in which the detection base 220D1 extends (X-axis direction) on the side of the detection base 220D1 on the third mass unit 300 side.

- the acceleration detectors 204A1, 204B1, 204C1 are connected to the fixed portion 111 side of the inner frame 101A and have a shape protruding to the fixed portion 111 side.

- the acceleration detector 204A1 includes a detection base 240A1, a plurality of protrusions 241A1, a plurality of protrusions 242A1, and a capacitance forming part 243A1.

- the detection base 240A1 has a long shape extending in the X-axis direction, and one end thereof is connected to the inner frame portion 101A.

- the plurality of protrusions 241A1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 241A1 are arranged on the side of the detection base 240A1 on the third mass unit 300 side at a predetermined interval along the direction in which the detection base 240A1 extends (X-axis direction).

- the plurality of protrusions 242A1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 242A1 are arranged at predetermined intervals along the direction in which the detection base 240A1 extends (X-axis direction) on the side of the detection base 240A1 on the second mass unit 20 side.

- the capacitance forming portion 243A1 is formed at the end of the detection base portion 240A1 on the detector holding portion 201A1 side.

- the capacitance forming portion 243A1 is formed so that the area seen along the X-axis direction is wider than the area of the detection base portion 240A1.

- the area of the electrostatic capacity forming unit 243A1 viewed along the X-axis direction is appropriately set to a value suitable for correcting a change in electrostatic capacity during vibration described later. Further, by adjusting the length of the capacitance forming portion 243A1 in the X-axis direction, the distance between the capacitance forming portion 243A1 and the inner frame portion 101A is suitable for correcting a change in capacitance during vibration described later. The value is set appropriately.

- the acceleration detector 204B1 includes a detection base 240B1, a plurality of protrusions 241B1, a plurality of protrusions 242B1, and a capacitance forming part 243B1.

- the detection base 240B1 has a long shape extending in the X-axis direction, and one end thereof is connected to the inner frame portion 101A.

- the plurality of protrusions 241B1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 241B1 are arranged at predetermined intervals along the direction in which the detection base 240B1 extends (X-axis direction) on the side of the detection base 240B1 on the third mass unit 300 side.

- the plurality of protrusions 242B1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 242B1 are arranged at predetermined intervals along the direction (X-axis direction) in which the detection base 240B1 extends on the side of the detection base 240B1 on the second mass unit 20 side.

- the capacitance forming part 243B1 is formed at the end of the detection base part 240B1 on the detector holding part 201A1 side.

- the capacitance forming portion 243B1 is formed so that the area viewed along the X-axis direction is wider than the area of the detection base portion 240B1.

- the area of the electrostatic capacity forming unit 243B1 viewed along the X-axis direction is appropriately set to a value suitable for correcting a change in electrostatic capacity during vibration described later. Further, by adjusting the length of the capacitance forming portion 243B1 in the X-axis direction, the distance between the capacitance forming portion 243B1 and the inner frame portion 101A is suitable for correcting the capacitance change during vibration described later. The value is set appropriately.

- the acceleration detector 204C1 includes a detection base 240C1, a plurality of protrusions 241C1, a plurality of protrusions 242C1, and a capacitance forming part 243C1.

- the detection base 240C1 has a long shape extending in the X-axis direction, and one end thereof is connected to the inner frame portion 101A.

- the plurality of protrusions 241C1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 241C1 are arranged at predetermined intervals along the direction in which the detection base 240C1 extends (X-axis direction) on the side of the detection base 240C1 on the third mass unit 300 side.

- the plurality of protrusions 242C1 have a rectangular shape having a predetermined width in the X-axis direction.

- the plurality of protrusions 242C1 are arranged at predetermined intervals along the direction (X-axis direction) in which the detection base 240C1 extends on the side of the detection base 240C1 on the second mass unit 20 side.

- the capacitance forming portion 243C1 is formed at the end of the detection base portion 240C1 on the detector holding portion 201A1 side.

- the capacitance forming portion 243C1 is formed so that the area viewed along the X-axis direction is larger than the area of the detection base portion 240C1.

- the area of the electrostatic capacity forming unit 243C1 viewed along the X-axis direction is appropriately set to a value suitable for correcting a change in electrostatic capacity during vibration described later. Further, by adjusting the length of the capacitance forming portion 243C1 in the X-axis direction, the distance between the capacitance forming portion 243C1 and the inner frame portion 101A is suitable for correcting the capacitance change during vibration described later. The value is set appropriately.

- the acceleration detectors 202A1, 202B1, 202C1, 202D1 and the acceleration detectors 204A1, 204B1, 204C1 are alternately arranged along the Y-axis direction. Specifically, the acceleration detector 204A1 is disposed between the acceleration detectors 202A1 and 202B1. The acceleration detector 204B1 is disposed between the acceleration detectors 202B1 and 202C1. The acceleration detector 204C1 is disposed between the acceleration detectors 202C1 and 202D1.

- each component of one movable-side acceleration detector and each component of two fixed-side movable-side detectors sandwiching the movable-side acceleration detector are respectively components of the present invention.

- the detection base of the movable acceleration detector sandwiched in the Y-axis direction corresponds to the “movable side detection base” of the present invention.

- the protrusion protruding to the side opposite to the center of gravity G of the detection base of the movable acceleration detector is the present invention.

- the protrusion protruding toward the center of gravity G of the detection base of the movable-side acceleration detector (in the case of the first mass unit 10, the positive direction in the Y-axis direction and the second mass unit 20 side) This corresponds to the “movable side second protrusion”.

- the detection base portion of the fixed-side acceleration detector adjacent to the movable-side acceleration detector and disposed on the side opposite to the center of gravity G corresponds to the “first fixed-side detection base” of the present invention.

- the protrusion that protrudes toward the acceleration detector on the movable portion side of the fixed-side detection main shaft corresponds to the “fixed-side first protrusion” of the present invention.

- the detection base of the fixed-side acceleration detector arranged adjacent to the movable-side acceleration detector and located on the center of gravity G side corresponds to the “second fixed-side detection base” of the present invention.

- the protrusion that protrudes toward the acceleration detector on the movable portion side of the fixed-side detection main shaft corresponds to the “fixed-side second protrusion” of the present invention.

- the detection base 240A1 corresponds to the “movable-side detection base”.

- the protrusion 241A1 corresponds to the “movable side first protrusion” of the present invention.

- the protrusion 242A1 corresponds to the “movable side second protrusion” of the present invention.

- the detection base 220A1 of the fixed-side acceleration detector 202A1 corresponds to a “first fixed-side detection base”.

- the protrusion 222A1 corresponds to a “fixed-side first protrusion”.

- the detection base 220B1 of the fixed-side acceleration detector 202B1 corresponds to a “second fixed-side detection base”.

- the protrusion 221B1 corresponds to a “fixed-side second protrusion”.

- the protrusions of the acceleration detectors 202A1, 202B1, 202C1, and 202D1 and the protrusions of the acceleration detectors 204A1, 204B1, and 204C1 are arranged to face each other with a predetermined area.

- the protrusion 222A1 of the acceleration detector 202A1 and the protrusion 241A1 of the acceleration detector 204A1 face each other.

- the protrusion 242A1 of the acceleration detector 204A1 and the protrusion 221B1 of the acceleration detector 202B1 face each other.

- the protrusion 222B1 of the acceleration detector 202B1 and the protrusion 241B1 of the acceleration detector 204B1 face each other.

- the protrusion 242B1 of the acceleration detector 204B1 and the protrusion 221C1 of the acceleration detector 202C1 face each other.

- the protrusion 222C1 of the acceleration detector 202C1 and the protrusion 241C1 of the acceleration detector 204C1 face each other.

- the protrusion 242C1 of the acceleration detector 204C1 and the protrusion 221D1 of the acceleration detector 202D1 face each other.

- the projections of the acceleration detectors 202A1, 202B1, 202C1, and 202D1 and the projections of the acceleration detectors 204A1, 204B1, and 204C1 do not face each other, but each of the projections that face each other has an X axis. Opposite in the direction. At this time, the protrusions of the acceleration detectors 202A1, 202B1, 202C1, and 202D1 are displaced in different directions in the X-axis direction with respect to the protrusions of the acceleration detectors 204A1, 204B1, and 204C1 that are sandwiched therebetween.

- each protrusion 222A1 of the fixed-side acceleration detector 202A1 is positioned on the detector holding portion 201A1 side along the X-axis direction with respect to each protrusion 241A1 of the movable-side acceleration detector 204A1.

- the protrusions 221B1 of the fixed-side acceleration detector 202B1 are shifted toward the inner frame 101A adjacent to the protrusions 242A1 of the movable-side acceleration detector 204A1 along the X-axis direction.

- each protrusion is formed so that the amount of deviation is the same. More preferably, each protrusion is formed such that the amount of deviation is half of the protrusion in the X-axis direction.

- the acceleration sensors 204A1, 204B1, 204C1 on the movable side can be moved in the X-axis direction by adding these capacitances. Even if it vibrates, the change in capacitance due to the vibration can be prevented.

- the acceleration detectors 202E1, 202F1, 202G1 are connected to the center axis 101C side of the detector holding portion 201A1 and have a shape projecting toward the center axis 101C side.

- the acceleration detector 202E1 is formed symmetrically with the acceleration detector 202A1 with respect to the detector holder 201A1.

- the acceleration detector 202F1 is formed symmetrically with the acceleration detector 202B1 with respect to the detector holder 201A1.

- the acceleration detector 202G1 is formed at a position symmetrical to the acceleration detector 202C1 with respect to the detector holder 201A1, and the shape of the acceleration detector 202G1 is the same as that of the acceleration detector 202D1 projected in line symmetry. .

- the acceleration detectors 204D1 and 204E1 are connected to the detector holding unit 201A1 side of the detector holding unit 2051 and have a shape protruding to the detector holding unit 201A1 side.

- the acceleration detector 204D1 has a shape symmetrical with the acceleration detector 204A1 with respect to the detector holder 201A1.

- the acceleration detector 204E1 has a shape symmetrical with the acceleration detector 204B1 with respect to the detector holder 201A1.

- Acceleration detectors 202E1, 202F1, 202G1 and acceleration detectors 204D1, 204E1 are alternately arranged along the Y-axis direction. Specifically, the acceleration detector 204D1 is disposed between the acceleration detectors 202E1 and 202F1. An acceleration detector 204E1 is disposed between the acceleration detectors 202F1 and 202G1. The projections of the acceleration detectors 202E1, 202F1, 202G1 and the projections of the acceleration detectors 204D1, 204E1 are the projections of the acceleration detectors 202A1, 202B1, 202C1, 202D1, and the acceleration detectors 204A1, 204B1, 204C1. As in the projections of FIG. 2, they face each other in a state shifted in the X-axis direction, and the arrangement order thereof is the same along the X-axis direction.

- the acceleration detectors 204F1 and 204G1 are connected to the detector holding unit 201B1 side of the detector holding unit 2051 and have a shape protruding to the detector holding unit 201B1 side.

- the acceleration detector 204F1 has a shape symmetrical with the acceleration detector 204D1 with respect to the detector holder 2051.

- the acceleration detector 204G1 has a shape symmetrical with the acceleration detector 204E1 with respect to the detector holder 2051.

- the acceleration detectors 202H1, 202I1, and 202J1 are connected to the detector holding unit 2051 side of the detector holding unit 201B1 and have a shape protruding to the detector holding unit 2051 side.

- the acceleration detector 202H1 is formed symmetrically with the acceleration detector 202E1 with respect to the detector holder 2051.

- the acceleration detector 202I1 is formed symmetrically with the acceleration detector 202F1 with respect to the detector holder 2051.

- the acceleration detector 202J1 is formed symmetrically with the acceleration detector 202G1 with respect to the detector holder 2051.

- Acceleration detectors 202H1, 202I1, 202J1 and acceleration detectors 204F1, 204G1 are alternately arranged along the Y-axis direction. Specifically, the acceleration detector 204F1 is disposed between the acceleration detectors 202H1 and 202I1. An acceleration detector 204G1 is disposed between the acceleration detectors 202I1 and 202J1.

- the projections of the acceleration detectors 202H1, 202I1, 202J1 and the projections of the acceleration detectors 204F1, 204G1 are the projections of the acceleration detectors 202A1, 202B1, 202C1, 202D1, and the acceleration detectors 204A1, 204B1, 204C1. As in the projections of FIG. 2, they face each other in a state shifted in the X-axis direction, and the arrangement order thereof is the same along the X-axis direction.

- the acceleration detectors 202K1, 202L1, 202M1, and 202N1 are connected to the center axis 101C side of the detector holding portion 201B1 and have a shape protruding toward the center axis 101C side.

- the acceleration detector 202K1 is formed symmetrically with the acceleration detector 202A1 with reference to an axis passing through the center in the width direction of the detector holder 2051 and extending in the Y-axis direction.

- the acceleration detector 202L1 is formed in line symmetry with the acceleration detector 202B1 with reference to an axis that passes through the center in the width direction of the detector holder 2051 and extends in the Y-axis direction.

- the acceleration detector 202M1 is formed in line symmetry with the acceleration detector 202C1 with reference to an axis that passes through the center in the width direction of the detector holder 2051 and extends in the Y-axis direction.

- the acceleration detector 202N1 is formed in line symmetry with the acceleration detector 202D1 with reference to an axis passing through the center in the width direction of the detector holder 2051 and extending in the Y-axis direction.

- the acceleration detectors 204H1, 204I1, and 204J1 are connected to the fixed portion 111 side of the central axis 101C and have a shape that protrudes toward the fixed portion 111 side.

- the acceleration detector 204H1 is formed in line symmetry with the acceleration detector 204A1 with reference to an axis passing through the center in the width direction of the detector holder 2051 and extending in the Y-axis direction.

- the acceleration detector 204I1 is formed in line symmetry with the acceleration detector 204B1 with reference to an axis that passes through the center in the width direction of the detector holder 2051 and extends in the Y-axis direction.

- the acceleration detector 204J1 is formed in line symmetry with the acceleration detector 204C1 with reference to an axis that passes through the center in the width direction of the detector holder 2051 and extends in the Y-axis direction.

- Acceleration detectors 202K1, 202L1, 202M1, 202N1 and acceleration detectors 204H1, 204I1, 204J1 are alternately arranged along the Y-axis direction. Specifically, the acceleration detector 204H1 is disposed between the acceleration detectors 202K1 and 202L1. An acceleration detector 204I1 is disposed between the acceleration detectors 202L1 and 202M1. An acceleration detector 204J1 is disposed between the acceleration detectors 202M1 and 202N1.

- the projections of the acceleration detectors 202K1, 202L1, 202M1, and 202N1 and the projections of the acceleration detectors 204H1, 204I1, and 204J1 are the projections of the acceleration detectors 202A1, 202B1, 202C1, and 202D1, and the acceleration detector 204A1.

- 204B1 and 204C1 are opposed to each other while being displaced in the X-axis direction, and the arrangement order thereof is the same along the X-axis direction.

- the acceleration detectors 202A1 to 202N1 and 204A1 to 204J1 are vibrated.

- the opposing distance of the protrusions of the slab changes. Since the capacitance changes corresponding to the change in the facing distance, the acceleration can be detected by detecting the amount of change. Since the direction of change in capacitance (capacitance from large to small, or from small to large) varies depending on the direction of acceleration, the direction of acceleration can also be detected.

- a plurality of angular velocity detectors 3011 and 3021 are formed in the space on the support beam 4A side and the space on the central axis 101C side of the fixed portion 111.

- the angular velocity detector 3011 has a long shape with one end connected to the fixed portion 111.

- the angular velocity detector 3021 has a long shape with one end connected to the central axis 101C.

- the angular velocity detector 3011 on the support beam 4 ⁇ / b> A side and the angular velocity detector 3011 on the central axis 101 ⁇ / b> C side are arranged at symmetrical positions via the fixing portion 111.

- the angular velocity detectors 3011 and 3021 are alternately arranged along the Y-axis direction. At this time, the distance to the angular velocity detector 3021 on the second mass unit 20 side is set wider than the interval to the angular velocity detector 3021 on the third mass unit 300 side based on one angular velocity detector 3011. .

- the angular velocity detectors 3011 and 3021 By configuring the angular velocity detectors 3011 and 3021 in such a structure, the angular velocity ⁇ with the Z-axis direction (the direction orthogonal to the X-axis and the Y-axis) as an axis is applied to the sensor element 1 in a state of vibrating in the X-axis direction.

- the Coriolis force in the Y-axis direction is applied to the inner frame portion 101A of the first mass unit 10, and the capacitance between the angular velocity detectors 3011 and 3021 changes. By detecting this amount of change, the angular velocity ⁇ can be detected.

- the Y axis If Coriolis force is applied in the negative direction of the direction, the capacitance decreases, and if Coriolis force is applied in the positive direction in the Y-axis direction, the capacitance increases. Therefore, the direction of the angular velocity ⁇ can also be detected.

- the angular velocity detectors 3011 and 3021 are elongated in the X-axis direction, have a large area with respect to the Y-axis direction, and have a large area facing each other, so that the mechanical Q value in the acceleration application direction is reduced. be able to. Thereby, the damping effect with respect to acceleration detection can be obtained.

- FIG. 4 is an enlarged plan view showing the configuration of the second detection unit according to the embodiment of the present invention.

- the second detector 12 includes a fixed part 121, acceleration detectors 202A2, 202B2, 202C2, 202D2, 202E2, 202F2, 202G2, 202H2, 202I2, 202J2, 202K2, 202L2, 202M2, 202N2, and acceleration detectors 204A2, 204B2.

- the fixing part 121 is arranged in the other internal space divided by the central axis 101C in the internal space of the inner frame part 101A.

- the fixed part 121 has a shape symmetrical with the fixed part 111 with respect to the Y axis passing through the center of gravity G.

- the detector holders 201A2 and 201B2 connected to the fixed part 121 are symmetrical with the detector holders 201A1 and 201B1, respectively, with respect to the Y axis.

- the detector holding unit 2052 connected to the inner frame 103B has a shape symmetrical with the detector holding unit 2051 with respect to the Y axis.

- the acceleration detectors 202A2 to 202N2 are roughly symmetrical with the acceleration detectors 202A1 to 202N1 with respect to the Y axis, respectively.

- the acceleration detectors 204A2 to 204J2 are roughly The acceleration detectors 204A1 to 204J1 are symmetrical with respect to the acceleration detectors 204A1 to 204J1, but the order of arrangement of the protrusions of the acceleration detectors 202A2 to 202N2 and the protrusions of the acceleration detectors 204A2 to 204J2 is the acceleration detection.

- the order of arrangement of the projections of the children 202A1 to 202N1 and the projections of the acceleration detectors 204A1 to J1 is not symmetrical with respect to the arrangement order, but is in the same order along the X-axis direction.

- acceleration detection signals having the same amplitude and the same phase as the acceleration detectors 202A1 to 202N1 and 204A1 to 204J1 can be obtained.

- the arrangement group of the plurality of angular velocity detectors 3012 and 3022 is substantially symmetrical with the arrangement group of the plurality of angular velocity detectors 3011 and 3021 with respect to the Y axis, but the arrangement order along the arrangement direction is reversed. It is.

- an angular velocity detection signal having the same amplitude as that of the angular velocity detectors 3011 and 3021 can be obtained.

- FIG. 5 is an enlarged plan view showing the configuration of the third detection unit according to the embodiment of the present invention.

- the third detector 13 includes a fixed portion 131, acceleration detectors 202A3, 202B3, 202C3, 202D3, 202E3, 202F3, 202G3, 202H3, 202I3, 202J3, 202K3, 202L3, 202M3, 202N3 and acceleration detectors 204A3, 204B3.

- 204C3, 204D3, 204E3, 204F3, 204G3, 204H3, 204I3, 204J3 are provided.

- the fixed portion 131 is disposed in one internal space divided by the central axis 101D in the internal space of the inner frame portion 101B.

- the fixed portion 131 has a shape symmetrical with the fixed portion 111 with respect to the X axis passing through the center of gravity G.

- the detector holders 201A3 and 201B3 connected to the fixed part 131 are symmetrical with the detector holders 201A1 and 201B1, respectively, with respect to the X axis.

- the detector holding unit 2053 connected to the inner frame portion 103D has a shape symmetrical with the detector holding unit 2051 with respect to the X axis.

- the acceleration detectors 202A3 to 202N3 have a shape symmetrical with the acceleration detectors 202A1 to 202N1 with respect to the X axis.

- the acceleration detectors 204A3 to 204J3 have line-symmetric shapes with respect to the acceleration detectors 204A1 to 204J1, respectively, with respect to the X axis.

- the projections of the acceleration detectors 202A3 to 202N3 and the projections of the acceleration detectors 204A3 to 204J3 are the same as the projections of the acceleration detectors 202A1 to 202N1 and the projections of the acceleration detectors 204A1 to J1, respectively. Opposing in a state shifted in the X-axis direction.

- acceleration detection signals having the same amplitude and the same phase as the acceleration detectors 202A1 to 202N1 and 204A1 to 204J1 can be obtained.

- the plurality of angular velocity detectors 3013 and 3023 have line-symmetric shapes with the plurality of angular velocity detectors 3011 and 3021, respectively, with respect to the X axis.

- an angular velocity detection signal having the same amplitude and the same phase as the angular velocity detectors 3011 and 3021 can be obtained.

- FIG. 6 is an enlarged plan view showing the configuration of the fourth detection unit according to the embodiment of the present invention.

- the fourth detector 14 includes a fixed portion 141, acceleration detectors 202A4, 202B4, 202C4, 202D4, 202E4, 202F4, 202G4, 202H4, 202I4, 202J4, 202K4, 202L4, 202M4, 202N4 and acceleration detectors 204A4, 204B4.

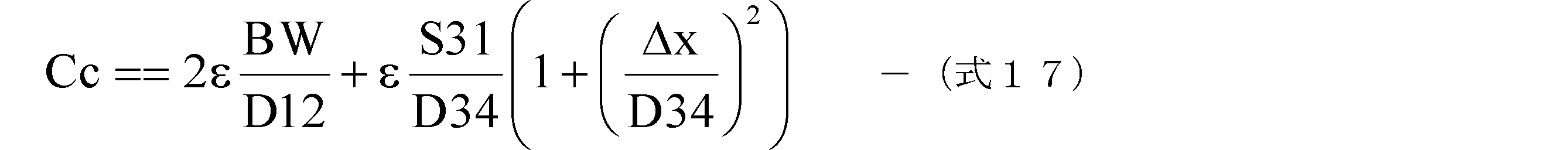

- 204C4, 204D4, 204E4, 204F4, 204G4, 204H4, 204I4, 204J4 are provided.