WO2013065620A1 - Disposable diaper - Google Patents

Disposable diaper Download PDFInfo

- Publication number

- WO2013065620A1 WO2013065620A1 PCT/JP2012/077834 JP2012077834W WO2013065620A1 WO 2013065620 A1 WO2013065620 A1 WO 2013065620A1 JP 2012077834 W JP2012077834 W JP 2012077834W WO 2013065620 A1 WO2013065620 A1 WO 2013065620A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- panel

- elastic

- region

- crotch

- rear waist

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/496—Absorbent articles specially adapted to be worn around the waist, e.g. diapers in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/49011—Form-fitting, self-adjusting disposable diapers with elastic means the elastic means is located at the waist region

- A61F13/49012—Form-fitting, self-adjusting disposable diapers with elastic means the elastic means is located at the waist region the elastic means being elastic panels

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

- A61F13/49009—Form-fitting, self-adjusting disposable diapers with elastic means

- A61F13/4902—Form-fitting, self-adjusting disposable diapers with elastic means characterised by the elastic material

Definitions

- the present invention relates to a disposable wearing article, and more specifically, a disposable diaper having a crotch panel and an elastic waist panel and having a buttocks panel covering a wearer's buttocks, disposable toilet training pants, disposable incontinence pants, disposable

- the present invention relates to disposable wearing articles such as sanitary pants and disposable absorbent pads.

- Patent Document 1 discloses a disposable wearing article that includes an elastic waist panel that forms a front and rear waist region and a crotch panel that extends to the front and rear waist region around the crotch region.

- the front and rear end portions of the crotch panel are interposed and attached between the inner and outer surface sheets forming the front and rear waist panels, and the both sides are in the longitudinal direction of the wearing article.

- a pair of elastic side flaps in which extending leg elastic bodies are disposed are located. In the wearing state of the wearing article, the pair of elastic side flaps rises toward the wearer's body, and a pocket capable of accommodating excrement is formed between the front and rear waist panels and the crotch panel.

- a waste storage space for absorbing and holding a relatively large amount of waste is defined.

- the subject of this invention is improvement of the conventional disposable wearing article, Comprising:

- the disposable wearing article which has sufficient excrement accommodation space and does not expose a wearer's buttocks during wearing is provided. There is.

- the present invention has a longitudinal direction and a lateral direction perpendicular thereto, and is located between the skin facing surface and the non-skin facing surface located on the opposite side, the front waist region, the rear waist region, and the front and rear waist regions.

- a crotch region, the front and rear waist regions are defined, and an elastic waist panel formed from the front and rear waist panels and attached to the elastic waist panel to define a part of the front and rear waist regions and the crotch region,

- the present invention relates to a disposable wearing article including a crotch panel including a liquid structure.

- the present invention further includes a buttocks panel separate from the elastic waist panel, and the buttocks panel is attached to a rear waist panel that forms the rear waist area at an outer end thereof, and the crotch area side.

- the collar panel may be elastically stretchable in the lateral direction at least on both lateral sides of the liquid absorbing structure.

- the buttock panel extends from the inner edge of the rear waist panel forming the rear waist region to the crotch region side, the crotch panel during wearing Even if a part of is caught in the crack, there is no possibility that the buttock is covered with the buttock panel and exposed to the outside. Further, since the buttock panel is elastically stretchable at least in the lateral direction on both sides of the liquid absorption structure of the crotch panel, both sides are bent away from the buttock of the wearer or deformed during wearing. There is no fear.

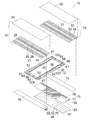

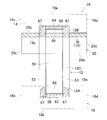

- FIG. 4 is a schematic cross-sectional view taken along line VI-VI in FIG. 1.

- a disposable diaper 10 shown as an example of the disposable wearing article of the present invention includes a longitudinal direction Y and a transverse direction X orthogonal thereto, and a virtual longitudinal center line that bisects the width dimension of the transverse direction X. PP and a virtual horizontal center line QQ that bisects the width dimension in the vertical direction X.

- the diaper 10 is formed symmetrically with respect to the virtual vertical center line PP.

- the diaper 10 includes a skin facing surface, a non-skin facing surface facing the skin, an annular elastic waist panel 11 extending in the direction of the waist, a crotch panel 12 attached to the non-skin facing surface of the elastic waist panel 11, and each panel.

- 11 and 12 includes a front waist region 13, a rear waist region 14, and a crotch region (intermediate region) 15 extending between the front and rear waist regions 13 and 14 in the longitudinal direction Y.

- the elastic waist panel 11 includes a front waist panel 18 located in the front waist region 13 and a rear waist panel 19 located in the rear waist region 14.

- a buttock panel 20 is located facing and covering the wearer's buttock while the diaper 10 is worn.

- the front waist panel 18 intersects the crotch panel 12 and extends in the lateral direction X.

- the outer end edge 18b extends in the lateral direction X while being spaced apart from the inner end edge 18a in the longitudinal direction Y. It has a horizontally long rectangular shape defined by both side edges 18c, 18d extending in the longitudinal direction Y between the edges 18a, 18b.

- the rear waist panel 19 is substantially the same shape and size as the front waist panel 18, intersects the crotch panel 12, and has an inner end edge 19 a that extends in the lateral direction X and is spaced apart from the inner end edge 19 a in the longitudinal direction Y. It has a horizontally long rectangular shape defined by an outer edge 19b extending in the horizontal direction X and both side edges 19c, 19d extending in the vertical direction Y between the inner and outer edges 19a, 19b.

- Each of the side edges 18c, 18d of the front waist panel 18 and each of the side edges 19c, 19d of the rear waist panel 19 are overlapped with each other and connected by side seam portions 22 extending intermittently in the longitudinal direction Y.

- An opening 23 and a pair of leg openings 24 are defined (see FIG. 1).

- the side seam 22 portion is applied by a known joining means, for example, various heat welding means such as hot embossing and sonic processing.

- the front waist panel 18 has a first inner sheet 24 positioned on the skin facing surface side and a first outer sheet 25 positioned on the non-skin facing surface side.

- the first inner and outer sheet 24, 25 is a substantially liquid-impervious SMS (spunbond / meltblown / spainbond) fiber nonwoven fabric, a spunbond nonwoven fabric, a plastic sheet or a nonwoven fabric having a mass of about 10 to 30 g / m 2. It can be formed from one laminate sheet. Both sheets 24 and 25 are joined to each other by a hot melt adhesive applied intermittently to at least one of the inner surfaces or the heat welding means.

- a plurality of strand-like or string-like elastic bodies 27 extending in the transverse direction X are disposed between both sheets 24 and 25.

- the front waist panel 18 is elasticized so that it can contract at least in the lateral direction X by the elastic body 27 being disposed under the extension in the lateral direction X.

- Both sheets 24 and 25 are made of hot-melt adhesive applied to almost the entire circumferential surface of the elastic body 27 as long as there is no fear that the sheets 24 and 25 are peeled off during handling or wearing of the diaper 10.

- the elastic body 27 includes a plurality of elastic bodies 28 extending in the lateral direction X along the outer end edge 18b of the front waist panel 18, and a plurality of elastic bodies 29 extending in the lateral direction X along the inner end edge 18a. Composed. A part of the elastic body 29 is arranged denser than the elastic body 28.

- the rear waist panel 19 has a second inner sheet 30 positioned on the skin facing surface side and a second outer sheet 31 positioned on the non-skin facing surface side.

- the second inner and outer sheets 30, 31 are substantially liquid-impervious SMS (spunbond / meltblown / spainbond) fiber nonwoven fabrics, spunbond fiber nonwoven fabrics, plastic sheets or nonwoven fabrics having a mass of about 10 to 30 g / m 2.

- SMS spunbond / meltblown / spainbond

- Both sheets 30 and 31 are joined by a hot melt adhesive applied intermittently to at least one of the inner surfaces or by the heat welding means.

- a plurality of strand-like or string-like elastic bodies 32 extending in the transverse direction X are arranged extending in the transverse direction X.

- the rear waist panel 19 is elasticized so as to be contractible at least in the lateral direction X by providing the elastic body 32. Both sheets 30 and 31 may be joined to each other only via a hot melt adhesive applied to substantially the entire circumferential surface of the elastic body 32.

- the elastic body 32 includes a plurality of elastic bodies 33 extending in the lateral direction X along the upper end edge 19b of the rear waist panel 19 and a plurality of elastic bodies 34 extending in the horizontal direction X along the inner end edge 19a. Is done. A part of the elastic body 34 is arranged denser than the elastic body 33.

- the elastic bodies 27 and 32 can be formed of an elastic material having a thickness (wire diameter) of about 400 to 1000 dtex and an expansion ratio of about 1.8 to 3.0 times. Further, the separation dimension (pitch, distance between the center portions of the elastic bodies) in the longitudinal direction Y between the elastic bodies is about 5.0 to 30.0 mm, and preferably at least 6.0 mm or more.

- the collar panel 20 includes an inner end edge 20a extending in the lateral direction X, an outer end edge 20b extending in the lateral direction X spaced apart from the outer end edge 20b in the longitudinal direction Y, and inner and outer ends. It has a horizontally long rectangular shape defined by both side edges 20c and 20d extending in the longitudinal direction Y between the edges 20a and 20b.

- the buttocks panel 20 includes an inner layer sheet 36 and an outer layer sheet 37.

- the inner and outer layer sheets 36 and 37 are substantially liquid-impervious SMS (spunbond / meltblown / spunbond) fiber nonwoven fabrics, spunbond fiber nonwoven fabrics, plastic sheets or plastic sheets having a mass of about 10 to 20 g / m 2. It can be formed from one laminate sheet. Both sheets 36 and 37 are joined by a hot melt adhesive or the above-mentioned heat welding means.

- an elastic body 38 made of a plurality of strand-like or string-like elastic bodies extending in the lateral direction X is disposed extending in the lateral direction X.

- the elastic body 40 is located on the rear waist panel 19 side

- the elastic body 42 is located on the front waist panel 18 side

- the elastic body 43 is located between the elastic body 40 and the elastic body 42.

- Both sheets 36 and 37 may be joined to each other only via a hot melt adhesive applied to substantially the entire peripheral surface of each elastic body constituting the elastic body.

- the buttock panel 20 may be formed by bending a single sheet formed from the fiber nonwoven sheet into two with an elastic body 38 interposed therebetween, or the elastic body 38 is formed of an elastic stretch sheet. May be.

- you may form collar part panel 20 itself with an elastic sheet.

- the elastic body 38 is cut so that a non-elastic region 45 is formed in the central portion of the collar panel 20 that overlaps the central portion of the region of the liquid absorbing structure 49.

- a first elastic region 46 and a second elastic region 47 that can contract at least in the lateral direction are formed on both sides. Since the first and second elastic regions 46 and 47 are provided, both side portions of the buttock panel 20 fit the wearer's buttock, so that they are bent away from the buttock or deformed during wearing. There is no fear.

- the collar panel 20 is formed of a stretchable sheet, it is preferable to process (for example, break a part of the sheet) so that the stretchable elasticity is not expressed or reduced in the non-elastic region 45.

- the collar panel 20 and the back waist panel 19 can also be formed integrally, when forming the collar panel 20 separately from the back waist panel 19 like this embodiment, in the manufacturing process, After manufacturing the normal disposable diaper which does not have the buttocks panel 20, the buttocks panel 20 can be attached to the outer surface of the rear waist region 14 of the diaper. Therefore, the manufacturing apparatus of a normal diaper can be utilized, and a manufacturing cost can be suppressed compared with the case where the collar panel 20 and the rear waist panel 19 are formed integrally.

- non-elastic region means that a plurality of elastic bodies forming the elastic region are cut or removed at the site and are not substantially present, or an elastic body is present. This means that the elastic elasticity is not expressed.

- the joining regions overlap” and “the joining regions and the elastic body overlap” mean that they overlap or cross over three-dimensionally in addition to directly or indirectly overlapping in a plane.

- the crotch panel 12 has a vertically long and substantially rectangular shape, and has a front end portion 12A connected to a non-skin facing surface (outer surface) of the front waist panel 18 and a non-skin of the rear waist panel 19. A rear end portion 12B connected to the opposing surface and an intermediate portion 12C extending in the vertical direction Y between the front and rear end portions 12A and 12B.

- the crotch panel 12 includes a base sheet 48, a liquid absorbent structure 49 disposed on the inner surface of the base sheet 48, and a body side liner 50 formed of a liquid permeable sheet that covers the liquid absorbent structure 49. Have.

- the front and rear end edges of the front and rear end portions 12A and 12B of the crotch panel 12 are covered with front and rear cover sheets 70 and 71 that are formed from a fiber nonwoven fabric and extend in the lateral direction X.

- the base sheet 48 is formed by inner and outer surface crotch sheets 51 and 52, at least one of which is made of a substantially liquid-impervious fiber nonwoven fabric sheet or a liquid-impervious plastic film. Also, the inner and outer surface crotch sheets 51 and 52 are joined to each other via a hot melt adhesive (not shown), and both sides thereof are bent inward and have a gasket function extending in the longitudinal direction Y.

- the elastic side flap 53 is formed.

- Each elastic side flap 53 is provided with a plurality of strand-like or string-like elastic bodies 54 and 55 extending in the longitudinal direction Y, and is elasticized at least in the longitudinal direction Y.

- the elastic body 54 is curved toward the longitudinal axis P at the central portion of the crotch region 15 and extends in the direction around the wearer's leg when the diaper 10 is worn, while the elastic body 55 is the elastic side flap 53. It extends in a straight line in the longitudinal direction Y along the inner edge 53a.

- the elastic bodies 54 and 55 are arranged in the longitudinal direction Y between the sheets 51 and 52 via a hot melt adhesive (not shown) applied to the inner surface of one of the inner and outer surface crotch sheets 51 and 52. It is fixed in the extended state.

- the elastic body 54 has a central portion that is convex toward the vertical axis P, is close to the other elastic body 54, and in the elastic region of the elastic bodies 54 and 55, the elongation stress at those adjacent portions is elastic body 54. , 55 is increased compared to the elongation stress at the front and rear waist panels 18 and 19 side. Thereby, the central part vicinity of the elastic side flap 53 which should contact a wearer's thigh closely_contact

- the body side liner 50 is a fiber non-woven sheet having a liquid permeability of about 15 to 35 g / m 2 , preferably hydrophilized, such as a spunbond fiber non-woven fabric, a point bond fiber non-woven fabric and an air-through non-woven fabric. These can be formed from various known fiber nonwoven fabrics.

- the liquid absorbing structure 49 is formed from a mixture of water-absorbing fibers such as fluff pulp and so-called absorbent polymer particles that are water-insoluble and have a water absorption capacity of 10 times or more of the self-mass.

- the absorbent core 59 can also be formed only from absorbent polymer particles in order to form it thinner. In that case, the absorbent core 59 may be divided into a plurality of absorption regions in order to prevent the shape of the absorbent polymer particles from being deformed after absorbing the body fluid. Further, the liquid absorbing structure 49 is fixed to the inner surface of the base sheet 48 via joints 62A and 62B located at the front and rear end portions thereof.

- the crotch panel 12 includes a front joint area 63 and a rear joint area 64 formed by applying hot melt adhesive to the inner surfaces of the front end portion 12A and the rear end portion 12B. It is connected to the outer surfaces of the front and rear waist panels 18,19. In this way, the front and rear end portions 12A and 12B of the crotch panel 12 are connected to the outer surfaces of the front and rear waist panels 18 and 19, so that they are excreted as compared with the case where they are connected to the inner surfaces of the front and rear waist panels 18 and 19.

- the accommodation space 83 can be formed large (see FIG. 6). In addition, as long as the excrement accommodation space 83 has a required size, only one of the front and rear waist regions 13 and 14 may be connected to the outer surface of the front and rear waist panels 18 and 19.

- the front and rear joining regions 63 and 64 have a concave shape that opens toward the crotch region 15, and both side portions 67 formed by applying a hot melt adhesive to the skin facing surface of the elastic side flap 53, respectively, 67 and a central portion 68 extending in the transverse direction X.

- the central portion 68 is located outward in the longitudinal direction Y from the liquid absorbing structure 49, and a non-bonding region 69 where no hot-melt adhesive is applied between the side portions 67 and the central portion 68. Is defined.

- the non-bonding area 69 is formed at a position facing the liquid absorbing structure 49.

- both side portions 67 of the front joint region 63 have a stepped shape

- both side portions 67 of the rear joint region 64 have a rectangular shape.

- Both side portions 67 of the regions 63 and 64 may have various shapes such as a stepped shape, a rectangular shape, and a curved shape.

- the front waist panel 19 and the rear waist panel 19 are indicated by virtual lines, and various dimensions are shown.

- the dimension L1 in the longitudinal direction Y of the diaper 10 varies depending on each size (S, M, L, LL), and is about 450 to 900 mm.

- the dimension L2 in the longitudinal direction Y of the panels (front and rear waist regions 13, 14) 18 and 19 is about 150 to 180 mm when the diaper 10 is S or M size, and about 180 to 210 mm when the diaper 10 is L or LL size. It is.

- the dimension of the crotch region 15 in the longitudinal direction Y is substantially the same for various sizes, and is about 400 to 500 mm.

- the dimension W1 in the lateral direction X of the front and rear waist panels 18 and 19 is about 450 to 500 mm when the diaper 10 is an S size for adults, and about 530 to 560 mm when the diaper 10 is an M size. In this case, it is 600 to 650 mm, and in the case of the LL size, it is about 700 to 750 mm.

- the dimension L4 in the longitudinal direction Y of the buttock panel 20 is specifically about 30 to 330 mm, preferably about 100 to 200 mm, and more preferably about 110 to 140 mm.

- the dimension L2 in the longitudinal direction Y of the front and rear waist regions 13 and 14 is about 170 mm

- the dimension L4 in the longitudinal direction Y of the buttock panel 20 is about 120 mm

- the inner edge 19a of the buttock panel 20 is moved to the crotch region 15 side.

- the dimension L5 in the longitudinal direction Y of the extending part (the part of the buttocks panel 20 extending downward from the rear waist panel 19 when the diaper 10 is worn) is about 100 mm

- the dimension L2 is about 1.7 times larger than the dimension L5.

- the dimension L2 in the longitudinal direction Y of the rear waist region 14 is not more than 2.0 times the size L5 in the longitudinal direction Y of the part extending from the rear waist region 14 to the crotch region 15 side, the former.

- a conventional diaper having a size of 2.0 times or more of the latter and covering a part of the wearer's buttocks with a portion slightly extending from the rear waist region to the crotch region 15 side It has a unique shape in view and can give a sense of security that the buttocks are not exposed even when worn by the wearer. In particular, when the diaper 10 is used for adults, there is no risk of causing the wearer to be embarrassed by exposing the buttocks.

- a buttock panel joining region 75 for joining the buttock panel 20 to the rear waist panel 19 is a transverse joint X between the side joining edges 20c and 20d of the buttock panel 20 intersecting with the center joining portion 77 located at the center. And a transverse joint portion 76 extending straight. Since the transverse joining portion 75 extends in the entire dimension in the lateral direction X of the butt panel 20, the outer end portion of the butt panel 20 is stably fixed to the rear waist panel 19 and the rear end portion 12 ⁇ / b> B of the crotch panel 12. ing.

- central joint portion 77 is formed in a region overlapping the non-elastic region 45 where the elastic body 38 does not substantially exist, even if the buttock panel 20 is fixed to the crotch panel 12 via the portion, those central joint portions 77 are not formed. There is no possibility that the liquid absorption performance of the liquid absorption structure 49 is lowered by the expansion and contraction action.

- the central joint portion 77 extends over the entire dimension W2 in the lateral direction X of the crotch panel 12, but in order to suppress the influence of the expansion and contraction action of the first and second elastic regions 46, 47 as much as possible,

- the dimension W3 in the lateral direction X of the central joint part 77 is preferably as small as possible as long as the entire region 75 has the required joint strength.

- the dimension W3 in the lateral direction X of the central joint part 77 is preferably crotch panel.

- the size is preferably about 50% or less of the dimension W2 in the horizontal direction X of 12.

- the transverse joining portion 76 of the buttock panel joining region 75 is located below the central portion 68 of the rear joining region 64 for joining the crotch panel 12 to the rear waist panel 19 and does not overlap each other.

- the overlapping part may be harder than the other part of the diaper 10, and there is a risk of giving the wearer a tactile feeling, in this embodiment, Since these joining areas do not overlap with each other in the central part of the diaper 10, the sheet member does not become too hard, and there is no possibility of causing such a disadvantage.

- both side portions 67 of the rear joining region 64 and the transverse joining portion 76 of the buttock panel joining region 75 are positioned so as to overlap each other.

- Both side portions 67 are for fixing the elastic side flaps 53 to the rear waist panel 19, and a portion of the base sheet 48 that forms the elastic side flaps 53 that faces the rear waist panel 19 is interposed via the both side portions 67. Even if fixed, the fixed part and the part fixed to the elastic side flap 53 of the buttocks panel 20 are separated from each other, so that the sheet member does not become hard.

- the elastic body 38 of the buttocks panel 20 is formed of an elastic material having a thickness (wire diameter) of about 700 to 800 dtex and an expansion ratio of about 2.2 times.

- the separation dimension (pitch, distance between the centers of the elastic bodies) P1 in the longitudinal direction Y is about 35 mm.

- the thickness of the elastic body 38 is uniform.

- the thickness of the elastic body 40 is about 450 to 500 dtex

- the thickness of the elastic body 43 is about 770 to 830 dtex

- the thickness of the elastic body 42 is By setting the thickness to about 920 to 970 dtex and increasing the thickness of the elastic material to be used as it goes downward, the stretching force by them may be adjusted.

- the expansion / contraction force of the buttocks panel 20 increases toward the crotch region 15 side, the inner edge 20a of the buttocks panel 20 is not separated from the wearer's body when worn, and the shape of the buttocks It can be made to fit a heel part more by exhibiting the curved shape along.

- the fixing portion 79 (the region where the cross-joining region 76 is present) fixed to the rear waist panel 19 of the butt panel 20 is composed of two elastic bodies 81 located on the inner end edge 19b side of the elastic body 34. , 82 only overlap, in other words, the two or more elastic bodies 34 do not overlap.

- the cross-joining part 76 has overlapped with the two or more elastic bodies 34, they face the fixing part 79 of the buttock panel 20 of the rear waist panel 19 by their outer shape and the heel formed by them.

- part has an uneven

- fixed part 79 when the fixing

- the fixing portion 79 since the fixing portion 79 does not overlap with the two or more elastic bodies 34, the buttock panel 20 can be stably fixed via the cross-joining portion 76, and the portion is compared to other portions. It wo n’t be too hard.

- the separation dimension (pitch) P3 between the elastic bodies 34B located on the crotch region 15 side is the separation dimension (pitch) P2 between the elastic bodies 34A located on the outer edge 19b side. Is bigger than. This is because an elastic body located on the outer edge 19b side is set to have a separation dimension P3 between the elastic bodies 34B located on the crotch region 15 side so that the elastic force exerted by the elastic body 34 is as small as possible on the transverse joint portion 76. This is because the separation dimension P2 between the elastic bodies 34A positioned on the outer end edge 19b side is about 7 in the present embodiment.

- the distance P3 between the elastic bodies 34B located on the crotch region 15 side is about 15.0 mm.

- the elastic body 34A on the outer end edge 19b side is relatively densely arranged to fit the rear waist panel 19 to the wearer's body.

- the elastic member 34B on the crotch region 15 side is relatively sparsely arranged so that the elastic force is lower than that on the outer edge 19b side, and the fixing portion 79 is provided. The influence on can be suppressed.

- at least the separation dimension in the longitudinal direction Y between the elastic bodies 81 and 82 located at the fixed portion 79 may be set larger than that of the other elastic bodies.

- the elastic side flap 53 rises toward the body side due to the extending action of the elastic bodies 54 and 55.

- the diaper 10 has a large-capacity excrement storage space 83 as compared with other articles of this type, and a relatively large amount of excrement.

- the crotch panel 12 is suspended in a state of being separated from the wearer's buttocks to form a bag shape, and the wearer's buttocks can be prevented from being soiled by excrement.

- a non-joining area 69 is defined between the front and rear joining areas 63 and 64, so that the non-joining area 69 includes front and rear pockets (space portions) 84 between the front and rear waist panels 18 and 19 and the crotch panel 12. 85 is formed.

- the waste storage space 83 defined in the crotch panel 12 can be made larger.

- the buttock panel 20 extends downward from the leg opening 24.

- the buttock panel 20 covers the buttock of the wearer and the buttock is not exposed to the outside.

- the crotch panel 12 is attached to the outside of the elastic waist panel 11 as in the diaper 10 of the present embodiment, even if the elastic waist panel 11 is pulled in the waist direction of the wearer, the crotch panel 12 responds accordingly.

- the crotch panel 12 is sandwiched between the wearer's thighs without being pulled in the waist direction, and a part of the crotch panel 12 may be caught in the fissure. Since it coat

- the buttocks joint region 75 is formed only from the transverse joint part 76 and does not have the central joint part 77.

- the heel panel 20 is all separated from the rear waist panel 19 except for the fixing portion 79. Therefore, even if a part of the crotch panel 12 is sandwiched between cracks, there is no possibility that the buttocks panel 20 will be sandwiched.

- the buttock panel 20 has a skirt shape in appearance and can improve the aesthetics and further give the wearer a sense of security that the buttock is not exposed before wearing.

- the elastic body 38 is not cut at the central portion, is curved downward at the central portion, and extends in the lateral direction X. It has a curved shape extending in a series.

- the center part of the buttocks panel 20 exhibits a curved shape along the shape of the wearer's buttocks when the diaper 10 is worn. Can be further improved.

- the distance between the elastic bodies 38 is smaller than that of the embodiment of FIG. 9 (a), and the lower portion located on the crotch region 15 side in the central portion. Can be fitted to the wearer's body.

- the elastic force of the entire elastic body 38 may be suppressed, or the elastic force may be locally reduced in the central portion.

- the lower both ends (inner both ends) of the buttock panel 20 have a curved shape.

- the diaper 10 can have a more underwear-like appearance, and the wear of the wearer on the buttocks is improved. In order to obtain such an effect, it is sufficient that at least one lower end portion has a curved shape.

- a crotch region located between the front and rear waist regions, a skin facing surface and a non-skin facing surface located on the opposite side, a front waist region, a rear waist region, and a longitudinal direction and a lateral direction perpendicular thereto;

- the front and rear waist regions are defined, elastic waist panels formed from front and rear waist panels, and attached to the elastic waist panels to define a part of the front and rear waist regions and the crotch region,

- the disposable wearing article comprising a crotch panel comprising, further comprising a buttocks panel separate from the elastic waist panel, the buttocks panel is attached to the back waist panel forming the back waist region at the outer end thereof, And it extends to the crotch region side, and the buttock panel is the lateral direction at least on both sides of the lateral direction of the liquid absorbing structure.

- the wearing article is elastically stretchable.

- the present invention disclosed in the above paragraph 0046 can include at least the following embodiments.

- the heel panel has a first elastic region and a second elastic region that are spaced apart from each other in the lateral direction on both sides of the liquid absorbing structure in the lateral direction, and an inelastic region therebetween. Is defined.

- the crotch panel is attached to the outer surface of the rear waist panel via a rear joint region located on the inner surface thereof, and the outer end portion of the buttock panel is disposed via the buttock joint region located on the inner surface thereof. It is attached to the rear waist panel and the crotch panel, and the buttock joining area is located closer to the crotch area than the rear joining area.

- region is located in the side of the said crotch area rather than the center part of the said back joining area

- the buttocks joint region has a center joint portion that intersects the transverse joint portion at the center of the buttocks panel and further extends toward the crotch region.

- the buttock panel is elastically disposed between the inner layer sheet positioned on the skin facing surface side, the outer layer sheet positioned on the non-skin facing surface side, and the inner and outer layer sheets so as to be elastically stretchable. Having a body.

- the elastic body of the buttocks is formed of a string-like or strand-like elastic material, and an upper hip elastic body extending in the lateral direction X along the inner edge of the rear waist panel; A lower hook elastic body extending in the lateral direction along an inner edge, and an intermediate hook elastic body extending in the horizontal direction X between the upper and lower hook elastic bodies, and the thickness of the lower hook elastic body is the intermediate It is larger than that of the heel elastic body, and the thickness of the intermediate heel elastic body is larger than that of the upper heel elastic body.

- the elastic body of the collar portion has a curved shape in which a central portion thereof is curved toward the crotch region side.

- the rear waist panel has a plurality of elastic bodies extending in the lateral direction X, and the separation distance in the vertical direction between the elastic bodies overlapping the buttocks joint area of the elastic bodies is different from each other. It is larger than the separation dimension in the longitudinal direction between the elastic bodies.

- a lower end portion of the collar panel has a curved shape.

Abstract

Provided is a disposable diaper which has sufficient waste receiving space and which does not expose the wearer's buttocks when worn. A buttocks panel (20) separate from an elastic waist panel (11) is attached to a back waist panel (19) which forms a back waist area (14), and extends from the inner edge (19a) of the back waist panel towards the crotch area (15). The buttocks panel (20) is at least elastically stretchable in the transverse direction (X) on both sides of a liquid-absorbent structure (49) in the transverse direction (X).

Description

本発明は、使い捨て着用物品に関し、より詳しくは、クロッチパネルと弾性ウエストパネルとを有し、着用者の臀部を被覆する臀部パネルを有する使い捨ておむつ、使い捨てのトイレット・トレーニングパンツ、使い捨て失禁パンツ、使い捨ての生理用パンツ、使い捨て吸収パッド等の使い捨て着用物品に関する。

The present invention relates to a disposable wearing article, and more specifically, a disposable diaper having a crotch panel and an elastic waist panel and having a buttocks panel covering a wearer's buttocks, disposable toilet training pants, disposable incontinence pants, disposable The present invention relates to disposable wearing articles such as sanitary pants and disposable absorbent pads.

従来、クロッチパネルと弾性ウエストパネルとを有する使い捨て着用物品は公知である。例えば、特許文献1には、前後ウエスト域を形成する弾性ウエストパネルと、クロッチ域を中心として前後ウエスト域に延びるクロッチパネルとを備える使い捨て着用物品が開示されている。

Conventionally, disposable wearing articles having a crotch panel and an elastic waist panel are known. For example, Patent Document 1 discloses a disposable wearing article that includes an elastic waist panel that forms a front and rear waist region and a crotch panel that extends to the front and rear waist region around the crotch region.

特許文献1に開示の着用物品によれば、クロッチパネルの前後端部が前後ウエストパネルを形成する内外面シートの間に介在し取り付けられており、その両側部には、着用物品の縦方向へ延びるレッグ弾性体が配設された一対の弾性サイドフラップが位置している。着用物品の着用状態において、一対の弾性サイドフラップは着用者の身体側へ向かって立ち上がり、前後ウエストパネルとクロッチパネルとの間には排泄物を収容可能なポケットが形成されるので、クロッチパネルの内部には、比較的に多量の排泄物を吸収、保持するための排泄物収容スペースが画定される。

According to the wearing article disclosed in Patent Document 1, the front and rear end portions of the crotch panel are interposed and attached between the inner and outer surface sheets forming the front and rear waist panels, and the both sides are in the longitudinal direction of the wearing article. A pair of elastic side flaps in which extending leg elastic bodies are disposed are located. In the wearing state of the wearing article, the pair of elastic side flaps rises toward the wearer's body, and a pocket capable of accommodating excrement is formed between the front and rear waist panels and the crotch panel. Inside, a waste storage space for absorbing and holding a relatively large amount of waste is defined.

しかし、かかる着用物品を着用したときには、前後ウエスト域とクロッチ域とが一体に形成された使い捨て着用物品に比して着用者の臀部が露出し易く、特に、着用中にクロッチパネルが臀部間(臀間裂)に挟まれた場合には、臀部全体が露出し、外観上好ましくない。特に、着用物品が大人用の場合には、臀部が露出することによる羞恥心を抱かせるおそれがある。

However, when such a wearing article is worn, the wearer's buttocks are more easily exposed than a disposable wearing article in which the front and rear waist areas and the crotch area are integrally formed. When sandwiched between (intercostal fissures), the entire buttock is exposed, which is not preferable in appearance. In particular, when the worn article is for adults, there is a risk of embarrassment due to exposure of the buttocks.

そこで、本発明の課題は、従来の使い捨て着用物品の改良であって、十分な排泄物収容スペースを有し、かつ、着用中において着用者の臀部が露出することのない使い捨て着用物品を提供することにある。

Then, the subject of this invention is improvement of the conventional disposable wearing article, Comprising: The disposable wearing article which has sufficient excrement accommodation space and does not expose a wearer's buttocks during wearing is provided. There is.

本発明は、縦方向及びそれに直交する横方向を有し、肌対向面及びその反対側に位置する非肌対向面と、前ウエスト域と、後ウエスト域と、前記前後ウエスト域間に位置するクロッチ域と、前記前後ウエスト域を画成し、前後ウエストパネルから形成される弾性ウエストパネルと、前記弾性ウエストパネルに取り付けられて、前記前後ウエスト域の一部及び前記クロッチ域を画定し、吸液構造体を備えるクロッチパネルとを含む使い捨て着用物品に係る。

The present invention has a longitudinal direction and a lateral direction perpendicular thereto, and is located between the skin facing surface and the non-skin facing surface located on the opposite side, the front waist region, the rear waist region, and the front and rear waist regions. A crotch region, the front and rear waist regions are defined, and an elastic waist panel formed from the front and rear waist panels and attached to the elastic waist panel to define a part of the front and rear waist regions and the crotch region, The present invention relates to a disposable wearing article including a crotch panel including a liquid structure.

本発明は、前記弾性ウエストパネルとは別体の臀部パネルをさらに含み、前記臀部パネルは、その外端部において前記後ウエスト域を形成する後ウエストパネルに取り付けられ、かつ、前記クロッチ域の側へ延びており、前記臀部パネルは、少なくとも前記吸液構造体の前記横方向の両側において前記横方向へ弾性的に伸縮可能であることを特徴とする。

The present invention further includes a buttocks panel separate from the elastic waist panel, and the buttocks panel is attached to a rear waist panel that forms the rear waist area at an outer end thereof, and the crotch area side. The collar panel may be elastically stretchable in the lateral direction at least on both lateral sides of the liquid absorbing structure.

本発明に係る一つ以上の実施態様における使い捨て着用物品によれば、後ウエスト域を形成する後ウエストパネルの内端縁からクロッチ域の側へ臀部パネルが延びているので、着用中にクロッチパネルの一部が臀裂に挟み込まれたとしても、臀部パネルによって臀部が被覆されて外部に露出するおそれはない。また、臀部パネルは、クロッチパネルの吸液構造体の両側において少なくとも横方向へ弾性的に伸縮可能であるので、着用中に、両側部が着用者の臀部から離れて折れ曲がったり、変形したりするおそれはない。

According to the disposable wearing article in one or more embodiments according to the present invention, since the buttock panel extends from the inner edge of the rear waist panel forming the rear waist region to the crotch region side, the crotch panel during wearing Even if a part of is caught in the crack, there is no possibility that the buttock is covered with the buttock panel and exposed to the outside. Further, since the buttock panel is elastically stretchable at least in the lateral direction on both sides of the liquid absorption structure of the crotch panel, both sides are bent away from the buttock of the wearer or deformed during wearing. There is no fear.

図1~4を参照すると、本発明の使い捨て着用物品の一例として示す使い捨ておむつ10は、縦方向Y及びそれに直交する横方向Xと、横方向Xの幅寸法を二等分する仮想縦中心線P-Pと、縦方向Xの幅寸法を二等分する仮想横中心線Q-Qとを有する。おむつ10は、仮想縦中心線P-Pに関して対称に形成されている。

1 to 4, a disposable diaper 10 shown as an example of the disposable wearing article of the present invention includes a longitudinal direction Y and a transverse direction X orthogonal thereto, and a virtual longitudinal center line that bisects the width dimension of the transverse direction X. PP and a virtual horizontal center line QQ that bisects the width dimension in the vertical direction X. The diaper 10 is formed symmetrically with respect to the virtual vertical center line PP.

おむつ10は、肌対向面及びそれに対向する非肌対向面と、ウエスト回り方向へ延びる環状の弾性ウエストパネル11と、弾性ウエストパネル11の非肌対向面に取り付けられたクロッチパネル12と、各パネル11,12によってそれぞれ画定される前ウエスト域13と、後ウエスト域14と、前後ウエスト域13,14間を縦方向Yに延びるクロッチ域(中間域)15とを含む。弾性ウエストパネル11は、前ウエスト域13に位置する前ウエストパネル18と、後ウエスト域14に位置する後ウエストパネル19とから構成されている。後ウエストパネル19に隣接するクロッチ域15の部位には、おむつ10の着用状態で着用者の臀部と対向してそれを被覆する臀部パネル20が位置している。

The diaper 10 includes a skin facing surface, a non-skin facing surface facing the skin, an annular elastic waist panel 11 extending in the direction of the waist, a crotch panel 12 attached to the non-skin facing surface of the elastic waist panel 11, and each panel. 11 and 12 includes a front waist region 13, a rear waist region 14, and a crotch region (intermediate region) 15 extending between the front and rear waist regions 13 and 14 in the longitudinal direction Y. The elastic waist panel 11 includes a front waist panel 18 located in the front waist region 13 and a rear waist panel 19 located in the rear waist region 14. At the portion of the crotch region 15 adjacent to the rear waist panel 19, a buttock panel 20 is located facing and covering the wearer's buttock while the diaper 10 is worn.

前ウエストパネル18は、クロッチパネル12と交差し、横方向Xへ延びる内端縁18aと、縦方向Yにおいて内端縁18aと離間対向して横方向Xへ延びる外端縁18bと、内外端縁18a,18b間において縦方向Yへ延びる両側縁18c,18dとによって画定された横長矩形状を有する。

The front waist panel 18 intersects the crotch panel 12 and extends in the lateral direction X. The outer end edge 18b extends in the lateral direction X while being spaced apart from the inner end edge 18a in the longitudinal direction Y. It has a horizontally long rectangular shape defined by both side edges 18c, 18d extending in the longitudinal direction Y between the edges 18a, 18b.

後ウエストパネル19は、前ウエストパネル18とほぼ同形同大であって、クロッチパネル12と交差し、横方向Xへ延びる内端縁19aと、縦方向Yにおいて内端縁19aと離間対向して横方向Xへ延びる外端縁19bと、内外端縁19a,19b間において縦方向Yへ延びる両側縁19c,19dとによって画定された横長矩形状を有する。

The rear waist panel 19 is substantially the same shape and size as the front waist panel 18, intersects the crotch panel 12, and has an inner end edge 19 a that extends in the lateral direction X and is spaced apart from the inner end edge 19 a in the longitudinal direction Y. It has a horizontally long rectangular shape defined by an outer edge 19b extending in the horizontal direction X and both side edges 19c, 19d extending in the vertical direction Y between the inner and outer edges 19a, 19b.

前ウエストパネル18の両側縁18c,18dのそれぞれと後ウエストパネル19の両側縁19c,19dのそれぞれとは、互いに重ね合わされて、縦方向Yへ断続的に延びるサイドシーム部22によって連結され、ウエスト開口23及び一対のレッグ開口24とが画定されている(図1参照)。サイドシーム22部は、公知の接合手段、例えば、熱エンボス加工、ソニック加工等の各種の熱溶着手段によって施されている。

Each of the side edges 18c, 18d of the front waist panel 18 and each of the side edges 19c, 19d of the rear waist panel 19 are overlapped with each other and connected by side seam portions 22 extending intermittently in the longitudinal direction Y. An opening 23 and a pair of leg openings 24 are defined (see FIG. 1). The side seam 22 portion is applied by a known joining means, for example, various heat welding means such as hot embossing and sonic processing.

前ウエストパネル18は、肌対向面側に位置する第1内面シート24と、非肌対向面側に位置する第1外面シート25を有する。第1内外面シート24,25は、質量約10~30g/m2の実質的に不透液性のSMS(スパンボンド・メルトブローン・スアパンボンド)繊維不織布、スパンボンド不織布、プラスチックシート又はそれら不織布の少なくとも一つとのラミネートシートとから形成することができる。両シート24,25は、少なくともいずれか一方の内面に間欠的に塗布されたホットメルト接着剤又は前記熱溶着手段によって接合される。

The front waist panel 18 has a first inner sheet 24 positioned on the skin facing surface side and a first outer sheet 25 positioned on the non-skin facing surface side. The first inner and outer sheet 24, 25 is a substantially liquid-impervious SMS (spunbond / meltblown / spainbond) fiber nonwoven fabric, a spunbond nonwoven fabric, a plastic sheet or a nonwoven fabric having a mass of about 10 to 30 g / m 2. It can be formed from one laminate sheet. Both sheets 24 and 25 are joined to each other by a hot melt adhesive applied intermittently to at least one of the inner surfaces or the heat welding means.

再び、図3を参照すると、両シート24,25間には、横方向Xへ延びる複数条のストランド状又はストリング状の弾性体27が配設される。前ウエストパネル18は、弾性体27が横方向Xへの伸長下に配設されることによって少なくとも横方向Xへ収縮可能に弾性化されている。両シート24,25は、両シート24,25の接合状態がおむつ10の取り扱い中、着用中などにおいて剥離するおそれがない限りにおいて、弾性体27のほぼ全周面に塗布したホットメルト接着剤を介してのみ互いに接合されていてもよい。弾性体27は、前ウエストパネル18の外端縁18bに沿って横方向Xへ延びる複数条の弾性体28と、内端縁18aに沿って横方向Xへ延びる複数条の弾性体29とから構成される。弾性体29は、弾性体28に比してその一部が密の状態で配設されている。

Referring to FIG. 3 again, a plurality of strand-like or string-like elastic bodies 27 extending in the transverse direction X are disposed between both sheets 24 and 25. The front waist panel 18 is elasticized so that it can contract at least in the lateral direction X by the elastic body 27 being disposed under the extension in the lateral direction X. Both sheets 24 and 25 are made of hot-melt adhesive applied to almost the entire circumferential surface of the elastic body 27 as long as there is no fear that the sheets 24 and 25 are peeled off during handling or wearing of the diaper 10. May be joined to each other only via The elastic body 27 includes a plurality of elastic bodies 28 extending in the lateral direction X along the outer end edge 18b of the front waist panel 18, and a plurality of elastic bodies 29 extending in the lateral direction X along the inner end edge 18a. Composed. A part of the elastic body 29 is arranged denser than the elastic body 28.

後ウエストパネル19は、肌対向面側に位置する第2内面シート30と、非肌対向面側に位置する第2外面シート31を有する。第2内外面シート30,31は、質量約10~30g/m2の実質的に不透液性のSMS(スパンボンド・メルトブローン・スアパンボンド)繊維不織布、スパンボンド繊維不織布、プラスチックシート又はそれらの不織布の少なくとも一つとのラミネートシートとから形成することができる。両シート30,31は、少なくともいずれか一方の内面に間欠的に塗布されたホットメルト接着剤又は前記熱溶着手段よって接合される。

The rear waist panel 19 has a second inner sheet 30 positioned on the skin facing surface side and a second outer sheet 31 positioned on the non-skin facing surface side. The second inner and outer sheets 30, 31 are substantially liquid-impervious SMS (spunbond / meltblown / spainbond) fiber nonwoven fabrics, spunbond fiber nonwoven fabrics, plastic sheets or nonwoven fabrics having a mass of about 10 to 30 g / m 2. And a laminate sheet with at least one of the above. Both sheets 30 and 31 are joined by a hot melt adhesive applied intermittently to at least one of the inner surfaces or by the heat welding means.

第2内外面シート30,31間には、横方向Xへ延びる複数条のストランド状又はストリング状の弾性体32が横方向Xへ伸長下に配設されている。後ウエストパネル19は、弾性体32が配設されることによって少なくとも横方向Xに収縮可能に弾性化されている。両シート30,31は、弾性体32のほぼ全周面に塗布したホットメルト接着剤を介してのみ互いに接合されてもよい。弾性体32は、後ウエストパネル19の上端縁19bに沿って横方向Xへ延びる複数条の弾性体33と、内端縁19aに沿って横方向Xへ延びる複数条の弾性体34とから構成される。弾性体34は、弾性体33に比してその一部が密の状態で配設されている。

Between the second inner and outer surface sheets 30, 31, a plurality of strand-like or string-like elastic bodies 32 extending in the transverse direction X are arranged extending in the transverse direction X. The rear waist panel 19 is elasticized so as to be contractible at least in the lateral direction X by providing the elastic body 32. Both sheets 30 and 31 may be joined to each other only via a hot melt adhesive applied to substantially the entire circumferential surface of the elastic body 32. The elastic body 32 includes a plurality of elastic bodies 33 extending in the lateral direction X along the upper end edge 19b of the rear waist panel 19 and a plurality of elastic bodies 34 extending in the horizontal direction X along the inner end edge 19a. Is done. A part of the elastic body 34 is arranged denser than the elastic body 33.

弾性体27,32は太さ(線径)が約400~1000dtex、伸長倍率が約1.8~3.0倍の弾性材料から形成することができる。また、各弾性体間の縦方向Yにおける離間寸法(ピッチ。弾性体の中心部間の距離)は、約5.0~30.0mmであって、少なくとも6.0mm以上であることが好ましい。

The elastic bodies 27 and 32 can be formed of an elastic material having a thickness (wire diameter) of about 400 to 1000 dtex and an expansion ratio of about 1.8 to 3.0 times. Further, the separation dimension (pitch, distance between the center portions of the elastic bodies) in the longitudinal direction Y between the elastic bodies is about 5.0 to 30.0 mm, and preferably at least 6.0 mm or more.

図5及び6を参照すると、臀部パネル20は、横方向Xへ延びる内端縁20aと、縦方向Yにおいて外端縁20bと離間対向して横方向Xへ延びる外端縁20bと、内外端縁20a,20b間において縦方向Yへ延びる両側縁20c,20dとによって画定された横長矩形状を有する。臀部パネル20は、内層シート36と、外層シート37とを有する。内外層シート36,37は、質量約10~20g/m2の実質的に不透液性のSMS(スパンボンド・メルトブローン・スパンボンド)繊維不織布、スパンボンド繊維不織布、プラスチックシート又はそれら不織布の少なくとも一つとのラミネートシートとから形成することができる。両シート36,37は、ホットメルト接着剤又は前記熱溶着手段よって接合される。

Referring to FIGS. 5 and 6, the collar panel 20 includes an inner end edge 20a extending in the lateral direction X, an outer end edge 20b extending in the lateral direction X spaced apart from the outer end edge 20b in the longitudinal direction Y, and inner and outer ends. It has a horizontally long rectangular shape defined by both side edges 20c and 20d extending in the longitudinal direction Y between the edges 20a and 20b. The buttocks panel 20 includes an inner layer sheet 36 and an outer layer sheet 37. The inner and outer layer sheets 36 and 37 are substantially liquid-impervious SMS (spunbond / meltblown / spunbond) fiber nonwoven fabrics, spunbond fiber nonwoven fabrics, plastic sheets or plastic sheets having a mass of about 10 to 20 g / m 2. It can be formed from one laminate sheet. Both sheets 36 and 37 are joined by a hot melt adhesive or the above-mentioned heat welding means.

内外層シート36,37間には、横方向Xへ延びる複数条のストランド状又はストリング状の弾性体からなる弾性体38が横方向Xへ伸長下に配設されている。具体的には、後ウエストパネル19側に位置する弾性体40と、前ウエストパネル18側に位置する弾性体42と、弾性体40と弾性体42との間に位置する弾性体43とから構成されている。両シート36,37は、弾性体を構成する各弾性体のほぼ全周面に塗布したホットメルト接着剤を介してのみ互いに接合されてもよい。また、臀部パネル20は、前記繊維不織布シートから形成された1枚のシートに弾性体38を介在させた状態で2つに折り曲げて形成してもよいし、弾性体38を弾性伸縮シートで形成してもよい。また、臀部パネル20自体を伸縮性シートで形成してもよい。

Between the inner and outer layer sheets 36, 37, an elastic body 38 made of a plurality of strand-like or string-like elastic bodies extending in the lateral direction X is disposed extending in the lateral direction X. Specifically, the elastic body 40 is located on the rear waist panel 19 side, the elastic body 42 is located on the front waist panel 18 side, and the elastic body 43 is located between the elastic body 40 and the elastic body 42. Has been. Both sheets 36 and 37 may be joined to each other only via a hot melt adhesive applied to substantially the entire peripheral surface of each elastic body constituting the elastic body. In addition, the buttock panel 20 may be formed by bending a single sheet formed from the fiber nonwoven sheet into two with an elastic body 38 interposed therebetween, or the elastic body 38 is formed of an elastic stretch sheet. May be. Moreover, you may form collar part panel 20 itself with an elastic sheet.

図5を参照すると、弾性体38は、吸液構造体49の領域の中央部と重なる臀部パネル20の中央部に非弾性域45が形成されるように切断されており、非弾性域45の両側には少なくも横方向へ収縮可能な第1弾性域46と第2弾性域47とが形成されている。第1及び第2弾性域46,47が設けられていることによって、臀部パネル20の両側部が着用者の臀部にフィットするので、着用中に、臀部から離間して折れ曲がったり、変形したりするおそれはない。臀部パネル20を伸縮性シートで形成する場合には、非弾性域45においてその伸縮弾性が発現されない又は低減するように加工(例えば、シートの一部を破断する等)することが好ましい。また、臀部パネル20と後ウエストパネル19とを一体に形成することもできるが、本実施形態のように、臀部パネル20を後ウエストパネル19と別体に形成する場合には、その製造工程において、臀部パネル20を有しない通常の使い捨ておむつを製造した後に臀部パネル20を該おむつの後ウエスト域14の外面に取り付けることができる。したがって、通常のおむつの製造装置を利用することができ、臀部パネル20と後ウエストパネル19とを一体で形成する場合に比して製造コストを抑えることができる。

Referring to FIG. 5, the elastic body 38 is cut so that a non-elastic region 45 is formed in the central portion of the collar panel 20 that overlaps the central portion of the region of the liquid absorbing structure 49. A first elastic region 46 and a second elastic region 47 that can contract at least in the lateral direction are formed on both sides. Since the first and second elastic regions 46 and 47 are provided, both side portions of the buttock panel 20 fit the wearer's buttock, so that they are bent away from the buttock or deformed during wearing. There is no fear. When the collar panel 20 is formed of a stretchable sheet, it is preferable to process (for example, break a part of the sheet) so that the stretchable elasticity is not expressed or reduced in the non-elastic region 45. Moreover, although the collar panel 20 and the back waist panel 19 can also be formed integrally, when forming the collar panel 20 separately from the back waist panel 19 like this embodiment, in the manufacturing process, After manufacturing the normal disposable diaper which does not have the buttocks panel 20, the buttocks panel 20 can be attached to the outer surface of the rear waist region 14 of the diaper. Therefore, the manufacturing apparatus of a normal diaper can be utilized, and a manufacturing cost can be suppressed compared with the case where the collar panel 20 and the rear waist panel 19 are formed integrally.

なお、本明細書において、「非弾性域」とは、弾性域を形成する複数の弾性体が該部位において切断又は取り除かれて実質的に存在しない場合又は弾性体が存在するが、実質的に伸縮弾性が発現されていない場合を意味する。また、「接合域どうしが重なる」、「接合域と弾性体とが重なる」とは、それらが平面的に直接又は間接的に重なり合う他に、立体的に重なり合う若しくは交叉することを意味する。

In the present specification, the “non-elastic region” means that a plurality of elastic bodies forming the elastic region are cut or removed at the site and are not substantially present, or an elastic body is present. This means that the elastic elasticity is not expressed. In addition, “the joining regions overlap” and “the joining regions and the elastic body overlap” mean that they overlap or cross over three-dimensionally in addition to directly or indirectly overlapping in a plane.

再び、図2を参照すると、クロッチパネル12は、縦長の略矩形状であって、前ウエストパネル18の非肌対向面(外面)に連結された前端部12Aと、後ウエストパネル19の非肌対向面に連結された後端部12Bと、前後端部12A,12B間において縦方向Yへ延びる中間部12Cとを有する。また、クロッチパネル12は、ベースシート48と、ベースシート48の内面に配置された吸液構造体49と、吸液構造体49を被覆する透液性シートから形成された身体側ライナ50とを有する。クロッチパネル12の前後端部12A,12Bの前後端縁は、繊維不織布から形成された横方向Xへ延びる前後カバーシート70,71によって被覆されている。

Referring to FIG. 2 again, the crotch panel 12 has a vertically long and substantially rectangular shape, and has a front end portion 12A connected to a non-skin facing surface (outer surface) of the front waist panel 18 and a non-skin of the rear waist panel 19. A rear end portion 12B connected to the opposing surface and an intermediate portion 12C extending in the vertical direction Y between the front and rear end portions 12A and 12B. The crotch panel 12 includes a base sheet 48, a liquid absorbent structure 49 disposed on the inner surface of the base sheet 48, and a body side liner 50 formed of a liquid permeable sheet that covers the liquid absorbent structure 49. Have. The front and rear end edges of the front and rear end portions 12A and 12B of the crotch panel 12 are covered with front and rear cover sheets 70 and 71 that are formed from a fiber nonwoven fabric and extend in the lateral direction X.

ベースシート48は、少なくとも一方が実質的に不透液性の繊維不織布シート又は不透液性のプラスチックフィルムから形成された内外面クロッチシート51,52によって形成される。また、内外面クロッチシート51,52は、ホットメルト接着剤(図示せず)を介して互いに接合され、それらの両側部は、内方へ折り曲げられて、縦方向Yへ延びるガスケット機能を有する一対の弾性サイドフラップ53が形成される。

The base sheet 48 is formed by inner and outer surface crotch sheets 51 and 52, at least one of which is made of a substantially liquid-impervious fiber nonwoven fabric sheet or a liquid-impervious plastic film. Also, the inner and outer surface crotch sheets 51 and 52 are joined to each other via a hot melt adhesive (not shown), and both sides thereof are bent inward and have a gasket function extending in the longitudinal direction Y. The elastic side flap 53 is formed.

各弾性サイドフラップ53には、これらに縦方向Yへ延びる複数条のストランド状又はストリング状の弾性体54,55が伸長下に配設されており、少なくとも縦方向Yにおいて弾性化されている。弾性体54は、クロッチ域15の中央部において縦軸Pへ向かって凸曲し、おむつ10の着用状態における着用者の脚回り方向へ延びており、一方、弾性体55は弾性サイドフラップ53の内側縁53aに沿って縦方向Yへ直状に延びている。弾性体54,55は、前記の内外面クロッチシート51,52のうちのいずれか一方の内面に塗布されたホットメルト接着剤(図示せず)を介して両シート51,52間に縦方向Yに伸長された状態で固定される。

Each elastic side flap 53 is provided with a plurality of strand-like or string-like elastic bodies 54 and 55 extending in the longitudinal direction Y, and is elasticized at least in the longitudinal direction Y. The elastic body 54 is curved toward the longitudinal axis P at the central portion of the crotch region 15 and extends in the direction around the wearer's leg when the diaper 10 is worn, while the elastic body 55 is the elastic side flap 53. It extends in a straight line in the longitudinal direction Y along the inner edge 53a. The elastic bodies 54 and 55 are arranged in the longitudinal direction Y between the sheets 51 and 52 via a hot melt adhesive (not shown) applied to the inner surface of one of the inner and outer surface crotch sheets 51 and 52. It is fixed in the extended state.

弾性体54は、その中央部が縦軸Pに向かって凸曲していて、他方の弾性体54と近接していて弾性体54,55による弾性域においてそれら近接部位の伸長応力が弾性体54,55どうしの離間間隔が大きい前後ウエストパネル18,19側の部位の伸長応力に比して高められる。それにより、着用者の大腿に接触すべき弾性サイドフラップ53の中央部近傍が大腿に密着し、レッグ開口縁部からの排泄物の漏れを効果的に防止することができる。

The elastic body 54 has a central portion that is convex toward the vertical axis P, is close to the other elastic body 54, and in the elastic region of the elastic bodies 54 and 55, the elongation stress at those adjacent portions is elastic body 54. , 55 is increased compared to the elongation stress at the front and rear waist panels 18 and 19 side. Thereby, the central part vicinity of the elastic side flap 53 which should contact a wearer's thigh closely_contact | adheres to a thigh, and can prevent the leakage of excretion from a leg opening edge part effectively.

身体側ライナ50は、好ましくは親水化処理された、質量約15~35g/m2の透液性を有する繊維不織布シートであって、例えば、スパンボンド繊維不織布、ポイントボンド繊維不織布及びエアスルー不織布等の各種公知の繊維不織布から形成することができる。

The body side liner 50 is a fiber non-woven sheet having a liquid permeability of about 15 to 35 g / m 2 , preferably hydrophilized, such as a spunbond fiber non-woven fabric, a point bond fiber non-woven fabric and an air-through non-woven fabric. These can be formed from various known fiber nonwoven fabrics.

特に、図6を参照すると、吸液構造体49は、不水溶性かつ自己質量の10倍以上の吸水力を有するいわゆる吸収性ポリマー粒子とフラッフパルプ等の吸水性繊維との混合から形成された吸収性コア59と、質量約8~15g/m2、好ましくは、質量約10g/m2の透水性の繊維不織布から形成された身体側ライナ60と、質量約8~15g/m2、好ましくは、11g/m2の透水性または難透水性のSMS繊維不織布から形成されたバックシート61とを含む。なお、吸収性コア59は、より薄く成形するために、吸収性ポリマー粒子のみから形成することもできる。その場合には、吸収性ポリマー粒子が体液を吸収した後にその形状が型崩れするのを防止するために、吸収性コア59を複数の吸収域に区分してもよい。また、吸液構造体49は、その前後端部に位置する接合部62A,62Bを介してベースシート48の内面に固定されている。

In particular, referring to FIG. 6, the liquid absorbing structure 49 is formed from a mixture of water-absorbing fibers such as fluff pulp and so-called absorbent polymer particles that are water-insoluble and have a water absorption capacity of 10 times or more of the self-mass. Absorbent core 59, body side liner 60 formed from a water permeable nonwoven fabric having a mass of about 8-15 g / m 2 , preferably about 10 g / m 2 , and a mass of about 8-15 g / m 2 , preferably Includes a back sheet 61 formed from a non-woven SMS fiber nonwoven fabric having a water permeability of 11 g / m 2 . The absorbent core 59 can also be formed only from absorbent polymer particles in order to form it thinner. In that case, the absorbent core 59 may be divided into a plurality of absorption regions in order to prevent the shape of the absorbent polymer particles from being deformed after absorbing the body fluid. Further, the liquid absorbing structure 49 is fixed to the inner surface of the base sheet 48 via joints 62A and 62B located at the front and rear end portions thereof.

再び、図2,3及び5を参照すると、クロッチパネル12は、前端部12A及び後端部12Bの内面にホットメルト接着剤を塗布して形成された前接合域63と後接合域64とにおいて前後ウエストパネル18,19の外面に連結される。このように、クロッチパネル12の前後端部12A,12Bを前後ウエストパネル18,19の外面に連結することによって、それらを前後ウエストパネル18,19の内面に連結する場合に比して、排泄物収容スペース83を大きく形成することができる(図6参照)。なお、排泄物収容スペース83が所要の大きさを有する限りにおいて、前後ウエスト域13,14のうちのいずれか一方のみが前後ウエストパネル18,19,の外面に連結してあればよい。

Referring again to FIGS. 2, 3 and 5, the crotch panel 12 includes a front joint area 63 and a rear joint area 64 formed by applying hot melt adhesive to the inner surfaces of the front end portion 12A and the rear end portion 12B. It is connected to the outer surfaces of the front and rear waist panels 18,19. In this way, the front and rear end portions 12A and 12B of the crotch panel 12 are connected to the outer surfaces of the front and rear waist panels 18 and 19, so that they are excreted as compared with the case where they are connected to the inner surfaces of the front and rear waist panels 18 and 19. The accommodation space 83 can be formed large (see FIG. 6). In addition, as long as the excrement accommodation space 83 has a required size, only one of the front and rear waist regions 13 and 14 may be connected to the outer surface of the front and rear waist panels 18 and 19.

前後接合域63,64は、クロッチ域15へ向かって開口した凹状を有し、それぞれ、弾性サイドフラップ53の肌対向面にホットメルト接着剤を塗布して形成された両側部67と、両側部67間において、横方向Xへ延びる中央部68とを有する。中央部68は、吸液構造体49よりも縦方向Yの外方に位置しており、両側部67と中央部68との間には、ホットメルト接着剤が塗布されていない非接合域69が画定される。非接合域69は、吸液性構造体49と対向する位置に形成されている。なお、本実施形態において、前接合域63の両側部67は段差状、後接合域64の両側部67は矩形状を有しているが、それらの形状に制限されるものではなく、前後接合域63,64の両側部67は、段差状、矩形状、曲状などの各種の形状を有していてもよい。

The front and rear joining regions 63 and 64 have a concave shape that opens toward the crotch region 15, and both side portions 67 formed by applying a hot melt adhesive to the skin facing surface of the elastic side flap 53, respectively, 67 and a central portion 68 extending in the transverse direction X. The central portion 68 is located outward in the longitudinal direction Y from the liquid absorbing structure 49, and a non-bonding region 69 where no hot-melt adhesive is applied between the side portions 67 and the central portion 68. Is defined. The non-bonding area 69 is formed at a position facing the liquid absorbing structure 49. In the present embodiment, both side portions 67 of the front joint region 63 have a stepped shape, and both side portions 67 of the rear joint region 64 have a rectangular shape. Both side portions 67 of the regions 63 and 64 may have various shapes such as a stepped shape, a rectangular shape, and a curved shape.

図4においては、説明の便宜上、前ウエストパネル19と後ウエストパネル19とを仮想線で示しており、各種寸法が示されている。まず、大人用のおむつ10全体の各種寸法について言えば、おむつ10の縦方向Yにおける寸法L1は各サイズ(S,M,L,LL)によって異なるが、約450~900mmであって、前後ウエストパネル(前後ウエスト域13,14)18,19の縦方向Yにおける寸法L2は、おむつ10がS,Mサイズの場合には約150~180mm、L,LLサイズの場合には、約180~210mmである。また、クロッチ域15の縦方向Yにおける寸法、すなわち、前ウエスパネル18(前ウエスト域13)の内端縁18aから後ウエストパネル19(後ウエスト域14)の内端縁19aまでの縦方向Yにおける離間寸法L3は、各種サイズともほぼ同じであって、約400~500mmである。また、前後ウエストパネル18,19の横方向Xにおける寸法W1は、おむつ10が大人用のSサイズの場合には、約450~500mm,Mサイズの場合には、約530~560mm、Lサイズの場合には、600~650mm、LLサイズの場合には、約700~750mmである。

In FIG. 4, for convenience of explanation, the front waist panel 19 and the rear waist panel 19 are indicated by virtual lines, and various dimensions are shown. First, regarding the various dimensions of the adult diaper 10 as a whole, the dimension L1 in the longitudinal direction Y of the diaper 10 varies depending on each size (S, M, L, LL), and is about 450 to 900 mm. The dimension L2 in the longitudinal direction Y of the panels (front and rear waist regions 13, 14) 18 and 19 is about 150 to 180 mm when the diaper 10 is S or M size, and about 180 to 210 mm when the diaper 10 is L or LL size. It is. Further, the dimension of the crotch region 15 in the longitudinal direction Y, that is, the longitudinal direction Y from the inner edge 18a of the front waist panel 18 (front waist region 13) to the inner edge 19a of the rear waist panel 19 (rear waist region 14). The separation dimension L3 is substantially the same for various sizes, and is about 400 to 500 mm. In addition, the dimension W1 in the lateral direction X of the front and rear waist panels 18 and 19 is about 450 to 500 mm when the diaper 10 is an S size for adults, and about 530 to 560 mm when the diaper 10 is an M size. In this case, it is 600 to 650 mm, and in the case of the LL size, it is about 700 to 750 mm.

臀部パネル20の縦方向Yにおける寸法L4は、具体的には、約30~330mm、好ましくは、約100~200mm、さらに好ましくは、約110~140mmである。本実施形態では、前後ウエスト域13,14の縦方向Yにおける寸法L2が約170mm、臀部パネル20の縦方向Yにおける寸法L4が約120mm、臀部パネル20の内端縁19aからクロッチ域15側へ延びる部位(おむつ10の着用時において後ウエストパネル19から下方に延びる臀部パネル20の部位)の縦方向Yにおける寸法L5が約100mmであって、寸法L2が寸法L5の約1.7倍の大きさを有する。このように、後ウエスト域14の縦方向Yにおける寸法L2が後ウエスト域14からクロッチ域15側へ延びる部位の縦方向Yにおける寸法L5の2.0倍以下の大きさであることから、前者が後者の2.0倍以上の大きさを有し、後ウエスト域から僅かにクロッチ域15側へ延びる部位によって着用者の臀部の一部を被覆するような従来のおむつに比して、外観視において特異な形状を有し、着用者に対して着用しても臀部が露出するおそれがないという安心感を与えることができる。特に、おむつ10が大人用として使用される場合には、臀部が露出することによる羞恥心を着用者に抱かせるおそれはない。

The dimension L4 in the longitudinal direction Y of the buttock panel 20 is specifically about 30 to 330 mm, preferably about 100 to 200 mm, and more preferably about 110 to 140 mm. In the present embodiment, the dimension L2 in the longitudinal direction Y of the front and rear waist regions 13 and 14 is about 170 mm, the dimension L4 in the longitudinal direction Y of the buttock panel 20 is about 120 mm, and the inner edge 19a of the buttock panel 20 is moved to the crotch region 15 side. The dimension L5 in the longitudinal direction Y of the extending part (the part of the buttocks panel 20 extending downward from the rear waist panel 19 when the diaper 10 is worn) is about 100 mm, and the dimension L2 is about 1.7 times larger than the dimension L5. Have Thus, since the dimension L2 in the longitudinal direction Y of the rear waist region 14 is not more than 2.0 times the size L5 in the longitudinal direction Y of the part extending from the rear waist region 14 to the crotch region 15 side, the former. Compared to a conventional diaper having a size of 2.0 times or more of the latter and covering a part of the wearer's buttocks with a portion slightly extending from the rear waist region to the crotch region 15 side It has a unique shape in view and can give a sense of security that the buttocks are not exposed even when worn by the wearer. In particular, when the diaper 10 is used for adults, there is no risk of causing the wearer to be embarrassed by exposing the buttocks.

臀部パネル20を後ウエストパネル19に接合するための臀部パネル接合域75は、中央部に位置する中央接合部位77と、それと交差して、臀部パネル20の両側縁20c,20d間において横方向Xへ直状に延びる横断接合部位76とを有する。横断接合部位75は、臀部パネル20の横方向Xにおける寸法全体に延びているので、臀部パネル20の外端部は安定的に後ウエストパネル19及びクロッチパネル12の後端部12Bとに固定されている。また、中央接合部位77は、弾性体38が実質的に存在しない非弾性域45と重なる領域に形成されているので、該部位を介して臀部パネル20がクロッチパネル12に固定されてもそれらの伸縮作用によって吸液構造体49の吸液性能が低下するおそれはない。本実施形態では、中央接合部位77はクロッチパネル12の横方向Xにおける寸法W2全体に延びているが、第1及び第2弾性域46,47の伸縮作用による影響を極力抑えるために、臀部接合域75全体において所要の接合強度を有する限りにおいて、中央接合部位77の横方向Xにおける寸法W3はできるだけ小さいことが好ましく、具体的には、中央接合部位77の横方向Xにおける寸法W3はクロッチパネル12の横方向Xにおける寸法W2の約50%以下の大きさであることが好ましい。

A buttock panel joining region 75 for joining the buttock panel 20 to the rear waist panel 19 is a transverse joint X between the side joining edges 20c and 20d of the buttock panel 20 intersecting with the center joining portion 77 located at the center. And a transverse joint portion 76 extending straight. Since the transverse joining portion 75 extends in the entire dimension in the lateral direction X of the butt panel 20, the outer end portion of the butt panel 20 is stably fixed to the rear waist panel 19 and the rear end portion 12 </ b> B of the crotch panel 12. ing. Further, since the central joint portion 77 is formed in a region overlapping the non-elastic region 45 where the elastic body 38 does not substantially exist, even if the buttock panel 20 is fixed to the crotch panel 12 via the portion, those central joint portions 77 are not formed. There is no possibility that the liquid absorption performance of the liquid absorption structure 49 is lowered by the expansion and contraction action. In the present embodiment, the central joint portion 77 extends over the entire dimension W2 in the lateral direction X of the crotch panel 12, but in order to suppress the influence of the expansion and contraction action of the first and second elastic regions 46, 47 as much as possible, The dimension W3 in the lateral direction X of the central joint part 77 is preferably as small as possible as long as the entire region 75 has the required joint strength. Specifically, the dimension W3 in the lateral direction X of the central joint part 77 is preferably crotch panel. The size is preferably about 50% or less of the dimension W2 in the horizontal direction X of 12.

また、臀部パネル接合域75の横断接合部位76は、クロッチパネル12を後ウエストパネル19に接合するための後接合域64の中央部68よりも下方に位置し、互いに重なり合っていない。これらの接合域どうしが互いに重なり合う場合には、該重なり合う部位がおむつ10の他の部位に比してシート部材が硬くなり、着用者にゴワゴワした触感を与えるおそれがあるところ、本実施形態では、おむつ10の中央部においてこれらの接合域が互いに重なっていないので、シート部材が硬くなり過ぎず、かかる不利益を生じるおそれはない。一方、後接合域64の両側部67と臀部パネル接合域75の横断接合部位76とは互いに重なり合って位置している。両側部67は弾性サイドフラップ53を後ウエストパネル19に固定するためのものであって、弾性サイドフラップ53を形成するベースシート48のうちの後ウエストパネル19と対向する部位が両側部67を介して固定されても、該固定部位と臀部パネル20のうちの弾性サイドフラップ53に固定された部位とは離間するので、シート部材が硬くなることはない。

Further, the transverse joining portion 76 of the buttock panel joining region 75 is located below the central portion 68 of the rear joining region 64 for joining the crotch panel 12 to the rear waist panel 19 and does not overlap each other. When these joining areas overlap each other, the overlapping part may be harder than the other part of the diaper 10, and there is a risk of giving the wearer a tactile feeling, in this embodiment, Since these joining areas do not overlap with each other in the central part of the diaper 10, the sheet member does not become too hard, and there is no possibility of causing such a disadvantage. On the other hand, both side portions 67 of the rear joining region 64 and the transverse joining portion 76 of the buttock panel joining region 75 are positioned so as to overlap each other. Both side portions 67 are for fixing the elastic side flaps 53 to the rear waist panel 19, and a portion of the base sheet 48 that forms the elastic side flaps 53 that faces the rear waist panel 19 is interposed via the both side portions 67. Even if fixed, the fixed part and the part fixed to the elastic side flap 53 of the buttocks panel 20 are separated from each other, so that the sheet member does not become hard.

再び、図5を参照すると、臀部パネル20の弾性体38は、太さ(線径)が約700~800dtex、伸長倍率が約2.2倍の弾性材料から形成されており、各弾性体間の縦方向Yにおける離間寸法(ピッチ。弾性体の中心間の距離)P1は、約35mmである。本実施形態では、弾性体38の太さは均一であるが、例えば、弾性体40の太さを約450~500dtex、弾性体43の太さを約770~830dtex、弾性体42の太さを約920~970dtexのように設定し、下方に向かうにつれて使用する弾性材料の太さを大きくすることによって、それらによる伸縮力を調整してもよい。この場合には、クロッチ域15側へ向かうにつれて臀部パネル20の伸縮力が高くなるので、着用時において臀部パネル20の内端縁20aを着用者の身体から離間させることなく、かつ、臀部の形状に沿った湾曲状を呈することによってより臀部にフィットさせることができる。

Referring to FIG. 5 again, the elastic body 38 of the buttocks panel 20 is formed of an elastic material having a thickness (wire diameter) of about 700 to 800 dtex and an expansion ratio of about 2.2 times. The separation dimension (pitch, distance between the centers of the elastic bodies) P1 in the longitudinal direction Y is about 35 mm. In this embodiment, the thickness of the elastic body 38 is uniform. For example, the thickness of the elastic body 40 is about 450 to 500 dtex, the thickness of the elastic body 43 is about 770 to 830 dtex, and the thickness of the elastic body 42 is By setting the thickness to about 920 to 970 dtex and increasing the thickness of the elastic material to be used as it goes downward, the stretching force by them may be adjusted. In this case, since the expansion / contraction force of the buttocks panel 20 increases toward the crotch region 15 side, the inner edge 20a of the buttocks panel 20 is not separated from the wearer's body when worn, and the shape of the buttocks It can be made to fit a heel part more by exhibiting the curved shape along.

また、臀部パネル20のうちの後ウエストパネル19に固定された固定部79(横断接合部位76の存在領域)は、弾性体34のうちの内端縁19b側に位置する2本の弾性体81,82とのみ重なっており、言い換えれば、2本以上の弾性体34とは重なっていない。横断接合部位76が2本以上の複数の弾性体34と重なっている場合には、それらの外形及びそれらによって形成された皺によって後ウエストパネル19のうちの臀部パネル20の固定部79と対向する部位が凹凸状を有し臀部パネル20を取り付けるときに安定的に取り付け難くなる。また、かかる凹凸部位に固定部79を固定した場合には、それらの互いに重なり合う部位がおむつ10の他の部位に比して硬くなり、着用者にごわごわとした触感を与えるおそれがある。本実施形態では、固定部79が2本以上の弾性体34と重なっていないので、横断接合部位76を介して臀部パネル20を安定的に固定でき、また、該部位が他の部位に比して硬くなり過ぎることはない。

In addition, the fixing portion 79 (the region where the cross-joining region 76 is present) fixed to the rear waist panel 19 of the butt panel 20 is composed of two elastic bodies 81 located on the inner end edge 19b side of the elastic body 34. , 82 only overlap, in other words, the two or more elastic bodies 34 do not overlap. When the cross-joining part 76 has overlapped with the two or more elastic bodies 34, they face the fixing part 79 of the buttock panel 20 of the rear waist panel 19 by their outer shape and the heel formed by them. A site | part has an uneven | corrugated shape, and when attaching the collar panel 20, it becomes difficult to attach stably. Moreover, when the fixing | fixed part 79 is fixed to this uneven | corrugated | grooved part, those overlapping parts will become hard compared with the other site | part of the diaper 10, and there exists a possibility of giving a stiff tactile feeling to a wearer. In the present embodiment, since the fixing portion 79 does not overlap with the two or more elastic bodies 34, the buttock panel 20 can be stably fixed via the cross-joining portion 76, and the portion is compared to other portions. It wo n’t be too hard.

図5に示すとおり、弾性体34は、クロッチ域15側に位置する弾性体34Bどうし間の離間寸法(ピッチ)P3が外端縁19b側に位置する弾性体34Aどうしの離間寸法(ピッチ)P2よりも大きくなっている。これは、横断接合部位76になるべく弾性体34による伸縮力が及ばないようにするために、クロッチ域15側に位置する弾性体34Bどうしの離間寸法P3を外端縁19b側に位置する弾性体34Aどうしの離間寸法P2に比して大きく設定しているためであって、具体的には、本実施形態においては、外端縁19b側に位置する弾性体34Aどうしの離間寸法P2は約7.0mm、クロッチ域15側に位置する弾性体34Bどうしの離間寸法P3は約15.0mmである。かかる場合には、弾性体34自体の伸長応力にもよるが、外端縁19b側の弾性体34Aが比較的に密に配設することによって後ウエストパネル19を着用者の身体にフィットさせるのに必要な伸縮力を付与することができるとともに、クロッチ域15側の弾性体34Bを比較的に疎に配設することによってその伸縮力を外端縁19b側よりも低くして、固定部79への影響を抑えることができる。なお、かかる効果を有する限りにおいて、少なくとも固定部79に位置する弾性体81,82どうしの縦方向Yにおける離間寸法が他の弾性体どうしのそれよりも大きく設定されていればよい。

As shown in FIG. 5, in the elastic body 34, the separation dimension (pitch) P3 between the elastic bodies 34B located on the crotch region 15 side is the separation dimension (pitch) P2 between the elastic bodies 34A located on the outer edge 19b side. Is bigger than. This is because an elastic body located on the outer edge 19b side is set to have a separation dimension P3 between the elastic bodies 34B located on the crotch region 15 side so that the elastic force exerted by the elastic body 34 is as small as possible on the transverse joint portion 76. This is because the separation dimension P2 between the elastic bodies 34A positioned on the outer end edge 19b side is about 7 in the present embodiment. The distance P3 between the elastic bodies 34B located on the crotch region 15 side is about 15.0 mm. In such a case, although depending on the elongation stress of the elastic body 34 itself, the elastic body 34A on the outer end edge 19b side is relatively densely arranged to fit the rear waist panel 19 to the wearer's body. The elastic member 34B on the crotch region 15 side is relatively sparsely arranged so that the elastic force is lower than that on the outer edge 19b side, and the fixing portion 79 is provided. The influence on can be suppressed. In addition, as long as it has such an effect, at least the separation dimension in the longitudinal direction Y between the elastic bodies 81 and 82 located at the fixed portion 79 may be set larger than that of the other elastic bodies.