WO2013005512A1 - Shock-absorbing structure and human body protector - Google Patents

Shock-absorbing structure and human body protector Download PDFInfo

- Publication number

- WO2013005512A1 WO2013005512A1 PCT/JP2012/064020 JP2012064020W WO2013005512A1 WO 2013005512 A1 WO2013005512 A1 WO 2013005512A1 JP 2012064020 W JP2012064020 W JP 2012064020W WO 2013005512 A1 WO2013005512 A1 WO 2013005512A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- shape

- elastic spherical

- elastic

- shock absorbing

- absorbing structure

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A42—HEADWEAR

- A42B—HATS; HEAD COVERINGS

- A42B1/00—Hats; Caps; Hoods

- A42B1/04—Soft caps; Hoods

- A42B1/08—Soft caps; Hoods with protection against blows

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D13/00—Professional, industrial or sporting protective garments, e.g. surgeons' gowns or garments protecting against blows or punches

- A41D13/015—Professional, industrial or sporting protective garments, e.g. surgeons' gowns or garments protecting against blows or punches with shock-absorbing means

- A41D13/0156—Professional, industrial or sporting protective garments, e.g. surgeons' gowns or garments protecting against blows or punches with shock-absorbing means having projecting patterns

-

- A—HUMAN NECESSITIES

- A42—HEADWEAR

- A42B—HATS; HEAD COVERINGS

- A42B3/00—Helmets; Helmet covers ; Other protective head coverings

- A42B3/04—Parts, details or accessories of helmets

- A42B3/10—Linings

- A42B3/12—Cushioning devices

- A42B3/124—Cushioning devices with at least one corrugated or ribbed layer

Definitions

- the present invention relates to a shock absorbing structure and a human body protector.

- the buffer body includes a porous body having deformation restoring properties, a bag body that encloses the porous body in an airtight manner, an intake means that sucks gas into the buffer body, and an exhaust that discharges gas to the outside of the buffer body. Means.

- polystyrene foam is conventionally known as a cushioning material for helmets, and is processed and formed to form a uniform hemisphere along the curved surface of the back surface of the helmet, and is provided on the back surface of the helmet.

- the porous body which exhibits the buffer function of the human body protector of the conventional patent document 1 it is excellent in flexibility and light weight, but since it is used by being worn on the human body, it is a material especially worn in summer The rise in temperature causes a decrease in shock absorption and stuffiness at the time of wearing.

- this porous body has low air permeability, there are many inconveniences such as low environmental temperature maintenance (temperature tends to be high) and low shock absorption to relatively sharp objects. .

- foamed polystyrene used as a cushioning material for general helmets has high impact absorption and light weight, but lacks breathability, environmental temperature maintenance performance and flexibility, lowers user comfort, and consequently helmets. It leads to dislike.

- the present invention has been made paying attention to the above-mentioned problems, and the shock absorbing structure and the human body protection satisfying all of the shock absorbing property, flexibility, breathability, light weight, and environmental temperature maintainability at a high level.

- the purpose is to provide ingredients.

- the external shape is spherical, and a plurality of elastic spherical bodies that elastically deform according to the magnitude and direction of external force applied from the outside,

- a structure that is provided between the elastic spheres in which the plurality of elastic spheres are assembled in a planar shape or a linear shape, and that secures a plurality of through gaps by opposing spherical surfaces that are separated from the plurality of elastic spheres, and is applied from the outside

- a soft-coupled structure that is coupled with low rigidity so that the shape of the structure can be deformed according to body deformation force; It is characterized by providing.

- the elastic sphere since the elastic sphere is spherical, it exhibits shock absorbing performance from all directions. Further, high air permeability and light weight can be obtained by the through gap formed between the elastic spherical bodies. Furthermore, since the elastic spheres are “soft-bonded”, high flexibility can be obtained that deforms following the shape of the portion provided with this structure. In addition, since the air permeability is high, problems such as “steaming” and “heat accumulation” due to the low air permeability do not occur, and the environmental temperature around the elastic spherical body suitably exhibits the above-mentioned shock absorption. It is difficult to deviate from the ambient temperature.

- the shock absorbing structure of the present invention can satisfy all of shock absorption, flexibility, breathability, light weight, and environmental temperature maintainability at a high level.

- FIG. 1 It is an external view which shows the protective hat which has the impact-absorbing structure of Example 1. It is a figure which shows the cross section (schematic diagram) of the protective cap of Example 1, and demonstrates an effect

- Example 2 It is a side view of the impact-absorbing structure of Example 2.

- 6 is a plan view showing an impact absorbing structure of Example 3.

- FIG. It is a side view of the impact-absorbing structure of Example 3.

- 6 is a plan view showing an impact absorbing structure of Example 4.

- FIG. It is a side view of the impact-absorbing structure of Example 4.

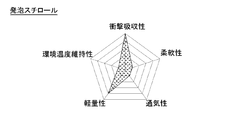

- It is a performance-evaluation figure which shows the impact-absorbing property by the impact-absorbing structure which concerns on Example 1 of this invention, a softness

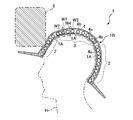

- FIG. 1 and FIG. 2 show a protective cap 1 as a human body protector according to Embodiment 1 of the present invention.

- FIG. 2 shows a cross-sectional view of the protective cap 1 of FIG.

- the protective hat 1 is made of a cloth material having good air permeability, a hat main body 1B as a body protecting body, and a sheet-like impact as an impact absorbing sheet provided inside the side and zenith of the hat main body 1B. Absorbing structures 2 and 3 are provided.

- the shock absorbing structure 2 is formed to have a vertical width substantially the same as the height of the side portion of the cap body 1B, and is provided so as to cover the side portion of the hat body 1B. Therefore, the shock absorbing structure 2 is also provided inside the side portion of the cap body 1B (not shown) shown in FIG.

- the shape and size (diameter, etc.) of the disk shape of the shock absorbing structure 3 provided inside the zenith portion of the hat body 1B are set to be substantially the same as the shape and size of the zenith portion of the hat body 1B. They are formed so as to coincide with each other.

- the hat main body 1B has a partially double structure, and this part serves as a seat pocket that functions as a storage part for the shock absorbing structure.

- the seat pocket is formed so as to exhibit a shape obtained by dividing the curved surface shape of the human body H into a plurality of parts.

- the double-structure portion of the cap body 1B is provided with an insertion opening 1A for storage, and the shock absorbing structures 2 and 3 can be taken in and out of the seat pocket through the insertion opening 1A.

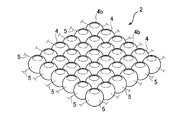

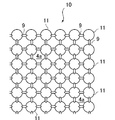

- ⁇ Shock absorbing structure on the side of the hat> 3A to 3C show the shock absorbing structure 2 provided inside the side portion of the cap body 1B.

- the shock absorbing structure 2 has a plurality of elastic spherical bodies 4 arranged in a plane and a plurality of elastic spherical bodies 4 penetrating the elastic spherical bodies 4 vertically. And a synthetic resin yarn 5 bonded to each other in the lateral direction.

- the vertical and horizontal directions are the front, depth, and left and right directions in FIG. 3B.

- a gap 4a is formed between the opposing spherical surfaces facing the elastic spherical bodies 4.

- the gap 4a is formed as a plurality of penetrating gaps by opposing spherical surfaces separated from each other by the elastic spherical bodies 4, and penetrates from the front surface side to the rear surface side of the shock absorption structure 2, so that the shock absorption structure 2 It is a ventilation passage.

- the synthetic resin yarn 5 binds the plurality of elastic spherical bodies 4 to each other and suppresses the rigidity to be low so that the shape of the shock absorbing structure 2 can be deformed according to the structure deformation force applied from the outside of the shock absorbing structure 2. Bonded (soft bond).

- soft coupling structures all structures for achieving such soft coupling are referred to as soft coupling structures.

- the shock absorbing structure 3 includes a plurality of elastic spheres 4 arranged in a line in a triple circle and a plurality of circular elastic spheres 4.

- a synthetic resin thread 5 that penetrates in the circumferential direction and is connected to each other to form a bead shape, and further includes a plurality of synthetic resin threads 5A that connect the three parallel synthetic resin threads 5 in the radial direction of the circle. It has a disk shape as a whole.

- the elastic spherical bodies 4 are softly bonded to each other by the synthetic resin threads 5 and 5A.

- a gap 4a is formed between the adjacent elastic spherical bodies 4 and 4 (see FIG. 4A).

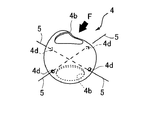

- each elastic spherical body 4 constituting each of the shock absorbing structures 2 and 3 has a spherical outer shape, depending on the magnitude and direction of external force applied from the outside. It is elastically deformed.

- the elastic spherical body 4 is made of polypropylene resin and is hollow.

- the elastic spherical body 4 is formed with vent holes 4b and 4c for communicating the inside and the outside.

- the elastic spherical body 4 has a shell thickness of about 0.3 mm, a sphere diameter of about 11 mm, and vent holes 4 b and 4 c having an opening diameter of about 6 mm.

- each elastic spherical body 4 has its vent holes 4b and 4c facing the front and back sides (upper and lower sides in FIG. 3B) of the shock absorbing structures 2 and 3. The orientation is arranged.

- the ventilation holes 4b and 4c and the internal space of the elastic spherical body 4 constitute a ventilation path different from the air gap 4a that connects the front surface side and the back surface side of the shock absorbing structures 2 and 3.

- a small thread hole 4d for allowing the synthetic resin thread 5 to pass therethrough is provided at the spherical top where the elastic spherical bodies 4 are close to each other.

- a knot 5n is formed at the end of the synthetic resin yarn 5, and the knot 5n prevents the shock absorbing structures 2 and 3 from falling apart.

- shock absorbing structures 2 and 3 of the protective hat 1 of the first embodiment are the “venting action”, “shock absorbing action”, “following deformation action”, “environment temperature maintaining action”, and “lightening action”. This will be explained separately.

- the elastic spherical bodies 4 gather in a flat shape to form a sheet, and because of the spherical shape, there are voids 4a (see FIGS. 3A and 4A) formed between the elastic spherical bodies 4 and 4. It functions as a ventilation path that passes from the front surface side to the rear surface side of the shock absorbing structures 2 and 3, and the air permeability of the shock absorbing structures 2 and 3 is ensured (see arrows W3 and W4 in FIG. 2).

- the ground contact area is reduced because the elastic spherical body 4 and the surface of the human body H and the back surface of the seat pocket of the hat body 1B are substantially point-contacted, thereby ensuring air permeability. (See FIG. 2).

- the elastic spherical body 4 is hollow and passes through each elastic spherical body 4 so as to penetrate from the front side to the back side of the sheet-like shock absorbing structures 2 and 3. Since the pores 4b and 4c are formed, the air permeability is further increased (see arrows W1 and W2 in FIG. 2 and FIG. 6A).

- shock absorption action Since the elastic spherical body 4 is spherical, it exhibits impact absorbing performance from all directions. Specifically, as shown in FIG. 6B, the shock absorbing performance is shown in any input direction (for example, the direction indicated by the black arrow). Unlike conventional honeycomb-shaped blocks and the like, it does not show excellent shock absorption in only one direction, but shows high shock absorption performance in all directions.

- the contact surface increases as a load is applied, and injury caused by local load concentration on the receiving side of the human body (such as the scalp of the human body) can be alleviated.

- the elastic spherical bodies 4 are softly coupled to each other, when the protective cap 1 provided with the shock absorbing structures 2 and 3 is worn, the head shape of any person H is also deformed to absorb individual differences. Fit (see FIG. 2). For this reason, when an impact is applied to the head via the protective cap 1, the impact force is dispersed without being concentrated in one place. Further, at this time, the sheet shape of the shock absorbing structure 2 is also deformed following the shape of the corner portion of the object 6, and the impact force is uniformly dispersed.

- the elastic spherical body 4 is hollow, and the formed vent holes 4b and 4c are oriented in both directions of the normal direction of the head of the human body H and the curved surfaces of the head.

- the elastic spherical body 4 is sandwiched between the object 6 and the head surface, and the vent holes 4b and 4c are substantially closed.

- the elastic spherical body 4 itself is also elastically deformed, for example, the elastic spherical body 4 is deformed following the fine irregularities on the body surface.

- the deforming force when a structure deforming force is applied, the deforming force is uniformly dispersed by soft coupling, and the entire body is deformed flexibly and only a part is not bent.

- the shock absorbing structures 2 and 3 are reduced in weight by the gap 4a between the elastic spherical bodies 4 and 4.

- the elastic spherical body is as described above. It is reduced in weight by the gap 4a between 4 and 4.

- Example 1 Since the elastic spherical body 4 of Example 1 is hollow, the weight is further reduced accordingly.

- shock absorbing structures 2 and 3 do not require the use of a high-mass resin unlike the conventional honeycomb block in order to maintain the shape, it can be said that the weight is high in this respect.

- the shock absorbing structures 2 and 3 are formed in a flexible sheet shape by being penetrated by a plurality of elastic spherical bodies 4 in a skewer shape so that the synthetic resin yarns 5 are orthogonal to each other, and further each elastic body is elastic. Since the spherical body 4 has the property of returning to its original shape even when it is crushed, even if the entire shock absorbing structure 2 or 3 is extremely deformed by absorbing the shock, the shock absorbing structure 2 3 can return to its original shape. For this reason, the entire shock absorbing structures 2 and 3 are not irreversibly collapsed like a polystyrene foam or a honeycomb block, and it is not necessary to use a high-mass resin for maintaining the shape.

- the foam material shown in FIG. 10B is particularly excellent in flexibility and light weight, but it can be said that the balance of each performance is similarly poor overall because of low shock absorption, environmental temperature maintenance, and air permeability.

- the polystyrene foam is excellent in shock absorption and has a certain amount of lightness, but has extremely low flexibility, air permeability and environmental temperature maintainability, and the overall balance of performance is very poor. It can be said.

- foam materials are required to improve air permeability and environmental temperature maintainability without impairing flexibility and lightness.

- Styrofoam is required to improve flexibility, air permeability and environmental temperature maintainability without impairing shock absorption.

- the shock absorbing structure 2 according to the first embodiment of the present invention has the above-described functions that can solve these problems, and satisfies each performance at a high level (see FIG. 10A).

- the outer shape is spherical and a plurality of elastic spherical bodies 4 that are elastically deformed according to the magnitude and direction of external force applied from the outside, and the plurality of elastic spherical bodies 4 are assembled into a planar shape or a linear shape

- a plurality of through-gap 4a is secured by opposing spherical surfaces of the plurality of elastic spheres 4 provided between the elastic spheres 4 so that the structure shape can be deformed according to the structure deformation force applied from the outside.

- a soft coupling structure 5 coupled with low rigidity.

- shock absorbing structure according to the present invention instead of the shock absorbing member included in the human body protector such as the conventional protective hat, it is possible to add performance which is insufficient to the conventional one.

- the elastic spherical body 4 has air flow lines W1 and W2 parallel to air flow lines W3 and W4 passing from the front surface side to the back surface side thereof through the through-holes 4a of the shock absorbing structures 2 and 3. Ventilation holes 4b and 4c to be added are provided. For this reason, in addition to the effect of (1), it can be set as the protective hat 1 with further high air permeability.

- the elastic spherical body 4 is a hollow elastic spherical body made of synthetic resin.

- the protective hat 1 which further improved air permeability, shock absorption, and environmental temperature maintenance property by the above-mentioned impact absorption action can be provided.

- the soft bond structure is a structure in which a plurality of elastic spherical bodies 4 assembled in a planar shape or a linear shape are connected by a synthetic resin thread 5. For this reason, in addition to the effects (1) to (3), it is possible to provide the protective cap 1 which has high flexibility and absorbs individual differences in the shape of the head at a higher dimension and can follow and deform.

- a hat that is normally used is a breathable cloth hat main body, a plurality of seat pockets provided on the back surface of the cloth hat main body, each having a curved head shape, and each of the plurality of seat pockets. And an impact absorbing sheet loaded in the container.

- the shock absorbing sheet has a spherical outer diameter, and a plurality of elastic spherical bodies that are elastically deformed according to the magnitude and direction of external force applied from the outside, and the plurality of elastic spherical bodies are planar or linear.

- the plurality of elastic spheres are separated from each other by opposing spherical surfaces, and a plurality of through gaps are secured, and the structure shape can be deformed according to a structure deformation force applied from the outside.

- the shock absorbing structure is provided with a soft coupling structure coupled with low rigidity, and has a predetermined divided sheet shape.

- shock absorbing structures 2 and 3 can be attached to the hats that are usually used to make the protective hat 1 satisfying all of the impact absorption, flexibility, breathability, light weight, and environmental temperature maintenance at a high level. This will not impair the original comfort and design of the hat. Human damage caused by sudden accidents that occur in daily life without wearing a disaster hood, etc. can be minimized.

- a relatively pointed object such as a metal pliers falls on the head from the top and hits you directly.

- the impact can be dispersed and absorbed.

- Example 7A and 7B show an impact absorbing structure 7 of Example 2 according to the present invention.

- the shock absorbing structure 7 includes an elastic spherical body 4 and an adhesive portion 8 that softly bonds the elastic spherical bodies 4 to each other.

- the elastic spherical bodies 4 are softly coupled to each other by the bonding portion 8 to form a soft coupling structure.

- symbol is attached

- the bonding area 8 increases the opening area of the gap 4a between the elastic spherical bodies 4, thereby improving the air permeability and the air permeability of the protective cap 1. As a result, the temperature environment around the elastic spherical body 4 is less likely to change, and the environmental temperature maintainability is also improved.

- the degree of strength of the partial soft bond of the shock absorbing structure 7 can be changed depending on the type of adhesive used for the bonding portion 8, a desired shock absorbing structure 7 having locally different rigidity is obtained. Can do.

- the strength of the soft bond may be locally changed.

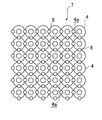

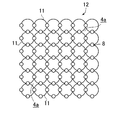

- Example 3 shows an impact absorbing structure 10 of Example 3 according to the present invention.

- the shock absorbing structure 10 includes a solid elastic spherical body 11 and an elongated bonding portion 9 that softly bonds the elastic spherical bodies 11 to each other. Then, the elastic spherical bodies 11 are softly coupled to each other by the adhesive portion 9 to form a soft coupling structure.

- symbol is attached

- the air permeability of the structure is higher.

- the elastic spherical body 11 is solid, the impact absorbing performance of the structure is further improved. Therefore, the air permeability can be improved without impairing the shock absorption of the structure.

- the protective hat 1 provided with the shock absorbing structure 10 ensures high breathability according to demand. be able to.

- the anti-stain property can be improved by making the elastic spherical body 11 solid compared to a hollow one.

- 9A and 9B show an impact absorbing structure 12 of Example 4 according to the present invention.

- the shock absorbing structure 12 includes an elastic spherical body 11 and an adhesive portion 8 as a soft coupling structure that softly bonds the elastic spherical bodies 11 to each other.

- the elastic spherical bodies 11 are softly bonded to each other by the bonding portion 8 to form a soft bond structure.

- symbol is attached

- the opening area of the gap 4a is narrower than that of the third embodiment by the adhesive portion 8 that softly bonds the elastic spherical bodies 11 to each other. , Breathability is low.

- the opening area of the gap 4a is adjusted to absorb the shock.

- the air permeability of the structure is adjusted.

- the impact absorbing structure 12 is formed by using a portion where the elastic spherical body 11 is softly coupled as an adhesive portion 9 in which the gap 4a is narrower than in the third embodiment.

- the protective hat 1 having a high heat retaining property by suitably adjusting the air permeability of the shock absorbing structure.

- the environmental temperature around the elastic spherical body 11 is maintained at an environmental temperature exhibiting high shock absorption, and the shock absorption of the elastic spherical body 11 is not impaired. As a result, a decrease in flexibility of the shock absorbing structure 12 can be suppressed.

- shock absorbing structure according to the present invention has been described based on Examples 1 to 4. However, the configuration can be changed without departing from the gist of the present invention.

- the “soft bond” between the elastic spheres 4 and 11 is realized by a flexible synthetic resin yarn in the shock absorbing structures 2 and 3 of the first embodiment, and a flexible adhesive in the second to fourth embodiments. Is realized. However, the configuration is not limited to these, and any configuration may be used as long as it can be “soft coupled”.

- the thickness, diameter, and vent holes of the elastic spherical body 4 are set to predetermined sizes and lengths, but are not limited to these as long as the desired performance is exhibited.

- the material of the elastic spheres 4 and 11 may be of any kind, and the resin constituting the elastic spheres 4 and 11 is not limited to polypropylene, and is known as a buffer material (other resins other than polypropylene and resins) Any other known material can be used.

- the shape of the elastic spherical bodies 4 and 11 may be any spherical shape, and for example, an elliptical cross section or an oval shape may be used.

- the overall breathability of the shock absorber can be further improved or decreased. Can be adjusted.

- the overall shape of the shock absorbing structure is not limited to that of the first embodiment, and may be any shape (three-dimensional shape or the like).

Abstract

The purpose of the present invention is to provide a shock-absorbing structure and a human body protector which achieve all of high-level shock absorbency, flexibility, air permeability, lightweight property, and environmental temperature maintenance property.

A shock-absorbing structure is provided with: a plurality of elastic spherical objects (4) each of which has the external shape of a spherical object and is elastically deformed according to the magnitude and direction of external force applied from the outside; and a loose coupling structure (5) which is provided between the elastic spherical objects (4) configured by gathering the plurality of elastic spherical objects (4) in a plane or in a line to secure a plurality of through gaps by facing spherical surfaces apart from each other of the plurality of elastic spherical objects (4), and performs coupling while providing low rigidity such that the structure shape can be deformed according to structure deforming force applied from the outside.

Description

本発明は、衝撃吸収構造体及び人体保護具に関するものである。

The present invention relates to a shock absorbing structure and a human body protector.

従来、人体保護具が知られ、装着時における蒸れの発生を防止する構成としたものが知られている(例えば、特許文献1参照)。

2. Description of the Related Art Conventionally, a human body protector is known, and a device that prevents the occurrence of stuffiness when worn is known (for example, see Patent Document 1).

この人体保護具は、ガンベルト状のベルトのポケットに緩衝体を収納して人体を衝撃から保護するものである。この緩衝体は、変形復元性を有する多孔質体と、この多孔質体を気密に包み込む袋体と、緩衝体の内部に気体を吸入させる吸気手段と、緩衝体の外部に気体を排出させる排気手段とを備えている。

This human body protector protects the human body from impact by storing a shock absorber in a gun belt-like belt pocket. The buffer body includes a porous body having deformation restoring properties, a bag body that encloses the porous body in an airtight manner, an intake means that sucks gas into the buffer body, and an exhaust that discharges gas to the outside of the buffer body. Means.

一方、従来から一般的にヘルメット用の緩衝材として発泡スチロールが知られており、ヘルメット裏面の曲面に沿って一様な半球を形成するように加工成形されてヘルメット裏面に設けられる。

On the other hand, polystyrene foam is conventionally known as a cushioning material for helmets, and is processed and formed to form a uniform hemisphere along the curved surface of the back surface of the helmet, and is provided on the back surface of the helmet.

従来の特許文献1の人体保護具の緩衝機能を発揮する多孔質体にあっては、柔軟性、軽量性に優れるが、人体に装着して使用するものであるので、特に夏場の装着による素材温度の上昇により、衝撃吸収性の低下や装着時の蒸れ等を生じさせる。

In the porous body which exhibits the buffer function of the human body protector of the conventional patent document 1, it is excellent in flexibility and light weight, but since it is used by being worn on the human body, it is a material especially worn in summer The rise in temperature causes a decrease in shock absorption and stuffiness at the time of wearing.

この多孔質体は通気性が低いことから環境温度維持性が低く(温度が高くなりやすく)、また、比較的に尖った物等に対する衝撃吸収性も低い等、不都合な点が数多くみられた。

Since this porous body has low air permeability, there are many inconveniences such as low environmental temperature maintenance (temperature tends to be high) and low shock absorption to relatively sharp objects. .

一方、一般的なヘルメット用の緩衝材として用いられる発泡スチロールは、衝撃吸収性、軽量性は高いが、通気性、環境温度維持性能および柔軟性に乏しく、使用者の快適性の低下、ひいては、ヘルメット嫌いなどに繋がっている。

On the other hand, foamed polystyrene used as a cushioning material for general helmets has high impact absorption and light weight, but lacks breathability, environmental temperature maintenance performance and flexibility, lowers user comfort, and consequently helmets. It leads to dislike.

また、その他の一般的に知られている緩衝材についても、上述したような一長一短があり、衝撃吸収性・柔軟性・通気性・軽量性・環境温度維持性の全ての性能を高い次元で満足するとは言い難い。

In addition, other commonly known cushioning materials also have the advantages and disadvantages described above, and satisfy all performances of shock absorption, flexibility, breathability, light weight, and environmental temperature maintenance at a high level. It's hard to say.

そこで、本発明は、上記問題に着目してなされたものであり、衝撃吸収性、柔軟性、通気性、軽量性、環境温度維持性の全てを高い次元で満足する衝撃吸収構造体および人体保護具を提供することを目的としている。

Therefore, the present invention has been made paying attention to the above-mentioned problems, and the shock absorbing structure and the human body protection satisfying all of the shock absorbing property, flexibility, breathability, light weight, and environmental temperature maintainability at a high level. The purpose is to provide ingredients.

上記目的を達成するため、本発明の衝撃吸収構造体では、外形形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形する複数の弾性球状体と、

前記複数の弾性球状体を平面状または線状に集合させた前記弾性球状体間に設けられ、前記複数の弾性球状体の乖離する対向球面により複数の貫通空隙を確保するとともに、外部から加わる構造体変形力にしたがって構造体形状が変形可能なように剛性を低く抑えて結合した軟結合構造と、

を備えることを特徴とする。 In order to achieve the above object, in the shock absorbing structure of the present invention, the external shape is spherical, and a plurality of elastic spherical bodies that elastically deform according to the magnitude and direction of external force applied from the outside,

A structure that is provided between the elastic spheres in which the plurality of elastic spheres are assembled in a planar shape or a linear shape, and that secures a plurality of through gaps by opposing spherical surfaces that are separated from the plurality of elastic spheres, and is applied from the outside A soft-coupled structure that is coupled with low rigidity so that the shape of the structure can be deformed according to body deformation force;

It is characterized by providing.

前記複数の弾性球状体を平面状または線状に集合させた前記弾性球状体間に設けられ、前記複数の弾性球状体の乖離する対向球面により複数の貫通空隙を確保するとともに、外部から加わる構造体変形力にしたがって構造体形状が変形可能なように剛性を低く抑えて結合した軟結合構造と、

を備えることを特徴とする。 In order to achieve the above object, in the shock absorbing structure of the present invention, the external shape is spherical, and a plurality of elastic spherical bodies that elastically deform according to the magnitude and direction of external force applied from the outside,

A structure that is provided between the elastic spheres in which the plurality of elastic spheres are assembled in a planar shape or a linear shape, and that secures a plurality of through gaps by opposing spherical surfaces that are separated from the plurality of elastic spheres, and is applied from the outside A soft-coupled structure that is coupled with low rigidity so that the shape of the structure can be deformed according to body deformation force;

It is characterized by providing.

本発明の衝撃吸収構造体によれば、弾性球状体が球状であるために、全方位からの衝撃吸収性能を発揮する。また、弾性球状体間に形成された貫通空隙により高い通気性、軽量性が得られる。さらに、弾性球状体同士が「軟結合」されているので、この構造が設けられた部分の形状に追従変形するような高い柔軟性が得られる。また、通気性が高いので、通気性が低いことによる「蒸れ」や「熱のこもり」などの問題が発生せず、弾性球状体の周囲の環境温度が、上記衝撃吸収性が好適に発揮される環境温度から外れにくいものとなる。

According to the shock absorbing structure of the present invention, since the elastic sphere is spherical, it exhibits shock absorbing performance from all directions. Further, high air permeability and light weight can be obtained by the through gap formed between the elastic spherical bodies. Furthermore, since the elastic spheres are “soft-bonded”, high flexibility can be obtained that deforms following the shape of the portion provided with this structure. In addition, since the air permeability is high, problems such as “steaming” and “heat accumulation” due to the low air permeability do not occur, and the environmental temperature around the elastic spherical body suitably exhibits the above-mentioned shock absorption. It is difficult to deviate from the ambient temperature.

すなわち、本発明の衝撃吸収構造体は、衝撃吸収性、柔軟性、通気性、軽量性、環境温度維持性の全てを、高い次元で満足することができる。

That is, the shock absorbing structure of the present invention can satisfy all of shock absorption, flexibility, breathability, light weight, and environmental temperature maintainability at a high level.

以下、本発明に係る衝撃吸収構造体および人体保護具を実現するための形態を、図面を参照しながら、各実施例1~4に基づいて説明する。

Hereinafter, modes for realizing the shock absorbing structure and the human body protector according to the present invention will be described based on Examples 1 to 4 with reference to the drawings.

まず、構成を説明する。

First, the configuration will be described.

図1および図2に、本発明の実施例1に係る人体保護具としての保護帽子1を示す。図2は図1の保護帽子1の断面図を示す。

FIG. 1 and FIG. 2 show a protective cap 1 as a human body protector according to Embodiment 1 of the present invention. FIG. 2 shows a cross-sectional view of the protective cap 1 of FIG.

保護帽子1は、通気性がよい布製素材により作られた人体保護具本体としての帽子本体1Bと、帽子本体1Bの側部と天頂部の内部に設けられた衝撃吸収シートとしてのシート状の衝撃吸収構造体2,3を有している。

The protective hat 1 is made of a cloth material having good air permeability, a hat main body 1B as a body protecting body, and a sheet-like impact as an impact absorbing sheet provided inside the side and zenith of the hat main body 1B. Absorbing structures 2 and 3 are provided.

衝撃吸収構造体2は、帽子本体1Bの側部の高さ寸法とほぼ同一の縦巾に形成され、帽子本体1Bの側部の周りを覆うように設けられている。したがって、図1に示す帽子本体1Bの図示されていない部分の側部の内部にも衝撃吸収構造体2が設けられている。

The shock absorbing structure 2 is formed to have a vertical width substantially the same as the height of the side portion of the cap body 1B, and is provided so as to cover the side portion of the hat body 1B. Therefore, the shock absorbing structure 2 is also provided inside the side portion of the cap body 1B (not shown) shown in FIG.

一方、帽子本体1Bの天頂部の内部に設けられた衝撃吸収構造体3の円盤形状の形状と大きさ(直径など)は、帽子本体1Bの天頂部の形状および大きさと略同一に設定され、互いに一致するように形成されている。

On the other hand, the shape and size (diameter, etc.) of the disk shape of the shock absorbing structure 3 provided inside the zenith portion of the hat body 1B are set to be substantially the same as the shape and size of the zenith portion of the hat body 1B. They are formed so as to coincide with each other.

帽子本体1Bは、図2に示すように、部分的に2重構造となっており、この部分が衝撃吸収構造体の収納部として機能するシートポケットとなっている。このシートポケットは、人体Hの頭部曲面形状を複数分割した形状を呈するように形成されている。

As shown in FIG. 2, the hat main body 1B has a partially double structure, and this part serves as a seat pocket that functions as a storage part for the shock absorbing structure. The seat pocket is formed so as to exhibit a shape obtained by dividing the curved surface shape of the human body H into a plurality of parts.

また、帽子本体1Bの2重構造部分には収納用の挿入口1Aが設けられており、この挿入口1Aを介して衝撃吸収構造体2,3をシートポケットに出し入れ可能となっている。

<帽子側部の衝撃吸収構造体>

図3A-図3Cに帽子本体1Bの側部の内部に設けた衝撃吸収構造体2を示す。 Further, the double-structure portion of thecap body 1B is provided with an insertion opening 1A for storage, and the shock absorbing structures 2 and 3 can be taken in and out of the seat pocket through the insertion opening 1A.

<Shock absorbing structure on the side of the hat>

3A to 3C show theshock absorbing structure 2 provided inside the side portion of the cap body 1B.

<帽子側部の衝撃吸収構造体>

図3A-図3Cに帽子本体1Bの側部の内部に設けた衝撃吸収構造体2を示す。 Further, the double-structure portion of the

<Shock absorbing structure on the side of the hat>

3A to 3C show the

この衝撃吸収構造体2は、図3A-図3Cに示すように、平面状に集合配置された複数の弾性球状体4と、複数の弾性球状体4に貫通されて弾性球状体4同士を縦と横の方向で互いに結合する合成樹脂糸5とを有している。この縦と横の方向は、図3Bにおいては、手前と奥行方向および左右の方向となる。

As shown in FIGS. 3A to 3C, the shock absorbing structure 2 has a plurality of elastic spherical bodies 4 arranged in a plane and a plurality of elastic spherical bodies 4 penetrating the elastic spherical bodies 4 vertically. And a synthetic resin yarn 5 bonded to each other in the lateral direction. The vertical and horizontal directions are the front, depth, and left and right directions in FIG. 3B.

図3Aに示すように、弾性球状体4を平面状に集合させることにより、弾性球状体4が対向する対向球面間に空隙4aが形成される。

As shown in FIG. 3A, by gathering the elastic spherical bodies 4 in a planar shape, a gap 4a is formed between the opposing spherical surfaces facing the elastic spherical bodies 4.

この空隙4aは、弾性球状体4同士の乖離した対向球面により複数の貫通した空隙として形成され、衝撃吸収構造体2の表面側から裏面側へと貫通するものであるため、衝撃吸収構造体2の通気路となっている。

The gap 4a is formed as a plurality of penetrating gaps by opposing spherical surfaces separated from each other by the elastic spherical bodies 4, and penetrates from the front surface side to the rear surface side of the shock absorption structure 2, so that the shock absorption structure 2 It is a ventilation passage.

一方、合成樹脂糸5は、複数の弾性球状体4を互いに結合し、衝撃吸収構造体2の外部から加わる構造体変形力に従って衝撃吸収構造体2の形状が変形可能なように剛性を低く抑える結合(軟結合)をしている。本願では、このような軟結合を達成するための構造を全て軟結合構造という。

On the other hand, the synthetic resin yarn 5 binds the plurality of elastic spherical bodies 4 to each other and suppresses the rigidity to be low so that the shape of the shock absorbing structure 2 can be deformed according to the structure deformation force applied from the outside of the shock absorbing structure 2. Bonded (soft bond). In the present application, all structures for achieving such soft coupling are referred to as soft coupling structures.

<帽子本体天頂部の衝撃吸収構造体>

衝撃吸収構造体3は、図4A,図4Bに示すように、3重円状に線状に集合して配列された複数の弾性球状体4と、この円形状の複数の弾性球状体4を円周方向で貫通して互いに連結して数珠状とする合成樹脂糸5と、さらに、この並行する3つの合成樹脂糸5同士を円の径方向で連結する複数の合成樹脂糸5Aとを備えたものであり、全体として円盤状を呈している。 <Shock absorbing structure at the top of the cap body>

As shown in FIGS. 4A and 4B, theshock absorbing structure 3 includes a plurality of elastic spheres 4 arranged in a line in a triple circle and a plurality of circular elastic spheres 4. A synthetic resin thread 5 that penetrates in the circumferential direction and is connected to each other to form a bead shape, and further includes a plurality of synthetic resin threads 5A that connect the three parallel synthetic resin threads 5 in the radial direction of the circle. It has a disk shape as a whole.

衝撃吸収構造体3は、図4A,図4Bに示すように、3重円状に線状に集合して配列された複数の弾性球状体4と、この円形状の複数の弾性球状体4を円周方向で貫通して互いに連結して数珠状とする合成樹脂糸5と、さらに、この並行する3つの合成樹脂糸5同士を円の径方向で連結する複数の合成樹脂糸5Aとを備えたものであり、全体として円盤状を呈している。 <Shock absorbing structure at the top of the cap body>

As shown in FIGS. 4A and 4B, the

この衝撃吸収構造体3では、合成樹脂糸5,5Aにより弾性球状体4同士を軟結合させている。隣接した弾性球状体4,4の間に空隙4aが形成される(図4A参照)。

In the shock absorbing structure 3, the elastic spherical bodies 4 are softly bonded to each other by the synthetic resin threads 5 and 5A. A gap 4a is formed between the adjacent elastic spherical bodies 4 and 4 (see FIG. 4A).

<弾性球状体>

図3Bや図6A,図6Bに示すように、各衝撃吸収構造体2,3を構成する個々の弾性球状体4は、外形形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形するものである。 <Elastic spherical body>

As shown in FIG. 3B, FIG. 6A, and FIG. 6B, each elasticspherical body 4 constituting each of the shock absorbing structures 2 and 3 has a spherical outer shape, depending on the magnitude and direction of external force applied from the outside. It is elastically deformed.

図3Bや図6A,図6Bに示すように、各衝撃吸収構造体2,3を構成する個々の弾性球状体4は、外形形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形するものである。 <Elastic spherical body>

As shown in FIG. 3B, FIG. 6A, and FIG. 6B, each elastic

この弾性球状体4は、ポリプロピレン樹脂製であり、中空に形成されている。そして、弾性球状体4には、その内側と外側を連通させる通気孔4b,4cがそれぞれ形成されている。

The elastic spherical body 4 is made of polypropylene resin and is hollow. The elastic spherical body 4 is formed with vent holes 4b and 4c for communicating the inside and the outside.

この弾性球状体4は、殻の肉厚が約0.3mm、球の直径は約11mm、通気孔4b,4cの開口径が約6mmに形成されている。

The elastic spherical body 4 has a shell thickness of about 0.3 mm, a sphere diameter of about 11 mm, and vent holes 4 b and 4 c having an opening diameter of about 6 mm.

図3A-図3Cに示すように、各弾性球状体4は、その通気孔4b,4cが衝撃吸収構造体2,3の表面側と裏面側(図3Bにおいて上方側と下方側)とに向くように配向配置されている。この通気孔4b,4cと弾性球状体4の内部空間とにより、衝撃吸収構造体2,3の表面側と裏面側を連通させる上記空隙4aとは別の通気路を構成している。

As shown in FIGS. 3A to 3C, each elastic spherical body 4 has its vent holes 4b and 4c facing the front and back sides (upper and lower sides in FIG. 3B) of the shock absorbing structures 2 and 3. The orientation is arranged. The ventilation holes 4b and 4c and the internal space of the elastic spherical body 4 constitute a ventilation path different from the air gap 4a that connects the front surface side and the back surface side of the shock absorbing structures 2 and 3.

また、図3Bに示すように、各弾性球状体4が互いに近接する球面頂部には、合成樹脂糸5を貫通させるための小さな糸孔4dが設けられている。

Further, as shown in FIG. 3B, a small thread hole 4d for allowing the synthetic resin thread 5 to pass therethrough is provided at the spherical top where the elastic spherical bodies 4 are close to each other.

なお、図5に示すように、合成樹脂糸5の端部には結び目5nが形成されており、この結び目5nにより、衝撃吸収構造体2,3がバラバラにならないようになっている。

As shown in FIG. 5, a knot 5n is formed at the end of the synthetic resin yarn 5, and the knot 5n prevents the shock absorbing structures 2 and 3 from falling apart.

次に、作用を説明する。

Next, the operation will be described.

まず、実施例1の保護帽子1の衝撃吸収構造体2,3の作用を、「通気作用」、「衝撃吸収作用」、「追従変形作用」、「環境温度維持作用」および「軽量化作用」に分けて説明する。

First, the effects of the shock absorbing structures 2 and 3 of the protective hat 1 of the first embodiment are the “venting action”, “shock absorbing action”, “following deformation action”, “environment temperature maintaining action”, and “lightening action”. This will be explained separately.

[通気作用(通気性)]

図3A-図3Cに示すように、弾性球状体4が平面状に集合してシート状を呈し、球状ゆえに弾性球状体4,4間に形成された空隙4a(図3A、図4A参照)が衝撃吸収構造体2,3の表面側から裏面側に通過する通気路として機能し、衝撃吸収構造体2,3の通気性が確保される(図2の矢印W3,W4等参照)。 [Breath action (breathability)]

As shown in FIGS. 3A to 3C, the elasticspherical bodies 4 gather in a flat shape to form a sheet, and because of the spherical shape, there are voids 4a (see FIGS. 3A and 4A) formed between the elastic spherical bodies 4 and 4. It functions as a ventilation path that passes from the front surface side to the rear surface side of the shock absorbing structures 2 and 3, and the air permeability of the shock absorbing structures 2 and 3 is ensured (see arrows W3 and W4 in FIG. 2).

図3A-図3Cに示すように、弾性球状体4が平面状に集合してシート状を呈し、球状ゆえに弾性球状体4,4間に形成された空隙4a(図3A、図4A参照)が衝撃吸収構造体2,3の表面側から裏面側に通過する通気路として機能し、衝撃吸収構造体2,3の通気性が確保される(図2の矢印W3,W4等参照)。 [Breath action (breathability)]

As shown in FIGS. 3A to 3C, the elastic

弾性球状体4が球状であるために、弾性球状体4と人体Hの表面や帽子本体1Bのシートポケットの裏面に略点接触するために接地面積が小さくなり、これによっても通気性が確保される(図2参照)。

Since the elastic spherical body 4 is spherical, the ground contact area is reduced because the elastic spherical body 4 and the surface of the human body H and the back surface of the seat pocket of the hat body 1B are substantially point-contacted, thereby ensuring air permeability. (See FIG. 2).

さらに、図3B,図3Cに示すように、弾性球状体4が中空であり、シート状の衝撃吸収構造体2,3の表面側から裏面側へと貫通するように各弾性球状体4に通気孔4b,4cが形成されているので、より通気性が高まる(図2の矢印W1,W2、図6A参照)。

Further, as shown in FIGS. 3B and 3C, the elastic spherical body 4 is hollow and passes through each elastic spherical body 4 so as to penetrate from the front side to the back side of the sheet-like shock absorbing structures 2 and 3. Since the pores 4b and 4c are formed, the air permeability is further increased (see arrows W1 and W2 in FIG. 2 and FIG. 6A).

[衝撃吸収作用(衝撃吸収性)]

弾性球状体4が球状であるために、全方位からの衝撃吸収性能を発揮する。具体的には、図6Bに示すように、どの入力方向(例えば黒塗矢印で示した方向)に対しても衝撃吸収性能を示す。従来のハニカム形状のブロック等のように一方向のみ優れた衝撃吸収性を示すというわけでなく、全方向に高い衝撃吸収性能を示す。 [Shock absorption action (shock absorption)]

Since the elasticspherical body 4 is spherical, it exhibits impact absorbing performance from all directions. Specifically, as shown in FIG. 6B, the shock absorbing performance is shown in any input direction (for example, the direction indicated by the black arrow). Unlike conventional honeycomb-shaped blocks and the like, it does not show excellent shock absorption in only one direction, but shows high shock absorption performance in all directions.

弾性球状体4が球状であるために、全方位からの衝撃吸収性能を発揮する。具体的には、図6Bに示すように、どの入力方向(例えば黒塗矢印で示した方向)に対しても衝撃吸収性能を示す。従来のハニカム形状のブロック等のように一方向のみ優れた衝撃吸収性を示すというわけでなく、全方向に高い衝撃吸収性能を示す。 [Shock absorption action (shock absorption)]

Since the elastic

加えて,弾性球状体4は外形形状が球状であることから、荷重が加わるに従い接触面が増え,人体の受側(人体の頭皮等)への局所的な荷重集中による傷害も緩和できる。

In addition, since the outer shape of the elastic spherical body 4 is spherical, the contact surface increases as a load is applied, and injury caused by local load concentration on the receiving side of the human body (such as the scalp of the human body) can be alleviated.

弾性球状体4同士が軟結合されているので、衝撃吸収構造体2,3を設けた保護帽子1を装着したとき、あらゆる人Hの頭部形状にも追従変形し、個人差を吸収してフィットする(図2参照)。このため、保護帽子1を介して頭部に衝撃を受けたときに、この衝撃力が一箇所に集中せず分散する。さらに、このとき、物6の角部形状に対しても衝撃吸収構造体2のシート形状が追従変形し、衝撃力が均一に分散される。

Since the elastic spherical bodies 4 are softly coupled to each other, when the protective cap 1 provided with the shock absorbing structures 2 and 3 is worn, the head shape of any person H is also deformed to absorb individual differences. Fit (see FIG. 2). For this reason, when an impact is applied to the head via the protective cap 1, the impact force is dispersed without being concentrated in one place. Further, at this time, the sheet shape of the shock absorbing structure 2 is also deformed following the shape of the corner portion of the object 6, and the impact force is uniformly dispersed.

また、図2に示すように、弾性球状体4が中空であり、形成した通気孔4b,4cが人体Hの頭部とその頭部の曲面各部における法線方向の両方向に向いているので、衝撃を受けたときに物6と頭部表面とによって弾性球状体4が挟まれて、その通気孔4b,4cが略閉塞される。これにより、弾性球状体4が空気袋のように機能し、時間の経過とともに徐々に空気が抜けていくことから、特に衝撃吸収性が高いものとなる。

Further, as shown in FIG. 2, the elastic spherical body 4 is hollow, and the formed vent holes 4b and 4c are oriented in both directions of the normal direction of the head of the human body H and the curved surfaces of the head. When receiving an impact, the elastic spherical body 4 is sandwiched between the object 6 and the head surface, and the vent holes 4b and 4c are substantially closed. Thereby, since the elastic spherical body 4 functions like an air bag and the air gradually escapes as time passes, the shock absorption is particularly high.

[追従変形作用(柔軟性)]

衝撃吸収構造体2,3が、弾性球状体4同士が軟結合されているので、人によって異なる頭部等の身体形状に追従してフィットする。 [Following deformation action (flexibility)]

Since the elasticspherical bodies 4 are softly coupled to each other, the shock absorbing structures 2 and 3 fit to follow the body shape such as the head, which varies from person to person.

衝撃吸収構造体2,3が、弾性球状体4同士が軟結合されているので、人によって異なる頭部等の身体形状に追従してフィットする。 [Following deformation action (flexibility)]

Since the elastic

弾性球状体4自体も弾性変形するので、例えば身体表面の細かい凹凸形状に対応して追従変形する。

Since the elastic spherical body 4 itself is also elastically deformed, for example, the elastic spherical body 4 is deformed following the fine irregularities on the body surface.

つまり、構造体変形力が加わったときに、軟結合により変形力が均一に分散され全体的に柔軟に変形して一部のみが屈曲することがない。

That is, when a structure deforming force is applied, the deforming force is uniformly dispersed by soft coupling, and the entire body is deformed flexibly and only a part is not bent.

さらに、弾性球状体4の中央部を連結したことで、衝撃吸収構造体3,4が身体形状にフィットした場合でも、他方の衝突面側に衝撃吸収性の低下に繋がる大きな隙間が空かないようになっている。

Furthermore, by connecting the central part of the elastic spherical body 4, even when the shock absorbing structures 3 and 4 are fitted to the body shape, a large gap that leads to a decrease in shock absorption is not left on the other collision surface side. It has become.

仮に、人体H側に位置する弾性球状体4の端部のみを結合した場合には、衝撃吸収構造体3,4の衝突面側に大きな隙間が空き易くなり、衝撃吸収性能の低下が生じる。そのため、弾性球状体4の人体H側の端部で結合したいのであれば、弾性球状体4間にある程度の隙間を設けて両端を結合する方が好ましい。

If only the ends of the elastic spherical body 4 located on the human body H side are coupled, a large gap is easily formed on the impact surface side of the impact absorbing structures 3 and 4, and the impact absorbing performance is deteriorated. Therefore, if it is desired to connect at the end of the elastic spherical body 4 on the human body H side, it is preferable to provide a certain gap between the elastic spherical bodies 4 and connect both ends.

[環境温度維持作用(環境温度維持性)]

衝撃吸収構造体2,3の通気性が確保されることで、衝撃吸収構造体2,3による「蒸れ」や「熱のこもり」が発生せず、衝撃吸収構造体2,3を構成する弾性球状体4の環境温度が変化しにくいものとなる。環境温度変化による弾性球状体4の衝撃吸収性能の低下が発生しにくいものとなる。 [Environmental temperature maintenance (environmental temperature maintenance)]

The air permeability of the shock absorbing structures 2 and 3 is ensured, so that “steaming” and “heat accumulation” due to the shock absorbing structures 2 and 3 do not occur, and the elasticity constituting the shock absorbing structures 2 and 3 The environmental temperature of the spherical body 4 is difficult to change. The impact-absorbing performance of the elastic spherical body 4 is not easily lowered due to environmental temperature changes.

衝撃吸収構造体2,3の通気性が確保されることで、衝撃吸収構造体2,3による「蒸れ」や「熱のこもり」が発生せず、衝撃吸収構造体2,3を構成する弾性球状体4の環境温度が変化しにくいものとなる。環境温度変化による弾性球状体4の衝撃吸収性能の低下が発生しにくいものとなる。 [Environmental temperature maintenance (environmental temperature maintenance)]

The air permeability of the

[軽量化作用(軽量性)]

弾性球状体4,4間の空隙4aにより、衝撃吸収構造体2,3の軽量化される。例えば、ヘルメット裏面に用いる一般的な発泡スチロールでは、空隙がない一様な半球層状に形成されているが、本発明に係る実施例1の衝撃吸収構造体2,3では上記のように弾性球状体4,4間の空隙4aにより軽量化される。 [Lightening effect (lightness)]

The shock absorbing structures 2 and 3 are reduced in weight by the gap 4a between the elastic spherical bodies 4 and 4. For example, in the general polystyrene used for the back of the helmet, it is formed in a uniform hemispherical layer shape without voids, but in the shock absorbing structures 2 and 3 of Example 1 according to the present invention, the elastic spherical body is as described above. It is reduced in weight by the gap 4a between 4 and 4.

弾性球状体4,4間の空隙4aにより、衝撃吸収構造体2,3の軽量化される。例えば、ヘルメット裏面に用いる一般的な発泡スチロールでは、空隙がない一様な半球層状に形成されているが、本発明に係る実施例1の衝撃吸収構造体2,3では上記のように弾性球状体4,4間の空隙4aにより軽量化される。 [Lightening effect (lightness)]

The

実施例1の弾性球状体4は中空であるので、その分さらに軽量化されることとなる。

Since the elastic spherical body 4 of Example 1 is hollow, the weight is further reduced accordingly.

衝撃吸収構造体2,3は、その形状を維持するために、従来のハニカム状ブロックのように高質量樹脂を用いる必要がないことから、この点でも軽量性が高いといえる。

Since the shock absorbing structures 2 and 3 do not require the use of a high-mass resin unlike the conventional honeycomb block in order to maintain the shape, it can be said that the weight is high in this respect.

具体的に説明すると、衝撃吸収構造体2,3は、合成樹脂糸5が直交するように串刺し状に複数の弾性球状体4に貫通されて可撓性のシート状を呈し、さらに個々の弾性球状体4は潰れても元の形状に戻る性質を有しているので、衝撃を吸収して衝撃吸収構造体2,3の全体が極端に構造体変形をしたとしても衝撃吸収構造体2,3が元の形状に戻ることが可能である。このことから、発泡スチロールやハニカム状ブロックのように、衝撃吸収構造体2,3の全体が不可逆的に崩れるということがなく、形状維持のために高質量の樹脂を用いる必要がない。

More specifically, the shock absorbing structures 2 and 3 are formed in a flexible sheet shape by being penetrated by a plurality of elastic spherical bodies 4 in a skewer shape so that the synthetic resin yarns 5 are orthogonal to each other, and further each elastic body is elastic. Since the spherical body 4 has the property of returning to its original shape even when it is crushed, even if the entire shock absorbing structure 2 or 3 is extremely deformed by absorbing the shock, the shock absorbing structure 2 3 can return to its original shape. For this reason, the entire shock absorbing structures 2 and 3 are not irreversibly collapsed like a polystyrene foam or a honeycomb block, and it is not necessary to use a high-mass resin for maintaining the shape.

[対比作用]

人体装着具に設けられ人体を衝撃から保護するためのフォーム材、発泡スチロールを比較例とする対比作用を説明する。 [Contrast effect]

A comparison effect using a foam material and polystyrene foam as a comparative example, which is provided on the human body wearing device and protects the human body from impact will be described.

人体装着具に設けられ人体を衝撃から保護するためのフォーム材、発泡スチロールを比較例とする対比作用を説明する。 [Contrast effect]

A comparison effect using a foam material and polystyrene foam as a comparative example, which is provided on the human body wearing device and protects the human body from impact will be described.

図10Bに示すフォーム材では、柔軟性、軽量性に特に優れるが、衝撃吸収性、環境温度維持性、通気性が低いことから、同様に各性能のバランスが全体的に悪いといえる。

The foam material shown in FIG. 10B is particularly excellent in flexibility and light weight, but it can be said that the balance of each performance is similarly poor overall because of low shock absorption, environmental temperature maintenance, and air permeability.

図10Cに示すように、発泡スチロールでは、衝撃吸収性に優れ、ある程度の軽量性を有するものの、柔軟性、通気性および環境温度維持性が極端に低く、各性能のバランスが全体的に非常に悪いといえる。

As shown in FIG. 10C, the polystyrene foam is excellent in shock absorption and has a certain amount of lightness, but has extremely low flexibility, air permeability and environmental temperature maintainability, and the overall balance of performance is very poor. It can be said.

このため、フォーム材では、柔軟性、軽量性を損ねず通気性や環境温度維持性を高めることが求められる。発泡スチロールでは、衝撃吸収性を損ねず柔軟性、通気性および環境温度維持性を高めることが求められる。

For this reason, foam materials are required to improve air permeability and environmental temperature maintainability without impairing flexibility and lightness. Styrofoam is required to improve flexibility, air permeability and environmental temperature maintainability without impairing shock absorption.

これに対し、本発明に係る実施例1の衝撃吸収構造体2では、これら課題を解決しうる上記各作用を有し、各性能を高次元で満足する(図10A参照)。

On the other hand, the shock absorbing structure 2 according to the first embodiment of the present invention has the above-described functions that can solve these problems, and satisfies each performance at a high level (see FIG. 10A).

次に、効果を説明する。

Next, the effect will be explained.

(1)外形形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形する複数の弾性球状体4と、複数の弾性球状体4を平面状や線状に集合させたときに弾性球状体4間に設けられ、複数の弾性球状体4の互いに乖離する対向球面により複数の貫通空隙4aを確保するとともに、外部から加わる構造体変形力にしたがって構造体形状が変形可能なように剛性を低く抑えて結合した軟結合構造5と、を備える。

このため、上述した各作用により、衝撃吸収性、柔軟性、通気性、軽量性、環境温度維持性の全てを高い次元で満足する衝撃吸収構造体を提供することができる。 (1) When the outer shape is spherical and a plurality of elasticspherical bodies 4 that are elastically deformed according to the magnitude and direction of external force applied from the outside, and the plurality of elastic spherical bodies 4 are assembled into a planar shape or a linear shape A plurality of through-gap 4a is secured by opposing spherical surfaces of the plurality of elastic spheres 4 provided between the elastic spheres 4 so that the structure shape can be deformed according to the structure deformation force applied from the outside. And a soft coupling structure 5 coupled with low rigidity.

For this reason, the impact-absorbing structure that satisfies all of the impact absorption, flexibility, breathability, lightness, and environmental temperature maintainability can be provided by the above-described actions.

このため、上述した各作用により、衝撃吸収性、柔軟性、通気性、軽量性、環境温度維持性の全てを高い次元で満足する衝撃吸収構造体を提供することができる。 (1) When the outer shape is spherical and a plurality of elastic

For this reason, the impact-absorbing structure that satisfies all of the impact absorption, flexibility, breathability, lightness, and environmental temperature maintainability can be provided by the above-described actions.

従来の保護帽子等の人体保護具に含まれる衝撃吸収部材に代えて、本発明に係る衝撃吸収構造体を用いることで、従来のものに不足した性能を付加することも可能である。

By using the shock absorbing structure according to the present invention instead of the shock absorbing member included in the human body protector such as the conventional protective hat, it is possible to add performance which is insufficient to the conventional one.

(2)弾性球状体4は、衝撃吸収構造体2,3の貫通空隙4aを介して、その表面側から裏面側へ通過する空気の流線W3,W4と平行な通気流線W1,W2を加える通気孔4b,4cを有する。

このため、(1)の効果に加えて、さらに通気性の高い保護帽子1とすることができる。 (2) The elasticspherical body 4 has air flow lines W1 and W2 parallel to air flow lines W3 and W4 passing from the front surface side to the back surface side thereof through the through-holes 4a of the shock absorbing structures 2 and 3. Ventilation holes 4b and 4c to be added are provided.

For this reason, in addition to the effect of (1), it can be set as theprotective hat 1 with further high air permeability.

このため、(1)の効果に加えて、さらに通気性の高い保護帽子1とすることができる。 (2) The elastic

For this reason, in addition to the effect of (1), it can be set as the

(3)弾性球状体4は、合成樹脂を素材とする中空の弾性球状体である。

このため、上記した衝撃吸収作用により、さらに通気性と衝撃吸収性、環境温度維持性を高めた保護帽子1を提供することができる。 (3) The elasticspherical body 4 is a hollow elastic spherical body made of synthetic resin.

For this reason, theprotective hat 1 which further improved air permeability, shock absorption, and environmental temperature maintenance property by the above-mentioned impact absorption action can be provided.

このため、上記した衝撃吸収作用により、さらに通気性と衝撃吸収性、環境温度維持性を高めた保護帽子1を提供することができる。 (3) The elastic

For this reason, the

(4)軟結合構造を、平面状または線状に集合させた複数の弾性球状体4を合成樹脂糸5により連結した構造とした。

このため、(1)~(3)の効果に加えて、高い柔軟性を有し、より高い次元で頭部形状の個人差を吸収して追従変形する保護帽子1を提供することができる。 (4) The soft bond structure is a structure in which a plurality of elasticspherical bodies 4 assembled in a planar shape or a linear shape are connected by a synthetic resin thread 5.

For this reason, in addition to the effects (1) to (3), it is possible to provide theprotective cap 1 which has high flexibility and absorbs individual differences in the shape of the head at a higher dimension and can follow and deform.

このため、(1)~(3)の効果に加えて、高い柔軟性を有し、より高い次元で頭部形状の個人差を吸収して追従変形する保護帽子1を提供することができる。 (4) The soft bond structure is a structure in which a plurality of elastic

For this reason, in addition to the effects (1) to (3), it is possible to provide the

(5)普段使用する帽子を、通気性を持つ布製帽子本体と、前記布製帽子本体の裏面に設けられ、頭部曲面形状を分割した形状による複数のシートポケットと、前記複数のシートポケットのそれぞれに装填した衝撃吸収シートとを備えたものとしている。

(5) A hat that is normally used is a breathable cloth hat main body, a plurality of seat pockets provided on the back surface of the cloth hat main body, each having a curved head shape, and each of the plurality of seat pockets. And an impact absorbing sheet loaded in the container.

さらに、この衝撃吸収シートを、外径形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形する複数の弾性球状体と、前記複数の弾性球状体を平面状または線状に集合させた前記弾性球状体間に設けられ、前記複数の弾性球状体の互いに乖離する対向球面により複数の貫通空隙を確保すると共に、外部から加わる構造体変形力にしたがって構造体形状が変形可能なように剛性を低く抑えて結合した軟結合構造と、を備える衝撃吸収構造体であって、所定の分割シート形状としたものとしている。

Further, the shock absorbing sheet has a spherical outer diameter, and a plurality of elastic spherical bodies that are elastically deformed according to the magnitude and direction of external force applied from the outside, and the plurality of elastic spherical bodies are planar or linear. Provided between the assembled elastic spheres, the plurality of elastic spheres are separated from each other by opposing spherical surfaces, and a plurality of through gaps are secured, and the structure shape can be deformed according to a structure deformation force applied from the outside. In this way, the shock absorbing structure is provided with a soft coupling structure coupled with low rigidity, and has a predetermined divided sheet shape.

そのため、普段使用する帽子に衝撃吸収構造体2,3を取り付けて衝撃吸収性、柔軟性、通気性、軽量性、環境温度維持性の全てを高い次元で満足する保護帽子1とすることができ、それにより帽子本来の快適さや意匠性が損なわれることがない。防災頭巾等を装着することのない日常生活で起きる突然の事故等による人体被害を極力抑えることができる。

For this reason, the shock absorbing structures 2 and 3 can be attached to the hats that are usually used to make the protective hat 1 satisfying all of the impact absorption, flexibility, breathability, light weight, and environmental temperature maintenance at a high level. This will not impair the original comfort and design of the hat. Human damage caused by sudden accidents that occur in daily life without wearing a disaster hood, etc. can be minimized.

例えば、外出中に金属製のペンチ等のように比較的に先の尖ったものが上方から頭部に落下して直撃したような場合や、心臓病等で急に倒れて頭部をぶつけた場合、観光地の洞窟内や上りエスカレータで頭上注意といったところで意図せず頭部をぶつけたような場合でも、その衝撃を分散吸収して和らげることができる。

For example, when you go out, a relatively pointed object such as a metal pliers falls on the head from the top and hits you directly. In such a case, even if the head is hit unintentionally in a cave at a sightseeing spot or in an overhead escalator, the impact can be dispersed and absorbed.

図7A,図7Bに、本発明に係る実施例2の衝撃吸収構造体7を示す。

7A and 7B show an impact absorbing structure 7 of Example 2 according to the present invention.

この衝撃吸収構造体7は、弾性球状体4と、これら弾性球状体4同士を軟結合する接着部8とを備えている。そして、弾性球状体4同士が接着部8により軟結合されて、軟結合構造をなしている。なお、同一の部材については、同一の符号を付してその説明を省略する。

The shock absorbing structure 7 includes an elastic spherical body 4 and an adhesive portion 8 that softly bonds the elastic spherical bodies 4 to each other. The elastic spherical bodies 4 are softly coupled to each other by the bonding portion 8 to form a soft coupling structure. In addition, about the same member, the same code | symbol is attached | subjected and the description is abbreviate | omitted.

実施例2に係る衝撃吸収構造体7の構成によれば、接着部8により弾性球状体4間の空隙4aの開口面積が増大して通気性が高まり、保護帽子1の通気性も高まる。また、その結果として弾性球状体4周囲の温度環境が変化しにくくなるため、環境温度維持性も高くなる。

According to the configuration of the shock absorbing structure 7 according to the second embodiment, the bonding area 8 increases the opening area of the gap 4a between the elastic spherical bodies 4, thereby improving the air permeability and the air permeability of the protective cap 1. As a result, the temperature environment around the elastic spherical body 4 is less likely to change, and the environmental temperature maintainability is also improved.

接着部8に用いる接着剤の種類により衝撃吸収構造体7の部分的な軟結合の強弱の程度を変更することができるので、局所的に異なる剛性を示す所望の衝撃吸収構造体7を得ることができる。

Since the degree of strength of the partial soft bond of the shock absorbing structure 7 can be changed depending on the type of adhesive used for the bonding portion 8, a desired shock absorbing structure 7 having locally different rigidity is obtained. Can do.

例えば帽子本体1Bの側部と天頂部とに適用した衝撃吸収構造体2,3を、帽子の形を決めたいときに、軟結合の強弱を局所的に変化させても良い。

For example, when the shock absorbing structures 2 and 3 applied to the side portion and the zenith portion of the hat main body 1B are desired to determine the shape of the hat, the strength of the soft bond may be locally changed.

図8A,図8Bに、本発明に係る実施例3の衝撃吸収構造体10を示す。

8A and 8B show an impact absorbing structure 10 of Example 3 according to the present invention.

この衝撃吸収構造体10は、上記実施例1,2とは異なり中実の弾性球状体11と、これら弾性球状体11同士を軟結合する細長の接着部9とを備えている。そして、弾性球状体11同士が接着部9により軟結合されて、軟結合構造をなしている。なお、同一の部材については、同一の符号を付してその説明を省略する。

Unlike the first and second embodiments, the shock absorbing structure 10 includes a solid elastic spherical body 11 and an elongated bonding portion 9 that softly bonds the elastic spherical bodies 11 to each other. Then, the elastic spherical bodies 11 are softly coupled to each other by the adhesive portion 9 to form a soft coupling structure. In addition, about the same member, the same code | symbol is attached | subjected and the description is abbreviate | omitted.

実施例3に係る衝撃吸収構造体10の構成によれば、実施例2の接着部9が実施例2の接着部8よりも細長であることにより、構造体の通気性がより高いものとなる。その一方で、弾性球状体11が中実であることにより、さらに構造体の衝撃吸収性能が高いものとなる。したがって、構造体の衝撃吸収性を損ねず通気性を高めることができる。

According to the configuration of the shock absorbing structure 10 according to the third embodiment, since the bonding portion 9 of the second embodiment is narrower than the bonding portion 8 of the second embodiment, the air permeability of the structure is higher. . On the other hand, when the elastic spherical body 11 is solid, the impact absorbing performance of the structure is further improved. Therefore, the air permeability can be improved without impairing the shock absorption of the structure.

例えば、夏季に装着する帽子はなるべく通気性が良いものを使用したいという需要があるところ、この衝撃吸収構造体10を設けた保護帽子1とすることで、需要に応じて高い通気性を確保することができる。また、夏季は汗等の汚れが発生しやすい季節であるが、弾性球状体11を中実とすることで、中空のものと比べて防汚性を高めることができる。

For example, when there is a demand for using a hat with good breathability as much as possible as a hat to be worn in summer, the protective hat 1 provided with the shock absorbing structure 10 ensures high breathability according to demand. be able to. Moreover, although the summer is a season in which dirt such as sweat is likely to occur, the anti-stain property can be improved by making the elastic spherical body 11 solid compared to a hollow one.

図9A,図9Bに、本発明に係る実施例4の衝撃吸収構造体12を示す。

9A and 9B show an impact absorbing structure 12 of Example 4 according to the present invention.

衝撃吸収構造体12は、弾性球状体11と、これら弾性球状体11同士を軟結合させる軟結合構造としての接着部8とを備えている。そして、弾性球状体11同士が接着部8により軟結合されて、軟結合構造をなしている。なお、同一の部材については、同一の符号を付してその説明を省略する。

The shock absorbing structure 12 includes an elastic spherical body 11 and an adhesive portion 8 as a soft coupling structure that softly bonds the elastic spherical bodies 11 to each other. The elastic spherical bodies 11 are softly bonded to each other by the bonding portion 8 to form a soft bond structure. In addition, about the same member, the same code | symbol is attached | subjected and the description is abbreviate | omitted.

この実施例4に係る衝撃吸収構造体12の構成によれば、弾性球状体11同士を軟結合させる接着部8により、実施例3のものよりも空隙4aの開口面積が狭小化させているので、通気性が低くなる。

According to the configuration of the shock absorbing structure 12 according to the fourth embodiment, the opening area of the gap 4a is narrower than that of the third embodiment by the adhesive portion 8 that softly bonds the elastic spherical bodies 11 to each other. , Breathability is low.

つまり、弾性球状体11,11を軟結合する接着部の構成を、接着部9(実施例3参照)や接着部8のように変化させることにより、空隙4aの開口面積を調節して衝撃吸収構造体の通気性を調節している。

That is, by changing the configuration of the adhesive portion that softly connects the elastic spherical bodies 11 and 11 as the adhesive portion 9 (see Example 3) or the adhesive portion 8, the opening area of the gap 4a is adjusted to absorb the shock. The air permeability of the structure is adjusted.

例えば冬季にはなるべく保温性の高い帽子を装着したいという需要があるが、弾性球状体11を軟結合する部分を、実施例3より空隙4aが狭小となる接着部9とした衝撃吸収構造体12と冬季に適した布製素材を組み合わせて用いることにより、衝撃吸収構造体の通気性が好適に調節されて保温性が高い保護帽子1を提供することができる。

For example, in winter, there is a demand for wearing a hat having as high a heat retention as possible. However, the impact absorbing structure 12 is formed by using a portion where the elastic spherical body 11 is softly coupled as an adhesive portion 9 in which the gap 4a is narrower than in the third embodiment. By using a combination of fabric materials suitable for the winter season, it is possible to provide the protective hat 1 having a high heat retaining property by suitably adjusting the air permeability of the shock absorbing structure.

これにより弾性球状体11の周囲の環境温度が、高い衝撃吸収性を示す環境温度に維持され、弾性球状体11の衝撃吸収性が損なわれない。この結果、衝撃吸収構造体12の柔軟性の低下を抑制することできる。

Thereby, the environmental temperature around the elastic spherical body 11 is maintained at an environmental temperature exhibiting high shock absorption, and the shock absorption of the elastic spherical body 11 is not impaired. As a result, a decrease in flexibility of the shock absorbing structure 12 can be suppressed.

以上、本発明に係る衝撃吸収構造体について、実施例1~4に基づいて説明してきたが、本発明の要旨を逸脱しない限り構成の変更は許される。

As described above, the shock absorbing structure according to the present invention has been described based on Examples 1 to 4. However, the configuration can be changed without departing from the gist of the present invention.

弾性球状体4や11同士の「軟結合」について、実施例1の衝撃吸収構造体2,3では柔軟性のある合成樹脂糸で実現し、実施例2~4では柔軟性のある接着剤等で実現している。しかし、これらに限られず「軟結合」できるものであれば、どのような構成としてもよい。

The “soft bond” between the elastic spheres 4 and 11 is realized by a flexible synthetic resin yarn in the shock absorbing structures 2 and 3 of the first embodiment, and a flexible adhesive in the second to fourth embodiments. Is realized. However, the configuration is not limited to these, and any configuration may be used as long as it can be “soft coupled”.

実施例1では弾性球状体4の肉厚、直径、通気孔を所定の大きさや長さに設定したが、所期の性能を発揮する限り、これらに限定されるものではない。

In Example 1, the thickness, diameter, and vent holes of the elastic spherical body 4 are set to predetermined sizes and lengths, but are not limited to these as long as the desired performance is exhibited.

弾性球状体4,11の材質は、どのような種類でもよく、弾性球状体4,11を構成する樹脂もポリプロピレンに限定されず、緩衝材として公知のもの(ポリプロピレン以外の他の樹脂や、樹脂以外の素材で公知のもの)の何れも用いることができる。

The material of the elastic spheres 4 and 11 may be of any kind, and the resin constituting the elastic spheres 4 and 11 is not limited to polypropylene, and is known as a buffer material (other resins other than polypropylene and resins) Any other known material can be used.

弾性球状体4,11の形状は、どのような球形状であってもよく、例えば、断面が楕円形状のものや、長円形状のものを用いることができる。

The shape of the elastic spherical bodies 4 and 11 may be any spherical shape, and for example, an elliptical cross section or an oval shape may be used.

弾性球状体4,11の人体Hや被服等に接地する部分の形状を先細りとなるようにして接地面積を小さくすることで、全体の衝撃吸収体としての通気性をさらに向上させたり、低下させたり調節することができる。

By reducing the ground contact area by tapering the shape of the elastic spherical bodies 4 and 11 that touch the human body H or clothing, the overall breathability of the shock absorber can be further improved or decreased. Can be adjusted.

衝撃吸収構造体の全体的な形状は実施例1のようなものに限定されず、どのような形状(立体形状等)としてもよい。

The overall shape of the shock absorbing structure is not limited to that of the first embodiment, and may be any shape (three-dimensional shape or the like).

本出願は、2011年7月4日に日本国特許庁に出願された特願2011-148026に基づいて優先権を主張し、その全ての開示は完全に本明細書で参照により組み込まれる。

This application claims priority based on Japanese Patent Application No. 2011-148026 filed with the Japan Patent Office on July 4, 2011, the entire disclosure of which is fully incorporated herein by reference.

Claims (5)

- 外形形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形する複数の弾性球状体と、

前記複数の弾性球状体を平面状または線状に集合させた前記弾性球状体間に設けられ、前記複数の弾性球状体の互いに乖離する対向球面により複数の貫通空隙を確保するとともに、外部から加わる構造体変形力にしたがって構造体形状が変形可能なように剛性を低く抑えて結合した軟結合構造と、

を備えることを特徴とする衝撃吸収構造体。 A plurality of elastic spherical bodies whose outer shape is spherical and elastically deformed according to the magnitude and direction of external force applied from the outside;

The plurality of elastic spherical bodies are provided between the elastic spherical bodies in which the plurality of elastic spherical bodies are assembled in a planar shape or a linear shape, and a plurality of through-gap spaces are secured by opposed spherical surfaces that are separated from each other, and are applied from the outside. A soft coupling structure coupled with low rigidity so that the structure shape can be deformed according to the structure deformation force; and

A shock absorbing structure characterized by comprising: - 請求項1に記載の衝撃吸収構造体において、

前記弾性球状体は、前記貫通空隙を介して構造体の表面側から裏面側へ通過する空気の流線と平行な通気流線を加える通気孔を有する

ことを特徴とする衝撃吸収構造体。 The shock absorbing structure according to claim 1,

The impact-absorbing structure according to claim 1, wherein the elastic spherical body has a ventilation hole for adding a ventilation stream line parallel to a stream line of air passing from the front surface side to the back surface side of the structure body through the through gap. - 請求項1又は2に記載の前記衝撃吸収構造体において、

前記弾性球状体は、合成樹脂を素材とする中空の弾性球状体である

ことを特徴とする衝撃吸収構造体。 The shock absorbing structure according to claim 1 or 2,

The elastic spherical body is a hollow elastic spherical body made of a synthetic resin. - 請求項1から請求項3までの何れか1項に記載された衝撃吸収構造体において、

前記軟結合構造は、平面状または線状に集合させた前記複数の弾性球状体を合成樹脂糸により連結した構造である

ことを特徴とする衝撃吸収構造体。 In the impact-absorbing structure according to any one of claims 1 to 3,

The impact-absorbing structure is characterized in that the soft coupling structure is a structure in which the plurality of elastic spherical bodies assembled in a planar shape or a linear shape are connected by a synthetic resin thread. - 通気性を持つ人体保護具本体と、

前記人体保護具本体の裏面に設けられ、頭部曲面形状を分割した形状による複数のシートポケットと、

前記複数のシートポケットのそれぞれに装填した衝撃吸収シートと、を備え、

前記衝撃吸収シートは、

外径形状が球状であり、外部から加わる外力の大きさと方向に応じて弾性変形する複数の弾性球状体と、

前記複数の弾性球状体を平面状または線状に集合させた前記弾性球状体間に設けられ、前記複数の弾性球状体の互いに乖離する対向球面により複数の貫通空隙を確保すると共に、外部から加わる構造体変形力にしたがって構造体形状が変形可能なように剛性を低く抑えて結合した軟結合構造と、

を備える衝撃吸収構造体を、所定の分割シート形状とすることで構成したものである

ことを特徴とする人体保護具。 A body protection body with breathability,

A plurality of seat pockets provided on the back surface of the human body protector main body, with a shape obtained by dividing the head curved surface shape,

An impact absorbing sheet loaded in each of the plurality of seat pockets,

The shock absorbing sheet is

A plurality of elastic spherical bodies whose outer diameter shape is spherical and elastically deformed according to the magnitude and direction of external force applied from the outside;

The plurality of elastic spherical bodies are provided between the elastic spherical bodies in which the plurality of elastic spherical bodies are assembled in a planar shape or a linear shape, and a plurality of through-gap spaces are secured by opposed spherical surfaces that are separated from each other, and are applied from the outside. A soft coupling structure coupled with low rigidity so that the structure shape can be deformed according to the structure deformation force; and

A human body protector comprising: a shock absorbing structure including: a predetermined divided sheet shape.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-148026 | 2011-07-04 | ||

| JP2011148026A JP5433642B2 (en) | 2011-07-04 | 2011-07-04 | Shock absorbing structure and personal protective equipment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013005512A1 true WO2013005512A1 (en) | 2013-01-10 |

Family

ID=47436870

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/064020 WO2013005512A1 (en) | 2011-07-04 | 2012-05-31 | Shock-absorbing structure and human body protector |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP5433642B2 (en) |

| WO (1) | WO2013005512A1 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013057138A (en) * | 2011-09-08 | 2013-03-28 | Tokushu Iryo:Kk | Protective headgear |

| GB201303048D0 (en) * | 2013-02-21 | 2013-04-03 | Wood John | Impact absorbing structure |

| JP6247061B2 (en) * | 2013-09-13 | 2017-12-13 | トヨタ自動車株式会社 | Shock-absorbing structure, protective equipment, and manufacturing method thereof |

| JP6174431B2 (en) * | 2013-09-13 | 2017-08-02 | トヨタ自動車株式会社 | Method for manufacturing shock absorbing structure |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007107176A (en) * | 2006-10-16 | 2007-04-26 | Nisshin Kikaku:Kk | Sportswear |

| JP2007224450A (en) * | 2006-02-23 | 2007-09-06 | Nisshinbo Ind Inc | Clothing and headgear |

| JP3149676U (en) * | 2009-01-16 | 2009-04-09 | 金子 博 | hat |

| JP2010084314A (en) * | 2008-10-01 | 2010-04-15 | Dong Il Sin | Head protective headgear |

-

2011

- 2011-07-04 JP JP2011148026A patent/JP5433642B2/en active Active

-

2012

- 2012-05-31 WO PCT/JP2012/064020 patent/WO2013005512A1/en active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007224450A (en) * | 2006-02-23 | 2007-09-06 | Nisshinbo Ind Inc | Clothing and headgear |

| JP2007107176A (en) * | 2006-10-16 | 2007-04-26 | Nisshin Kikaku:Kk | Sportswear |

| JP2010084314A (en) * | 2008-10-01 | 2010-04-15 | Dong Il Sin | Head protective headgear |

| JP3149676U (en) * | 2009-01-16 | 2009-04-09 | 金子 博 | hat |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013014855A (en) | 2013-01-24 |

| JP5433642B2 (en) | 2014-03-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105050439B (en) | Impact absorbing apparatus | |

| US4422183A (en) | Protective body shield | |

| US20060260026A1 (en) | Protective padding and protective padding systems | |

| JP5878202B2 (en) | Industrial safety cap | |

| JP5433642B2 (en) | Shock absorbing structure and personal protective equipment | |

| WO2010082537A1 (en) | Undercap | |

| JP2018500478A (en) | Protective helmet for sports, especially when skiing | |

| JP4172720B1 (en) | Riding and working helmets | |

| KR20060089967A (en) | Inner cell for safety cap, and safety cap equipped with the same | |

| JP6450600B2 (en) | hat | |

| JP6449360B2 (en) | protector | |

| KR20150128363A (en) | Helmet having shock absorbing function | |

| TWM630463U (en) | Helmet with breathable shock absorption function | |

| JP5117782B2 (en) | Chest protective pad and manufacturing method thereof | |

| JP6236243B2 (en) | Hammock for helmet | |

| CN214407176U (en) | Shock-absorbing and breathable military police bulletproof helmet | |

| JP3843120B2 (en) | Protective hat | |

| JP5994732B2 (en) | Hat protective equipment and hats | |

| JP3125428U (en) | protector | |

| JP2021147731A (en) | Helmet | |

| JP2002339140A (en) | Cap for protecting head | |

| KR101996536B1 (en) | A Cushioning helmet with ventilation duct | |

| KR20200041690A (en) | Helmet for head guard | |

| KR20090011189U (en) | Circulate air structure of helmet | |

| KR200474963Y1 (en) | Cork helmet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12807646 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12807646 Country of ref document: EP Kind code of ref document: A1 |