WO2011064316A2 - Mucosal delivery of peptides - Google Patents

Mucosal delivery of peptides Download PDFInfo

- Publication number

- WO2011064316A2 WO2011064316A2 PCT/EP2010/068257 EP2010068257W WO2011064316A2 WO 2011064316 A2 WO2011064316 A2 WO 2011064316A2 EP 2010068257 W EP2010068257 W EP 2010068257W WO 2011064316 A2 WO2011064316 A2 WO 2011064316A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- peptide

- active agent

- mucosal delivery

- delivery composition

- peptide active

- Prior art date

Links

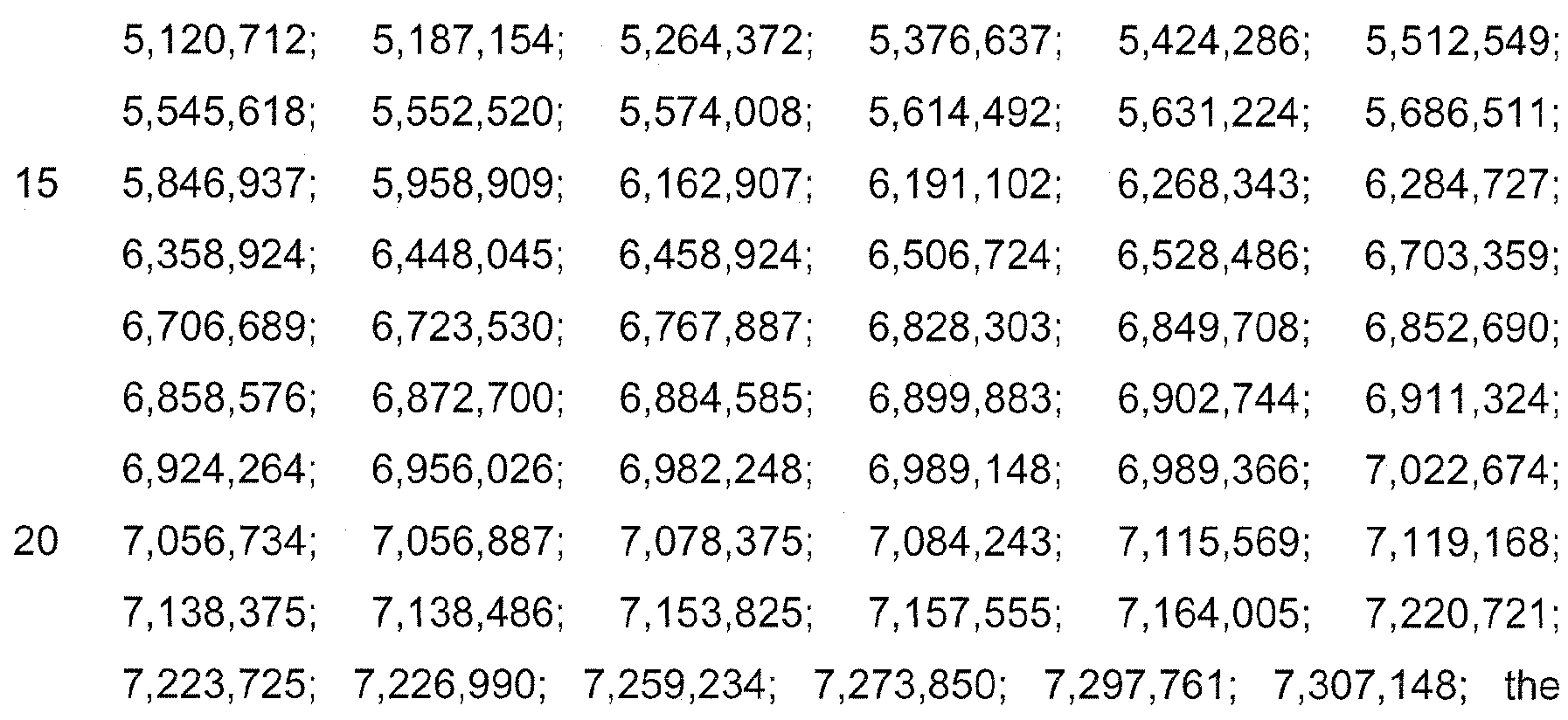

- 0 *=CC(C*C(C1OC2(*CCOCCOCCOCCOCCOC2)O[C@@]1[C@](O)OCC(CO)O)O)O Chemical compound *=CC(C*C(C1OC2(*CCOCCOCCOCCOCCOC2)O[C@@]1[C@](O)OCC(CO)O)O)O 0.000 description 1

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0053—Mouth and digestive tract, i.e. intraoral and peroral administration

- A61K9/006—Oral mucosa, e.g. mucoadhesive forms, sublingual droplets; Buccal patches or films; Buccal sprays

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K38/00—Medicinal preparations containing peptides

- A61K38/02—Peptides of undefined number of amino acids; Derivatives thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K38/00—Medicinal preparations containing peptides

- A61K38/16—Peptides having more than 20 amino acids; Gastrins; Somatostatins; Melanotropins; Derivatives thereof

- A61K38/17—Peptides having more than 20 amino acids; Gastrins; Somatostatins; Melanotropins; Derivatives thereof from animals; from humans

- A61K38/22—Hormones

- A61K38/26—Glucagons

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/06—Organic compounds, e.g. natural or synthetic hydrocarbons, polyolefins, mineral oil, petrolatum or ozokerite

- A61K47/22—Heterocyclic compounds, e.g. ascorbic acid, tocopherol or pyrrolidones

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/51—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent

- A61K47/54—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an organic compound

- A61K47/545—Heterocyclic compounds

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/10—Dispersions; Emulsions

- A61K9/12—Aerosols; Foams

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P3/00—Drugs for disorders of the metabolism

- A61P3/04—Anorexiants; Antiobesity agents

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P3/00—Drugs for disorders of the metabolism

- A61P3/08—Drugs for disorders of the metabolism for glucose homeostasis

- A61P3/10—Drugs for disorders of the metabolism for glucose homeostasis for hyperglycaemia, e.g. antidiabetics

Definitions

- the disclosure relates to compositions and methods for mucosal delivery of peptides, particularly oral mucosal delivery for absorption through oral mucosal membranes.

- Peptide-based drugs are typically delivered by injection, since oral delivery by ingestion is often hindered by poor intrinsic permeability and degradation in the gastrointestinal (Gl) tract. Nevertheless, the potential therapeutic benefit remains significant, including ease of use and better overall patient compliance.

- Mucosal delivery of peptides into the blood stream of a host across various mucosal membranes, such as found in the Gl tract, lung, nasal cavity and oral cavity, is possible for a number of peptides and peptide formulations.

- the fraction of an administered dose of unchanged peptide that reaches the systemic circulation normally varies depending on the particular route of delivery, peptide and formulation.

- the non-invasive delivery of peptide drugs by mucosal routes offers significant flexibility.

- delivery of drugs via oral mucosa provides direct access to the systemic circulation through the internal jugular vein, allowing them to bypass the gut and hepatic first-pass metabolism, and enter the bloodstream for rapid on-set of effect.

- the mucosal lining in the oral cavity represents a promising topical route for the delivery of large therapeutic molecules such as insulin, interferons, and inter!eukins (Visse et al. , Eur. J. Pharm. Biopharm. (2001 ) 51 :93-109; and Sudhakar et al., J. Control. Release (2006) 1 14: 1 5-40; and Amin ef al., Drug Delivery Technology (2007) 7(3) 48, 50-55).

- mucoadhesive dosage forms also have been reported to increase resident time of the delivery system in the oral cavity (Ishida et al., Chem. Pharm. Bull. (1981 ) 29:810-816; and Senel et al., Curr. Pharm. Biotechnol. (2001 ) 2:175-186), including, for example, pelleted mucoadhesive polymeric nanoparticles (Venugopalan et al., Pharmazie (2001 ) 56:217-219), and mucoadhesive tablets (Hosny et al., Boll. Chim. Farm. (2002) 141 :210- 217).

- Mucosal dosage forms employing various solvents have also been reported, such as insulin with soybean lecithin and propanediol (Xu et al., Pharmacol. Res. (2002) 46:459 ⁇ 467), and buccal aerosol sprays and capsules using non-polar solvent (U.S. Patent No. 5,955,098).

- Pulmonary delivery formulations of a solution or suspension of various organic solvents have been reported, for example, where the solvent is a class 3 residual solvent such as ethanol, acetone, ethyl acetate, tetrahydofuran, ethyl ether, and propanol (US 6,660,715).

- mucosal delivery systems often include absorption enhancing formulations that exhibit side effects, such as causing irritation of the various mucosal linings in the mouth or airways.

- absorption enhancing formulations that exhibit side effects, such as causing irritation of the various mucosal linings in the mouth or airways.

- Another problem is the repugnant taste of many compositions, particularly for bile salts, pointing to likely issues with patient acceptance and compliance.

- a different issue relates to the volume required for delivering a sufficient amount of an active peptide ingredient for biological effect, storage stability, and reproducibility.

- compositions and methods for administering peptides that are stable, well tolerated, provide enhanced and reliable mucosal delivery, particularly oral mucosal delivery, and suitable for treatment of diseases and other adverse conditions in mammalian subjects.

- a related need exists for methods and compositions that provide efficient delivery of larger drugs such as peptides via one or more mucosal routes in therapeutic amounts, which are fast acting, easily administered, have limited adverse side effects such as mucosal irritation or tissue damage, and reproducible.

- non-aqueous pharmaceutical and diagnostic compositions of peptides which have improved stability.

- An additional need relates to the manufacture of such materials, and compositions for the same. The present disclosure addresses these and other needs.

- compositions and methods related to mucosal delivery of peptide active agents include an effective amount of a stably hydrated peptide active agent complexed with a crown compound and/or a counter ion solubilized in a non-aqueous hydrophobic vehicle at a pH different from the isoelectric point of the peptide active agent.

- compositions that include a preformed peptide complex comprising a stably hydrated peptide active agent complexed with a crown compound and/or a counter ion, wherein the performed peptide complex is dried from a solution or suspension having a pH different, optionally remote, from the isoelectric point of the peptide active agent.

- Additional compositions include an effective amount of a stably hydrated peptide active agent complexed with a counter ion solubilized in a nonaqueous hydrophobic vehicle at a pH different from the isoelectric point of the peptide active agent, wherein the stably hydrated peptide active agent complexed with a counter ion is dried from a solution or suspension having a pH different, optionally remote, from the isoelectric point of the peptide active agent, and wherein the non-aqueous hydrophobic vehicle in many embodiments comprises at least one acylglycerol and at least one organic solvent and/or lipid. Further provided are pharmaceutical and/or diagnostic preparations of the subject compositions.

- the method comprises forming a soluble peptide complex in a non-aqueous hydrophobic vehicle at a pH different from the isoelectric point of the peptide active agent, the peptide complex comprising an effective amount of a stably hydrated peptide active agent complexed with a crown compound and a counter ion.

- a method for production of a preformed peptide complex comprising a stably hydrated peptide active agent complexed with a crown compound and a counter ion, the method involving (i) forming the peptide complex in a solution or suspension having a pH different, optionally remote, from the isoelectric point of the peptide active agent, and (ii) drying the peptide complex from the solution or suspension under conditions that retain a sufficient amount of water in association with the peptide active agent to stabilize the peptide active agent, whereby the preformed peptide complex is produced.

- Another method involves solubilizing an effective amount of a stably hydrated peptide active agent compiexed with a counter ion in a non-aqueous hydrophobic vehicle at a pH different from the isoelectric point of the peptide active agent, wherein the stably hydrated peptide active agent compiexed with a counter ion is dried from a solution or suspension having a pH different, optionally remote, from the isoelectric point of the peptide active agent, and wherein the non-aqueous hydrophobic vehicle in many embodiments comprises at least one acylglycerol and at least one organic solvent and/or lipid.

- Methods for the mucosal delivery of an effective amount of a peptide active agent to a host in need thereof involve administering to a mucosal membrane of the host an effective amount of a mucosal delivery composition of the disclosure, wherein the administering delivers an effective amount of the peptide active agent into the blood stream of the host.

- the mucosal delivery composition is an oral mucosal delivery composition

- the mucosal membrane is an oral mucosal membrane.

- kits that find use in practicing the subject methods.

- the kit comprises an effective amount of a mucosal delivery composition of the disclosure, and/or components thereof each individually provided in various combinations in the kit in effective amounts capable of forming the mucosal delivery composition upon combination.

- the subject methods and compositions find use in a wide range of different applications, including the treatment of a variety of different disease conditions.

- An exemplary application illustrating a significant advantage of the methods and compositions disclosed herein is the enhanced mucosal delivery of peptides, and in particular, reliably reproducible mucosal delivery imparted by formation and use of a stably hydrated form of the peptide active agent maintained in the peptide complex and non-aqueous hydrophobic vehicle.

- compositions and methods are particularly useful for mucosal delivery of peptide hormones, such as glucagon-like peptide-1 and analogs thereof exemplified by liraglutide and exendin-4 (exenatide) that can affect blood glucose levels in vivo for treatment of diabetes, obesity, and related disorders.

- peptide hormones such as glucagon-like peptide-1 and analogs thereof exemplified by liraglutide and exendin-4 (exenatide) that can affect blood glucose levels in vivo for treatment of diabetes, obesity, and related disorders.

- specific compositions and methods are provided for mucosal delivery of a peptide active agent for treatment of diabetes, obesity, and related disorders.

- Figure 1 depicts a set of results demonstrating the effect of the type of counter ion on sublingual delivery of exendin-4 in a representative mucosal delivery composition, and reduction of glucose levels in mice as measured by intraperitoneal glucose tolerance tests (IPGTT).

- IPGTT intraperitoneal glucose tolerance tests

- Figure 2 depicts a set of results demonstrating the effect of altering vehicle pH on sublingual delivery of exendin-4 in a representative mucosal delivery composition, and reduction of glucose levels in mice as measured by IPGTT.

- Figure 3 depicts a set of results demonstrating the effect of altering the stoicheometric amounts and ratios of crown compound and counter ion to peptide on sublingual delivery of exendin-4 in representative mucosal delivery composition, and reduction of glucose levels in mice as measured by IPGTT.

- Figure 4 depicts a set of results demonstrating the effect of water content and processing conditions on sublingual delivery of exendin-4 in a representative mucosal delivery composition, and reduction of glucose levels in mice as measured by IPGTT.

- amino acid refers to any of the naturally occurring amino acids (e.g. Ala, Arg, Asn, Asp, Cys, Glu, Gin, Gly, His, Hyl, Hyp, lie, Leu, Lys, Met, Phe, Pro, Ser, Thr, Trp, Tyr, and Val) in D, L, or DL form, as well as analogues/derivatives thereof.

- Naturally occurring amino acids e.g. Ala, Arg, Asn, Asp, Cys, Glu, Gin, Gly, His, Hyl, Hyp, lie, Leu, Lys, Met, Phe, Pro, Ser, Thr, Trp, Tyr, and Val

- the side chains of naturally occurring amino acids include, for example, hydrogen (e.g., as in glycine), alkyl (e.g., as in alanine, valine, leucine, isoleucine, proline), substituted alkyl (e.g., as in threonine, serine, methionine, cysteine, aspartic acid, asparagine, glutamic acid, giutamine, arginine, and lysine), alkaryl (e.g., as in phenylalanine and tryptophan), substituted arylalkyl (e.g., as in tyrosine), and heteroarylalkyl (e.g., as in histidine).

- the amino acids includes protected or modified amino acids, such as acylated amino acids, amidated amino acids and the like.

- Analogue or “derivative” refers to without limitation any compound which has a structure derived from the structure of the compounds of the present disclosure and whose structure is sufficiently similar to those disclosed herein and based upon that similarity, would be expected, by one skilled in the art, to exhibit the same or similar activities and utilities as the claimed and/or referenced compounds.

- Bosal mucosa refers to the membrane lining the inner wall of the cheek.

- Charge complexing agent refers to a compound that forms a non- cova!ent complex with an ion, atom or ionizab!e functional group of a molecule, where the complex represents a reversible association of the complexing agent with one or more ions, atoms, or molecules through non- covalent chemical bonds.

- Complexed or charge complex refers to a reversible association of a charge complexing agent such as a crown compound that forms a non- covalent complex with an ion, atom or ionizable functional group of a molecule through non-covalent chemical bonds.

- a charge complexing agent such as a crown compound that forms a non- covalent complex with an ion, atom or ionizable functional group of a molecule through non-covalent chemical bonds.

- the term complexed or charge complex is not confined to salt or metal ions bound to a complexing agent. It relates in general to complexes between a complexing agent and an ion or ionic group on a peptide, particularly a cation or cationic group on a peptide.

- Crown compound refers to macrocyclic polydentate compounds, usually uncharged, in which three or more coordinating ring atoms (usually oxygen or nitrogen) are or may become suitably close for easy formation of chelate complexes with cationic species (excludes planar analogues, such as porphyrins). See for example: M. Hiraoka, Crown Compounds: their Characteristics and Applications, Elsevier Science Publishers, 1982; and E. Weber and F. Vogtle, Inorg. Chim. Acta (1980) 45:L65-L67.

- “Dried peptide” refers to a peptide dried by a process, such as lyophilization, spray drying, centrifugal evaporation, and air drying, and which contains residual water in association with the peptide.

- the dried peptide is typically a powder or residue that can have the appearance of a dry powder, particulate, or residue material, including an oily or moistened residue appearance.

- an “anhydrous peptide” contains essentially no water. See for example, lyophilization (e.g., Williams and Polli (1984) J, Parenteral Sci. Technol.

- Effective means adequate to accomplish a desired, expected, or intended result.

- the term “effective amount” or “pharmaceutically effective amount” as provided herein is intended to mean a non-lethal but sufficient amount of the compound to provide the desired utility.

- the effective amount is the amount which elicits a useful response (e.g., reduction of blood glucose levels below control level, or to provide for a clinically meaningful reduction in blood glucose levels).

- the exact amount required will vary from subject to subject, depending on the species, age, and general condition of the subject, the severity of the condition or disease that is being treated, the particular compound used, its mode of administration, and the like. Thus, it is not possible to specify an exact "effective amount.” However, an appropriate effective amount may be determined by one of ordinary skill in the art using only routine experimentation.

- “lonizable functional group” refers to a group on an amino acid of a peptide capable of donating or accepting a charge at a pH different from the group's pKa.

- Mucosal delivery refers to application of an active agent (such as a drug) to one or more mucosal membranes of the gastrointestinal tract (Gl), rectum, vagina, lung, nasal cavity, or oral cavity, including buccal (cheek), sublingual (under tongue), lips, gums, palates, and tongue, and passage of the active agent through the membranes covering these places and its entry into the bloodstream.

- an active agent such as a drug

- “Mucosal delivery composition” refers to a drug delivery composition or system capable of mucosal delivery of an active agent.

- Protein refers to a polyamino acid containing up to 2, 5, 10, 20, 30, 40, 50, 75, 100 or about 200 amino acid residues, which can include coded and non-coded amino acids, chemically or biochemically modified or derivatized amino acids, linear, branched or cyclic peptide, and peptides having modified backbones. Sometimes referred to as polypeptide or protein, which may be used interchangeably herein.

- peptides which comprise one or more non-naturally occurring amino acids such as beta-aianine, aipha-amino butyric acid, gamma-amino butyric acid, alpha- amino isobutyric acid, norva!ine, norleucsne, ornithine, homoserine and hydroxyproline.

- peptides in which reactive groups are modified such as the N- and C-terminus of a peptide may be chemically modified by various labeling agents, polymers such as polyethylene glycol, lipids, carbohydrates and the like, blocked by protecting groups, and the like, as well as those bearing biological modifications, such as post-translational modifications.

- “Peptide active agent” refers to a biologically active peptide or an analogue/derivative thereof, including pharmaceutically acceptable salts, solvates, hydrates, and prodrug forms thereof.

- Percent solubility value refers to the equilibrium solubility limit or maximum solubility of a molecule in a solvent or solvent system at usual room temperature, expressed as the weight percent of the molecule in the composition.

- Permeability-enhancing lipid refers to charged or neutral hydrophobic or amphiphilic small molecules that may be either solid or liquid at normal room temperature, depending on their structure and composition, may be saturated or unsaturated, branched or linear, and are capable of enhancing the permeability of mucosal membranes to absorption of peptides.

- fat-soluble vitamins such as vitamins A, D, E and K

- monoglycerides such as vitamins A, D, E and K

- diglycerides diglycerides

- phospholipids such as oleic acid

- sterols such as cholesterol

- phospholipids such as phosphatidylcholine, and the like.

- permeability-enhancing fatty acid refers to aliphatic carboxylic acids that may be saturated or unsaturated, branched or linear, and are capable of enhancing the permeability of mucosal membranes to absorption of peptides.

- Oral mucosal delivery refers to application of an active agent (such as a drug) to one or more mucosal membranes of the oral cavity, including buccal (cheek), sublingual (under tongue), Hps, gums, palates, and tongue, and passage of the active agent through the membranes covering these places and its entry into the bloodstream.

- an active agent such as a drug

- Oral mucosal delivery vehicle refers to a drug delivery system capable of oral mucosal delivery of an active agent.

- solute refers to the interaction of a solute, such as a peptide, with a solvent, such as an aqueous, organic, or an aqueous organic solution, which leads to stabilization of the solute in the solvent.

- solvent such as an aqueous, organic, or an aqueous organic solution

- solubility refers to the dynamic equilibrium state achieved when the rate of dissolution equals the rate of precipitation. The extent of the solubility of a substance in a specific solvent is measured as the saturation

- “Stably hydrated peptide active agent” refers to a peptide active agent having a water content by weight and solubility in an organic or aqueous organic solvent comparable to or greater than the dried peptide active agent, and is essentially non-aggregated and unoxidized.

- Sublingual mucosa refers to the membrane that includes the ventral surface of the tongue and the floor of the mouth.

- pharmaceutically acceptable refers to a material that is not biologically or otherwise undesirable, i.e., the material is of a medically acceptable quality and composition that may be administered to an individual along with the selected active pharmaceutical ingredient without causing any undesirable biological effects or interacting in a deleterious manner with any of the other components of the pharmaceutical composition in which it is contained.

- compositions and methods of their preparation for mucosal delivery of peptide active agents are also provided. Also provided are kits and methods of use of the subject compositions.

- compositions include a mucosal delivery composition that comprises an effective amount of a peptide complex or a peptide salt solubilized in a non-aqueous hydrophobic vehicle.

- the peptide complex includes a stably hydrated peptide active agent complexed with a crown compound and/or a counter ion, and is solubilized in the non-aqueous hydrophobic vehicle at a pH different from the pi of the peptide active agent.

- the peptide salt includes a stably hydrated peptide active agent complexed with a counter ion, and is solubilized in the non-aqueous hydrophobic vehicle at a pH different from the p/ of the peptide active agent.

- the non-aqueous hydrophobic vehicle comprises at least one acylglycerol, and at least one organic solvent and/or lipid each individually present in an amount effective to (i) soiubilize the peptide complex or peptide salt, and (ii) enhance mucosa! delivery of the peptide active agent.

- the mucosal delivery composition generally includes various solubilizing agents in non-aqueous medium, such as a medium comprising an acylglycerol and an organic solvent and/or a lipid (as described in greater detail below).

- the mucosal delivery composition and components thereof may also include one or more additional pharmaceutically acceptable excipients, such as one or more of an non-ionic surfactant, antioxidant, buffer, preservative, and the like (as described in greater detail below).

- the peptide complex or the peptide salt is preformed, wherein the preformed peptide complex or preformed peptide salt is dried from a solution or suspension having a pH different, optionally remote, from the p/ of the peptide active agent.

- the nonaqueous hydrophobic vehicle is preformed.

- the preformed non-aqueous hydrophobic vehicle is dried from a solution or suspension having a pH different, optionally remote, from the isoelectric point of the peptide active agent.

- the mucosal delivery composition is dried from a solution or suspension having a pH different, optionally remote, from the isoelectric point of the peptide active agent.

- the solution or suspension is an aqueous organic mixture.

- further embodiments are directed to a composition comprising one or more of the preformed peptide complex, the preformed peptide salt, the preformed non-aqueous hydrophobic vehicle, and combinations thereof.

- a method of producing a mucosal delivery composition comprising: forming a peptide complex or peptide salt dispersed in a non-aqueous hydrophobic vehicle at a pH different from the pi of the peptide active agent, the peptide complex comprising an effective amount of a stably hydrated peptide active agent complexed with a crown compound and a counter ion, the peptide salt comprising an effective amount of a stably hydrated peptide active agent complexed with a counter ion.

- a featured embodiment is where the peptide complex or peptide salt is solubilized at a pH different from the p/ of the peptide active agent in the nonaqueous hydrophobic vehicle.

- the forming step of the subject method comprises combining an effective amount of each component (or any effective combination thereof) of the desired mucosal delivery composition (i.e., combining an effective amount of components comprising the stably hydrated peptide active agent, the crown compound, the counter ion, and the non-aqueous hydrophobic vehicle for mucosal delivery compositions in which a crown compound is included, or combining an effective amount of the components comprising the stably hydrated peptide active agent, the counter ion, and the non-aqueous hydrophobic vehicle for mucosal delivery compositions in which a crown compound is absent).

- the forming step of the subject method comprises combining an effective amount of (i) a first composition comprising the non-aqueous hydrophobic vehicle, and (ii) a second composition comprising the peptide complex or the peptide salt.

- the forming step of the subject method comprises combining an effective amount of (i) a first composition comprising the nonaqueous hydrophobic vehicle and the peptide salt, and (ii) a second composition comprising a crown compound.

- the peptide complex or peptide salt in many embodiments is comprised as a dried powder or residue obtainable by drying a solution or suspension, the solution or suspension comprising as components therein: (i) the peptide active agent, the crown compound, and the counter ion for forming the peptide complex, or (ii) the peptide active agent, and the counter ion for forming the peptide salt; and wherein the drying is under conditions that retain a sufficient amount of water in association with the peptide active agent to produce the peptide complex or peptide salt.

- the solution or suspension is at pH different, optionally remote, from the isoelectric point of the peptide active agent.

- the solution or suspension is an aqueous organic solution or suspension.

- the peptide complex and/or the peptide salt is preformed as a dried powder or residue.

- a featured aspect is where one or more of the dried powder or residue comprising the peptide complex, the peptide salt, the peptide active agent, the crown compound, and/or the counter ion is soluble in the aqueous organic solution or suspension.

- a specific embodiment is where the dried powder or residue comprising the peptide complex, or the peptide salt is soluble in the aqueous organic solution or suspension.

- step (b) combining the preformed peptide salt of step (a) with a second composition comprising a non-aqueous hydrophobic vehicle to form the mucosal delivery composition;

- step (c) combining the preformed peptide salt of step (a) with a second composition comprising a non-aqueous hydrophobic vehicle and a crown compound to form the mucosal delivery composition; or

- step (d) combining the preformed peptide salt of step (a) with a second composition comprising a crown compound in an organic or aqueous organic solution or suspension, and (i) drying the organic or aqueous organic solution or suspension to form a preformed peptide complex under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide active agent; and (ii) combining the preformed peptide complex with the non-aqueous hydrophobic vehicle to form the mucosal delivery composition.

- Methods are also provided for production of a preformed peptide complex and/or a preformed peptide salt, such as described above.

- the method involves (i) providing an aqueous organic solution or suspension comprising as components therein a peptide active agent, a crown compound, and a counter son, and (ii) drying the aqueous organic solution or suspension under conditions that retain a sufficient amount of water in association with the peptide active agent to produce the peptide complex.

- the aqueous organic solution or suspension is at a pH different, optionally remote, from the pi of the peptide active agent.

- the method involves administering to a mucosal membrane of the host an effective amount of a mucosal delivery composition of the disclosure, wherein the administering delivers an effective amount of the peptide active agent into the blood stream of the host.

- kits that find use in practicing the subject methods.

- the mucosal delivery compositions and its components are generally non-toxic and non-irritating, and facilitate enhanced and reliably reproducible mucosal delivery of the stably peptide active agent into the blood stream of the host, relative to the non-stably hydrated peptide active agent.

- the subject compositions may be administered alone or as part of a drug delivery system for delivery to one or more mucosal membranes of a host, such as administration to the oral cavity of a host for oral mucosal delivery through an oral mucosal membrane, such as a buccal membrane, sublingual membrane, or both buccal and sublingual membranes.

- the compositions can be provided in a free form, such as a liquid, gel, foam, cream, ointment, semisolid, or spray, or can comprise a device of determined physical form, such as tablets, patches, films, and troches.

- compositions and methods find use in a variety of different applications, including the treatment of a range of different disease conditions for which a given peptide active agent is indicated.

- An exemplary application illustrating a significant advantage of the methods and compositions of the disclosure is the effective and reliably reproducible oral mucosal delivery of peptide hormones such as insulin and incretin mimetic peptides that alter blood giucose levels in vivo for treatment of diabetes, obesity, and related disorders.

- the subject compositions and methods represent an important advance over the prior art.

- a significant problem overcome by the present disclosure is the reliable and reproducible mucosal delivery of peptide active agents, among other aspects.

- the present disclosure is based in part on the discovery that a remarkable improvement in the mucosal delivery of peptides can be achieved by providing a mucosal delivery composition comprising an effective amount of a stably hydrated peptide active agent complexed with a crown compound and a counter ion solubilized in a non-aqueous hydrophobic vehicle at a pH different from the isoelectric point (p/) of the peptide active agent.

- the stably hydrated peptide active agent complexed with a crown compound and a counter ion also referred to herein as the peptide complex, is readily prepared in situ in the non-aqueous hydrophobic vehicle or pre-formed ex situ, with the proviso that the peptide active agent is processed under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide active agent.

- the peptide complex is prepared ex situ as a preformed peptide complex, and then combined with the non-aqueous hydrophobic vehicle.

- the peptide complex is prepared in situ in the non-aqueous hydrophobic vehicle, for example, by combining (i) a crown compound with (ii) a non-aqueous hydrophobic vehicle comprising the stably hydrated peptide active agent in complex with a counter ion as a peptide salt, with the proviso that the peptide active agent is processed under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide active agent.

- the present disclosure is also based in part on the finding that a significant improvement in solubility of the peptide complex or peptide salt in a non-aqueous hydrophobic vehicle can be achieved when the peptide complex or peptide salt is dried from a solution or suspension at a pH different, optionally remote, from the pi of the peptide active agent.

- the mucosal delivery composition can be readily prepared in situ or ex situ utilizing such a dried peptide complex or peptide salt, with the proviso that the peptide active agent is processed under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide active agent.

- the mucosal delivery composition is formed by an in situ or ex situ process as described above, reliable and reproducible mucosal delivery of the peptide active agent strongly depends on the conditions under which the composition is prepared.

- the following process of the disclosure illustrates this point, and can be characterized as involving two basic steps.

- the peptide active agent is generally provided as a performed salt that is dried (e.g., by lyophilization or spray drying) from an aqueous or aqueous organic solution or suspension (e.g., water, water/acetonitrile mixtures) having a pH different, optionally remote, from the pi of the peptide active agent.

- an aqueous or aqueous organic solution or suspension e.g., water, water/acetonitrile mixtures having a pH different, optionally remote, from the pi of the peptide active agent.

- this step is readily employed whether the preformed salt is utilized straight from purification (e.g., HPLC using water/acetonitrile mixtures in the presence of desired counter ion, such as acetic acid) or prepared from a precursor peptide salt (e.g., peptide trifluoroacetic acid) that is subjected to desalting and counter ion exchange when a different counter ion is desired (e.g., peptide salicylic acid).

- purification e.g., HPLC using water/acetonitrile mixtures in the presence of desired counter ion, such as acetic acid

- a precursor peptide salt e.g., peptide trifluoroacetic acid

- aqueous or aqueous organic solutions or suspensions e.g., water, water/acetonitrile mixtures

- the desired preformed peptide salt is eventually dried (e.g., by concentrating as a residue by centrifugal evaporation / SpeedVac, lyophilization or spray drying) from a solution or suspension having a pH different, optionally remote, from the pi of the peptide active agent, to form the desired preformed peptide salt.

- care is taken so that the peptide active agent is processed under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide active agent.

- the mucosal delivery composition is then formed by either: (i) combining the dried preformed peptide salt of the first step with a crown compound (or without a crown compound in certain embodiments) and the non-aqueous hydrophobic vehicle to form the mucosal delivery composition; or (ii) (a) combining the dried preformed peptide salt of the first step with the crown compound in an organic or aqueous organic solution or suspension (e.g., methanol, water/methanol mixtures), (b) drying the organic or aqueous organic solution or suspension of step (ii)(b) (e.g., by concentrating as a residue in a centrifugal evaporator / SpeedVac), and then (c) combining the dried peptide material of step (ii)(b) (which comprises the preformed peptide complex) with the non-aqueous hydrophobic vehicle to form the mucosal delivery composition.

- care is taken so that the peptide active agent is processed under conditions

- an effective amount of one or more stabilizing excipients and/or water is optionally added to the dried peptide salt before, during, and/or after complexation with the crown compound in an amount that maintains solvation and stability of the peptide active agent.

- water can be combined with and used to first dissolve the preformed peptide salt, followed by the addition of a solvent mixture such as methanol and crown compound to aid in forming and/or maintaining the stably hydrated peptide during complexation (e.g., water added such that the final water concentration in the water-solvent mixture is in a range from 0.5%-50%, more preferably about 1 %-35%, often about 5%-25%, and typically about 10-15%, followed by drying to remove solvent).

- a solvent mixture such as methanol and crown compound

- Water also may be optionally combined with the peptide complex prior to and/or in conjunction with its combination with the non-aqueous hydrophobic vehicle (e.g., water added to the dried peptide complex prior to combination with the non-aqueous hydrophobic vehicle such that the final water concentration in the formulation mixture is about 0.1 %- 10%, usually about 0.5%-5%, and typically about 1 %-3%, with the proviso that the amount of water added is about or less than the amount capable of inducing unwanted phase separation of the formulation components).

- the non-aqueous hydrophobic vehicle e.g., water added to the dried peptide complex prior to combination with the non-aqueous hydrophobic vehicle such that the final water concentration in the formulation mixture is about 0.1 %- 10%, usually about 0.5%-5%, and typically about 1 %-3%, with the proviso that the amount of water added is about or less than the amount capable of inducing unwanted phase separation of the formulation components.

- an effective amount of one or more stabilizing excipients may be included in one or more steps of preparing the preformed peptide salt and/or peptide complex, such as in the counter ion exchange process before, during, and/or after drying, to aid in maintaining the stably hydrated peptide (e.g., a non-ionic detergent such as beta-D-octylglucoside, a tonicity modifying agent such as a mannitol, and the like). Additional water and/or one or more stabilizing excipients may be combined in the final mucosal delivery formulation as well in an amount sufficient to maintain solvation and stability of the peptide active agent.

- a non-ionic detergent such as beta-D-octylglucoside

- a tonicity modifying agent such as a mannitol, and the like.

- Additional water and/or one or more stabilizing excipients may be combined in the final mucosal delivery formulation as well in an amount sufficient to maintain solv

- the stably hydrated peptide active agent (alone or in complex with a crown compound and/or counter ion) is readily prepared by drying the desired peptide material from a solution or suspension at a pH different, optionally remote, from the p/ of the peptide active agent, with the proviso that the peptide active agent is processed under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide.

- the solution or suspension can be aqueous, organic, or mixtures thereof.

- the resultant dried peptide material (e.g., peptide alone, peptide salt, or peptide complex) can be stored for later use, and/or further processed, such as combined as above with one or more of the remaining components of the mucosal delivery composition.

- the pH range of the solution or suspension from which the peptide material is dried may overlap with the p/ of the stably hydrated peptide active agent, in general, the farther away the solution or suspension's midpoint pH is from the peptide's pi, the higher the dried peptide's solubility when subsequently combined with other solvents, particularly organics and aqueous mixtures thereof, as well as the non-aqueous hydrophobic vehicle.

- the pH of the solution or suspension from which the peptide material is dried is greater than about 0.2, 0.3, 0.4, or 0.5 pH units from the pi of the peptide active agent, usually greater than about 0.6, 0.7, 0.8, or 0.9 pH units from the pi of the peptide active agent, and more usually about 1 pH unit or greater from the pi of the peptide active agent.

- the peptide active agent can be or lyophilized or dried in a stable form at a pH at which the peptide is highly charged, and in a further embodiment at a pH at which the peptide active agent is mostly charged thus owning the highest possible number of charges.

- the stably hydrated peptide active agent When the stably hydrated peptide active agent is prepared in this manner and formulated with the non-aqueous hydrophobic vehicle without further rounds of solvent exchange and/or drying, the benefit of complexation and the solution or suspension pH from which the peptide material was originally dried can effectively be maintained. However, such benefit can be lost or substantially reduced unless care is taken to maintain stable hydration of the peptide. Specifically, reliable and reproducible mucosal delivery of the peptide active agent is adversely affected if the peptide is not stably hydrated.

- stable hydration when subjecting a stably hydrated peptide active agent to further processing steps involving solvent exchange and drying (e.g., desalting, counter ion exchange, and/or preparing the preformed peptide complex ex situ), stable hydration can be achieved and/or maintained by processing the stably dried peptide active agent in, and drying the resulting peptide material from a solution or suspension at a pH different, optionally remote, from the p/ of the peptide active agent, as described above.

- solvent exchange and drying e.g., desalting, counter ion exchange, and/or preparing the preformed peptide complex ex situ

- the pH of the solution or suspension can be adjusted by the careful addition or acid and/or base to achieve a target pH, typically a target pH in the range of about 0.5 to 8.5, more often from 2.0 to about 8.0, usually about 4.0 to 8.0 (depending on the pi of the peptide active agent), with the optional inclusion of one or more additional pharmaceutically acceptable excipients, such as buffer, isotonic agent, preservative, antioxidant, and the like to aid in the maintenance of the stably hydrated peptide active agent.

- a target pH typically a target pH in the range of about 0.5 to 8.5, more often from 2.0 to about 8.0, usually about 4.0 to 8.0 (depending on the pi of the peptide active agent)

- additional pharmaceutically acceptable excipients such as buffer, isotonic agent, preservative, antioxidant, and the like to aid in the maintenance of the stably hydrated peptide active agent.

- the solution or suspension in which the pH is adjusted is water, and/or acetonitrile/water mixtures, particularly acetonitri!e/water mixtures that contain about 10%-90% acetonitrile, including about 20%-80%, 30%-70%, 40%-60%, and more particularly about 55%-65%, usually about 50:50 mixtures.

- Stabie hydration can also be achieved and/or maintained by processing the stably hydrated peptide active agent, and drying the resulting peptide material from a solution or suspension comprising aqueous, organic, or mixtures thereof, provided drying is carried out under conditions that avoid unwanted water loss, particularly by maintaining appropriate temperature, pressure and drying time (e.g., about or less than 40°C, such as about or less than 35°C, typically about or less than 32°C, for about or less than 3 hours, such as less than 2 hours, more typically less than 1 .5 hours, in a centrifugal evaporator / SpeedVac).

- appropriate temperature, pressure and drying time e.g., about or less than 40°C, such as about or less than 35°C, typically about or less than 32°C, for about or less than 3 hours, such as less than 2 hours, more typically less than 1 .5 hours, in a centrifugal evaporator / SpeedVac.

- one or more additional pharmaceutically acceptable excipients can be added for

- the various processing steps discussed above may employ solutions or suspensions that are aqueous, organic, or mixtures thereof, usually depending on the particular processing step (e.g., water, acetonitrile, methanol, ethanol, aqueous mixtures thereof etc.), or organic solvents alone.

- the solution or suspension is an aqueous alcohol, such as an aqueous methanol or aqueous ethanol, including an aqueous alcohol having a water content of about 1 % to 50% by volume, such as about 1 % to about 25%, particularly about 1 % to 15%, and more particularly about a 2 to 8% aqueous alcohol, such as an aqueous alcohol having a water content of about 5% by volume.

- Aqueous methanol solutions and suspensions are of specific interest, as methanol is the organic solvent closest to water and able to dissolve a very broad range of organic compounds. Additional mixtures are DMSO/Water and Acetonitrile/water.

- the various processing steps discussed above may be employed in any effective combination to produce the desired end composition, for example, in steps involving: (i) optional desalting of the peptide active agent; (ii) optional counter ion exchange of the peptide active agent; and/or (iii) peptide complex formation ex situ and formulation in the non-aqueous hydrophobic vehicle, and/or peptide complex formation in situ in the non-aqueous hydrophobic vehicle; with the proviso that the peptide active agent is processed under conditions that take into consideration the pi of the peptide active agent and retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide.

- mucosal delivery of the peptide active agent can be further improved by other aspects of the disclosure, including choice of the crown compound, counter ion, and amounts thereof, as well as choice of the non-aqueous hydrophobic vehicle, optional excipients and amounts thereof.

- the peptide active agent is complexed with a sufficient amount of a complexing agent, such as a crown and counter ion of interest, which can be present in molar excess of the peptide active agent, generally in a ratio of about 2 to 1 , 5 to 1 , 10 to 1 , 15 to 1 , 20 to 1 , 30 to 1 , 60 to 1 or greater.

- a complexing agent such as a crown and counter ion of interest

- the crown and counter ion components are complexed at a molar ratio dependent on the type and number of ionizable groups present on the peptide active agent.

- the peptide active agent comprises one or more cationic groups (e.g., primary amine, a secondary amine, a guanidinium group, and combinations thereof), the crown compound is a cation-binding crown compound (e.g., a crown ether type compound), and the counter ion is an anionic counter ion (e.g., an acidic counter ion).

- the cation-binding crown compound and the anionic counter ion are each individually present at about 0.5 to 10 stoicheometric equivalents per cationic group, more particularly about 2 to 4 stoicheometric equivalents, and most particularly about 1 to 2 stoicheometric equivalents, per cationic group.

- the cation-binding crown compound is present at about 2 stoicheometric equivalents per primary amine, secondary amine, and/or guanidinium group, and the cationic counter ion is present at about 1 stoicheometric equivalents per primary amine, secondary amine, and/or guanidinium group of the peptide active agent.

- the cationic group is associated with one or more neutralized carboxylates, which cationic group can be derived from inorganic species including but not limited to Na + , K + , Li + , Mg ++ , Ca ++ and the like.

- Another feature in addition to the pi, the peptide hydration, and the crown/counter ion amounts, is the formulation and use of a non-aqueous hydrophobic vehicle having a pH range that stabilizes the peptide complex.

- a non-aqueous hydrophobic vehicle having a pH range that stabilizes the peptide complex can be lost or substantially reduced in mucosal delivery compositions if the pH of the non-aqueous hydrophobic vehicle strays too far out of the margin for maintaining the desired solubility of the peptide complex in the vehicle.

- the pH of the non-aqueous hydrophobic vehicle has a range of about +/-1 to about +/-4 pH units, usually about +/-3 pH units, such as a pH range of about 3-6, about 4-7, about 5-8, and more about usually about +1-2 pH units, such as a pH range of about 3-5, about 4-6, about 5-7, or about 6-8, and the like.

- the final pH range of the non-aqueous hydrophobic vehicle can be adjusted, including by the addition of acid, base, buffer and/or other excipients, as well as by the addition of the peptide salt and/or peptide complex itself depending on the components and amounts in association therewith.

- the pH range of the non-aqueous hydrophobic vehicle may overlap with the pi of the peptide active agent, in general, the farther away the vehicle's midpoint pH is from the peptide's pi, the higher the peptide complex's solubility in the vehicle. Also, by forming the peptide complex either in situ or ex situ at a pH remote from the pi of the peptide active agent, the target pH is readily approached without unnecessarily having to cross over the pi of the peptide active agent upon combination of the material with the vehicle.

- the peptide salt or peptide complex can be prepared ex situ by drying the material from a solution or suspension at a pH greater than 5.0, usually at least 1 pH unit greater, again with the proviso that the peptide active agent is processed under conditions that retain a sufficient amount of water in association with the peptide to maintain solvation and stability of the peptide.

- the pH of the combined mixture can be further adjusted and/or allowed to equilibrate in the composition to achieve solvation.

- compositions such as those comprising a non-aqueous hydrophobic vehicle having at least one acylglycerol and at least one organic solvent and/or lipid, significantly enhance, and in many cases, make possible mucosal delivery of an effective amount of the peptide active agent, among other desirable aspects, including storage stability.

- the non-aqueous hydrophobic vehicle comprises at least one acylglycerol, and at least one organic solvent, and optionally at least one lipid, each individually present in an amount effective to (i) soiubilize the stably hydrated peptide active agent complexed with the crown compound and the counter ion, and (ii) enhance mucosal delivery of the peptide active agent.

- non-aqueous is intended to mean less than about 10% water, more particularly, less than about 5% water.

- the mucosal delivery composition generally includes various solubilizing agents in non-aqueous medium, such as a medium comprising an acylglycerol, and an organic solvent, and optionally a lipid such as a fatty acid or neutral lipid (as described in greater detail below).

- the mucosal delivery composition and components thereof may also include one or more additional pharmaceutically acceptable excipients (as described in greater detail below), such as one or more of a non-ionic surfactant, antioxidant, buffer, viscosity modifier, preservative, isotonic agent, chelating agent, and the like.

- additional pharmaceutically acceptable excipients as one or more of a non-ionic surfactant, antioxidant, buffer, viscosity modifier, preservative, isotonic agent, chelating agent, and the like.

- an effective amount of the stably hydrated peptide active agent complex is solubilized in a mucosal delivery composition, and thus capable of delivering of an effective amount of the peptide active agent into the blood stream of the host when administered to a mucosal membrane thereof.

- mucosal delivery of the peptide active agent as provided in the mucosal delivery compositions of the disclosure is enhanced relative to the peptide active agent that is not stably hydrated.

- the enhancement is greater than about 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, or 90%, and usually greater than about 100% (i.e., 1-fold or greater).

- the amount of the peptide active agent that enters the blood stream of a host can be measured qualitatively and/or quantitatively, directly and/or indirectly, by various techniques known in the art, such as by chromatography (e.g., HPLC, Mass-Spectrophotometry etc.), enzymatically (measuring substrate consumption and/or modification, or product and/or byproduct production), antigen-antibody binding (e.g., Western Blot, Enzyme- Linked Immunosorbent Assay (ELISA) etc.), by biological effect (e.g., pharmacological bioavailability by indirect measure of amount of the peptide active agent that enters the blood stream, such as illustrated in the experimental section below), and the like.

- the enhancement can be readily determined.

- the mucosal delivery composition exhibits pharmacological bioavailability of the peptide active agent that is greater than about 10% relative to intrapleural (pi) administration, usually greater than about 15%, and typically about 16%, 17%, 18%, 19%, 20% or greater.

- the peptide active agent upon sublingual administration of the mucosal delivery composition has a pharmacological bioavailability of greater than about 10% relative to intrapleural administration, usually greater than about 15%, and more typically about 20% or greater.

- mucosal delivery of the peptide active agent as provided in the mucosal delivery compositions of the disclosure is enhanced and reliably reproducible relative to the peptide active agent that is not stably hydrated.

- “reliably reproducible” is intended the extent to which the measurements of a test remain consistent over repeated tests of essentially the same composition under identical conditions.

- mucosal delivery using a mucosal delivery composition of the disclosure is reliably reproducible if it yields consistent results of substantially the same measure.

- mucosal delivery of a mucosal delivery composition is unreliable if repeated tests give inconsistent results of substantially different measure.

- the stably hydrated peptide active agent has a water content by weight and solubility in an organic or aqueous organic solvent comparable to or greater than the dried peptide active agent, and is essentially non-aggregated and unoxidized.

- the stably hydrated peptide active agent has a water content by weight and solubility in an organic or aqueous organic solvent comparable to or greater than the peptide active agent dried (i) from a solution or suspension at a pH different, optionally remote, from the isoelectric point of the peptide, and (ii) under conditions that retain a sufficient amount of water to maintain solvation and stability of the peptide.

- the stably hydrated peptide active agent has a water content by weight comparable to a storage stable dried form of the peptide.

- storage stability of the dried form of the peptide is determinative when having a shelf life equal or greater than one month when stored at a temperature in the range of -20°C to 25°C.

- the storage stable dried form of the peptide is associated with one or more pharmaceutically acceptable excipients, for example, co-drying excipients such as counter ion, preservative, isotonic agent, and/or buffer.

- the water content of the stably hydrated peptide active agent relative to the anhydrous peptide can be about 0.1 % to about 50% by weight, and is usually about 0.5% to about 50%, 1 % to about 30%, 1 % to about 25%, more usually about 1 % to about 20%, about 1 % to about 15%, and typically about 1 % to about 10%, such as about 1 % to about 5%.

- Peptide hydration can be measured relative to the anhydrous peptide by standard techniques known in the art.

- water content can be measured using the Loss On Drying method and/or the Karl-Fischer method (e.g. J. A. Dean, Analytical Chemistry Handbook, Section 19, McGraw-Hill, New York, 1995, or by the United State Pharmacopeia's (USP) publication USP-NF (2004), which describes the US Food and Drug Administration (FDA) enforceable standards ((2004-USP-Chapter 921 ).

- the stably hydrated peptide active agent has a percent solubility value in a given organic or aqueous organic solvent at ambient temperature that is equal to or greater than 0.001 %, usually less than or equal to 125% of the percent solubility value, and typically less than or equal to the percent solubility value of the peptide active agent dried from a solution or suspension at a pH different, optionally remote, from the isoelectric point of the peptide.

- Solubility in organic or aqueous organic solution or suspension is readily measured as the concentration wherein adding more of the peptide does not increase its concentration in the solution or suspension. Solubility can also be estimated by visual inspection in relatively clear liquid or gel formulations (e.g., solubilized if peptide formulation is essentially limpid in appearance). pH and pi

- the pH of a subject composition is targeted so that the peptide active agent is sufficiently ionized to maintain complexation with the desired complexing agent(s), as well as capable of being soluble or re-soluble when combined in the non-aqueous hydrophobic vehicle.

- complexation with a cation-binding crown compound is favored when amino groups of the peptide are protonated (ionized).

- the pH of the subject compositions is different, often remote, from the pi of the peptide active agent in the composition, where the peptide is sufficiently ionized for complexation with the crown compound and counter ion.

- isoelectric point is intended the pH value at which the peptide active agent carries no overall net electrical charge.

- the pH is selected such that the peptide complex remains stable and soluble (or re-soluble when prepared as a dried, preformed peptide complex).

- “remote from the isoelectric point of the peptide active agent” is intended about 1 pH unit or greater from the isoelectric point of the peptide active agent.

- the pH may be above or below the isoelectric point of the peptide active agent, provided it is within a range that stabilizes the stably hydrated peptide active agent in the composition for a given end use.

- the pH is above the pi of the peptide active agent, whereas in other embodiments, the pH is below the pi of the peptide active agent.

- the pH is about 0.1 to about 4 pH units from the isoelectric point of the peptide active agent. In some embodiments, the pH is about 0.5 to about 3 pH units, including about 1 to about 2 pH units, from the isoelectric point of the peptide active agent.

- a buffer is included to maintain the pH within a given range.

- the pKa of buffer in solvent mixtures containing predominantly water are close to the water value.

- the buffer pKa changes.

- neutral weak acids such as acetic acid and anionic acids such as H 2 P0 4 " typically get weaker, and the pKa becomes larger as the proportion of organic solvent increases.

- Cationic acids such as NH 4 + get stronger, but this trend reverses at high organic concentration and they become weaker.

- the pH can be approached empirically, and/or estimated by calculation of the solution pH with reference to standard buffer solutions of known pH (e.g., Rondinini, S., Analytical Bioanalytical Chem (2004) 374(5):813-816; Bosch et al., Anal. Chem. (1996) 68(20):3651-3657; Subirats ef al., J Chrom A, (2007) 1138:203-215; Subirats et al. Separation & Purification Reviews (2007) 36(3):231 -255; and Gagliardi et al. J. Chromatography A (2005) 7077(2):159-169).

- the pKa (and isoelectric point) values of peptides under such conditions can also be determined (e.g., Sanz- Nebot er a/., J. Chromatography A (2002) 942(1 -2): 145).

- considerations for selection include buffering capacity, solubility, and ionic strength in the composition.

- optimizing the pH to increase the ratio of the ionized to the neutral form of the peptide can be accomplished in aqueous, organic, and aqueous organic solutions to favor crown and counter ion complexation.

- Peptide active agents of the present disclosure are those peptides whose mucosal delivery is facilitated or enhanced when administered in conjunction with the subject mucosal delivery compositions and methods. Whether or not a given peptide active agent is suitable for use according to the present disclosure can be readily determined, for example, using assays employed in the experimental section below.

- a peptide active agent is suitable for use in the subject methods if its mucosal delivery in conjunction with the subject non-aqueous hydrophobic vehicle of the disclosure delivers an effective amount of the agent into the blood stream of the host, particularly where such delivery is increased by 1 to 10-fold or more, such as by 50-fold or more and sometimes by 100-fold or more relative to mucosal administration of the peptide in the absence of the mucosal delivery vehicle (e.g., peptide in sterile saline solution), as determined by measuring peptide concentration present in the blood stream of a host, for example, using detection systems suitable for such purposes as discussed above and illustrated in the experimental section below.

- the peptide active agent is one whose occurrence and/or intensity of observable biological effects are increased by mucosal delivery, for example, as observed in the mouse assay described in the experimental section below.

- peptides of interest include, but are not limited to, acetalins (e.g., acetalin 1 , 2 and 3 (acetyl plus enkephalin), adrenocorticotropic hormone (ACTH) and related peptides, adipokinetic hormones (e.g., adrenomedullin), ADP-ribosylation factors (ARF), adrenomedullin peptides, Agouti related peptides, allatostatins, amylin peptides, amyloid peptides, angiotensins and related peptides, annexin, various anti-inflammatory peptides, antimicrobial and related peptides, antioxidant peptides, apelin peptides, apoptosis peptides, Bad and Bag Cell peptides, adrenal medulla peptides, basic fibroblast growth factor (bFGF), bombesins, bradykinins,

- peptide hormones which are a class of peptides that exhibit activity upon entry into the blood stream and have endocrine functions in living animals.

- peptide hormones of specific interest include, but are not limited to, glucagon, glucagon-like- peptide, insulin, somatostatin, calcitonin, parathyroid hormone, and the like, and analogues/derivatives thereof.

- the peptide active agent is a peptide hormone, for example, insulin and the incretin mimetics, such as the exendins and related analogues/derivatives (e.g., chemically synthesized and/or biologically produced exendins such as exendin-3 and exendin-4, liraglutide, glucagon-like peptide-1 (GLP-1 ), and Taspoglutide, Albiglutide.

- ZP10 (AVE0010), and various analogues/derivatives thereof.

- Naturally occurring incretins such as GLP-1 exhibit insulinotropic properties after release into the circulation from the gut.

- the actions of GLP-1 include (a) a stimulation of insulin secretion in a glucose-dependent manner, (b) a suppression of glucagon, (c) a reduction in appetite and food intake, (d) a deceleration of gastric emptying, (e) a stimulation of ⁇ -cell neogenesis, growth and differentiation in animal and tissue culture experiments, and (f) an in vitro inhibition of ⁇ -cell apoptosis induced by different toxins.

- Exendins are peptide hormones isolatable from an exocrine gland but have endocrine actions. Exendins stimulate insulin secretion in response to rising blood glucose levels, and modulate gastric emptying to slow the entry of ingested sugars into the bloodstream. Exendin- 3 is a 39-amino acid peptide that shares homology with VIP (vasoactive intestinal peptide), secretin, helospectin I and II and helodermin. It stimulates increases in cellular cAMP and amylase release from dispersed guinea pig pancreatic acini. Exendin-4, a 39-amino acid peptide originally isolated from the oral secretions of the lizard Heloderma suspectum, has been shown to share certain activities with glucagon-like-peptide-1 (GLP-1 ).

- GLP-1 glucagon-like-peptide-1

- Exenatide (the active ingredient of BYETTA® (exenatide injection), also called exendin-4) is a GLP-1 agonist that improves glucose homeostasis by mimicking the actions of naturally occurring GLP-1 . It improves glycemic control by reducing fasting and postprandial glucose concentrations through a combination of known mechanisms, including glucose-dependent insulin secretion, restoration of first-phase insulin response, regulation of glucagon secretion, delaying gastric emptying, and decreasing food intake.

- Exenatide is a subcutaneously injected incretin mimetic peptide approved for the treatment of type 2 diabetes mellitus (condition in which the body does not use insulin normally and, therefore, cannot control the amount of sugar in the blood).

- Exenatide is used in combination with metformin, a sulfonylurea, or a thiazolidinedione.

- Exenatide works by stimulating the pancreas to secrete insulin when blood sugar levels are high. Insulin helps move sugar from the blood into other body tissues where it is used for energy. Exenatide also slows the emptying of the stomach and causes a decrease in appetite.

- Exenatide is not used to treat type 1 diabetes (condition in which the body does not produce insulin and, therefore, cannot control the amount of sugar in the blood).

- Exenatide is usually injected twice a day within 60 minutes before the morning and evening meals.

- Liraglutide is a GLP-1 derivative that finds use similar to Exenatide, for example, in the treatment of type 2 diabetes. Liraglutide has a half-life after subcutaneous injection of 11-15 hours, making it suitable for once-daily dosing (in contrast to Byetta's twice daily). The prolonged action of liraglutide is achieved by a fatty acid molecule attached to the GLP-1 molecule, which binds to albumin within the subcutaneous tissue and bloodstream. The active GLP-1 is then released from albumin at a slow, consistent rate. Binding with albumin also results in slower degradation and reduced elimination of liraglutide from the circulation by the kidneys compared to GLP-1.

- peptide active agents for use in the subject methods and compositions of the disclosure may include incretin mimetics, such as GLP-1 , and various analogues/derivatives thereof including exendin-4, liraglutide, and various analogues/derivatives thereof.

- incretin mimetics and related compounds of interest are described in U.S. Patent Nos. 5, 1 18,666

- Additional peptide active agents for use in the subject methods and compositions of the disclosure may include insulin, such as human insulin and various analogues/derivatives thereof. Insulin and related compounds of interest are described in U.S. Patent Nos. 4,51 1 ,505; 5,631 ,347; 5,646,242

- peptide active agents for use in the subject methods and compositions of the disclosure may include parathyroid hormone, or calcitonin (e.g., for the treatment of Paget's disease, hypercalcemia and osteoporosis, including natural, synthetic or recombinant human, salmon, pig or eel calcitonin).

- parathyroid hormone, calcitonin and related compounds of interest are described in U.S. Patent Nos.: 4,692,433; and RE40.850; the disclosures of which are herein incorporated by reference.

- the peptide active agent is incretin mimetic peptide.

- the incretin mimetic is exendin-4 and analogues/derivatives thereof.

- the incretin mimetic is liraglutide and analogues/derivatives thereof.

- the peptide active agent is glucagon-like peptide-1 (GLP-1 ) and analogues/derivatives thereof.

- the peptide active agent is insulin and analogues/derivatives thereof.

- the peptide active agent is other than a peptide selected from one or more of the peptides described herein, such as insulin, including peptides larger than about 50 amino acids, such as peptides larger than about 100 amino acids.

- prodrugs of the peptide active agents are, in general, functional derivatives of the compounds that are readily convertible in vivo into the required compounds.

- administering encompasses administering the compound specifically disclosed or with a compound which may not be specifically disclosed, but which converts to the specified compound in vivo after administration to the subject in need thereof.

- Conventional procedures for the selection and preparation of suitable prodrug derivatives are described, e.g., in Wermuth, "Designing Prodrugs and Bioprecursors" in Wermuth, ed. The Practice of Medicinal Chemistry, 2d Ed., pp. 561 -586 (Academic Press 2003).

- Prodrugs include peptides bearing post-translational or synthesis modification sites, enzymatic or chemically cleavable bonds, such as peptides with protease cleavable leader residues or sequences, or esters that hydrolyze in vivo (e.g., in the human body) to produce a compound described herein suitable for the present disclosure.

- Suitable ester groups include, without limitation, those derived from pharmaceutically acceptable, aliphatic carboxylic acids, particularly alkanoic, alkenoic, cycloalkanoic and alkanedioic acids.

- Illustrative esters include formates, acetates, propionates, butyrates, acrylates, citrates, succinates, and ethylsuccinates.

- the crown compounds include, for example, cyclic polyethers (crown ethers, e.g., 18-crown-6) and cyclic polyesters (crown esters, e.g., polylactones such as nonactine and tetranactine, polyglycolic or lactic esters), and analogues/derivatives thereof (e.g., WO 08/037484; Lifson et al., J. Am. Chem. Soc. (1983) 105:3866-3875; Lifson et al., J. Am. Chem. Soc.

- the crown compounds are cyclic polyethers, cyclic polyesters, and cyclic depsipeptide (where "depsipeptide” refers to crown compounds which comprise or consist of alpha-hydroxy acids and alpha-amino acids, or mixtures thereof, which are linked to each other by ester linkages between the hydroxy group of an alpha-hydroxy acid and the carboxyl group of either a hydroxy acid or an amino acid as well as by amide linkages between the amino group of an alpha-amino acid and the carboxyl group of either a hydroxy acid or an amino acid).

- Linear forms of the subject crown compounds such as a cleavage form thereof, may be employed as charge complexing agents in some aspects of the disclosure.

- the crown compound in certain embodiments comprises a biodegradable linkage.

- the biodegradable linkage is cleavable in vivo.

- biodegradable linkages of particular interest include esters, such as carboxylic acid esters (-C(O)-O-), thioesters (-C(O)-S-), orthoesters (- C(OR 1 )(OR 2 ) and (-C(OR 1 )(OR 2 )(OR 3 )), and the like.

- biodegradable linkage is an ester, and more particularly an ester selected from a carboxylic acid ester, and an orthoester.

- Crown compounds of specific interest are disclosed in the co- pending patent application entitled Orthoester derivatives of crown ethers" and having attorney docket number "R1856" filed on even date herewith, which reference is incorporated in its entirety.

- carboxylic acid ester and an orthoester crown compounds include, but are not limited to, the oxo-crowns and analogues/derivatives thereof, particularly oxo-crown ethers.

- the oxo-crown ethers comprise 4 to 8 coordinating oxygen ring atoms, 8 to 16 ring carbon atoms, and at least one oxo- substituted side chain.

- oxo-(18-crown-6) compounds and analogues/derivatives thereof such as those comprising a structure selected from oxo-(18-crown-6), oxo-(18-crown-6)-diethyl tartrate, and oxo- (18-crown-6)-diglycerol tartrate, as illustrated below.

- the counter ion allows the formation of neutrally charged species of ionizable groups of the stably hydrated peptide active agent.

- the counter ion is present in an amount in combination with the crown compound under conditions that partially neutralize, or impart overall neutrality to the stably hydrated peptide active agent.

- the counter ion is a counter ion of an acidic salt (e.g., salicylic acid, acetic acid, trifluoroacetic acid, tartaric acid, phosphoric acid, lactic acid, fumaric acid, maleic acid, citric acid, methylsulfonic acid, p-toluensulfonic acid), an amino acid (e.g., lysine, glycine, histidine, arginine), or a modified amino acid (e.g., N-acetyl-lysine-amide, N-acetyl-arginine-amide). Combinations of different counter ions are also contemplated.

- an acidic salt e.g., salicylic acid, acetic acid, trifluoroacetic acid, tartaric acid, phosphoric acid, lactic acid, fumaric acid, maleic acid, citric acid, methylsulfonic acid, p-toluensulfonic acid

- an amino acid e.g

- the counter ion is selected from an acidic salt, an amino acid, a modified amino acid, and mixtures thereof.

- an acidic salt is a hydrophilic acid or lipophilic acid.

- hydrophilic acids of interest include, but are not limited to, trifluoroacetic acid, sulfonic acid, and benzoic acid.

- lipophilic acids of particular interest included, but are not limited to, aryl and alkyl sulfonic acids, such as dodecyl-sulfonic acid and higher homologues, phosphatidylglycerol deravtives such as dilauryloylphosphatidylglycerol (DLPG), lipoic acid, and the like.

- aryl and alkyl sulfonic acids such as dodecyl-sulfonic acid and higher homologues

- phosphatidylglycerol deravtives such as dilauryloylphosphatidylglycerol (DLPG), lipoic acid, and the like.

- DLPG dilauryloylphosphatidylglycerol

- lipoic acids can be employed.

- an acidic salt that is a strong lipophilic acid, such as an alkyl sulfonic acid and higher homologues.

- the hydrophilic acid is selected from the group consist

- the lipophilic acid is dodecyl-sulfonic acid.

- relatively strong acidic counter ions such as dodecyl-sulfonic acid

- care is taken to avoid oxidation of peptides that may be susceptible, for example, by inclusion of an antioxidant, limiting the concentration of the counter ion, and so forth.

- lipophilic acids such as alkyl sulfonic acids having an alkyl chain with between 2 and 30, and usually between 8 and 10 carbon atoms are of specific interest.

- Certain phospholipids may also be employed as a counter ion in some embodiments.

- phospholipids with at least an acidic proton on the phosphate such as a phosphatidyl glycerol or phosphatidyl sugar with one acidic proton, or a phosphatidic acid with two acidic protons are of interest.

- Phospholipids comprising two alkanoic acids may either symmetric or asymmetric. In the latter case, a phospholipid molecule comprises two different fatty acids.

- the phospholipds are of natural origin, like for example phosphatidylinositol.

- the counter ion can be acids with multiple acidic valence (multi protic) or poly carboxylic acids.

- inorganic acids that include, but are not limited to, phosphoric sulfuric acid, and the like

- organic acids that include, but not limited to, bis-carboxylic aromatic acids such as Phthalic acid and Terephthalic Acid, and from alkylic oxalic acid, malonic acid, succinic acid, tartaric acid, maleic acid, fumaric acid, and the like.

- a bis carboxylic acid of choice can be used as a counter ion to generate a cationic charge with an amino group of the peptide side chain, notably Lysine and Arginine.