WO2000004880A1 - A wet granulation method for preparing a stable pharmaceutical formulation - Google Patents

A wet granulation method for preparing a stable pharmaceutical formulation Download PDFInfo

- Publication number

- WO2000004880A1 WO2000004880A1 PCT/DK1999/000416 DK9900416W WO0004880A1 WO 2000004880 A1 WO2000004880 A1 WO 2000004880A1 DK 9900416 W DK9900416 W DK 9900416W WO 0004880 A1 WO0004880 A1 WO 0004880A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- granulation

- mixture

- formulation

- solid dosage

- oral solid

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/435—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having six-membered rings with one nitrogen as the only ring hetero atom

- A61K31/44—Non condensed pyridines; Hydrogenated derivatives thereof

- A61K31/445—Non condensed piperidines, e.g. piperocaine

- A61K31/4523—Non condensed piperidines, e.g. piperocaine containing further heterocyclic ring systems

- A61K31/4535—Non condensed piperidines, e.g. piperocaine containing further heterocyclic ring systems containing a heterocyclic ring having sulfur as a ring hetero atom, e.g. pizotifen

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/075—Ethers or acetals

- A61K31/085—Ethers or acetals having an ether linkage to aromatic ring nuclear carbon

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/13—Amines

- A61K31/135—Amines having aromatic rings, e.g. ketamine, nortriptyline

- A61K31/138—Aryloxyalkylamines, e.g. propranolol, tamoxifen, phenoxybenzamine

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/16—Amides, e.g. hydroxamic acids

- A61K31/165—Amides, e.g. hydroxamic acids having aromatic rings, e.g. colchicine, atenolol, progabide

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/335—Heterocyclic compounds having oxygen as the only ring hetero atom, e.g. fungichromin

- A61K31/35—Heterocyclic compounds having oxygen as the only ring hetero atom, e.g. fungichromin having six-membered rings with one oxygen as the only ring hetero atom

- A61K31/352—Heterocyclic compounds having oxygen as the only ring hetero atom, e.g. fungichromin having six-membered rings with one oxygen as the only ring hetero atom condensed with carbocyclic rings, e.g. methantheline

- A61K31/353—3,4-Dihydrobenzopyrans, e.g. chroman, catechin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/38—Heterocyclic compounds having sulfur as a ring hetero atom

- A61K31/381—Heterocyclic compounds having sulfur as a ring hetero atom having five-membered rings

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/40—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having five-membered rings with one nitrogen as the only ring hetero atom, e.g. sulpiride, succinimide, tolmetin, buflomedil

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/40—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having five-membered rings with one nitrogen as the only ring hetero atom, e.g. sulpiride, succinimide, tolmetin, buflomedil

- A61K31/4025—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having five-membered rings with one nitrogen as the only ring hetero atom, e.g. sulpiride, succinimide, tolmetin, buflomedil not condensed and containing further heterocyclic rings, e.g. cromakalim

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1682—Processes

- A61K9/1694—Processes resulting in granules or microspheres of the matrix type containing more than 5% of excipient

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P15/00—Drugs for genital or sexual disorders; Contraceptives

- A61P15/18—Feminine contraceptives

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P35/00—Antineoplastic agents

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P5/00—Drugs for disorders of the endocrine system

- A61P5/24—Drugs for disorders of the endocrine system of the sex hormones

- A61P5/32—Antioestrogens

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1605—Excipients; Inactive ingredients

- A61K9/1617—Organic compounds, e.g. phospholipids, fats

- A61K9/1623—Sugars or sugar alcohols, e.g. lactose; Derivatives thereof; Homeopathic globules

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1605—Excipients; Inactive ingredients

- A61K9/1629—Organic macromolecular compounds

- A61K9/1635—Organic macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyvinyl pyrrolidone, poly(meth)acrylates

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1605—Excipients; Inactive ingredients

- A61K9/1629—Organic macromolecular compounds

- A61K9/1652—Polysaccharides, e.g. alginate, cellulose derivatives; Cyclodextrin

Definitions

- This invention relates to a novel granulate and a novel oral solid dosage formulation comprising an active ingredient and one or more carriers. Moreover the invention relates to a wet granulation method for preparing the granulate as well as a wet granulation method for preparing the oral solid dosage form.

- High shear mixers are widely used in the pharmaceutical industry for blending and granulation (cf. Handbook of pharmaceutical granulation technology, chapter 7, "Drugs and the pharmaceutical sciences", vol. 81 , 1997). Blending and wet massing is accomplished by high mechanical agitation by an impellar and chopper. High shear mixers have applications other than wet granulation, as it can be used for melt granulation and pelletization. When melt granulation or pelletization is performed, energy for melting the binder is supplied by agitation of the impellar and external heating of the bowl.

- Centchroman which is 3,4-trans-2,2-dimethyl-3-phenyl-4-[4-(2-pyrrolidin-1- yl)ethoxy)phenyl]-7-methoxychroman, is a non-steroidal compound known to have antiestrogenic activity. It is in use in India as an oral contraceptive (see, for example, Salman et aj., U.S. Patent No.

- Centchroman has also been investigated as an anti-cancer agent for treatment of advanced breast cancer (Misra et a]., Int J Cancer 43 (1989), 781 - 783. Recently, centchroman as a racemate has been found as a potent cholesterol lowering pharmaceutical agent expressed by a significant decrease of the serum concentrations (S.D. Bain et al., J Min Bon Res 9 (1994), S 394).

- Levormeloxifene ( - ) - 3R,4R - trans- 7-methoxy-2,2-dimethyl-3-phenyl-4- ⁇ 4- [2-(pyrrolidin-1-yl)ethoxy]phenyl ⁇ chromane, is a particular preferred compound from this series of 3,4-diarylchromans.

- Levormeloxifene may be used in human and veterinary medicine for the regulation of bone metabolism.

- osteoporosis including post-menopausal osteoporosis and glucocorticoid-related osteoporosis

- Paget ' s disease hyperparathyroidism

- hypercalcemia of malignancy other conditions characterized by excessive rates of bone resorption and/or decreased rates of bone formation.

- the 3,4-diarylchromans are prepared according to known methods, such as those disclosed in U.S. Patent No. 3,340,276 to Carney et aj., U.S. Patent No. 3,822,287 to Bolger, and Ray et aj., J Med Chem 19 (1976), 276 - 279, the contents of which are incorporated herein by reference. Conversion of the cis isomer to the trans configuration by means of an organometallic base-catalyzed rearrangement is disclosed in U.S. Patent No. 3,822,287.

- the optically active d- and l-enantiomers may be prepared as disclosed by Salman et al. in U.S. Patent No.

- levormeloxifene the compound of formula II is referred to as levormeloxifene.

- levormeloxifene the compound of formula II is referred to as levormeloxifene.

- the compounds of formula I may be administered as pharmaceutically acceptable salts.

- a particularly useful pharmaceutically acceptable salt of levormeloxifene is the hydrogen fumarate salt. This salt form is prepared by dissolving fumaric acid and (-)-3R,4R- trans-7-methoxy-2,2-dimethyl-3-phenyl-4- ⁇ 4-[2- (pyrrolidin-1-yl)ethoxy]phenyl ⁇ chromane in a common solvent such as e.g. methanol, and crystallizing the resulting salt from the solution.

- Tamoxifene is disclosed in US 4,536,516 incorporated herein by reference. 4-hydroxy Tamoxifene is disclosed in US 4,623,660 incorporated herein by reference. Toremifene is disclosed in US 4,996,225 incorporated herein by reference. Droloxifene is disclosed in EP 792640 incorporated herein by reference.

- An object of the present invention is to provide a novel granulate or oral solid dosage form with improved stability properties.

- a further object of the present invention is to provide a novel tablet or capsule with possibility of extension of long term shelf-life.

- the present invention relates to a wet granulation method for preparing a granulate comprising an active ingredient and one or more carriers, the method comprising a) formation of a mixture of the active ingredient and one or more carriers, b) granulation of the mixture and c) drying the mixture, wherein the granulation is performed in a high shear mixing means with a temperature regulating means for keeping the temperature below about 40°C in the mixture during granulation.

- the wet granulation method for preparing a granulate comprising an active ingredient and one or more carriers further comprises processing the granulate into an oral solid dosage formulation.

- the present invention relates to a wet granulation method for preparing an oral solid dosage formulation comprising an active ingredient and one or more carriers, the method comprising a) formation of a mixture of the active ingredient and one or more carriers, b) granulation of the mixture, c) drying the mixture, and d) processing the granulate into an oral solid dosage formulation, wherein the granulation is performed in a high shear mixing means with a temperature regulating means for keeping the temperature below about 40°C in the mixture during granulation.

- the oral solid dosage formulation is a tablet.

- the oral solid dosage formulation is a capsule.

- the oral solid dosage formulation, such as tablet or capsule is coated with a film.

- the temperature in the granulation mixture is lower than about 35°C.

- the temperature is from about 0°C to about 35°C, more preferred from about 0°C to about 30°C, even more preferred from about 0°C to about 25°C, still even more preferred from about 15°C to about 30°C, and most preferred from about 20°C to about 25°C.

- the temperature in the granulation mixture is from about -20°C to about 40°C, from about -10°C to about 40°C, from about -10°C to about 0°C, from about 0°C to about 10°C, from about 10°C to about 20°C, from about 20°C to about 30°C, from about 30°C to about 40°C, from about 0°C to about 40°C, from about 10°C to about 35°C, from about 15°C to about 25°C, or from about 20°C to about 25°C.

- the active ingredient is selected from non-peptide organic molecules, small peptides and peptide mimetics. In one embodiment the active ingredient is a non-peptide organic molecule. In another embodiment the active ingredient is a small peptide. In a further embodiment the active ingredient is a peptide mimetic. In a further embodiment the active ingredient has a molecular weight of below 1500 daltons, such as from 200 to 1500 daltons, preferably from 500 to 1000 daltons.

- the active ingredient is selected from non-peptide organic molecules, small peptides and peptide mimetics, such as centchroman, levormeloxifene, tiagabine, (2E)-5-amino-5-methylhex-2-enoic acid N-methyl-N-((1 R)-1-(N-methyl-N-((1R)-1-(methylcarbamoyl)-2- phenylethyl)carbamoyl)-2-(2-naphthyl)ethyl)amide, ipamorelin, raloxifene, idoxifene, tamoxifene and droloxifene or pharmaceutically acceptable salts thereof, each of which is considered to be an alternative embodiment.

- non-peptide organic molecules such as centchroman, levormeloxifene, tiagabine, (2E)-5-amino-5-methylhex-2-enoic acid N-methyl-N-((1 R)-1-(

- the active ingredient is levormeloxifene or a pharmaceutically acceptable salt thereof, more preferred levormeloxifene hydrogen fumarate or levormeloxifene hydrogen maleate, most preferred levormeloxifene hydrogen fumarate.

- the active ingredient is selected from a compound of formula I

- R is hydrogen or C 1-6 alkyl; or a pharmaceutically acceptable salt thereof.

- R is methyl.

- the compound of formula I is in the trans configuration.

- the compound of formula I is 3,4- trans-2,2-dimethyl-3-phenyl-4-[4-(2-pyrrolidin-1-yl)ethoxy)phenyl]-7-methoxychroman (centchroman).

- the compound of formula I is an isolated l-enantiomer.

- the compound of formula I is ( - ) - 3R,4R - trans-7-methoxy-2,2-dimethyl-3-phenyl-4- ⁇ 4-[2-(pyrrolidin-1-yl)ethoxy]phenyl ⁇ chromane (levormeloxifene).

- the compound of formula I is in the form of the hydrogen fumarate salt.

- the compound of formula I is in the form of the hydrogen maleate salt.

- the one or more carriers are such which are commonly used in the pharmaceutical chemistry for preparing granulates, see eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) and/or Handbook of pharmaceutical granulation technology, chapter 7, "Drugs and the pharmaceutical sciences", vol.

- the one or more carriers are selected from hydrophilic binders, water-soluble diluents, surfactants, detergents, lubricants, disintegrants, antioxidants, non water-soluble diluents and/or other fillers known to the skilled person.

- the one or more carriers comprises at least a hydrophilic binder and a water-soluble diluent.

- the present invention relates to a granulate comprising an active ingredient and one or more carriers, obtainable by the wet granulation method for preparing a granulate comprising an active ingredient and one or more carriers, the method comprising a) formation of a mixture of the active ingredient and one or more carriers, b) granulation of the mixture and c) drying the mixture, wherein the granulation is performed in a high shear mixing means with a temperature regulating means for keeping the temperature below about 40°C in the mixture during granulation.

- the granulate is obtained by said method.

- the present invention relates to an oral solid dosage formulation comprising an active ingredient and one or more carriers, obtainable by the wet granulation method for preparing an oral solid dosage formulation comprising an active ingredient and one or more carriers, the method comprising a) formation of a mixture of the active ingredient and one or more carriers, b) granulation of the mixture, c) drying the mixture, and d) processing the granulate into an oral solid dosage formulation, wherein the granulation is performed in a high shear mixing means with a temperature regulating means for keeping the temperature below about 40°C in the mixture during granulation.

- the oral solid dosage formulation is obtained by said method.

- the oral solid dosage formulation is a tablet or capsule, preferably a tablet.

- the preferred range of total mass may be from about 40 mg to about 500 mg depending on the strength of the formulation, more preferred from about 80 mg to about 320 mg, most preferred from about 80 mg to about 120 mg.

- a stable powder instead of a stable granulation will be obtained, which powder may be used for administration to a patient, eg. in solution or suspension, or may be compressed into an oral solid dosage form, eg. tablets.

- Oral solid dosage formulations or compositions containing an active ingredient, eg. a compound of formula I may be administered one or more times per day or week.

- An effective amount of such an active ingredient, eg. a compound of formula I is the amount required to effect prophylaxis or treatment of relevant disease-states. Such amount will depend, in part, on the particular disease-state and its severity, and age, weight, and general health of the patient, and other factors evident to those skilled in the art, but can be determined routinely by one of ordinary skill in the art having regard to his own knowledge.

- a typical daily dose will contain a nontoxic dosage range of from about 0.0001 to about 75 mg/kg patient per day of an active ingredient, eg. a compound of formula I, in particular levormeloxifene.

- a suitable dose of a compound of formula I, such as levormeloxifene is e.g. from 0.01 to 2.5 mg per day to a patient, eg. a woman.

- C ⁇ alkyl includes straight and branched chain alkyl radicals containing from 1 to 6 carbon atoms, such as methyl, ethyl, n-propyl, isopropyl, n-butyl, tert-butyl, n-amyl, sec-amyl, n-hexyl, 2-ethylbutyl, 2,3-dimethylbutyl and the like.

- a wet granulation method represents a conventional way of making granules and is disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) and/or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997.

- the wet method usually comprises the steps of weighing, mixing, granulation, screening the damp mass, drying, and optionally dry screening, lubrication and compression.

- a granulate is intended to mean the granulate obtainable by using the wet granulation method and has the general meaning as disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) and/or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997.

- the granules may have any suitable size, depending on the carriers and/or equipment used and the preparation of granules with a particular size and structure is within the technical knowledge of the skilled person.

- an active ingredient is intended to mean any compound having a therapeutic effect, and which is suitable for administration as an oral solid dosage formulation, such as non-peptide organic molecules, small peptides and peptide mimetics, and the like, as well as their pharmaceutically acceptable salts, in particular, but not limited to, a compound of formula I eg.

- centchroman or levormeloxifene centchroman or levormeloxifene; tiagabine, (2E)-5-amino-5-methylhex-2-enoic acid N-methyl-N- ((1 R)-1-(N-methyl-N-((1 R)-1-(methylcarbamoyl)-2-phenylethyl)carbamoyl)-2-(2- naphthyl)ethyl)amide, ipamorelin, raloxifene, idoxifene, tamoxifene, 4-hydroxy tamoxifene, toremifene, or droloxifene or pharmaceutically acceptable salts thereof.

- the active ingredient itself may be stable upon storage or under stress conditions, but when formulated with one or more carriers it shows stability problems, eg. it starts to degrade.

- one or more carriers is intended to mean such carriers which are commonly used in the pharmaceutical chemistry for preparing granulates and oral solid dosage formulations, see eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) and/or Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997.

- such one or more carriers are selected from, but not limited to, hydrophilic binders, water-soluble diluents, surfactants, lubricants, disintegrants, antioxidants, non water-soluble diluents and/or other fillers known to the skilled person.

- the term "formation of a mixture of the active ingredient and one or more carriers” is intended to have its usual meaning, ie. mixing the active ingredient and carriers, in a suitable container, so as to form a mixture.

- the container may be the high shear mixing means wherein the granulation of the mixture takes place, but it is not limited hereto.

- granulation of the mixture is intended to have its usual meaning, as disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997; and include one or more of dry blending, wet massing, and after granulation.

- drying the mixture is intended to have its usual meaning, as disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997; and comprises drying the granulation mixture in a conventional manner either inside or outside the high shear mixing means, such as, but is not limited to, by placing the moist granulation mixture in drying cabinets with circulating air current and thermostatic heat control.

- a high shear mixing means is intended to mean a high shear mixer, high speed mixer or high shear granulator or similar mixer/granulator as disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997; and comprises, but is not limited to, a high shear mixer, such as a high speed, high shear mixer, such as a vertical axis high shear mixer or a horisontal axis high shear mixer.

- the high shear mixer may be selected from the following types: Gral, Lodige/Littleford, Diosna, Fielder or Baker- Perkins.

- a temperature regulating means is intended to comprise any such means that can increase or lower the temperature in a mixture, eg. contained in a high shear mixing means.

- Such temperature regulating means comprises, but is not limited to, internal or external temperature regulating means, such as an internal or external cooling mantle with a fluid such as cold water (4-5 °C), or internal cooling tubes, or dry ice added in the high shear mixing means, or the high shear mixing means may be placed in a larger container which operates as a freezer.

- a high shear mixing means with a temperature regulating means is intended to mean that the high shear mixing means is either equiped with the temperature regulating means, which may constitute an integrated part thereof, or the temperature regulating means may be separate from the high shear mixing means and still regulate temperature, for instance if the high shear mixing means is placed in a larger container which operates as a freezer.

- the term "during granulation” is intended to mean during the entire granulation period, or during a part or parts of the granulation period, such as, but not limited to, during wet massing.

- processing the granulate is intended to mean the further conventional processing of the granulate into an oral solid dosage formulation as disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997; and comprises, but is not limited to, reducing the granulate to a particular size, lubrication, and compressing into tablets or filling into gelatine capsules.

- an oral solid dosage formulation or "an oral solid dosage form” is intended mean such solid dosage formulations as disclosed in eg. Remington: The Science and Practice of Pharmacy, 19th Edition (1995) or in Handbook of pharmaceutical granulation technology, chapter 7, “Drugs and the pharmaceutical sciences", vol. 81 , 1997; and comprises, but is not limited to, tablets, incl. chewable tablets, capsules, pills, lozenges, troches, cachets and pellets.

- pharmaceutically acceptable salt represents salt forms of an active ingredient, eg. a compound of formula I, that are physiologically suitable for pharmaceutical use.

- the pharmaceutically acceptable salts can exist in conjunction with a compound of formula I as acid addition primary, secondary, tertiary, or quaternary ammonium, alkali metal, or alkaline earth metal salts.

- the acid addition salts are prepared by the reaction of an acid with an active ingredient, eg. a compound of formula I.

- the alkali metal and alkaline earth metal salts are generally prepared by the reaction of the metal hydroxide of the desired metal salt with a compound of formula I, wherein R is hydrogen.

- the active ingredient eg. compounds of formula I may be prepared in the form of a salt such as pharmaceutically acceptable salts, especially acid-addition salts, including salts of organic acids and mineral acids.

- a salt such as pharmaceutically acceptable salts, especially acid-addition salts, including salts of organic acids and mineral acids.

- such salts include salts of organic acids such as formic acid, fumaric acid, acetic acid, propionic acid, glycolic acid, lactic acid, pyruvic acid, oxalic acid, succinic acid, malic acid, maleic acid, tartaric acid, citric acid, benzoic acid, salicylic acid and the like.

- Suitable inorganic acid-addition salts include salts of hydrochloric, hydrobromic, sulphuric and phosphoric acids and the like.

- the acid addition salts may be obtained as the direct products of compound synthesis.

- the free base may be dissolved in a suitable solvent containing the appropriate acid, and the salt isolated by

- hydrophilic binder represents binders commonly used in the formulation of pharmaceuticals, such as polyvinylpyrrolidone, copolyvidone (cross- linked polyvinylpyrrolidone), polyethylene glycol, sucrose, dextrose, corn syrup, polysaccharides (including acacia, tragacanth, guar, and alginates), gelatin, and cellulose derivatives (including hydroxypropyl methylcellulose, hydroxypropyl cellulose, and sodium carboxymethylcellulose).

- pharmaceuticals such as polyvinylpyrrolidone, copolyvidone (cross- linked polyvinylpyrrolidone), polyethylene glycol, sucrose, dextrose, corn syrup, polysaccharides (including acacia, tragacanth, guar, and alginates), gelatin, and cellulose derivatives (including hydroxypropyl methylcellulose, hydroxypropyl cellulose, and sodium carboxymethylcellulose).

- water-soluble diluent represents compounds typically used in the formulation of pharmaceuticals, such as sugars (including lactose, sucrose, and dextrose), polysaccharides (including dextrates and maltodextrin), polyols (including mannitol, xylitol, and sorbitol), and cyclodextrins.

- non water-soluble diluent represents compounds typically used in the formulation of pharmaceuticals, such as calcium phosphate, calcium sulfate, starches, modified starches and microcrystalline cellulose.

- non water-soluble diluent with non-swelling properties represents the non water-soluble diluents as indicated above, but excluding starches and modified starches and the like.

- surfactant represents ionic and nonionic surfactants or wetting agents commonly used in the formulation of pharmaceuticals, such as ethoxylated castor oil, polyglycolyzed glycerides, acetylated monoglycerides, sorbitan fatty acid esters, poloxamers, polyoxyethylene sorbitan fatty acid esters, polyoxyethylene derivatives, monoglycerides or ethoxylated derivatives thereof, diglycerides or polyoxyethylene derivatives thereof, sodium docusate, sodium laurylsulfate, cholic acid or derivatives thereof, lecithins, alcohols and phospholipids.

- antioxidant represents the three groups of antioxidants, true antioxidants, reducing agents and antoxidant synergists, such as tocopherols, tocopherolesters, alkyl gallates, butylated hydroxyanisole, butylated hydroxytoluene, ascorbic acid, citric acid, edetic acid and its salts, lecithin and tartaric acid.

- disintegrant represents compounds such as starches, clays, celluloses, alginates, gums, cross-linked polymers (such as cross-linked polyvinylpyrrolidone and cross-linked sodium carboxymethylcellulose), sodium starch glycolate, low-substituted hydroxypropyl cellulose, and soy polysaccharides.

- the disintegrant is a modified cellulose gum such as e.g. cross-linked sodium carboxymethylcellulose.

- lubricant represents compounds frequently used as lubricants or glidants in the preparation of pharmaceuticals, such as talc, magnesium stearate, calcium stearate, stearic acid, colloidal silicon dioxide, magnesium carbonate, magnesium oxide, calcium silicate, microcrystalline cellulose, starches, mineral oil, waxes, glyceryl behenate, polyethylene glycol, sodium benzoate, sodium acetate, sodium chloride, sodium laurylsulfate, sodium stearyl fumarate, and hydrogenated vegetable oils.

- the lubricant is magnesium stearate or talc, more preferably magnesium stearate and talc in combination.

- the hydrophilic binder is gelatin, cellulose derivative, polyvinylpyrrolidone or copolyvidone.

- the water-soluble diluent is a sugar, a polysaccharide or cyclodextrin.

- the formulation (granulate or oral solid dosage formulation) further comprises a non water-soluble diluent.

- the non water-soluble diluent is a non water-soluble diluent with non-swelling properties, preferably microcrystalline cellulose.

- the formulation further comprises an antioxidant.

- the antioxidant is tocopherols and tocopherolesters, such as alpha-tocopherol succinate.

- the formulation further comprises a surfactant.

- the surfactant is present, preferably it is an anionic or nonionic surfactant.

- Representative surfactants from this preferred group include sodium laurylsulfate, polyglycolyzed glycerides, polyoxyethylene sorbitan fatty acid esters, monoglycerides, diglycerides or glycerol.

- the formulation further comprises a lubricant(s) and/or a disintegrant.

- the hydrophilic binder is polyvinylpyrrolidone or copolyvidone. More preferably, the water-soluble diluent is a sugar, such as lactose, sucrose, dextrose. More preferably, the surfactant, when present, is a nonionic surfactant, such as polyoxyethylene sorbitan fatty acid esters or glycerol. Certain formulations of the present invention are most preferred. Most preferably, the hydrophilic binder is copolyvidone. Most preferably, the water-soluble diluent is lactose.

- the amount of hydrophilic binder in the pharmaceutical formulation according to the invention is preferably from about 1 % to about 25% (w/w), more preferably from about 1 % to about 15% (w/w), most preferably from about 2,5% to about 15% (w/w).

- the amount of water-soluble diluent in the pharmacutical formulation according to the invention is preferably from about 20% to about 98% (w/w), more preferred from about 20% to about 80% (w/w).

- the amount of non water-soluble diluent in the pharmacutical formulation according to the invention is preferably from about 1% to about 50% (w/w), more preferred from about 5% to about 30% (w/w).

- the amount of the active ingredient, eg. compound of formula I, in the pharmaceutical formulation according to the invention is preferably from about 0,05% to about 50% (w/w), such as from about 0,1 % to about 40% (w/w).

- Tablets for this invention are prepared utilizing conventional tabletting techniques.

- a general method of manufacture involves blending of a compound of formula I, or a salt thereof, the water-soluble diluent, hydrophilic binder and optionally a portion of a disintegrant. This blend is then granulated with an aqueous solution of the hydrophilic binder or an aqueous solution of the hydrophilic binder and surfactant and milled, if necessary. The granules are dried and reduced to a suitable size. Any other ingredients, such as lubricants, (e.g. magnesium stearate) and additional disintegrants, are added to the granules and mixed.

- lubricants e.g. magnesium stearate

- additional disintegrants are added to the granules and mixed.

- Capsules for this invention are prepared utilizing conventional methods.

- a general method of manufacture involves blending of a compound of formula I, or a salt thereof, the water-soluble diluent, a hydrophilic binder, and optionally a portion of a disintegrant. This blend is then granulated with an aqueous solution of the hydrophilic binder or an aqueous solution of the hydrophilic binder and surfactant in water, and milled, if necessary.

- the granules are dried and reduced to a suitable size. Any other ingredients, such as a lubricant, are added to the granules and mixed. The resulting mixture is then filled into a suitable size hard-shell gelatin capsule using conventional capsule- filling machines.

- the preferred range of pharmaceutical formulation (such as oral solid dosage form, e.g. capsule or tablet) strength may be from about 0.1 mg to about 40 mg of a compound of formula I, more preferred from about 0.25 mg to about 5 mg of a compound of formula I, preferably levormeloxifene.

- the preferred range of total mass may be from about 40 mg to about 500 mg depending on the strength of the formulation, more preferred from about 80 mg to about 320 mg.

- Tablets and capsules may be prepared using the ingredients and procedures as described below.

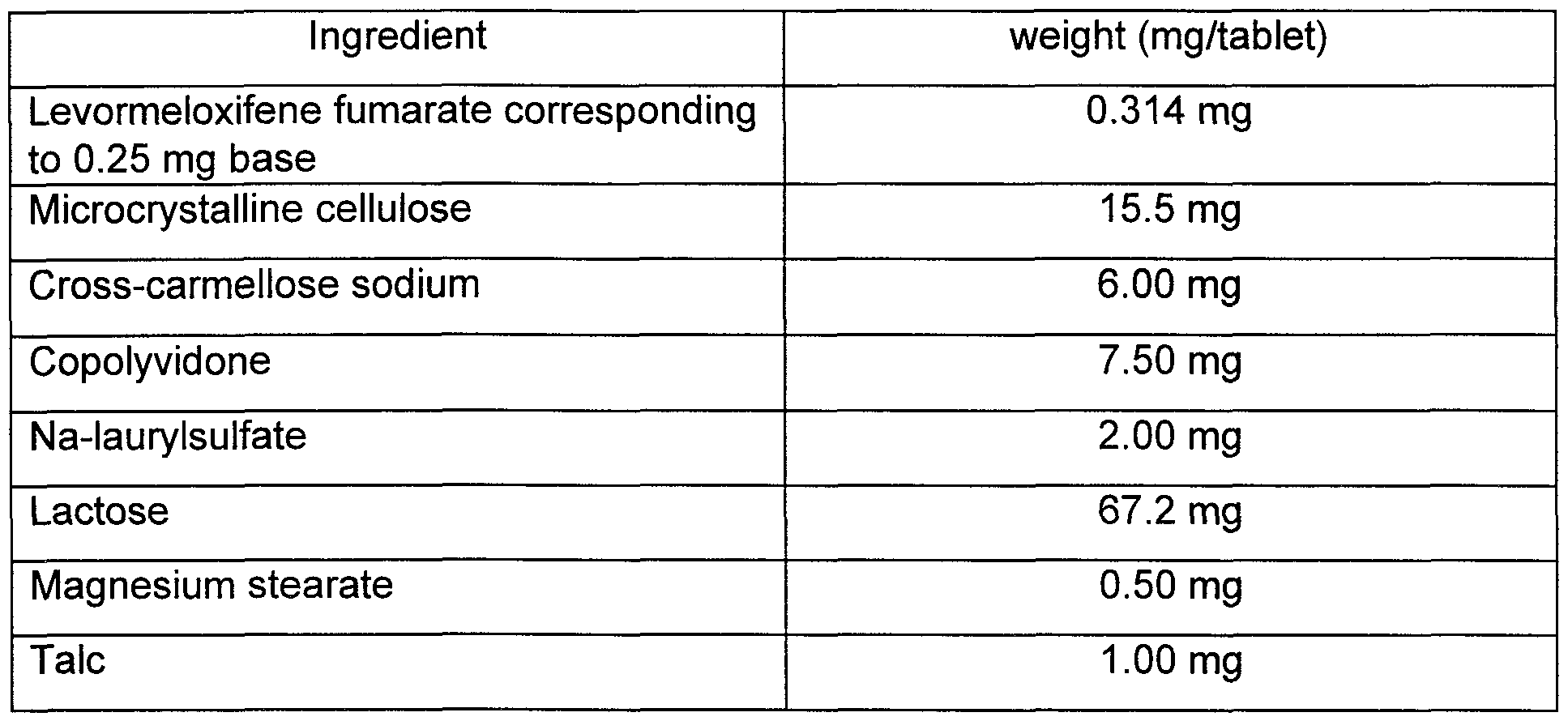

- Table 1 Investigation of granulation temperature.

- the stability of a levormeloxifene formulation can be improved by lowering the process temperature in the high shear mixer, especially the granulation temperature below 40°C.

- the most optimal temperature interval is 20 - 25°C.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone. During granulation cooling is added. The granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium. The mixture is compressed into individual tablets yielding a tablet weight of 320 mg. It is possible to manufacture levormeloxifene tablet strenghts in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 320 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone. During granulation cooling is added. The granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium. The mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone containing dissolved sodium laurylsulfate.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 320 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40mg with a total mass in the range of 160 mg to 320 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone containing dissolved sodium laurylsulfate.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, dextrose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 320 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 320 mg.

- the mixture of levormeloxifene fumarate, dextrose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 400 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 400 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, dextrose, microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 400 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 400 mg.

- the mixture of levormeloxifene fumarate, dextrose, microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone containing Tween 80.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross- carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 400 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 400 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone containing Tween 80.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross- carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone containing glycerol.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross- carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 400 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 400 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone containing glycerol.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross- carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, dextrose, microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine and glycerol.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 400 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 40 mg with a total mass in the range of 160 mg to 400 mg.

- the mixture of levormeloxifene fumarate, dextrose, microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine and glycerol.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, dextrose, hydroxypropyl-betacyclodextrin microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine containing glycerol.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 500 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 1.25 mg to 80 mg with a total mass in the range of 160 mg to 500 mg.

- the mixture of levormeloxifene fumarate, dextrose, hydroxypropyl-betacyclodextrin microcrystalline cellulose, and a portion of cross-carmellose sodium is granulated with an aqueous solution of gelatine containing glycerol.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight with in the range of 80 mg to 160 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.1 mg to 5 mg with a total mass with in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, lactose and microcrystalline cellulose is granulated with an aqueous solution of polyvinylpyrrolidone or copolyvidone.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate.

- the mixture is then filled into size 0 hard-shell gelatine capsules utilizing conventional encapsulating equipment. In order to obtain different capsule strenghts in the range of 0.18 mg to 7.50 mg, different quantities are weighed out in the range of 15 mg to 500 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, antioxidant, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 80 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.125 mg to 10 mg with a total mass in the range of 80 mg to 160 mg.

- the mixture of levormeloxifene fumarate, lactose, microcrystalline cellulose, antioxidant, and a portion of cross-carmellose sodium and copolyvidone is granulated with an aqueous solution of copolyvidone.

- the granules are dried, reduced to a suitable size and mixed with magnesium stearate, talc and remaining cross-carmellose sodium.

- the mixture is compressed into individual tablets yielding a tablet weight of 100 mg. It is possible to manufacture levormeloxifene tablet strengths in the range of 0.125 mg to 20 mg with a total mass of 100 mg.

Abstract

Description

Claims

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP99934513A EP1098636A1 (en) | 1998-07-23 | 1999-07-22 | A wet granulation method for preparing a stable pharmaceutical formulation |

| JP2000560873A JP2002521322A (en) | 1998-07-23 | 1999-07-22 | Wet granulation process for the production of stable pharmaceutical formulations |

| AU50265/99A AU5026599A (en) | 1998-07-23 | 1999-07-22 | A wet granulation method for preparing a stable pharmaceutical formulation |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DKPA199800970 | 1998-07-23 | ||

| DKPA199800970 | 1998-07-23 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2000004880A1 true WO2000004880A1 (en) | 2000-02-03 |

Family

ID=8099551

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/DK1999/000416 WO2000004880A1 (en) | 1998-07-23 | 1999-07-22 | A wet granulation method for preparing a stable pharmaceutical formulation |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1098636A1 (en) |

| JP (1) | JP2002521322A (en) |

| AU (1) | AU5026599A (en) |

| WO (1) | WO2000004880A1 (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1177726A1 (en) * | 2000-08-04 | 2002-02-06 | Aventis Animal Nutrition S.A. | Process for the production of granules of methionine |

| WO2002058673A1 (en) * | 2001-01-26 | 2002-08-01 | Giuliani S.P.A. | Method of preparing pharmaceutical or dietary compositions for conveying labile substances into the intestine |

| EP1319409A1 (en) * | 2000-09-22 | 2003-06-18 | Takeda Chemical Industries, Ltd. | Solid preparations |

| JP2004502733A (en) * | 2000-07-06 | 2004-01-29 | ワイス | Pharmaceutical composition of estrogen |

| US6872405B2 (en) | 2001-05-10 | 2005-03-29 | Yamanouchi Pharmaceutical Co., Ltd. | Quick-disintegrating tablet in buccal cavity and manufacturing method thereof |

| EP2088154A1 (en) | 2004-03-09 | 2009-08-12 | Ironwood Pharmaceuticals, Inc. | Methods and compositions for the treatment of gastrointestinal disorders |

| US7964734B2 (en) | 2002-09-30 | 2011-06-21 | A/S Gea Farmaceutisk Fabrik | Raloxifene acid addition salts and/or solvates thereof, improved method for purification of said raloxifene acid addition salts and/or solvates thereof and pharmaceutical compositions comprising these |

| US8748573B2 (en) | 2009-08-06 | 2014-06-10 | Ironwood Pharmaceuticals, Inc. | Formulations comprising linaclotide |

| US8802628B2 (en) | 2008-08-15 | 2014-08-12 | Ironwood Pharmaceuticals, Inc. | Stable solid formulation of a GC-C receptor agonist polypeptide suitable for oral administration |

| US8933030B2 (en) | 2010-02-17 | 2015-01-13 | Ironwwod Pharmaceuticals, Inc. | Treatments for gastrointestinal disorders |

| US9708371B2 (en) | 2011-08-17 | 2017-07-18 | Ironwood Pharmaceuticals, Inc. | Treatments for gastrointestinal disorders |

| US10675325B2 (en) | 2010-08-11 | 2020-06-09 | Ironwood Pharmaceuticals, Inc. | Stable formulations of linaclotide |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8642079B2 (en) * | 2004-02-23 | 2014-02-04 | Hormos Medical Corporation | Solid formulations of ospemifene |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63275519A (en) * | 1987-05-06 | 1988-11-14 | Taisho Pharmaceut Co Ltd | Production of granule containing slightly soluble drug |

| JPS63280025A (en) * | 1987-05-13 | 1988-11-17 | Taisho Pharmaceut Co Ltd | Production of agent to accelerate absorption of medicine |

| ZA937382B (en) * | 1992-10-06 | 1994-04-29 | Warner Lambert Co | Novel composition for peroral therapy of cognitionimpairment and a process therefor |

| GB9424766D0 (en) * | 1994-12-07 | 1995-02-08 | Wellcome Found | Pharmaceutical composition |

-

1999

- 1999-07-22 WO PCT/DK1999/000416 patent/WO2000004880A1/en not_active Application Discontinuation

- 1999-07-22 AU AU50265/99A patent/AU5026599A/en not_active Abandoned

- 1999-07-22 EP EP99934513A patent/EP1098636A1/en not_active Withdrawn

- 1999-07-22 JP JP2000560873A patent/JP2002521322A/en active Pending

Non-Patent Citations (5)

| Title |

|---|

| G.J.B. HORSTHUIS ET AL: "Studies on upscaling parameters of the Gral high shear granulation process", INTERNATIONAL JOURNAL OF PHARMACEUTICS, vol. 92, 1993, pages 143 - 150, XP002921900 * |

| JOHAN A. WESTERHUIS ET AL: "Multivariate modelling of the tablet manufacturing process with wet granulation for tablet optimization and in-process control", INTERNATIONAL JOURNAL OF PHARMACEUTICS, vol. 156, 1997, pages 110 - 117, XP002921898 * |

| P. WEHRLE ET AL: "Response surface methodology: an interesting statistical tool for process optimization and validation: example of wet granulation in a high-shear mixer", DRUG DEVELOPMENT AND INDUSTRIAL PHARMACY, vol. 19, no. 13, 1993, pages 1637 - 1653, XP002921901 * |

| T. SCHAEFER ET AL: "Wet Granulation in a Laboratory Scale High Shear Mixer", PHARM. IND., vol. 52, no. 9, 1990, pages 1147 - 1153, XP002921899 * |

| The 25th International Symposium on Controlled Release of Bioactive Materials and the First Consumer and Diversified Products Conference, Publisher: Controlled Release Society, Inc., Vol. 25, 1998, L. LIU et al: "The effect of process variables on a wet-granulation by high- shear mixer and fluid bed granulator of a * |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004502733A (en) * | 2000-07-06 | 2004-01-29 | ワイス | Pharmaceutical composition of estrogen |

| EA007606B1 (en) * | 2000-08-04 | 2006-12-29 | Адиссео Франс С.А.С. | Process for the preparation of granules of methionine |

| WO2002011555A1 (en) * | 2000-08-04 | 2002-02-14 | Adisseo France S.A.S. | Process for the preparation of granules of methionine |

| EP1177726A1 (en) * | 2000-08-04 | 2002-02-06 | Aventis Animal Nutrition S.A. | Process for the production of granules of methionine |

| US6989464B2 (en) | 2000-08-04 | 2006-01-24 | Adisseo France S.A.S. | Process for the preparation of granules of methionine |

| EP1319409A1 (en) * | 2000-09-22 | 2003-06-18 | Takeda Chemical Industries, Ltd. | Solid preparations |

| EP1319409A4 (en) * | 2000-09-22 | 2006-05-03 | Takeda Pharmaceutical | Solid preparations |

| WO2002058673A1 (en) * | 2001-01-26 | 2002-08-01 | Giuliani S.P.A. | Method of preparing pharmaceutical or dietary compositions for conveying labile substances into the intestine |

| US6872405B2 (en) | 2001-05-10 | 2005-03-29 | Yamanouchi Pharmaceutical Co., Ltd. | Quick-disintegrating tablet in buccal cavity and manufacturing method thereof |

| US7964734B2 (en) | 2002-09-30 | 2011-06-21 | A/S Gea Farmaceutisk Fabrik | Raloxifene acid addition salts and/or solvates thereof, improved method for purification of said raloxifene acid addition salts and/or solvates thereof and pharmaceutical compositions comprising these |

| EP2088154A1 (en) | 2004-03-09 | 2009-08-12 | Ironwood Pharmaceuticals, Inc. | Methods and compositions for the treatment of gastrointestinal disorders |

| US8802628B2 (en) | 2008-08-15 | 2014-08-12 | Ironwood Pharmaceuticals, Inc. | Stable solid formulation of a GC-C receptor agonist polypeptide suitable for oral administration |

| US8748573B2 (en) | 2009-08-06 | 2014-06-10 | Ironwood Pharmaceuticals, Inc. | Formulations comprising linaclotide |

| US8933030B2 (en) | 2010-02-17 | 2015-01-13 | Ironwwod Pharmaceuticals, Inc. | Treatments for gastrointestinal disorders |

| US10675325B2 (en) | 2010-08-11 | 2020-06-09 | Ironwood Pharmaceuticals, Inc. | Stable formulations of linaclotide |

| US10702576B2 (en) | 2010-08-11 | 2020-07-07 | Ironwood Pharmaceuticals, Inc. | Stable formulations of linaclotide |

| US9708371B2 (en) | 2011-08-17 | 2017-07-18 | Ironwood Pharmaceuticals, Inc. | Treatments for gastrointestinal disorders |

Also Published As

| Publication number | Publication date |

|---|---|

| AU5026599A (en) | 2000-02-14 |

| JP2002521322A (en) | 2002-07-16 |

| EP1098636A1 (en) | 2001-05-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0744946B1 (en) | Compositions containing micronized nebivolol | |

| CN1119530A (en) | Methods of use for inhibiting bone loss and lowering serum cholesterol | |

| WO2000004880A1 (en) | A wet granulation method for preparing a stable pharmaceutical formulation | |

| JP2013209419A (en) | Bazedoxifene acetate formulation | |

| US6525084B2 (en) | Stable pharmaceutical formulation | |

| ZA200502792B (en) | Novel pharmaceutical formulations of modafinil | |

| PL211062B1 (en) | New pharmaceutical compositions containing flibanserin polymorph a | |

| WO2009080364A1 (en) | Raloxifene composition | |

| US20120010216A1 (en) | Pharmaceutical compositions containing vanoxerine | |

| US5977158A (en) | Pharmaceutical formulations comprising levormeloxifene compounds | |

| EP2448562B1 (en) | Raloxifene composition | |

| RU2355397C2 (en) | Bazedoxifene treatment schedule | |

| US10117939B2 (en) | Pharmaceutical compositions comprising nebivolol or a nebivolol analogue | |

| EP0959880A1 (en) | Pharmaceutical formulation | |

| WO2013132512A1 (en) | "pharmaceutical composition of raloxifene hydrochloride" | |

| HUT77381A (en) | Process for producing pharmaceutical compositions usefule for inhibiting growth hormone effects containing benzotiophene derivatives | |

| WO1999024031A1 (en) | Pharmaceutical composition comprising 3,4-diarylchromans in low dose | |

| SK9772003A3 (en) | R- and S-enantiomer of 2-amino-1-(4-hydroxy-3- methanesulphonamidophenyl)ethanol, pharmaceutical composition containing them and their use | |

| KR20110030256A (en) | Raloxifene-containing pharmaceutical composition having improved dissolution rate and manufacturing method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AK | Designated states |

Kind code of ref document: A1 Designated state(s): AE AL AM AT AU AZ BA BB BG BR BY CA CH CN CU CZ DE DK EE ES FI GB GD GE GH GM HR HU ID IL IN IS JP KE KG KP KR KZ LC LK LR LS LT LU LV MD MG MK MN MW MX NO NZ PL PT RO RU SD SE SG SI SK SL TJ TM TR TT UA UG UZ VN YU ZA ZW |

|

| AL | Designated countries for regional patents |

Kind code of ref document: A1 Designated state(s): GH GM KE LS MW SD SL SZ UG ZW AM AZ BY KG KZ MD RU TJ TM AT BE CH CY DE DK ES FI FR GB GR IE IT LU MC NL PT SE BF BJ CF CG CI CM GA GN GW ML MR NE SN TD TG |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application | ||

| DFPE | Request for preliminary examination filed prior to expiration of 19th month from priority date (pct application filed before 20040101) | ||

| WWE | Wipo information: entry into national phase |

Ref document number: 1999934513 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref country code: JP Ref document number: 2000 560873 Kind code of ref document: A Format of ref document f/p: F |

|

| WWP | Wipo information: published in national office |

Ref document number: 1999934513 Country of ref document: EP |

|

| REG | Reference to national code |

Ref country code: DE Ref legal event code: 8642 |

|

| NENP | Non-entry into the national phase |

Ref country code: CA |

|

| WWW | Wipo information: withdrawn in national office |

Ref document number: 1999934513 Country of ref document: EP |