USRE19082E - Duplicator - Google Patents

Duplicator Download PDFInfo

- Publication number

- USRE19082E USRE19082E US19082DE USRE19082E US RE19082 E USRE19082 E US RE19082E US 19082D E US19082D E US 19082DE US RE19082 E USRE19082 E US RE19082E

- Authority

- US

- United States

- Prior art keywords

- drum

- paper

- sheet

- roll

- impression

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 229920000159 gelatin Polymers 0.000 description 29

- 235000019322 gelatine Nutrition 0.000 description 29

- 108010010803 Gelatin Proteins 0.000 description 18

- 239000008273 gelatin Substances 0.000 description 18

- 235000011852 gelatine desserts Nutrition 0.000 description 18

- 239000001828 Gelatine Substances 0.000 description 11

- 230000002093 peripheral effect Effects 0.000 description 5

- 238000000034 method Methods 0.000 description 2

- RUPBZQFQVRMKDG-UHFFFAOYSA-M Didecyldimethylammonium chloride Chemical compound [Cl-].CCCCCCCCCC[N+](C)(C)CCCCCCCCCC RUPBZQFQVRMKDG-UHFFFAOYSA-M 0.000 description 1

- 241000218652 Larix Species 0.000 description 1

- 235000005590 Larix decidua Nutrition 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000012840 feeding operation Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41L—APPARATUS OR DEVICES FOR MANIFOLDING, DUPLICATING OR PRINTING FOR OFFICE OR OTHER COMMERCIAL PURPOSES; ADDRESSING MACHINES OR LIKE SERIES-PRINTING MACHINES

- B41L9/00—Apparatus for indirectly duplicating from hectographic originals by means of hectographic intermediaries or transfer surfaces, i.e. "dry duplicators"

- B41L9/10—Apparatus for indirectly duplicating from hectographic originals by means of hectographic intermediaries or transfer surfaces, i.e. "dry duplicators" with rotary cylinders carrying sheets of hectographic gelatin-paper

Definitions

- Another feature of the invention resides in the means for automatically stripping the sheets from the gelatinized surface and positively discharging them from the machine.

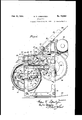

- Fig. 1 is an elevation of the right hand side of the machine

- Fig. 2 is an elevation of the machine

- Fig. 3 is a top plan view of the machine

- Fig. 4 is a central verticalsection on the line 44 of Fig. 3;

- Fig. 5 is an elevation of the right hand side of the impression drum and showsthe mechanism for securing the gelatin spindle rolls;

- Fig. 6 is a horizontal section on the line 6-6 of Fig. 5, and shows the spindle securing mechanism inlocked position;

- Fig. 7 is a view similar to Fig. 6 but shows one of the spindles removed and its pivot gate in unlocked position;

- Figs. 8 to 11 are diagrammatic views of the impression drum and gelatin rolls mounted therein showing the procedure for interchanging the gelatin rolls;

- Fig. 12 is a fragmentary view of the stripper drum

- Fig. 13 is a section taken on 12 and shows tioh

- Figs. 14 to 16 are detail views showing the manner of mounting the heads on the gripper fingers;

- Fig. 17 is a fragmentary view showing details of the feeding mechanism;

- the gripper fingers in open posi- Fig. 18 is a fragmentary section showing-the gripper fingers about to grip .the free end of the printed sheet;

- Fig. 19 is a detail view showing the manner in which the gripper fingers grip the paper

- Figs. 20 to 22 are detail views of the clutch and brake mechanism

- Figs. 23 to 25 are detail views of one of the adjustable paper guides.

- the framework of the machine includes two 66 side frames 10 connected by suitable tie members and carrying in journals the impression drum 11.

- the leftend of the impression drum carries the gear teeth 12 which mesh with teeth 13 formed on the stripper drum 14, the latter also being Journaled in the framework;

- the stripper drum is driven through a reduction gear 15 by an electric motor 16. 1

- the impression drum is composed of two end members 17 and 18 and a peripheral surface 19 78 that extends over more than half of the circumference of the drum.

- the peripheral surface is covered by a layer of felt 20 to provide a cushion support for the gelatin paper 21.

- the gelatin paper after passing over the peripheral surface of the drum is carried around a guide roller 22 located at each end of the surface 19, and has one of its ends attached to the hollow delivery spindle 23 and its opposite end attached to the hollow receiving spindle 24.

- the end member 18 carries 86 studs 25 adapted to rotatably support one end of each of the spindles 23 and 24.

- the opposite ends of-spindles 23 and 24 are supported and rotated through studs 26 carried by pivoted gates 27 which are identically constructed and move about pivot 28.

- Each gate is biased to open position by a compression spring 29 and carries an angular projection 30 that limits the opening movement of the gate.

- the inner part of stud 26 carries a cross pin 31 for engaging notches 32 formed The outer end of the in the end of the spindle. stud is squared at 33 for cooperation with a detachable crank and carries a ratchet wheel 34.

- pawl 35 pivoted to cooperate with the ratchet wheel, carries a handle 36 and is provided with a a spring 3'? arranged to move across dead center and hold the dog in either engaged or disengaged position.

- the gate is held in closed .position by a pivoted spring latch 38.

- the inclined feed table 39 is attached to the up- 9 per part of the framework and carries at its lowerend an angular pocket 40 (Fig. 4) adapted to hold the sheets which are to receive the impressions.

- the 'shaft 41 which extends across the frame in front of pocket 40, carries the feed rolls 42 and is driven from stripper drum 14 by gearing arranged to give rolls 42 the same peripheral speed as that of the impression drum 11.

- the delivery chute 43 which is carried by shaft 44, has idler rolls 45 extending through its lower member 46 and has a curved upper guard member 4'7.

- An apron 48 is loosely supported on the member 46 and falls by'gravity against the sheets in the pocket.

- Shaft 44 carries at one end an arm 49 having a roller 50 cooperating with a cam 51 adjustably mounted on the stripper drum 14.

- a spring 52 tends to depress the arm 49.

- a shaft 53 is mounted on the pivoted arms 54 andcarries the platen roller 55.

- Each of the arms 54 carries a stub shaft 55 on which is journaled a roller 56 cooperating with a cam 5'7 on the impression drum 11.

- a spring 58 tends to depress arms 54.

- the idler rolls 45 press the sheet against feed rolls 42 which feed it through stationary guides 61 and 62 into contact with the platen roller.

- the rollers 56 are allowed to descend by cams 5'7, thereby causing the platen roller to press the sheet against the gelatin paper on surface 19. It will be noted that-the delivery of the sheet is so timed that its forward edge projects beyond the gelatinized surface.

- the paper is directed in such a manner that it first contacts with the platen roller which presses it evenly and positively against the gelatinized surface. This procedure avoids trapping air between the paper and the gelatinized surface of impression roll and insures an even impression.

- the shaft 63 also carries loosely journaled thereon a plurality of-gripper fingers 6'7, the ends of which carry heads 68 universally pivoted thereon as shown in Figs. 1446.

- a spring 69 normally holds each gripper finger in the position shown in Fig. 4 with its head incontact with a surface '70, extending inwardly at an angle from the surface of the drum.

- the shaft carries a pin '71 adapted to engage the finger 6'7 upon certain movement of shaft and move the finger outwardly to the position shown in Fig. 18.

- An arm '72 is mounted on one end of shaft 63 and carries a roller '73 riding along a stationary cam 74 mounted on the framework of the machine.

- the snubbing member '75 provides a projecting ledge '76 which acts as a sart of snubbing post about which the sheet of paper is bent to give added firmness to the will carry the sheet along with it until the roller '73 again rides up the high part of the cam '74, thereby causing the gripper fingers to release the sheet and moving the gripper fingers outwardly to positively push the sheet from the stripper roll.

- This positive discharge of the sheet prevents its adhesion to the roll on account of static electricity or any other cause.

- the sheets are discharged into the pan '7'7.”

- the motor 16 is connected to the driving gears by. a clutch. '78 of a conventional type which is controlled by lever '79.

- a second control lever 80 is pivoted on the opposite side of the frame and is connected to lever.'79,. so that the clutch can be operated from either side of the machine.

- a brake 81. is mounted on the outer end of the clutch shaft and is operated by a lever 82.

- a pin 83 is carried by lever '79 and is adapted to move lever 82 to braking position and to hold the lever in such position by engaging in a notch 84 formed gaged; while when it is in the other extreme position the brake is applied and locked in braking position.

- Bracket 84 carries a stub 86 adapted to fit within the spindle and having a pin 8'7 adapted to en gage thenotches formed in the spindle, while bracket 85 carries a U-shaped saddle 88.

- the pawl 35 is then returned to 19,082 necessary a fresh gelatin roll is placed in the dewhen the spindles are in the positions of Fig; 9 they are exactly parallel, and hence the paper will be properly alined upon the receiving spindle.

- the brake is now released and, the impression drum is moved by hand, rim 89 being provided for this purpose, in the reverse direction as'shown in Fig. 10 to lead the gelatin paper across-the surface of the drum. This reverse rotation is continued until the parts reach the position shown in Fig. 11, when the brake is again locked.

- the spindle on the alining brackets is now placed in the receiving position within the drum and the paper is tightened as previously explained.

- the feed table 39 carries two paper guides 90 composed as shown in Figs. 23 to 25, of an L- shaped guide member 91, and a supporting arm 92.

- a spring arm 93 is adapted to ride in a guidej way 94 formed below the table and frictionally grip the table.

- a spring 95 is mounted on the framework of the machine and presses against the spring arm 93. The guide is thus accurately alined by the guide-way 94 and is frictionally held in any working position without the use of set screws or similar fastening devices.

- the duplicator is adapted to be rotated continuously by the electric motor, although it can be instantly stopped by movement of either lever 79 or lever 80.

- the sheets are fed by hand into the delivery chutewhich delivers them at exactly the proper time to the feed rolls, which are moving at the same peripheral speed as the impression drum.

- the feed rolls deliver the sheet to the platen roller which presses the paper evenly and with uniform pressure upon the'impression drum.

- the gripper fingers release the sheet and the stripper fingers positively discharge it from the stripper drum.

- impressiondrum provides for easy replacement and adjustment of the gelatin rolls, while the alining brackets insure even winding of the paper upon the receiving spindle.

- an impression drum having a duplicating band, a platen roll cooperating with said drum, a roll feeding a sheet of paper in one direct continuous movement toward said drum to a position wherein it will be engaged by said duplicating band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a movable table, and means connected with said drum to operate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

- an impression drum having a gelatine band, a platen roll cooperating with said drum, a roll feeding a sheet of paper in one direct continuous movement to a position wherein it will beengagedby saidgelatinemband and said platen roll, means operatively connecting said feeding roll to said impressiondrum to rotate it in synchronism therewith and in a'single direc- 3' tion, a movable table, and means connected with said drum to operate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

- an impression drum having a gelatin band, a platen roll cooperating with said drum, a roll for feeding a sheet of paper in one direct continuous movementto a position wherein it will be engaged by said gelatine band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a tiltable table, and means connected with-said drum to operate in synchronism therewith for tilting said table to bring said sheet of paper into frictional engagement with said feeding roll.

- an impression drum having'a gelatine band, a platen roll cooperating withsaid drum, a roll for feeding a sheet of paper in one direct continuous movement to a position wherein it will be engaged'by said gelatine band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith and in a single direction, a tiltable table, and means connected with said drum to operate in synchronism therewith for tilting said table to bring said sheet of paper into frictional engagement with said feeding roll.

- a cylindrical impresa sion drum having an opening in its cylindrical surface, a gelatine band on said cylindrical surface, a platen roll cooperating with said drum, a roll for feeding a sheet of paper in one direct continuous movement to a position wherein its forward end will register with said opening while said drum is being rotated, said gelatine band and said platen roll being adapted to engage said sheet of paper when it is brought into said position, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a movable table, and means connected with said drum to operate in synchronismtherewith for displacing said table to bring said sheet of paper into fr'ctional engagement with said feeding roll.

- a cylindrical impression drum having an opening in its cylindrical surface, a gelatine band on said cylindrical surface, a platen roll cooperating with said drum, a

- said gelatine band and said platen roll being adapted to engage said sheet of paper when it is brought into said position, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a tiltable table, and means connected with said drum to nism therewith for tilting said table to bring said sheet of paper into frictional engagement with said feeding roll.

- a cylindrical impression drum having an opening in its cylindrical surface, a gelatine band on said cylindrical surface, a platen roll cooperating with said drum, a roll frictionally engageable with a sheet of paper for feeding it in one direct continuous movement to a position wherein its forward end will register with said opening while said drum is being rotated, said gelatine band and said platen roll being adapted to engage said is brought into said position, means operatively connecting said feeding roll to said impression operate in synchrosheet of paper when it a platen roll and engageable by both faces of drum to rotate it in synchronism therewith,

- a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, a roll frictionally engageable with a sheet of paper to feed it in one direct continuous movement-tea position wherein its forward end will project beyond the gelatinized surface and it will be engageable by said gelatinized surface and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, means intermediate said feeding roll and said platen roll and engageable by both faces of said sheet of paper to guide it to said platen roll and drum, a movable table, and means operatively connected with said drum to rotate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

- a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, means'having an axis of rotation, and frictionally engageable with a sheet of paper for feeding it in one direct continuous movement to a position wherein it will be engaged by said gelatinized surface and said platen roll, means operatively connecting said feeding means to said impression drumto actuate it in synchronism therewith, a movable table disposed beneath said feeding means, and means operatively connected with said drum to operate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding means.

- an impression drum having a gelatinized surface

- a feed roller actuated in synchronism with said impression drum and frictionally engageable with sheets of paper to feed them to said drum with their forward ends projecting beyond the gelatinized surface, and means for positively gripping the projecting ends of said sheets of paper and pulling solely on said endsto strip the sheets of paper from said gelatinized surface.

- a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, a roll for frictionally engaging a sheet of paper and feeding it in one .direct continuous'movement to a position wherein it is engageable by said gelatinized surface and said platen roll, means operatively connecting said feeding roll to said impression drum 1 to rotate it in synchronism therewith, and a movable member actuated in synchronism with said drum to bring said sheet of paper into frictional engagement with said feeding roll.

- a rotatable impression drum having a gelatinizedsurface, a platen *roll cooperating with said drum, a roll frictionally engageable with a sheet of paper and feeding it in one directcontinuous movement to a position wherein its forward position will be engaged by said gelatinized surface and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, means intermediate said feeding roll and said platen roll and engageable by both faces of said sheet of paper to guide it I to said platen roll and said drum, and a movable member actuated in synchronism with said drum for bringing said sheet of paper into frictional engagement with said feeding roll.

- a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, a roll frictionally engageable with a sheet of paper to feed it.

- an impression drum In a rotary duplicator, an impression drum, stub shafts carried by said drum, a hollowspindle carrying gelatin paper, a notch' formed in one end of the spindle, stub shafts upon-which the spindle is mounted, one of said shafts having a pin adapted to engage in the notch of the spindle, and a hinged gate supporting one of the shafts, for easy insertion and removal of the spindle.

- an impression drum a gelatin roll mounted in said drum, one end of said roll being carried by a movable gate, and a latch retaining the gate in closed position.

- a duplicating machine comprising a frame, an impression drum rotatably mounted in said frame and provided with a gelatinized surface, means to receive a manually fed sheet of paper at any time during more than half of each revolution of the drum, a stop member to prevent said sheet from advancing to said drum from said receiving means, means operating in synchronism with said drum to release said sheet at a predetermined point of the rotation of the drum and means operated in synchronism with said drum to pull said sheet from the gelatinized surface.

- a duplicating machine comprising a frame, an impression drum rotatably mounted in said frame and provided with a gelatinized surface,

- a stop member to prevent said sheet from advancing to said drum from said receiving means,' means operating in 'synchronism with said drum to engage said sheet in said receiving means and advance it to said drum at a predetermined point of the'rotation thereof, and means operated in synchronism with said drum to pull said sheet from the gelatinized surface'.

- a duplicating machine comprising aframe, an impression drum rotatably mounted in said inder mounted to rotate .engageable with the back and front ated in synchronismwith frame and provided with a gelatinized surface, means to receive a manually fed sheet of paper at any time during more than half of each revolution of said drum, a stop member to prevent said sheet from advancing to said drum from said receiving means, means operated in synchronism with said drum to release said means at a predetermined point of the rotation of the drum, means operated in synchronism with said drum to pull said sheet from the gelatinized surface, and power driven means for driving said drum.

- a duplicating machine comprising a rotatable impression drum provided with a gelatinized surface, means to feed a sheet oi paper thereto and a stripping drum to pull said sheet from said gelatinized surface and to hold it until said sheet leaves said gelatinized surface.

- a duplicating cylinder mounted to rotate on a horizontal axis, paper holding means disposed above said cylinder, said paper holding means including a stop against which the paper gravitates, means actuated in synchronism with the cylinder to release said paper, and means frictionally engaging said paper to feed it to leased.

- a duplicating cylon a horizontal axis, paper holding means disposed at a higher elevation than said axis, said paper holding means comprising a paper stop against which the paper gravitates, means actuated in synclironismwith said cylinder for releasing said paper from said stop, and means engaging said paper toadvance it to said cylinder when it is released.

- a duplicating cylinder mounted for rotation around a horizontal axis, paper holding means disposed above said cylinder, said paper holding means comprising a stop against which said paper gravitates, means actuated in synchronism with said cylinder to release said paper from said stop, and rollers surfaces of said paper to advance it to said cylinder when it is released.

- a duplicating cylinder mounted for rotation around a horizontal axis, paper holding means adjacent the upper side of said cylinder to receive manually fed sheets of paper, said paper holding means including astop against which said paper gravitates, means actusaid cylinder to release said paper from said stop, and means for advancing said paper to said cylinder when it is re leased.

- a duplicating cylinder having a horizontal axis of rotation, power said cylinder when it is redriven means for rotating said cylinder continuously for any desired number of revolutions, manua1ly fed means for holding a single sheet of paper, to be duplicated, in a predetermined position above said axis of rotation, said holding means including a stop against which said sheet of paper gravitates, and means operating in synchronism with said cylinder for releasing said sheet and feeding it to said cylinder.

- a duplicating machine comprising a frame, a drum rotatably mounted in said frame and carrying a flexible printing member, means for rotating the drum, a table, a feed roll-operated in synchronism with said drum for feeding sheets to be duplicated in one direct continuous movement to said drum, a stop member associated with the table between said drum and said feed roll, said sheets beingadvanced manually against said" stop member and between said table and said feed roll before they are advanced by said 'feed roll, a platen roll driven in synchronism with said drum for pressing said sheets into contact with said printing member, and means actuated in synchronism with said drum for stripping said sheets from said drum.

- a duplicating machine comprising a frame, a duplicating drum rotatably mounted in the frame, means for rotating said drum, a table over which sheets to be duplicated are advanced man-' ually one by one, a feed roll driven in synchronism with said drum for advancing said sheets theretoiinone direct continuous movement, a stop disposed between said feed roll and said drum, means for changing therelative positions of said stop and said table when said sheets are to be advanced by said feed roll, a platen roll driven in synchronism with said ing said sheets against said drum, and means actuated in synchronism with said drum for removing said sheets therefrom.

- a duplicating machine comprising a frame, a duplicating drum rotatably mounted in the frame, means for rotating-said drum, oppositely disposed feed rolls for advancing sheets to be duplicated to said drum in one direct continuous movement, means for driving .at least one of said rolls in synchronism with said drum, a table over which said sheets are advanced manually one by one to lie between said feed rolls, a stop between said feed rolls and said drum, means actuated in synchronism with said drum for changing the relative positions of said table and said stop when a sheet is to be advanced by said feed rolls, a platen roll driven in synchronism with said drum for. pressing said sheets against said drum and means actuated in synchronism with said drum for removing said sheets therefrom.

Landscapes

- Feeding Of Articles By Means Other Than Belts Or Rollers (AREA)

Description

Feb. 13, 1934. HR. LORENTZEN I 39,0532

DUPLICATOR I Original Filed March 25', 1926 10 Sheets-Sheet 1 Feb. 13, 1934. H. K. LORENTZEN a9,982

DUPLIGATOR Original Filed March 25. 1926' 10 Sheets-Sheet; 2

Feb 1934-. H. K. LORE-NTZEN IDUPLICATOR Original Filed March 25. 1926 1O Sheets-Sheet 3 Feb, 13, 1934 LORENTZEN Re. 19,082 I DUPLICATOR Original Filed March 25.; 1926 10 Sheets-Sheet 4 vz M'a Feb. 13, 1934.' D v H K"LOREINTZEN4 19,682

DUPLICATOR Original Filed March25. 1926 10 Sheets-Sheet 5 v Feb. 13, 1934.; H. K. LCRENTZEN Re. 19,082

DUPLICAT'OR Driginal Filed March 25, 1926 l0 Sheets-.Shee t 6 I Re. 19,082"

Feb. 13, 1934. H. K. LQRENTZEN DUPLICATOR Original Filed March 25, 1926 lb sheets-sheet 7 III/I 64. 1-168 anvwnvl oz' w Fel x 13, 1934. H. K. LORENTZEN DUPLICATOR Original Filed March 25, 19 26 10 Sheets-Sheet 8 Feb. 13, 1934. K. LQRENTZEN Re. 19,082-

' DUPLICATOH Origihal Filed l larch 25.1926 10 Sheets-Shoot 9 Ill! I l i I I z I I l |l l r v I \n/ Feb. 13, ,1934.

. H. K. LORENTZEN Re. 19,082

DUPLICATOR Original Filed March 25.1926 10 Sheets-Sheet 1o Reissued Feb. 13, 1934.

NT oFFlcE 19,082 v DUPLICATOB Hans K Lorentzen, New York, N. Y., assignor to Ditto Incorporated, a corporation of West Virginia Original No. 1,760,152; dated May 27, 1930, Serial No. 97,189, reissue May March 25, 1926. Application for 24, 1932. Serial No. 613,331

' 28 Claims. (01. 101-132) proved and simple means for feeding the blank sheets of paper into the machine in proper timed relation to the cycle of operation of the machine and further to' provide mechanism for smoothly pressing the sheets against the gelatinized surface.

Another feature of the inventionresides in the means for automatically stripping the sheets from the gelatinized surface and positively discharging them from the machine.

Other features are found in the arrangement of parts facilitating the adjustment and replacement of the gelatin rolls, as well as in the means for controlling the movement of the revolving drums.

While I have disclosed a preferred embodiment of the machine for purposes of illustration, it should be understood that the structure may be modified in various ways without departure from ,the true spirit and scope of the invention as hereinafter defined and claimed.

In the drawings;

Fig. 1 is an elevation of the right hand side of the machine;

Fig. 2 is an elevation of the machine;

Fig. 3 is a top plan view of the machine; I

Fig. 4 is a central verticalsection on the line 44 of Fig. 3;

Fig. 5 is an elevation of the right hand side of the impression drum and showsthe mechanism for securing the gelatin spindle rolls;

Fig. 6 is a horizontal section on the line 6-6 of Fig. 5, and shows the spindle securing mechanism inlocked position;

Fig. 7 is a view similar to Fig. 6 but shows one of the spindles removed and its pivot gate in unlocked position;

Figs. 8 to 11 are diagrammatic views of the impression drum and gelatin rolls mounted therein showing the procedure for interchanging the gelatin rolls;

Fig. 12 is a fragmentary view of the stripper drum;

Fig. 13 is a section taken on 12 and shows tioh;

Figs. 14 to 16 are detail views showing the manner of mounting the heads on the gripper fingers; Fig. 17 is a fragmentary view showing details of the feeding mechanism;

the left hand side of line 13-13 of Fig. the gripper fingers in open posi- Fig. 18 is a fragmentary section showing-the gripper fingers about to grip .the free end of the printed sheet;

Fig. 19 is a detail view showing the manner in which the gripper fingers grip the paper;

Figs. 20 to 22 are detail views of the clutch and brake mechanism;

Figs. 23 to 25 are detail views of one of the adjustable paper guides.

The framework of the machine includes two 66 side frames 10 connected by suitable tie members and carrying in journals the impression drum 11. The leftend of the impression drum carries the gear teeth 12 which mesh with teeth 13 formed on the stripper drum 14, the latter also being Journaled in the framework; The stripper drum is driven through a reduction gear 15 by an electric motor 16. 1

The impression drum is composed of two end members 17 and 18 and a peripheral surface 19 78 that extends over more than half of the circumference of the drum. The peripheral surface is covered by a layer of felt 20 to provide a cushion support for the gelatin paper 21. The gelatin paper after passing over the peripheral surface of the drum is carried around a guide roller 22 located at each end of the surface 19, and has one of its ends attached to the hollow delivery spindle 23 and its opposite end attached to the hollow receiving spindle 24. The end member 18 carries 86 studs 25 adapted to rotatably support one end of each of the spindles 23 and 24. The opposite ends of- spindles 23 and 24 are supported and rotated through studs 26 carried by pivoted gates 27 which are identically constructed and move about pivot 28. Each gate is biased to open position by a compression spring 29 and carries an angular projection 30 that limits the opening movement of the gate. The inner part of stud 26 carries a cross pin 31 for engaging notches 32 formed The outer end of the in the end of the spindle. stud is squared at 33 for cooperation with a detachable crank and carries a ratchet wheel 34. A

The inclined feed table 39 is attached to the up- 9 per part of the framework and carries at its lowerend an angular pocket 40 (Fig. 4) adapted to hold the sheets which are to receive the impressions. The 'shaft 41, which extends across the frame in front of pocket 40, carries the feed rolls 42 and is driven from stripper drum 14 by gearing arranged to give rolls 42 the same peripheral speed as that of the impression drum 11. The delivery chute 43, which is carried by shaft 44, has idler rolls 45 extending through its lower member 46 and has a curved upper guard member 4'7. An apron 48 is loosely supported on the member 46 and falls by'gravity against the sheets in the pocket.

A shaft 53 is mounted on the pivoted arms 54 andcarries the platen roller 55. Each of the arms 54 carries a stub shaft 55 on which is journaled a roller 56 cooperating with a cam 5'7 on the impression drum 11. A spring 58 tends to depress arms 54. I

During the operation of the machine-the top sheet of paper is lifted from the stack in'the pocket until it is free from the apron. It is then allowed to fall down over the apron into the delivery chute to the dotted line position 59. When the chute is in the position shown in Fig. 4 its lower end is closed by the surface 60 formed on the stationary guide 61. The chute is held in this position as long as roller 50 rides on the raised periphery of cam 51.. As the surface 19' of the impression drum approaches the platen roller, roller 5!) falls into the depressed portion of cam 51, and the chute is elevated to delivery position as. shownin' Fig. 17. In this position the idler rolls 45 press the sheet against feed rolls 42 which feed it through stationary guides 61 and 62 into contact with the platen roller. Just after the sheet has passed undr the platen roller the rollers 56 are allowed to descend by cams 5'7, thereby causing the platen roller to press the sheet against the gelatin paper on surface 19. It will be noted that-the delivery of the sheet is so timed that its forward edge projects beyond the gelatinized surface. It should further be noted that the paper is directed in such a manner that it first contacts with the platen roller which presses it evenly and positively against the gelatinized surface. This procedure avoids trapping air between the paper and the gelatinized surface of impression roll and insures an even impression.

. they project through openings 66 in the surface 65. The shaft 63 also carries loosely journaled thereon a plurality of-gripper fingers 6'7, the ends of which carry heads 68 universally pivoted thereon as shown in Figs. 1446. A spring 69 ,normally holds each gripper finger in the position shown in Fig. 4 with its head incontact with a surface '70, extending inwardly at an angle from the surface of the drum. The shaft carries a pin '71 adapted to engage the finger 6'7 upon certain movement of shaft and move the finger outwardly to the position shown in Fig. 18. An arm '72 is mounted on one end of shaft 63 and carries a roller '73 riding along a stationary cam 74 mounted on the framework of the machine.

After the sheet of paper has been rolled into 'contact with the impression drum it is carried by said drum until it reaches the position shown in Fig. 18, and meanwhile the stripper drum hasassumed the position illustrated. As the drums continue to rotate the roller '73 Titles down ofl the high part of cam '14, permitting springs 69 to close the gripping fingers upon the projecting end of,the sheet as hown in Fig. 19.

It shouldb'e noted that the snubbing member '75 provides a projecting ledge '76 which acts as a sart of snubbing post about which the sheet of paper is bent to give added firmness to the will carry the sheet along with it until the roller '73 again rides up the high part of the cam '74, thereby causing the gripper fingers to release the sheet and moving the gripper fingers outwardly to positively push the sheet from the stripper roll. This positive discharge of the sheet prevents its adhesion to the roll on account of static electricity or any other cause. The sheets are discharged into the pan '7'7." I

The motor 16 is connected to the driving gears by. a clutch. '78 of a conventional type which is controlled by lever '79. A second control lever 80 is pivoted on the opposite side of the frame and is connected to lever.'79,. so that the clutch can be operated from either side of the machine. A brake 81. is mounted on the outer end of the clutch shaft and is operated by a lever 82. A pin 83 is carried by lever '79 and is adapted to move lever 82 to braking position and to hold the lever in such position by engaging in a notch 84 formed gaged; while when it is in the other extreme position the brake is applied and locked in braking position. v

It will be understood that the matter to be reproduced is impressed upon-the gelatinized surface in a well-known manner. After a run has been made from one section of the gelatin paper it is desirable to bring a fresh section into position. In performing, this operation the brake is first applied and locked, thereby holding thedrums immovable. The pawl 35 controlling the delivery spindle 23 is then thrown out'of engagement with its ratchet the crank is applied to the shaft 33 'of receiving spindle 24, and the used portion of the gelatin paper is wound on to the receiving roll. stop rotation of spindle 23 and spindle 24 is further rotated to tighten the gelatin paper upon the drum. v

After all of the gelatin paper has been used over and has been wound onto the receiving roll,

as shown in Fig. 8, it becomes necessary to inter- 1 change the position of the rolls, if the gelatin paper is capable offurther use, or to insert a fresh roll. In order to facilitate this interchange alining and supporting brackets 84 and 85 are attached to the frame above the impression drum. Bracket 84 carries a stub 86 adapted to fit within the spindle and having a pin 8'7 adapted to en gage thenotches formed in the spindle, while bracket 85 carries a U-shaped saddle 88.

With the impression drum locked in the position illustrated in Fig. 8, the gate 2'7 holding the delivery spindle 23 in position is opened and this spindle is removed from the drum and the end of the paper is detached therefrom.- This spindle is now placed in the brackets 84 and 85. ,The spindle 24 carrying the paper thereon is now removed from the receiving position and is placed in the delivery position as shown-in Fig. 9. If

The pawl 35 is then returned to 19,082 necessary a fresh gelatin roll is placed in the dewhen the spindles are in the positions of Fig; 9 they are exactly parallel, and hence the paper will be properly alined upon the receiving spindle. The brake is now released and, the impression drum is moved by hand, rim 89 being provided for this purpose, in the reverse direction as'shown in Fig. 10 to lead the gelatin paper across-the surface of the drum. This reverse rotation is continued until the parts reach the position shown in Fig. 11, when the brake is again locked. The spindle on the alining brackets is now placed in the receiving position within the drum and the paper is tightened as previously explained.

The feed table 39 carries two paper guides 90 composed as shown in Figs. 23 to 25, of an L- shaped guide member 91, and a supporting arm 92. A spring arm 93 is adapted to ride in a guidej way 94 formed below the table and frictionally grip the table. To further improve the frictional grip a spring 95 is mounted on the framework of the machine and presses against the spring arm 93. The guide is thus accurately alined by the guide-way 94 and is frictionally held in any working position without the use of set screws or similar fastening devices.

It will'be clear from the above description that the duplicator is adapted to be rotated continuously by the electric motor, although it can be instantly stopped by movement of either lever 79 or lever 80. The sheets are fed by hand into the delivery chutewhich delivers them at exactly the proper time to the feed rolls, which are moving at the same peripheral speed as the impression drum. The feed rolls deliver the sheet to the platen roller which presses the paper evenly and with uniform pressure upon the'impression drum. As the impression drum rotates the projeci'ing end of the sheet is grasped by the gripper fingers and the sheet is smoothly pulled from the gelatinized surface of the impression drum and is carried around by the stripper drum until .the gripper fingers release the sheet and the stripper fingers positively discharge it from the stripper drum.

The construction of the impressiondrum provides for easy replacement and adjustment of the gelatin rolls, while the alining brackets insure even winding of the paper upon the receiving spindle.

I claim: i

1. In a rotary duplicator, an impression drum having a duplicating band, a platen roll cooperating with said drum, a roll feeding a sheet of paper in one direct continuous movement toward said drum to a position wherein it will be engaged by said duplicating band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a movable table, and means connected with said drum to operate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

2. In a rotary duplicator, an impression drum having a gelatine band, a platen roll cooperating with said drum, a roll feeding a sheet of paper in one direct continuous movement to a position wherein it will beengagedby saidgelatinemband and said platen roll, means operatively connecting said feeding roll to said impressiondrum to rotate it in synchronism therewith and in a'single direc- 3' tion, a movable table, and means connected with said drum to operate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

3. In a rotary duplicator, an impression drum having a gelatin band, a platen roll cooperating with said drum, a roll for feeding a sheet of paper in one direct continuous movementto a position wherein it will be engaged by said gelatine band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a tiltable table, and means connected with-said drum to operate in synchronism therewith for tilting said table to bring said sheet of paper into frictional engagement with said feeding roll.

4. In a rotary duplicator, an impression drum having'a gelatine band, a platen roll cooperating withsaid drum, a roll for feeding a sheet of paper in one direct continuous movement to a position wherein it will be engaged'by said gelatine band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith and in a single direction, a tiltable table, and means connected with said drum to operate in synchronism therewith for tilting said table to bring said sheet of paper into frictional engagement with said feeding roll.

5. In a rotary duplicator, a cylindrical impresa sion drum having an opening in its cylindrical surface, a gelatine band on said cylindrical surface, a platen roll cooperating with said drum, a roll for feeding a sheet of paper in one direct continuous movement to a position wherein its forward end will register with said opening while said drum is being rotated, said gelatine band and said platen roll being adapted to engage said sheet of paper when it is brought into said position, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a movable table, and means connected with said drum to operate in synchronismtherewith for displacing said table to bring said sheet of paper into fr'ctional engagement with said feeding roll.

6. In a rotary duplicator, a cylindrical impression drum having an opening in its cylindrical surface, a gelatine band on said cylindrical surface, a platen roll cooperating with said drum, a

roll for feeding a sheet of paper in one direct continuous movement to a position wherein its forward end will register with said opening while said drum is being rotated, said gelatine band and said platen roll being adapted to engage said sheet of paper when it is brought into said position, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a tiltable table, and means connected with said drum to nism therewith for tilting said table to bring said sheet of paper into frictional engagement with said feeding roll.

7. In a rotary duplicator, a cylindrical impression drum having an opening in its cylindrical surface, a gelatine band on said cylindrical surface, a platen roll cooperating with said drum, a roll frictionally engageable with a sheet of paper for feeding it in one direct continuous movement to a position wherein its forward end will register with said opening while said drum is being rotated, said gelatine band and said platen roll being adapted to engage said is brought into said position, means operatively connecting said feeding roll to said impression operate in synchrosheet of paper when it a platen roll and engageable by both faces of drum to rotate it in synchronism therewith,

means intermediate said feeding roll and said each of said sheets of paperflto guide them to said .platen roll and said drum, a movable table, and

means connected with said drum to rotate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

8. In a rotary duplicator, a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, a roll frictionally engageable with a sheet of paper to feed it in one direct continuous movement-tea position wherein its forward end will project beyond the gelatinized surface and it will be engageable by said gelatinized surface and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, means intermediate said feeding roll and said platen roll and engageable by both faces of said sheet of paper to guide it to said platen roll and drum, a movable table, and means operatively connected with said drum to rotate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll.

9. In a rotary duplicator, a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, means'having an axis of rotation, and frictionally engageable with a sheet of paper for feeding it in one direct continuous movement to a position wherein it will be engaged by said gelatinized surface and said platen roll, means operatively connecting said feeding means to said impression drumto actuate it in synchronism therewith, a movable table disposed beneath said feeding means, and means operatively connected with said drum to operate in synchronism therewith for displacing said table to bring said sheet of paper into frictional engagement with said feeding means.

10. In a rotary duplicator, an impression drum having a gelatinized surface, a feed roller actuated in synchronism with said impression drum and frictionally engageable with sheets of paper to feed them to said drum with their forward ends projecting beyond the gelatinized surface, and means for positively gripping the projecting ends of said sheets of paper and pulling solely on said endsto strip the sheets of paper from said gelatinized surface.

11. In airotary duplicator, a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, a roll for frictionally engaging a sheet of paper and feeding it in one .direct continuous'movement to a position wherein it is engageable by said gelatinized surface and said platen roll, means operatively connecting said feeding roll to said impression drum 1 to rotate it in synchronism therewith, and a movable member actuated in synchronism with said drum to bring said sheet of paper into frictional engagement with said feeding roll.

12'. In a rotary duplicator, a rotatable impression drum having a gelatinizedsurface, a platen *roll cooperating with said drum, a roll frictionally engageable with a sheet of paper and feeding it in one directcontinuous movement to a position wherein its forward position will be engaged by said gelatinized surface and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, means intermediate said feeding roll and said platen roll and engageable by both faces of said sheet of paper to guide it I to said platen roll and said drum, and a movable member actuated in synchronism with said drum for bringing said sheet of paper into frictional engagement with said feeding roll.

13. In a rotary duplicator, a rotatable impression drum having a gelatinized surface, a platen roll cooperating with said drum, a roll frictionally engageable with a sheet of paper to feed it.

in one direct continuous movement to a position wherein it will be engaged by said gelatine band and said platen roll, means operatively connecting said feeding roll to said impression drum to rotate it in synchronism therewith, a membe! against which the forward end of the paper abuts before the feeding operation, a movable table, and means operating in synchronism with said drum for displacing said table to bring said sheet of paper into frictional engagement with said feeding roll. w

14. In a rotary duplicator, an impression drum, stub shafts carried by said drum, a hollowspindle carrying gelatin paper, a notch' formed in one end of the spindle, stub shafts upon-which the spindle is mounted, one of said shafts having a pin adapted to engage in the notch of the spindle, and a hinged gate supporting one of the shafts, for easy insertion and removal of the spindle.

15. In a rotary duplicator, an impression drum, a gelatin roll mounted in said drum, one end of said roll being carried by a movable gate, and a latch retaining the gate in closed position.

16. A duplicating machine comprising a frame, an impression drum rotatably mounted in said frame and provided with a gelatinized surface, means to receive a manually fed sheet of paper at any time during more than half of each revolution of the drum, a stop member to prevent said sheet from advancing to said drum from said receiving means, means operating in synchronism with said drum to release said sheet at a predetermined point of the rotation of the drum and means operated in synchronism with said drum to pull said sheet from the gelatinized surface.

1'7. A duplicating machine comprising a frame, an impression drum rotatably mounted in said frame and provided with a gelatinized surface,

means to receive a manually. fed sheet of paper.

at any time during more than half of each revolution of the drum, a stop member to prevent said sheet from advancing to said drum from said receiving means,' means operating in 'synchronism with said drum to engage said sheet in said receiving means and advance it to said drum at a predetermined point of the'rotation thereof, and means operated in synchronism with said drum to pull said sheet from the gelatinized surface'.

the axis of the drum and.means operated in synchronism with said drum for pulling said sheet from said gelatinized surface.

19. A duplicating machine comprising aframe, an impression drum rotatably mounted in said inder mounted to rotate .engageable with the back and front ated in synchronismwith frame and provided with a gelatinized surface, means to receive a manually fed sheet of paper at any time during more than half of each revolution of said drum, a stop member to prevent said sheet from advancing to said drum from said receiving means, means operated in synchronism with said drum to release said means at a predetermined point of the rotation of the drum, means operated in synchronism with said drum to pull said sheet from the gelatinized surface, and power driven means for driving said drum.

20. A duplicating machine comprising a rotatable impression drum provided with a gelatinized surface, means to feed a sheet oi paper thereto and a stripping drum to pull said sheet from said gelatinized surface and to hold it until said sheet leaves said gelatinized surface.

21. In a duplicating machine, a duplicating cylinder mounted to rotate on a horizontal axis, paper holding means disposed above said cylinder, said paper holding means including a stop against which the paper gravitates, means actuated in synchronism with the cylinder to release said paper, and means frictionally engaging said paper to feed it to leased.

22. In a duplicating machine, a duplicating cylon a horizontal axis, paper holding means disposed at a higher elevation than said axis, said paper holding means comprising a paper stop against which the paper gravitates, means actuated in synclironismwith said cylinder for releasing said paper from said stop, and means engaging said paper toadvance it to said cylinder when it is released.

23. In a duplicating machine, a duplicating cylinder mounted for rotation around a horizontal axis, paper holding means disposed above said cylinder, said paper holding means comprising a stop against which said paper gravitates, means actuated in synchronism with said cylinder to release said paper from said stop, and rollers surfaces of said paper to advance it to said cylinder when it is released.

24. In a duplicating machine, a duplicating cylinder mounted for rotation around a horizontal axis, paper holding means adjacent the upper side of said cylinder to receive manually fed sheets of paper, said paper holding means including astop against which said paper gravitates, means actusaid cylinder to release said paper from said stop, and means for advancing said paper to said cylinder when it is re leased.

, 25. In a duplicating machine, a duplicating cylinder having a horizontal axis of rotation, power said cylinder when it is redriven means for rotating said cylinder continuously for any desired number of revolutions, manua1ly fed means for holding a single sheet of paper, to be duplicated, in a predetermined position above said axis of rotation, said holding means including a stop against which said sheet of paper gravitates, and means operating in synchronism with said cylinder for releasing said sheet and feeding it to said cylinder.

26. A duplicating machine comprising a frame, a drum rotatably mounted in said frame and carrying a flexible printing member, means for rotating the drum, a table, a feed roll-operated in synchronism with said drum for feeding sheets to be duplicated in one direct continuous movement to said drum, a stop member associated with the table between said drum and said feed roll, said sheets beingadvanced manually against said" stop member and between said table and said feed roll before they are advanced by said 'feed roll, a platen roll driven in synchronism with said drum for pressing said sheets into contact with said printing member, and means actuated in synchronism with said drum for stripping said sheets from said drum. 1

27. A duplicating machine comprising a frame, a duplicating drum rotatably mounted in the frame, means for rotating said drum, a table over which sheets to be duplicated are advanced man-' ually one by one, a feed roll driven in synchronism with said drum for advancing said sheets theretoiinone direct continuous movement, a stop disposed between said feed roll and said drum, means for changing therelative positions of said stop and said table when said sheets are to be advanced by said feed roll, a platen roll driven in synchronism with said ing said sheets against said drum, and means actuated in synchronism with said drum for removing said sheets therefrom.

28. A duplicating machine comprising a frame, a duplicating drum rotatably mounted in the frame, means for rotating-said drum, oppositely disposed feed rolls for advancing sheets to be duplicated to said drum in one direct continuous movement, means for driving .at least one of said rolls in synchronism with said drum, a table over which said sheets are advanced manually one by one to lie between said feed rolls, a stop between said feed rolls and said drum, means actuated in synchronism with said drum for changing the relative positions of said table and said stop when a sheet is to be advanced by said feed rolls, a platen roll driven in synchronism with said drum for. pressing said sheets against said drum and means actuated in synchronism with said drum for removing said sheets therefrom.

' HANS K. LORENTZEN.

drum for press

Publications (1)

| Publication Number | Publication Date |

|---|---|

| USRE19082E true USRE19082E (en) | 1934-02-13 |

Family

ID=2082916

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US19082D Expired USRE19082E (en) | Duplicator |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | USRE19082E (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2782713A (en) * | 1953-01-09 | 1957-02-26 | Standard Register Co | Tympan roll adjusting means for rotary printing mechanism |

| US5809881A (en) * | 1996-04-30 | 1998-09-22 | Heidelberger Druckmaschinen Ag | Form cylinder having a gap closed by a cover element having a roller mounted thereon |

-

0

- US US19082D patent/USRE19082E/en not_active Expired

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2782713A (en) * | 1953-01-09 | 1957-02-26 | Standard Register Co | Tympan roll adjusting means for rotary printing mechanism |

| US5809881A (en) * | 1996-04-30 | 1998-09-22 | Heidelberger Druckmaschinen Ag | Form cylinder having a gap closed by a cover element having a roller mounted thereon |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2374668A (en) | Printing press | |

| US4186662A (en) | Duplexing copying system | |

| US2915970A (en) | Inking and dampening means for an offset printing machine | |

| US2358284A (en) | Printing press | |

| USRE19082E (en) | Duplicator | |

| US3874290A (en) | Master plate feed and discharge device for duplicating apparatus | |

| US1954550A (en) | Duplicating device | |

| US2737109A (en) | Inking means for rotary direct printing lithographic duplicators | |

| US1760152A (en) | Duplicator | |

| US2220264A (en) | Intermittent sheet forwarding apparatus for duplicating machines | |

| US2034208A (en) | Duplicating apparatus | |

| US2051376A (en) | Duplicating mechanism | |

| US2021894A (en) | Device for attaching printing members on drums | |

| US2558157A (en) | Drum stop and gripper actuator for duplicating apparatus | |

| US1836764A (en) | Duplicator | |

| US1627663A (en) | Printing machine with changeable form | |

| US1968850A (en) | Inking mechanism for printing machines | |

| US3049076A (en) | Rotary lithographic multicolor printing machine | |

| US1960482A (en) | Feeding mechanism for rotary duplicators | |

| US2081386A (en) | Sheet feeding device for duplicators | |

| US2419345A (en) | Addressing machine and sheet feeding means therefor | |

| US2150744A (en) | Duplicating apparatus | |

| US1518959A (en) | Duplicating apparatus | |

| US2138682A (en) | Sheet margin stop for duplicators | |

| US2561015A (en) | Sheet feeding mechanism for printing presses |