US955152A - Hames-fastening device. - Google Patents

Hames-fastening device. Download PDFInfo

- Publication number

- US955152A US955152A US50665709A US1909506657A US955152A US 955152 A US955152 A US 955152A US 50665709 A US50665709 A US 50665709A US 1909506657 A US1909506657 A US 1909506657A US 955152 A US955152 A US 955152A

- Authority

- US

- United States

- Prior art keywords

- chain

- extensions

- buckle

- hook

- hames

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 244000105975 Antidesma platyphyllum Species 0.000 description 16

- 235000009424 haa Nutrition 0.000 description 16

- 239000002184 metal Substances 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 8

- 238000010276 construction Methods 0.000 description 2

- 238000004873 anchoring Methods 0.000 description 1

- 230000003190 augmentative effect Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B68—SADDLERY; UPHOLSTERY

- B68B—HARNESS; DEVICES USED IN CONNECTION THEREWITH; WHIPS OR THE LIKE

- B68B3/00—Traction harnesses; Traction harnesses combined with devices referred to in group B68B1/00

- B68B3/04—Horse collars; Manufacturing same

- B68B3/12—Locks therefor

Definitions

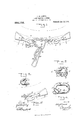

- the principal object of the present invention is to provide a simple, durable and efficient fastener for collar hames.

- Figure 1 is the front view of the fragmentary ends of hames, having a fastening device constructed in accordance with the present invention

- Fig. 2 is a top view of an anchoring hook constructed in. accordance with the present invention

- Fig. 3 is a top view of a buckle adapted to receive and hold a chain, and constructed in accordance with the present invention

- Fig. 4 is a longitudinal section of the same, enlarged and taken on the line lt in Fig. 3

- Fig. 5 is a front view of the fragmentary end of a hame, showing the hook employed in its shortened connection with the chain.

- the fastening for the hames has consisted most usually in a strap passed through loops on the lower end of the hames metal, while the upper end has been drawn together by cinch thongs.

- the hames metals 5-5 are bent around the ends of the hames to form recesses 66 to hold the body of the metal rings or loops 7-7.

- the loops 77 are of suflicient size and proper shape to receive a hook 8 and a buckle 9.

- the hook 8 is formed substantially as shown at Figs. 1 and 2 of drawings, being a ring flattened and bent upon itself to form hook-like extensions 10 and 11, which it is intended shall loop within the ring 7.

- the hook 8 is de signed to aid in adjusting the chain.

- extensions 10 and 11 are of diflerent lengths.

- the chain links are engaged by the shorter extension the chain is shorter between the loops 77 than when the chain is engaged by the extension 11, other connections remaining constant.

- the buckle 9 is designed to engage Specification of Letters Patent.

- the buckle is formed from any suitable metal, bent to form an eyelet l3 and parallel extensions 1l 1- as shown in Figs. 3 and 4t of the drawings.

- the extensions 14 lt are up-set and returned over the eyelet 13, and are separated to receive a tongue 15 and perforated to receive a hinge pin 16 upon which the said tongue is mounted.

- the tongue may be constructed from solid material; that preferred by me, however, is to form the same from sheet or plate metal, as shown in Fig. 4: of the drawings, striking the metal down to form side extensions 1717 which constitute the wings for the hinge pin 16 and adds rigidity and strength to the form of the tongue.

- the sides 17 also form a housing for a coiled spring 18, which is wound upon the pin 16, and the free end whereof bears against the under side of the tongue 15.

- the anchored end of the spring B is held by a suitable extension or bur 19, set out from one of the extensions 14:-14:. It will be seen that the construction of this buckle is exceedingly simple, requiring very little assembling and no fitting. It will be seen, also, that through the eyelet 13 may be passed the body of a chain, any of the links whereof may be threaded over the tongue 15 and be thereby securely held.

- the operation of securing the chain would be as follows: The chain is passed from the lower side of the buckle upward through the eyelet 13, and when sufiicient stress has been imparted to the chain to draw it taut through the buckle, the tongue 15 is permitted to seat within one of the links, thereby locking the chain firmly in position.

- the ring 7 or, if desired, any suitable form of chain link may be introduced.

- the tongue 15 is raised from the body of the buckle, 9, and inserted through the said ring or link.

- the extensions l4-14:- and tail piece 20 are then protruded from the said ring or link until the same is in position where it engages the double metal of the buckle below the extensions 1414 as shown at Fig. l of the drawings.

- Fig. 1 of the drawings the take-up device, which I may employ as an adjunct in tightening the chain of my hames fastener.

- This consists of a lever, which is formed from suitable rod metal to produce the end hook 21 and the middle hook 22.

- the hook 21 is formed at the one end of the rod from which this lever is constructed, while the hook 22 is formed from the other end of the rod.

- the position on the lever of the hook 22 is that produced by bending the rod to form a handle 23 after the rod has been extended through the loop of the chain 12 and at the end of the said chain.

- the rod is bent upon itself to form a cross section 24, which rests against the other section of the rod which carries the hook 21.

- hook 8 is formed of a size not adapted to pass through the buckle. The accidental separation of the chain and hook 8 is in this manner avoided.

- a hames fastening device comprising a buckle having an eyelet, two raised parallel and returned extensions contracted to engage a ring or link to be held thereby, and a tongue pivotally mounted between the said extensions and adapted to extend through the links of a chain to rest upon the forward bar of the said buckle.

- a hames fastening device comprising a buckle forming an eyelet adapted to receive the links of a chain, having raised parallel and returned extensions, the middle section whereof is contracted to engage a ring or link, a tongue pivotally mounted between said extensions and adapted to extend within the links of the said chain to rest upon the forward bar of the said eyelet, a hinge pin driven through perforations in the said extensions and said tongue, and a coiled spring mounted upon said hinge pin and adapted to seat the forward end of said tongue.

- a hames fastening device comprising a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper end thereof and the said eyelet to engage a ring or link to be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, and a coiled spring mounted upon said hinge pin and adapted to normally hold the said tongue against the said bar of said buckle.

- a hames fastening device comprising a hook formed from an elongated link bent upon itself to form extensions from the bent section of unequal length, a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper end thereof and the said eyelet to engage a ring or link and be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, a coiled spring mounted upon said hinge pin and adapted to normally hold the said tongue against the said bar of said buckle, and a link chain secured to the said hook and adapted to extend through the said buckle.

- a hames fastening device comprising a hook formed from an elongated link bent upon itself to form extensions of unequal lengths to receive a chain, a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper ends thereof and the said eyelet to engage a ring or link and be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, a coiled spring mounted upon said hinge pin and adapted to normally hold the said ton ue against the said bar of said eyelet, a link chain permanently secured to the said hook and adapted to extend through the said buckle, a lever having a hook located at the end thereof and a hook intermediate the ends thereof, both of said hooks being adapted to engage the links of the said chain, and means for connecting the said lever to the said chain.

- a hames fastening device comprising a hook formed from an elongated link bent upon itself to form extensions of unequal lengths to receive a chain, a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper ends thereof and the said eyelet to engage a ring or link and be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, a coiled spring mounted upon said pin and bearing against the tongue, a link chain secured to the said hook and adapted to extend 15 being adapted to engage the links of the said 20 chain.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Buckles (AREA)

Description

J. W. GONGE.

HAMES FASTENING DEVICE.

APPLICATION FILED JULY 9, 1909.

955,152. Pa ented Apr, 19,1910,

\ 'Tiq- 1 5' INVENTOI? "'11 fl WITNESSES T W 5 Jo/mh/ 01mm ATTORNEYS UNITED STATES PATENT OFFICE.

JOHN W. GONCE, OF CHATTANOOGA, TENNESSEE.

I-IAMES-FASTENING DEVICE.

To all whom it may concern:

Be it known that I, JOHN WV. GoNon, a citizen of the United States, and a resident of Chattanooga, in the county of Hamilton and State of Tennessee, have invented a new and Improved Hames-Fastening Device, of which the following is a full, clear, and exact description.

The principal object of the present invention is to provide a simple, durable and efficient fastener for collar hames.

One embodiment of the present invention is disclosed in the structure illustrated in the accompanying drawings, in which like characters of reference denote corresponding parts in all the views, and in which Figure 1 is the front view of the fragmentary ends of hames, having a fastening device constructed in accordance with the present invention; Fig. 2 is a top view of an anchoring hook constructed in. accordance with the present invention; Fig. 3 is a top view of a buckle adapted to receive and hold a chain, and constructed in accordance with the present invention; Fig. 4 is a longitudinal section of the same, enlarged and taken on the line lt in Fig. 3; and Fig. 5 is a front view of the fragmentary end of a hame, showing the hook employed in its shortened connection with the chain.

It is the desire of the hostler that the adjustment of the hames shall be easy, rapid and strong. Heretofore the fastening for the hames has consisted most usually in a strap passed through loops on the lower end of the hames metal, while the upper end has been drawn together by cinch thongs. In the present invention the hames metals 5-5 are bent around the ends of the hames to form recesses 66 to hold the body of the metal rings or loops 7-7. The loops 77 are of suflicient size and proper shape to receive a hook 8 and a buckle 9. The hook 8 is formed substantially as shown at Figs. 1 and 2 of drawings, being a ring flattened and bent upon itself to form hook- like extensions 10 and 11, which it is intended shall loop within the ring 7. The hook 8 is de signed to aid in adjusting the chain. For

this purpose the extensions 10 and 11 are of diflerent lengths. When the chain links are engaged by the shorter extension the chain is shorter between the loops 77 than when the chain is engaged by the extension 11, other connections remaining constant. The buckle 9 is designed to engage Specification of Letters Patent.

Application filed July 9, 1909.

Patented Apr. 19, 1910.

Serial No. 506,657.

the opposite ring 7, it being assembled therethrough only by intention. The buckle is formed from any suitable metal, bent to form an eyelet l3 and parallel extensions 1l 1- as shown in Figs. 3 and 4t of the drawings. The extensions 14 lt are up-set and returned over the eyelet 13, and are separated to receive a tongue 15 and perforated to receive a hinge pin 16 upon which the said tongue is mounted. The tongue may be constructed from solid material; that preferred by me, however, is to form the same from sheet or plate metal, as shown in Fig. 4: of the drawings, striking the metal down to form side extensions 1717 which constitute the wings for the hinge pin 16 and adds rigidity and strength to the form of the tongue. The sides 17 also form a housing for a coiled spring 18, which is wound upon the pin 16, and the free end whereof bears against the under side of the tongue 15. The anchored end of the spring B is held by a suitable extension or bur 19, set out from one of the extensions 14:-14:. It will be seen that the construction of this buckle is exceedingly simple, requiring very little assembling and no fitting. It will be seen, also, that through the eyelet 13 may be passed the body of a chain, any of the links whereof may be threaded over the tongue 15 and be thereby securely held.

With a buckle of the character described, the operation of securing the chain would be as follows: The chain is passed from the lower side of the buckle upward through the eyelet 13, and when sufiicient stress has been imparted to the chain to draw it taut through the buckle, the tongue 15 is permitted to seat within one of the links, thereby locking the chain firmly in position.

Between the extensions 14:1 and the body of the buckle 9, the ring 7 or, if desired, any suitable form of chain link, may be introduced. To mount the ring 7, or the said link of a chain, upon the buckle in the manner shown in the drawings, the tongue 15 is raised from the body of the buckle, 9, and inserted through the said ring or link. The extensions l4-14:- and tail piece 20 are then protruded from the said ring or link until the same is in position where it engages the double metal of the buckle below the extensions 1414 as shown at Fig. l of the drawings.

I have shown in Fig. 1 of the drawings the take-up device, which I may employ as an adjunct in tightening the chain of my hames fastener. This consists of a lever, which is formed from suitable rod metal to produce the end hook 21 and the middle hook 22. The hook 21 is formed at the one end of the rod from which this lever is constructed, while the hook 22 is formed from the other end of the rod. The position on the lever of the hook 22 is that produced by bending the rod to form a handle 23 after the rod has been extended through the loop of the chain 12 and at the end of the said chain. The rod is bent upon itself to form a cross section 24, which rests against the other section of the rod which carries the hook 21. By this engagement of the cross section 2a, the rigidity of the hook 22 is augmented. By means of this construction the lever is attached to the chain 12. In its operation it is placed substantially as shown in Fig. 1 of the drawings, wherein the hook 21 engages the chain between the hook 8 and the buckle 9 and wherein the hook 22 engages a convenient link of the chain to the free or loose side of the buckle 9 and tongue 15. In this position, by pulling the handle 23 toward the hook 8 there is exerted upon the chain 12 a force the strength of which is amplified by the leverage thus obtained.

I11 constructing and assembling the elements composing the hames fastener, the

hook 8 is formed of a size not adapted to pass through the buckle. The accidental separation of the chain and hook 8 is in this manner avoided.

Having thus described my invention, what I claim as new and desire to secure by Letters Patent is 1. A hames fastening device, comprising a buckle having an eyelet, two raised parallel and returned extensions contracted to engage a ring or link to be held thereby, and a tongue pivotally mounted between the said extensions and adapted to extend through the links of a chain to rest upon the forward bar of the said buckle.

2. A hames fastening device, comprising a buckle forming an eyelet adapted to receive the links of a chain, having raised parallel and returned extensions, the middle section whereof is contracted to engage a ring or link, a tongue pivotally mounted between said extensions and adapted to extend within the links of the said chain to rest upon the forward bar of the said eyelet, a hinge pin driven through perforations in the said extensions and said tongue, and a coiled spring mounted upon said hinge pin and adapted to seat the forward end of said tongue.

3. A hames fastening device, comprising a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper end thereof and the said eyelet to engage a ring or link to be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, and a coiled spring mounted upon said hinge pin and adapted to normally hold the said tongue against the said bar of said buckle.

4. A hames fastening device, comprising a hook formed from an elongated link bent upon itself to form extensions from the bent section of unequal length, a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper end thereof and the said eyelet to engage a ring or link and be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, a coiled spring mounted upon said hinge pin and adapted to normally hold the said tongue against the said bar of said buckle, and a link chain secured to the said hook and adapted to extend through the said buckle.

5. A hames fastening device, comprising a hook formed from an elongated link bent upon itself to form extensions of unequal lengths to receive a chain, a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper ends thereof and the said eyelet to engage a ring or link and be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, a coiled spring mounted upon said hinge pin and adapted to normally hold the said ton ue against the said bar of said eyelet, a link chain permanently secured to the said hook and adapted to extend through the said buckle, a lever having a hook located at the end thereof and a hook intermediate the ends thereof, both of said hooks being adapted to engage the links of the said chain, and means for connecting the said lever to the said chain.

6. A hames fastening device, comprising a hook formed from an elongated link bent upon itself to form extensions of unequal lengths to receive a chain, a buckle having an eyelet formed therein adapted to pass the links of a chain and provided with extensions raised above the said eyelet and returned forward over the same in parallel disposition, said extensions being contracted between the upper ends thereof and the said eyelet to engage a ring or link and be held thereby, a tongue pivotally mounted between said extensions and adapted to rest upon the forward bar of said buckle, a hinge pin adapted to be driven through perforations formed in said extensions and said tongue, a coiled spring mounted upon said pin and bearing against the tongue, a link chain secured to the said hook and adapted to extend 15 being adapted to engage the links of the said 20 chain.

In testimony whereof I have signed my name to this specification in the presence of two subscribing witnesses.

JOHN W. GONCE.

W'itnesses:

A. T. Moorun, EDGAR MOKENNEY.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US50665709A US955152A (en) | 1909-07-09 | 1909-07-09 | Hames-fastening device. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US50665709A US955152A (en) | 1909-07-09 | 1909-07-09 | Hames-fastening device. |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US955152A true US955152A (en) | 1910-04-19 |

Family

ID=3023556

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US50665709A Expired - Lifetime US955152A (en) | 1909-07-09 | 1909-07-09 | Hames-fastening device. |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US955152A (en) |

-

1909

- 1909-07-09 US US50665709A patent/US955152A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US955152A (en) | Hames-fastening device. | |

| US377709A (en) | Assighoe to him | |

| US342730A (en) | Safety-hook | |

| US708359A (en) | Harness-buckle. | |

| US404659A (en) | Swivel | |

| US187834A (en) | Improvement in harness-trimmings | |

| US182452A (en) | Improvement in buckles | |

| US504378A (en) | Trace or rein supporter | |

| US370031A (en) | Melancthon b | |

| US839809A (en) | Horse-collar. | |

| US509449A (en) | Harness-strap attachment | |

| US461848A (en) | Bag-fastener | |

| US741232A (en) | Spring attachment for straps. | |

| US300354A (en) | Latch-clasp for driving-reins | |

| US348186A (en) | burg-ess | |

| US923523A (en) | Curtain-fastener. | |

| US409939A (en) | Riveting-machine | |

| US863162A (en) | Hame-fastener. | |

| US306484A (en) | Hitching device | |

| US862782A (en) | Harness-loop. | |

| US628370A (en) | Strap-fastening. | |

| US913577A (en) | Winker-strap for bridles. | |

| US251862A (en) | Feed feazee | |

| US389471A (en) | Harness attachment | |

| US339022A (en) | Harness |