US3772636A - Connector - Google Patents

Connector Download PDFInfo

- Publication number

- US3772636A US3772636A US00218305A US3772636DA US3772636A US 3772636 A US3772636 A US 3772636A US 00218305 A US00218305 A US 00218305A US 3772636D A US3772636D A US 3772636DA US 3772636 A US3772636 A US 3772636A

- Authority

- US

- United States

- Prior art keywords

- plug

- socket

- reservoir

- electrical

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 34

- 239000002184 metal Substances 0.000 claims abstract description 18

- 229910052751 metal Inorganic materials 0.000 claims abstract description 18

- 239000007788 liquid Substances 0.000 claims description 17

- 238000003780 insertion Methods 0.000 claims description 6

- 230000037431 insertion Effects 0.000 claims description 6

- 238000000034 method Methods 0.000 claims description 4

- 229910001369 Brass Inorganic materials 0.000 claims description 3

- 239000010951 brass Substances 0.000 claims description 3

- 238000005260 corrosion Methods 0.000 claims description 3

- 230000007797 corrosion Effects 0.000 claims description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 2

- 229910052802 copper Inorganic materials 0.000 claims description 2

- 239000010949 copper Substances 0.000 claims description 2

- 238000005868 electrolysis reaction Methods 0.000 claims description 2

- 239000003921 oil Substances 0.000 description 9

- 229920001971 elastomer Polymers 0.000 description 5

- 239000003822 epoxy resin Substances 0.000 description 3

- 229920000647 polyepoxide Polymers 0.000 description 3

- 238000005476 soldering Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 1

- 229920001807 Urea-formaldehyde Polymers 0.000 description 1

- GZCGUPFRVQAUEE-SLPGGIOYSA-N aldehydo-D-glucose Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)[C@@H](O)C=O GZCGUPFRVQAUEE-SLPGGIOYSA-N 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000010688 mineral lubricating oil Substances 0.000 description 1

- 239000012811 non-conductive material Substances 0.000 description 1

- 239000003208 petroleum Substances 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- 229920001225 polyester resin Polymers 0.000 description 1

- 239000004645 polyester resin Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/52—Dustproof, splashproof, drip-proof, waterproof, or flameproof cases

- H01R13/523—Dustproof, splashproof, drip-proof, waterproof, or flameproof cases for use under water

Definitions

- ABSTRACT An underwater connector for connecting electrical cables consists of a plug and socket.

- the connector operates when it is oil filled, the socket having a reservoir in its body filled with oil with the opening of the body facing down, there is a metal depression in the reservoir connected to one cable.

- the plug has a hollow body and a metal projection connected to the other cable which fits into the socket body.

- This invention relates to connectors for use under water, more particularly it relates to connectors suitable for use in making electrical connections under water.

- a connector comprising a socket consisting of a rubber plug with holes passing through it. Part way down the holes electrical contact pieces are mounted which are joined to one end of the cable which is to be joined.

- the other portion of the connector comprises a plug having the same number of solid rubber cylinders projecting out of it as there are holes in the socket.

- the solid rubber cylinders have a slightly outwardly flared end and have electrical contact pieces mounted part way. along them, which contact pieces are connected to the other part of the cable which is to be joined.

- an electrical connector comprising a socket having a hollow reservoir open at one end and closed at the other, there being at least one depression in the closed end which depression contains an electrical contact piece adapted to be connected to a cable, and a plug containing at least one projecting member having an electrical contact mounted thereon adapted to be connected to a cable, and a reservoir with one opening adjacent the projecting member and a second opening at the other end of the reservoir so that when the plug is inserted into the socket the body of the plug fills the reservoir space of the socket and projecting member or members of the plug fit into the depression or depressions of the socket and make electrical contact therewith.

- the contact pieces of the socket are connected to one part of the cable to be joined and the socket is held with the opening of its reservoir facing down.

- a liquid lighter than water is floated up into the socket reservoir to fill the depressions in the reservoir and at least partly fill the reservoir.

- the connector pieces of the plug are connected to the other part of the cable to be joined and the plug inserted into the socket.

- the oil is forced through the opening in the plug reservoir adjacent the projecting member, and water is forced out of the other opening in the plug reservoir.

- the projecting members of the plug preferably have 6 a groove down their sides or a hollow channel, in-order to facilitate displacement of the oil as they are inserted into the depression into the socket.

- the projecting member of the plug is made of metal e.g. copper or brass and is connected to the cable using conventional means e.g. soldering.

- the depressions in 'the socket are preferably metal inserts in the form of hollow metal cylinders, into which the projecting metal members of the plug fit, the metal cylinders can be connected to the cable using conventional connection means e.g. soldering.

- the plug preferably has sealing rings round its outside in order to fit closely into the socket reservoir.

- the body of the socket and plugs can be made of any non conductive material e.g. an epoxy resin, a phenol formaldehyde resin -a urea-formaldehyde resin or a polyester resin.

- the plug can be held in place inthe socket by any suitable means e.g. a snap-fitting or by a band passing over the assembled'plug and socket.

- the liquid used in the connector can be any liquid lighter than water which is non conductive and immiscible with water e.g. a mineral lubricating oil.

- the socket 1 comprises an epoxy resin casing 2 having metal inserts 3 mounted and connected to cables 4 and reservoir space 5.

- the plug 6 comprises an epoxy resin casing 7 having a cable penetrator assembly 8 moulded into it.

- Two metal projection pieces 9 are fixed in casing 7 and connected to cable 10 through cable penetrator assembly 8.

- 0 rings 11 and 12 are mounted round plug body as shown.

- the reservoir 13 is open through openings 14 and 15.

- the gap A is the same in socket and plug.

- socket 1 In operation socket 1 is held vertical under water and an oil is floated up into it to fill socket reservoir space 5 and metal insert space 3.

- plug 6 When plug 6 is inserted oil is forced through opening 14 and forces water out through opening 15 till projections 9 fit into inserts 3 thus making an electrical connection.

- the connector is held assembled by band 16 passing over the connector.

- An electrical connector suitable for underwater use comprising a plug and a socket for the plug

- said socket having an internal space providing a reservoir for an electrically non-conductive liquid lighter than water, said reservoir being open at one end for insertion of said plug and being closed at the other end, there being at least one depression in said closed end, said depression containing an electrical contact member having provision for connection to an electrical cable, and

- said plug having at least one electrical contact member projecting from one end, said plug contact member having provision for connection to an electrical cable, and said plug also having an internal space providing a storage reservoir for liquid, a reduced diameter opening leading from one end of the plug reservoir to the exterior of the plug adjacent said projecting member and a second reduced diameter opening leading from the other end of the plug reservoir to the exterior of said plug at the corresponding end, said plug being of a configuration to enter and fill the socket reservoir, whereby, when the plug is inserted into the socket, the plug will force said electrically non-conductive liquid present in the socket reservoir through the opening adjacent the projecting member into the plug storage reservoir, and water present in the plug storage reservoir, will thereby be displaced and forced through the opening at the other end of the plug reservoir, out of the plug, and the electrical contact member projecting from the plug will fit into the depression in the socket and make electrical connection with the electrical contact piece in the depression.

- a method of reducing corrosion from electrolysis in the use of an electrical connector making an electrical connection under water between two electrical cables the connector having a plug and a a socket for the plug, the socket having an internal space providing a reservoir for a liquid open at one end for insertion of the plug and closed at the other end and having a depression in the closed end containing an electrical contact member, and the plug being of a configuration to enter and fill the socket reservoir and having an electrical contact member projecting from one end for insertion in the depression in the socket and a reservoir for liquid open at both ends, one of said cables being connected to the electrical contact member of the plug and the other to the electrical contact member of the plug, which method comprises: holding the socket below the water surface with the open end facing downwards, thereafter filling the socket reservoir with a water immiscible electrically non-conductive liquid lighter than water and then, while maintaining the downward facing position of the socket, inserting the plug in the socket, whereby the liquid lighter than water is forced from the socket reservoir into the open-ended plug reservoir and water in the plug reservoir is displaced

Landscapes

- Connector Housings Or Holding Contact Members (AREA)

Abstract

An underwater connector for connecting electrical cables consists of a plug and socket. The connector operates when it is oil filled, the socket having a reservoir in its body filled with oil with the opening of the body facing down, there is a metal depression in the reservoir connected to one cable. The plug has a hollow body and a metal projection connected to the other cable which fits into the socket body. When the plug is inserted into the socket the oil in the socket reservoir is forced into the reservoir in the plug body and electrical contact between the plug and socket is made without any water coming in contact with the electrical contact in the socket.

Description

Limited, London, England Filed: Jan. 17, 1972 Appl. No.: 218,305

[30] Foreign Application Priority Data Feb. 4, 1971 Great Britain 3,886/71 US. (:1. 339/117 R, 339/111 1111. c1 non 3/09 Field of Search 3397114 117,111,94;

h References Cited UNITED STATES PATENTS 11/1964 Lovitt et al 339/94 M X 6/1967 McLoad 339/117 R 10/1958 lmhof 339/117 R UX 3/1966 Phillips 339/117 RX O Unlted States Patent 1 3,772,636

Webb Nov. 13, 1973 [54] CONNECTOR 3,602,873 8/1971 Childers..... 339/117 R [75] Inventor: Alan David Webb, I-linchley Wood, FOREIGN PATENTS OR APPLICATIONS England 1,012,351 7/1957 Germany 339/94 R Assigneez Petroleum Company 1,1 Germany or R Primary Examiner-Marvin A. Champion Assistant Examiner-Lawrence J. Staab Attorney-George B. Finnegan, Jr. et al.

[5 7] ABSTRACT An underwater connector for connecting electrical cables consists of a plug and socket. The connector operates when it is oil filled, the socket having a reservoir in its body filled with oil with the opening of the body facing down, there is a metal depression in the reservoir connected to one cable. The plug has a hollow body and a metal projection connected to the other cable which fits into the socket body. When the plug is inserted into the socket the oil in the socket reservoir is forced into the reservoir in the plug body and electrical contact between the plug and socket is made without any water coming in contact with the electrical contact in the socket.

6 Claims, 1 Drawing Figure CONNECTOR This invention relates to connectors for use under water, more particularly it relates to connectors suitable for use in making electrical connections under water.

It is known to make electrical connections under water e.g. sea, using a connector comprising a socket consisting of a rubber plug with holes passing through it. Part way down the holes electrical contact pieces are mounted which are joined to one end of the cable which is to be joined. The other portion of the connector comprises a plug having the same number of solid rubber cylinders projecting out of it as there are holes in the socket. The solid rubber cylinders have a slightly outwardly flared end and have electrical contact pieces mounted part way. along them, which contact pieces are connected to the other part of the cable which is to be joined. When the connector is assembled the rubber clyinders of the plug fit into the holes in the socket and the two sets of contact pieces make an electrical connection. When the connection is made under water the flared end of the rubber cylinders of the plug force the water out of socket as the plug is inserted thus ensuring a dry contact.

However when it is desired to break contact the electric power in the circuit has to be switched off otherwise electrolytic action will take place causing corrosion. Thus the connector can not be left disconnected with the power still on. This drawback is particularly severe in under-sea operations.

I have now devised a connector which can reduce this difficulty.

According to the invention there is provided an electrical connector comprising a socket having a hollow reservoir open at one end and closed at the other, there being at least one depression in the closed end which depression contains an electrical contact piece adapted to be connected to a cable, and a plug containing at least one projecting member having an electrical contact mounted thereon adapted to be connected to a cable, and a reservoir with one opening adjacent the projecting member and a second opening at the other end of the reservoir so that when the plug is inserted into the socket the body of the plug fills the reservoir space of the socket and projecting member or members of the plug fit into the depression or depressions of the socket and make electrical contact therewith.

In making a connection under water the contact pieces of the socket are connected to one part of the cable to be joined and the socket is held with the opening of its reservoir facing down. A liquid lighter than water is floated up into the socket reservoir to fill the depressions in the reservoir and at least partly fill the reservoir.

The connector pieces of the plug are connected to the other part of the cable to be joined and the plug inserted into the socket. As the body of the plug enters the reservoir in the socket the oil is forced through the opening in the plug reservoir adjacent the projecting member, and water is forced out of the other opening in the plug reservoir. When the plug is fully inserted in the socket an electrical connection is made between the two connector pieces.

The projecting members of the plug preferably have 6 a groove down their sides or a hollow channel, in-order to facilitate displacement of the oil as they are inserted into the depression into the socket.

Preferably the projecting member of the plug is made of metal e.g. copper or brass and is connected to the cable using conventional means e.g. soldering.

The depressions in 'the socket are preferably metal inserts in the form of hollow metal cylinders, into which the projecting metal members of the plug fit, the metal cylinders can be connected to the cable using conventional connection means e.g. soldering.

The plug preferably has sealing rings round its outside in order to fit closely into the socket reservoir.

The body of the socket and plugs can be made of any non conductive material e.g. an epoxy resin, a phenol formaldehyde resin -a urea-formaldehyde resin or a polyester resin.

The plug can be held in place inthe socket by any suitable means e.g. a snap-fitting or by a band passing over the assembled'plug and socket.

The liquid used in the connector can be any liquid lighter than water which is non conductive and immiscible with water e.g. a mineral lubricating oil.

When the connector is connected and the assembled circuit is to be broken the plug is withdrawn and water flows in through the bottom opening in the plug reservoir and oil passes through the opening adjacent the projecting member of the plug into the reservoir in the socket, thus no water comes into contact with the electrically conductive parts of the socket so no electrolytic action can take place. If the contact is to be left broken for a considerable period then a dummy plug will normally be inserted in the socket.

There can be any number of electrical connections made using the connector of the present invention, depending on the number of projecting members and the corresponding depressions in the socket. For electric power there will normally be three connections though for use in communication systems there may be a different number.

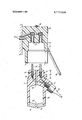

The invention will now be described with reference to the accompanying drawings which illustrate a crosssection through a plug and socket.

The socket 1 comprises an epoxy resin casing 2 having metal inserts 3 mounted and connected to cables 4 and reservoir space 5.

The plug 6 comprises an epoxy resin casing 7 having a cable penetrator assembly 8 moulded into it. Two metal projection pieces 9 are fixed in casing 7 and connected to cable 10 through cable penetrator assembly 8. 0 rings 11 and 12 are mounted round plug body as shown. The reservoir 13 is open through openings 14 and 15. The gap A is the same in socket and plug.

In operation socket 1 is held vertical under water and an oil is floated up into it to fill socket reservoir space 5 and metal insert space 3. When plug 6 is inserted oil is forced through opening 14 and forces water out through opening 15 till projections 9 fit into inserts 3 thus making an electrical connection. The connector is held assembled by band 16 passing over the connector.

Upon disengagement water flows through opening 15 and oil flows out of reservoir 13 through opening 14 into reservoir 5 and inserts 3, thus preventing water coming into contact with inserts 3.

I claim:

1. An electrical connector suitable for underwater use comprising a plug and a socket for the plug,

a. said socket having an internal space providing a reservoir for an electrically non-conductive liquid lighter than water, said reservoir being open at one end for insertion of said plug and being closed at the other end, there being at least one depression in said closed end, said depression containing an electrical contact member having provision for connection to an electrical cable, and

b. said plug having at least one electrical contact member projecting from one end, said plug contact member having provision for connection to an electrical cable, and said plug also having an internal space providing a storage reservoir for liquid, a reduced diameter opening leading from one end of the plug reservoir to the exterior of the plug adjacent said projecting member and a second reduced diameter opening leading from the other end of the plug reservoir to the exterior of said plug at the corresponding end, said plug being of a configuration to enter and fill the socket reservoir, whereby, when the plug is inserted into the socket, the plug will force said electrically non-conductive liquid present in the socket reservoir through the opening adjacent the projecting member into the plug storage reservoir, and water present in the plug storage reservoir, will thereby be displaced and forced through the opening at the other end of the plug reservoir, out of the plug, and the electrical contact member projecting from the plug will fit into the depression in the socket and make electrical connection with the electrical contact piece in the depression.

2. An electrical connector as claimed in claim 1 in which the projecting member of the plug is made of metal.

3. An electrical connector as claimed in claim 2 in which the metal is copper.

4. An electrical connector as claimed in claim 1 in which the projecting member or members have a groove in their side.

5. An electrical connector as claimed in claim 2 in which the metal is brass.

6. A method of reducing corrosion from electrolysis in the use of an electrical connector making an electrical connection under water between two electrical cables, the connector having a plug and a a socket for the plug, the socket having an internal space providing a reservoir for a liquid open at one end for insertion of the plug and closed at the other end and having a depression in the closed end containing an electrical contact member, and the plug being of a configuration to enter and fill the socket reservoir and having an electrical contact member projecting from one end for insertion in the depression in the socket and a reservoir for liquid open at both ends, one of said cables being connected to the electrical contact member of the plug and the other to the electrical contact member of the plug, which method comprises: holding the socket below the water surface with the open end facing downwards, thereafter filling the socket reservoir with a water immiscible electrically non-conductive liquid lighter than water and then, while maintaining the downward facing position of the socket, inserting the plug in the socket, whereby the liquid lighter than water is forced from the socket reservoir into the open-ended plug reservoir and water in the plug reservoir is displaced and forced out of the plug reservoir, and contact is made between the respective contact members in the plug and socket.

Claims (6)

1. An electrical connector suitable for underwater use comprising a plug and a socket for the plug, a. said socket having an internal sPace providing a reservoir for an electrically non-conductive liquid lighter than water, said reservoir being open at one end for insertion of said plug and being closed at the other end, there being at least one depression in said closed end, said depression containing an electrical contact member having provision for connection to an electrical cable, and b. said plug having at least one electrical contact member projecting from one end, said plug contact member having provision for connection to an electrical cable, and said plug also having an internal space providing a storage reservoir for liquid, a reduced diameter opening leading from one end of the plug reservoir to the exterior of the plug adjacent said projecting member and a second reduced diameter opening leading from the other end of the plug reservoir to the exterior of said plug at the corresponding end, said plug being of a configuration to enter and fill the socket reservoir, whereby, when the plug is inserted into the socket, the plug will force said electrically non-conductive liquid present in the socket reservoir through the opening adjacent the projecting member into the plug storage reservoir, and water present in the plug storage reservoir, will thereby be displaced and forced through the opening at the other end of the plug reservoir, out of the plug, and the electrical contact member projecting from the plug will fit into the depression in the socket and make electrical connection with the electrical contact piece in the depression.

2. An electrical connector as claimed in claim 1 in which the projecting member of the plug is made of metal.

3. An electrical connector as claimed in claim 2 in which the metal is copper.

4. An electrical connector as claimed in claim 1 in which the projecting member or members have a groove in their side.

5. An electrical connector as claimed in claim 2 in which the metal is brass.

6. A method of reducing corrosion from electrolysis in the use of an electrical connector making an electrical connection under water between two electrical cables, the connector having a plug and a a socket for the plug, the socket having an internal space providing a reservoir for a liquid open at one end for insertion of the plug and closed at the other end and having a depression in the closed end containing an electrical contact member, and the plug being of a configuration to enter and fill the socket reservoir and having an electrical contact member projecting from one end for insertion in the depression in the socket and a reservoir for liquid open at both ends, one of said cables being connected to the electrical contact member of the plug and the other to the electrical contact member of the plug, which method comprises: holding the socket below the water surface with the open end facing downwards, thereafter filling the socket reservoir with a water immiscible electrically non-conductive liquid lighter than water and then, while maintaining the downward facing position of the socket, inserting the plug in the socket, whereby the liquid lighter than water is forced from the socket reservoir into the open-ended plug reservoir and water in the plug reservoir is displaced and forced out of the plug reservoir, and contact is made between the respective contact members in the plug and socket.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB388671A GB1374812A (en) | 1971-02-04 | 1971-02-04 | Electrical connector |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3772636A true US3772636A (en) | 1973-11-13 |

Family

ID=9766729

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US00218305A Expired - Lifetime US3772636A (en) | 1971-02-04 | 1972-01-17 | Connector |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US3772636A (en) |

| FR (1) | FR2124261B1 (en) |

| GB (1) | GB1374812A (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3982812A (en) * | 1973-10-01 | 1976-09-28 | General Electric Company | Power cable separable connector having gasket means for restricting the flow of arc-generated gases therefrom |

| FR2502408A1 (en) * | 1981-03-17 | 1982-09-24 | Inst Francais Du Petrole | |

| US4363168A (en) * | 1979-06-16 | 1982-12-14 | Vo Offshore Ltd. | Method of forming an electrical connection underwater |

| US4553807A (en) * | 1983-03-31 | 1985-11-19 | Bicc Public Limited Company | Separable electrical connectors with fluid escape path |

| US4693540A (en) * | 1983-03-31 | 1987-09-15 | Bicc Public Limited Company | Pressure regulating devices |

| US5762481A (en) * | 1995-03-23 | 1998-06-09 | Nippondenso Co., Ltd. | In-tank type fuel pump |

| US6095838A (en) * | 1998-09-21 | 2000-08-01 | Brickett; Benjamin P. | Sliding bypass valve connector |

| US20050101172A1 (en) * | 2003-11-10 | 2005-05-12 | Ting Shi | Zero force socket for laser / photodiode alignment |

| US20100311260A1 (en) * | 2007-11-13 | 2010-12-09 | Martin Kahr Knudsen | Actuator System |

| US20110021049A1 (en) * | 2009-07-23 | 2011-01-27 | Teledyne Odi, Inc. | Wet mate connector |

| US20110034066A1 (en) * | 2009-08-05 | 2011-02-10 | Teledyne Odi, Inc. | Multiple layer conductor pin for electrical connector and method of manufacture |

| US20120149226A1 (en) * | 2010-12-13 | 2012-06-14 | Sumitomo Wiring Systems, Ltd. | Waterproof connector |

| US8968018B2 (en) | 2009-08-05 | 2015-03-03 | Teledyne Instruments, Inc. | Electrical penetrator assembly |

| US9263824B2 (en) | 2014-05-21 | 2016-02-16 | Stillwater Trust | Electrical connector having an end-seal with slit-like openings and nipples |

| US9673605B2 (en) | 2015-05-04 | 2017-06-06 | Pontus Subsea Connectors Llc | Boot seal |

| US9715068B2 (en) | 2015-06-30 | 2017-07-25 | Pontus Subsea Connectors Llc | Cable termination |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63136482A (en) * | 1986-11-27 | 1988-06-08 | 動力炉・核燃料開発事業団 | Connection in liquid and connector |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1012351B (en) * | 1955-10-01 | 1957-07-18 | Arno Fischer | Electric coupling device for making contact under water |

| US2857557A (en) * | 1953-03-06 | 1958-10-21 | Moser Glaser & Co Ag | High voltage substation |

| DE1114876B (en) * | 1960-08-20 | 1961-10-12 | Calor Emag Elektrizitaets Ag | Detachable connection for individual components that can be assembled like a plug |

| US3158680A (en) * | 1962-02-01 | 1964-11-24 | Gen Telephone & Electronies Co | Telephone cable system |

| US3241095A (en) * | 1962-10-29 | 1966-03-15 | Gray & Huleguard Inc | Sealed terminal structure |

| US3324449A (en) * | 1964-06-19 | 1967-06-06 | Schlumberger Technology Corp | Underwater electrical connections |

| US3602873A (en) * | 1969-02-13 | 1971-08-31 | Exxon Production Research Co | Underwater electrical connection station |

-

1971

- 1971-02-04 GB GB388671A patent/GB1374812A/en not_active Expired

-

1972

- 1972-01-17 US US00218305A patent/US3772636A/en not_active Expired - Lifetime

- 1972-01-25 FR FR727202399A patent/FR2124261B1/fr not_active Expired

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2857557A (en) * | 1953-03-06 | 1958-10-21 | Moser Glaser & Co Ag | High voltage substation |

| DE1012351B (en) * | 1955-10-01 | 1957-07-18 | Arno Fischer | Electric coupling device for making contact under water |

| DE1114876B (en) * | 1960-08-20 | 1961-10-12 | Calor Emag Elektrizitaets Ag | Detachable connection for individual components that can be assembled like a plug |

| US3158680A (en) * | 1962-02-01 | 1964-11-24 | Gen Telephone & Electronies Co | Telephone cable system |

| US3241095A (en) * | 1962-10-29 | 1966-03-15 | Gray & Huleguard Inc | Sealed terminal structure |

| US3324449A (en) * | 1964-06-19 | 1967-06-06 | Schlumberger Technology Corp | Underwater electrical connections |

| US3602873A (en) * | 1969-02-13 | 1971-08-31 | Exxon Production Research Co | Underwater electrical connection station |

Cited By (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3982812A (en) * | 1973-10-01 | 1976-09-28 | General Electric Company | Power cable separable connector having gasket means for restricting the flow of arc-generated gases therefrom |

| US4363168A (en) * | 1979-06-16 | 1982-12-14 | Vo Offshore Ltd. | Method of forming an electrical connection underwater |

| FR2502408A1 (en) * | 1981-03-17 | 1982-09-24 | Inst Francais Du Petrole | |

| DE3209727A1 (en) * | 1981-03-17 | 1982-10-07 | Institut Français du Pétrole, 92502 Rueil-Malmaison, Hauts-de-Seine | ELECTRICAL CONNECTOR CONNECTABLE IN LIQUID MEDIUM |

| AU568335B2 (en) * | 1983-03-31 | 1987-12-24 | Bicc Public Limited Company | Electrical connector |

| US4693540A (en) * | 1983-03-31 | 1987-09-15 | Bicc Public Limited Company | Pressure regulating devices |

| US4553807A (en) * | 1983-03-31 | 1985-11-19 | Bicc Public Limited Company | Separable electrical connectors with fluid escape path |

| US5762481A (en) * | 1995-03-23 | 1998-06-09 | Nippondenso Co., Ltd. | In-tank type fuel pump |

| US6095838A (en) * | 1998-09-21 | 2000-08-01 | Brickett; Benjamin P. | Sliding bypass valve connector |

| US20050101172A1 (en) * | 2003-11-10 | 2005-05-12 | Ting Shi | Zero force socket for laser / photodiode alignment |

| US7686521B2 (en) * | 2003-11-10 | 2010-03-30 | Finisar Corporation | Zero force socket for laser / photodiode alignment |

| US7980877B2 (en) | 2007-11-13 | 2011-07-19 | Linak A/S | Actuator system |

| US20100311260A1 (en) * | 2007-11-13 | 2010-12-09 | Martin Kahr Knudsen | Actuator System |

| US20110021049A1 (en) * | 2009-07-23 | 2011-01-27 | Teledyne Odi, Inc. | Wet mate connector |

| US7959454B2 (en) | 2009-07-23 | 2011-06-14 | Teledyne Odi, Inc. | Wet mate connector |

| US20110034041A1 (en) * | 2009-08-05 | 2011-02-10 | Teledyne Odi, Inc. | Electrical penetrator assembly |

| US20110034066A1 (en) * | 2009-08-05 | 2011-02-10 | Teledyne Odi, Inc. | Multiple layer conductor pin for electrical connector and method of manufacture |

| US8123549B2 (en) | 2009-08-05 | 2012-02-28 | Teledyne Instruments, Inc. | Multiple layer conductor pin for electrical connector and method of manufacture |

| US8287295B2 (en) | 2009-08-05 | 2012-10-16 | Teledyne Instruments, Inc. | Electrical penetrator assembly |

| US8968018B2 (en) | 2009-08-05 | 2015-03-03 | Teledyne Instruments, Inc. | Electrical penetrator assembly |

| US20120149226A1 (en) * | 2010-12-13 | 2012-06-14 | Sumitomo Wiring Systems, Ltd. | Waterproof connector |

| US8491323B2 (en) * | 2010-12-13 | 2013-07-23 | Sumitomo Wiring Systems, Ltd. | Waterproof connector |

| US9263824B2 (en) | 2014-05-21 | 2016-02-16 | Stillwater Trust | Electrical connector having an end-seal with slit-like openings and nipples |

| US9673605B2 (en) | 2015-05-04 | 2017-06-06 | Pontus Subsea Connectors Llc | Boot seal |

| US9715068B2 (en) | 2015-06-30 | 2017-07-25 | Pontus Subsea Connectors Llc | Cable termination |

Also Published As

| Publication number | Publication date |

|---|---|

| GB1374812A (en) | 1974-11-20 |

| FR2124261A1 (en) | 1972-09-22 |

| FR2124261B1 (en) | 1974-06-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3772636A (en) | Connector | |

| US3634806A (en) | Matched impedance connector | |

| US7731515B2 (en) | High voltage wet mateable electrical connector | |

| US7316593B2 (en) | Electrical connector with embedded canted coil spring | |

| US3173737A (en) | Connector with tab terminal latching means | |

| US4973262A (en) | Conduct member for electrical conductors | |

| EP0120714A2 (en) | Electrical connectors capable of withstanding great changes in ambient pressure and temperature | |

| US2742624A (en) | Electrical plug and socket assembly | |

| KR870010650A (en) | Cable tie terminal block | |

| CN104752888A (en) | Waterproof anti-interference socket electric connector | |

| CN110277703A (en) | A kind of oil sac pressure balance type underwater pluggable electric connector | |

| US3701074A (en) | Grounding receptacle | |

| SU1539865A1 (en) | Electric connector with zero mating effort | |

| CN102570168A (en) | Two-core high-voltage quick-locking connector | |

| US6402541B1 (en) | Electric connector using elements penetrating the insulation | |

| CN106532305B (en) | Electric connector with short-circuit function | |

| CN216120950U (en) | Waterproof wire harness | |

| CN106532355B (en) | A kind of short-circuit electric connector | |

| CN212934516U (en) | Plug-in circuit breaker convenient to operate | |

| CN112821125B (en) | Miniature waterproof connector with self-locking function | |

| CN211530246U (en) | Sealing connector with self-protection state | |

| KR890016709A (en) | Conductor member unlocking connector from conductor pin | |

| CN218548881U (en) | Waterproof connector convenient to change | |

| CN218849882U (en) | Micro-rectangular electric connector with integrated head and base | |

| US6386887B2 (en) | Connector provided with configurable contacts |