US3423922A - Twisting fibrous strands - Google Patents

Twisting fibrous strands Download PDFInfo

- Publication number

- US3423922A US3423922A US651092A US3423922DA US3423922A US 3423922 A US3423922 A US 3423922A US 651092 A US651092 A US 651092A US 3423922D A US3423922D A US 3423922DA US 3423922 A US3423922 A US 3423922A

- Authority

- US

- United States

- Prior art keywords

- strand

- package

- spindle

- forming

- fluid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000012530 fluid Substances 0.000 description 71

- 241001589086 Bellapiscis medius Species 0.000 description 36

- 239000004753 textile Substances 0.000 description 29

- 239000000463 material Substances 0.000 description 25

- 239000000835 fiber Substances 0.000 description 23

- 230000002441 reversible effect Effects 0.000 description 15

- 238000001035 drying Methods 0.000 description 14

- 238000000034 method Methods 0.000 description 14

- 238000004519 manufacturing process Methods 0.000 description 12

- 239000003365 glass fiber Substances 0.000 description 11

- 239000008267 milk Substances 0.000 description 10

- 210000004080 milk Anatomy 0.000 description 10

- 235000013336 milk Nutrition 0.000 description 10

- 239000000047 product Substances 0.000 description 7

- 238000000576 coating method Methods 0.000 description 6

- 230000007246 mechanism Effects 0.000 description 6

- 230000002093 peripheral effect Effects 0.000 description 6

- 239000011248 coating agent Substances 0.000 description 5

- 238000010276 construction Methods 0.000 description 5

- 238000005299 abrasion Methods 0.000 description 4

- 239000011230 binding agent Substances 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 229920006395 saturated elastomer Polymers 0.000 description 4

- 238000004804 winding Methods 0.000 description 4

- 230000002787 reinforcement Effects 0.000 description 3

- 230000000717 retained effect Effects 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 230000001427 coherent effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000002349 favourable effect Effects 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 1

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 241001125879 Gobio Species 0.000 description 1

- KVBYPTUGEKVEIJ-UHFFFAOYSA-N benzene-1,3-diol;formaldehyde Chemical compound O=C.OC1=CC=CC(O)=C1 KVBYPTUGEKVEIJ-UHFFFAOYSA-N 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 239000011651 chromium Substances 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 210000003128 head Anatomy 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000006060 molten glass Substances 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229920001084 poly(chloroprene) Polymers 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 239000005060 rubber Substances 0.000 description 1

- 239000000523 sample Substances 0.000 description 1

- 238000002791 soaking Methods 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 239000001993 wax Substances 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01H—SPINNING OR TWISTING

- D01H13/00—Other common constructional features, details or accessories

- D01H13/30—Moistening, sizing, oiling, waxing, colouring, or drying yarns or the like as incidental measures during spinning or twisting

- D01H13/306—Moistening, sizing, oiling, waxing, colouring, or drying yarns or the like as incidental measures during spinning or twisting by applying fluids, e.g. steam or oiling liquids

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01H—SPINNING OR TWISTING

- D01H1/00—Spinning or twisting machines in which the product is wound-up continuously

- D01H1/10—Spinning or twisting machines in which the product is wound-up continuously for imparting multiple twist, e.g. two-for-one twisting

- D01H1/105—Arrangements using hollow spindles, i.e. the yarns are running through the spindle of the unwound bobbins

- D01H1/106—Two-for-one twisting

Definitions

- This invention relates to method and apparatus for twisting strands or yarns made up of a plurality of fibers.

- this invention relates to twisting strands of continuous glass fibers wherein the strand is removed from the forming cake or package and twisted and then placed directly onto a serving package in a continuous operation without intermediate processing steps or handling as has been the case in the prior art.

- a beamer package is a very large serving package containing as many as 1,000 separate strands wound in parallel, side-by-side relationship onto a support core about 12 inches in diameter by about 54 inches long.

- a finished beamer package is about 32 inches in diameter and contains a great quantity of strands.

- a strand from a fiber forming package, wherein the strand has no twist is twisted, for strand coherency, and rewound from the forming package onto a serving package of, for example, a milk bottle-like shape.

- the coherent serving package strand is rewound onto the beamer package. It has not been possible to wind from the forming package directly to the beamer package and twist at the same time for necessary strand coherency.

- the first step, for imparting twist is a simple sounding operation. However, it involves an expensive tube drive twist frame wherein a plurality of packages are rotatably supported. Additionally, the tube drive twist frame contains an equivalent plurality of milk bottle build serving package spindles upon which tube cores are mounted to be rotatably driven while surrounded by an axially reciprocated ring and traveler mechanism to impart twist for coherency as the strand passes onto the core to produce the serving package.

- the tube drive twist frame suitably supports the forming package at the top on rotatable, cage-like cores that are individually driven. Each strand is passed tangentially off the rotating forming package and downwardly through a suitable tension device and then through the traveler of the ring and traveler device where twist is imparted 3,423,922 Patented Jan. 28, 1969 and thence onto the milk bottle build package core which is rapidly rotated.

- NECESSITY FOR PACKAGE ROTATION STRAND COHERENCY Due to the fact that a strand comprises 102 or more very fine fibers very delicately held together by the size, and without twist, coherency maintenance is a diflicult task in any rewinding operation.

- the speed at which the forming package can be rotated on the tube drive twist frame is limited.

- the forming package is a dynamically unstable mass and this prevents fast rotation and high speed strand pay out.

- twist frames of the tube-drive type which of course are more expensive than the free run tube type, because a separate drive mechanism is required to rotate each of the forming packages at a controlled rate of speed for uniformity of twist along the strand.

- strand Due to the unbalance of the package, strand will feed from one side more rapidly than from the other because of varying speeds of rotation between one side and the other caused by the unbalanced or heavier weight on the one side of the package. This causes loping or over run of the strand, producing slack. When the package slows down, the slack will be taken up suddenly and snap taut and often break. Also, loping often produces slack in the serving package and this develops loops in the finally plied yarn. At the point of the loop, within the yarn, the yarn strength is substantially nil.

- a forming package as freshly made, is wet or saturated with liquid size and contains a high moisture content.

- the size is required to hold the fibers of the strand together for enough coherency for the rewind and twist operation. To be elfective, however, the size must be dried to a degree to bring out its adhesive character to very lightly bond the fibers together, else there will be no strand form, and just a mass of fibers.

- the drying that is necessary to produce the strand coherency causes bonding of the strands to one another at least to a degree. Since the strand is laid on in nearly side-by-side turns, the turns tend to adhere to one another. Over end take-oif abrasion pulls the strands apart.

- the forming cake is a compact mass, inherent in the fact that it is formed of fibers that are under attenuating tension. This factor also contributes substantially to strand-to-strand adherence. Over end take-off abrasion thus pulls the strands apart.

- a forming cake has either a cylindrical or barrel build exterior that adds difficulty as regards over end take-off.

- the exterior is cylindrical and this inhibits over end take-off because the strand will rub over the surface.

- barrel build packages the outside surface is of generally arcuate axial contour and the strand will rub over the surface even more severely than encountered with fiat build packages.

- German Patent 572,050 dated Mar. 10, 1933, FIGURE 2 of the drawings Attention is called to German Patent 572,050 dated Mar. 10, 1933, FIGURE 2 of the drawings. It will be noted that the German patent spins the package. This is possible because that package is a dynamically balanced mass, as distinguished from a glass fiber forming cake, and also is tapered so that both over end feed-off and inside-out feed are apparently possible.

- a further object is to provide a method of processing continuous glass fiber strand from a forming cake to a serving package such as milk bottle package with a greater amount of twist and at greater processing speeds on a more economical basis.

- a further object is to provide apparatus for rewinding and twisting strand from glass firber forming packages at high speed, wherein the forming package is retained in a stationary condition, thereby avoiding the defects of lopping, snapping with strand breakage, and looping of the prior art.

- a further object is to provide apparatus for rewinding and twisting strands of continuous glass fibers from the forming package directly to a serving package on a continuous basis, where the package is held stationary.

- a further object is to provide method and apparatus for rewinding and twisting strands of continuous glass fibers from the forming package by removing the strand from the inside of the package, whereby outside, over-end processing difficulties are avoided by an inside-out takeoff.

- a further object is to provide method and apparatus for rewinding from a forming cake, and twisting and plying, all in a continuous manner, and using inside-out takeoff.

- a further object is a method and apparatus for producing a twisted textile product with fluid applied to it by withdrawing textile material from the inside of a stationary package through a fluid and subsequently imparting twist to it.

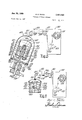

- FIGURE 1 is a vertical sectional view of an inside-out twister of the present invention schematically feeding to a beamer package, using a fiat build forming cake, from a glass fiber forming operation;

- FIGURE 2 is a sectional view of an inside-out twister of invention, illustrating use of the twister with a barrel build package from a glass fiber forming operation, and

- FIGURE 2a is an enlarged, fragmentary, sectional view more clearly showing the orifice cap

- FIGURE 3 is a sectional view of a third construction of the present invention wherein a vortex-like throat is used for strand take-off from the package to provide smooth, high speed and more straight-line flow to even further facilitate fiber feed-off from the cylindrical interior surface of a glass fiber forming cake;

- FIGURE 4 is an elevational view, partly in section, of an inside-out twister as shown in FIGURE 1, feeding strand to a conventional milk bottle build serving package and illustrating substitution of the present invention onto a conventional twister frame in place of the tube drive;

- FIGURE 5 is an elevational view, partly in section, of an inside-out twister wherein the package is submerged in a fluid and a twisted strand leaving the twister with fluid applied to it passes through a drying or curing zone prior to winding the strand into a package on a take-up unit;

- FIGURE 6 is an elevational view, partly in section, of apparatus wherein the package is submerged in a fluid and an untwisted strand with the fluid applied to it passes through a drying or curing zone prior to winding the strand into a package on a take-up unit.

- the present invention provides novel method and apparatus for high speed processing of continuous glass strands from a forming cake directly onto a serving package with application of suflicient twist for strand coherency, which has not heretofore been done.

- two turns of twist are given to the strand for each revolution of the rotating portion of the apparatus.

- the strand is withdrawn from the inside of a stationary package, e.g. forming package, and passed through a passageway in a whirling spindle to an outlet region whirling with the spindle to impart one turn of twist for each spindle revolution.

- the second turn is added by directing the strand to follow a path in the reverse direction upon its exit from the outlet region to a point beyond the zone of strand withdrawal and rotating the reverse direction path of the traveling strand in balloon fashion about the zone of strand withdrawal, viz. the package.

- Subsequent operations may include the application of the so twisted strand directly onto a beamer package along with up to 1,000 other similarly processed and twisted strands; or alternately the passing of the so twisted strand to a second twisting operation such as a conventional ring and traveler mechanism for producing a serving package of the milk bottle build type or other.

- high speed strand processing is provided with a simplified mechanism by virtue of the fact that the forming cake remains stationary and thus the dynamic unbalanced forces inherent therein are nullified and effectively removed from the system. Further, over end strand abrasion and take-off problems are avoided.

- strand coherence, forming package compactness and density are factors which have been effectively nullified and effectively removed from the system by the manner in which the fibers are taken out of the forming package by a novel inside-out feed.

- the strand is given suflicient twist for coherency.

- suflicient twist for coherency.

- the strand after first being removed from the inside of the forming cake or package is directed in a reverse manner around the package as a balloon to provide the Second of the two twists.

- the twisted strand can be alternately followed, without interruption, by subsequent twisting as by a ring and traveler mechanism, giving added twist in a single pass through rewinding equipment.

- the numeral represents a flat build forming package typical of the glass fiber forming art. This is made by attenuating a plurality of streams of molten glass that exude from a heated b ushing. Attenfllation of the streams produces fibers of filaments that are gathered together, just after application of a liquid binder and size, into a single strand.

- the strand is wound wet and at high speed upon a rapidly rotated, moisture-resistant forming tube.

- the rotated forming tube provides the force for attenuation of the glass streams into the very small diameter fibers making up the strand.

- the flat build is effected by a constant traverse the full length of the package.

- the so-produced forming package is highly saturated with moisture and is a mobile mass that is not self-supporting. It therefore requires drying to a suflicient degree to render it self-supporting so that the forming tube can be removed for the inside-out processing.

- the drying process need only be carried just far enough to render the package self-supporting.

- the residual moisture can be tolerated by the present invention.

- the forming package 10 is held stationary within the novel twister 12 of the present invention.

- the twister 12 is suitably supported at the creel height position of a rewinding frame. Any suitable support can be used.

- the numeral 14 represents a suitable support member to which a bracket 16 is fastened as by welds 18.

- the twister 12 is mounted to the top of bracket 16 by bolts 20.

- Twister 12 includes a base member 22 that has a thrust bearing socket 24 and an axial bearing 26 in alignment therewith.

- the bearing members 24 and 26 are formed at the opposite ends of a tubular body portion 28.

- the bolts 20 are passed through the foot of the base member 22 to attach the twister 12 to the bracket 16.

- a spindle 30 is rotatably mounted on the base member 22.

- the spindle 30 includes a shaft 32 coaxial within a tubular drive whorl 34.

- the shaft 32 turns in the bearings 24 and 26.

- a belt 36 wraps the whorl 34 in driving relationship.

- the bottom of the whorl 34 has a retainer flange 35 to hold the belt 36 in driving relationship.

- the upper part of the spindle 30 includes a coaxial strand guide tube 38.

- a strand outlet passage or region 40 extends between the bottom of the strand guide tube 38 and the periphery of the spindle 30, terminating beneath the peripheral, upturned, highly polished flange 42 which serves as a strand feed-off lip.

- the strand guide tube 38 has a smooth outside contour and serves to journal a package support 44.

- the package support 44 is of annular construction and includes a fiber forming package support basket 46 and a weight chamber 48.

- the outer wall 50 is cylindrical at the top at the basket 46 portion, and tapers inwardly around the weight chamber 48 to cradle within the flange 42 of spindle 30.

- a weight 52 is secured within the Weight chamber 48. This keeps the forming package 10 stationary.

- the spindle 30 is mounted at a vertical inclination of about 20 or so to make this possible.

- a transverse wall 54 separates the weight chamber 48 from the package support basket 46 and forms a bottom upon which the package 10 rests.

- the package support 44 stands still while the tube 38 and spindle 30 rotate to balloon the strand as indicated at 69.

- a conventional tensioning device is positioned either within the strand guide tube 38 or within the outlet passage 40, in this and subsequent embodiments of the invention.

- the package 10 is simply lowered by gravity into the support basket 46 to load the device.

- a disc 60 is formed around the top of the tubular wall 56 of the package support 44.

- the disc 60 has grooves 62 provided around the periphery to slidably receive a traveler 64.

- the traveler is of loop-like structure of highly polished metal for low friction. Enough clearance is provided between the inside of the traveler and the disc 60 to freely pass the strand 66 in guiding relationship.

- a strand 66 is found on the inside of the package and threaded through the traveler 64 and then downwardly through the strand guide tube 38 as by a small feed tube with air or using other probe device. This strand 66 is pulled out through the strand outlet passage 40 and its direction is reversed to proceed upwardly by balloon 69 to guide eye 68.

- Twist is imparted to the strand at two zones.

- One twist for each revolution of the spindle 30 is given to the strand between its entrance into the strand guide tube 38 and the strand outlet passage 40.

- the second twist for each revolution of the spindle is imparted as the strand is rotated with the spindle 30 in balloon fashion about the zone of strand withdrawal from the package 10, viz. the package 10.

- a twisted strand 67 is thus formed having two turns imparted to it for each revolution of the spindle 30.

- the number of twists-per-inch can be controlled by the linear speed of the strand in relation to the r.p.m. of the spindle, e.g. the slower the linear strand speed for a given spindle r.p.m. the greater the number of twists-per-inch given to the strand.

- the twisted strand 67 is directed to a tension disc 70, from which it passes to a beamer pressure roll 72.

- a suitable guide not shown, the twisted strand is directed over the pressure roll 72 and thence onto the beamer package 74.

- the beamer package 74 includes a beam tube 76 that is carried upon the beam 78 of a collet 80.

- the collet 80 is connected to a gear motor or the like for rotation.

- FIGURE 1 The showing of FIGURE 1 regarding the beamer package is somewhat schematic for clarity.

- a beamer package is normally held on gudgeons or sub-shafts which fit on the driving head of the beamer frame, and either one or both ends of the beamer may be power driven. In the event only one end is driven, the other end is supported in a suitable anti-friction bearing.

- twister 12 In the present description of the beamer operation, it is to be understood that only one twister 12 is shown. In actual production of a beamer package, up to 1,000 strands 66 would be supplied. Also, as many twisters 12 would be used, one for each strand 66. These are necessary to fill a typical beamer package because the core is about 54 inches long and a finished package size could have an outside diameter of about 32 inches.

- a suflicient twist is provided to the strand to round up the multiple fibers forming the strand.

- the strand is properly tensioned at 70 as it passes from the balloon 69 to the beamer package 74.

- the speed of. rotation of the spindle 30 is synchronized to beamer take-up speed. For example, two turns per inch can be put into the strand 66 at approximately 3,000 r.p.m. of the spindle 30 and at a beamer take-up rate of about 250 feet (or 3,000 inches) per minute. This is the same rate of throughput as produced by the tube drive twist frames today at good r.p.m.

- an advantage of the invention is that there is no intermediate handling between forming package and beamer package. Therefore, on a time basis the production should be substantially increased because of the lack of intermediate handling, including loading and end finding.

- one beamer and a thousand twisters of the invention would be equivalent to approximately ten 100 spindle tube drive frames.

- capital investment is reduced because the ring and traveler set-ups as shown at the bottom of FIGURE 4 which were required by the prior art for the belt driven milk bottle serving package are not used in accordance with the present invention.

- tube drive mechanisms necessary.

- Beamer output by the present invention is therefore more economically favorable than the prior art method of making a serving package and then rewinding th serving package onto the beamer.

- the lack of rotation of the forming packages as at the bottom of FIGURE 4 also has a favorable effect on power consumption.

- FIGURE 1 A beamer package operation has been illustrated in FIGURE 1.

- the extended scope of the invention would include the production of serving packages on the order of standard textile cone packages, or other, containing enough twist to provide strand coherency and thus avoid loss of ends by ringers stripping out.

- This type of package could be used to serve strands for paper reinforcement operations and the like.

- a package of this type desirably has a high rate of feed out, on the order of 3,000 feet per minute using conventional rewinding equipment. This is clearly possible by using the principles of the present invention.

- a suitable traverser In producing cone-type serving packages, a suitable traverser will be employed, commensurate with the processing speed utilized. Generally a rapid traverse for crisscross lay produces higher rate strand feed out. If desired, however, a slow traverser can be used and a substantially parallel wind produced. This involves more costly spools but is satisfactory for some customers.

- the weight 52 has been shown in FIGURE 1 as the means by which the forming package 10 is retained in a stationary position, the broad scope of the invention would include permanent magnets to perform this function.

- the balloon 69 will circle through an air gap between the vertically mounted spindle 30 and the outward magnet of a cooperating pair.

- a disc 60 and traveler 64 have been illustrated in FIG- URE 1. However, the equivalent in the nature of a fiier, as will be evident to those skilled in the art, also can be used.

- FIGURE 1 Vortex-like strand guide on tube 38

- a disc and traveler 60, 64 are used to feed the strand 66 off the inside wall of the package 10 to the interior of strand guide tube 38 whereby it is guided through the spindle 30 and out the strand outlet region passage 40.

- This is particularly useful for packages where substantial strand-to-strand coherence is present as either by highly adhesive binders or perhaps by unduly drying the cake to more firmly set the size and binder.

- the present embodiment provides another means by which strand feed out from the package can be effected, where the package build will permit it.

- this embodiment may be used.

- Less parallel wind helps reduce the strand-to-strand adherence.

- the less parallel wind produces a more nearly crisscross lay of the strands in the package,

- a glass that pulls with less tension tends to produce a less compact package.

- a high lubricant binder will contribute to easier strand release after the package is dried sufficiently to become self-supporting.

- a low friction guide element 82 is fitted over the top end of the strand guide 38.

- This may comprise a highly polished and hard chromium plated member or other suitably made member such as of phenolic resin.

- the guide 82 is of annular shape and the wall is of a tear drop construction to provide a rounded top edge 84 for free strand flow over the unit and into the guide tube 38.

- the guide 82 is of course accurately balanced for vibration-free rotation on top of the strand guide tube 38.

- the length of the strang guide tube 38 has been illustrated in FIGURES 1 and 2 as positioning the upper end at about the middle of the forming package or 86. This provides approximately radial strand take off at least on an average, from the inside of the package. However, this may be subject to variation depending upon the characteristics of the strand in the package being processed.

- FIGURE 2 it will be evident that the wall 56 has been foreshortened and disc 60 removed, to make room for the guide member 82.

- BARREL BUILD PACKAGE This embodiment also illustrates application of the principles of the present invention to a barrel build package 86, FIGURE 2.

- This package 86 is characterized by sloping ends 38 as distinguished from the square ends of the flat build package 10 of FIGURE 1. This package is formed by a decreasing traverse sweep as will be evident from the shape of the package.

- annular insert 90 may be used. This has a tapered inside wall and can be inserted into the inside of wall 50 to cradle the lower end of the package 86.

- the high speed processing of a barrel build package by the inside out route provides a substantial contribution to the art, and avoids the prior art difficulties.

- the weight chamber 94 of the package support 95 is made a little longer to embrace enough of the shortened strand guide tube 96 or appropriate bearing support thereon.

- the package basket portion 98 is essentially the same length as that shown in FIGURES l and 2 because the package 10 is of the same size.

- the transverse wall 100 is provided centrally with the vortex-like throat 92 and thus is distinguishable from the transverse wall 54 of FIGURES 1 and 2.

- the forming package of either the flat build type 10, as shown in FIGURE 3, or the barrel build type 86, as shown in FIGURE 2, is supported within the annular wall 50 and is held in place by gravity.

- a weight 52 cooperates with the tilt of the spindle 30 to hold the forming package 10 against rotation.

- a tension device of known configuration is provided either in the strand guide tube 96 or outlet passage 40, as mentioned above.

- the strand 66 is drawn into the smooth and highly polished vortex-like throat 92 without whipping action.

- the polished, aerodynamic contour of the throat reduces friction with the strand. Further, the smooth vortexlike throat 92 lets air flow through in an aerodynamic 10. manner. The draw of air is produced by whirling spindle 30 and thus the throat 92 facilitates its flow.

- the effect of this free-flowing air through the throat 92 is to provide an air bearing-type lubrication to the strand 66 and substantially facilitates its easy flow through the equipment.

- the strand 66 balloons at 69 and enters a strand guide 106.

- strand 66 from a forming cake 10 is non-rotatably positioned as at the creel level of a twist frame.

- the strand 66 is provided with a 2 for l twist at guide 106 after which it is fed down to a milk bottle build serving package 102, at which point it is provided with a third twist.

- This embodiment of the invention therefore provides twist at three zones in a continuous operation, taking the strand from the forming package 10 and pulling it direct 1y onto the serving package 102 without intermediate handling or processing by human hands.

- the numeral 104 would represent a support member of a twister frame or the like, to which the bracket 16 is welded at 18. This provides support for the twister 12 of the invention.

- the strand 66 feeds from inside out as described rela tive to FIGURE 1 and balloons at 69. From the balloon 69 the strand enters a first guide ring 106 and then proceeds to a second guide ring 108. From the second guide ring 108 the strand proceeds to a conventional ring and traveler twister 110 that includes a third guide ring 112.

- nip rolls 114 which are driven at appropriate speed.

- the strand 66 is run between the rolls 114 which provide the linear moving force for the strand.

- Twister 110 comprises a spindle support bearing 116 fastened in a support plate 118.

- a spindle 120 is journaled in bearing 116 and has a flat belt pulley 122 over which a belt 124 laps in driving relation.

- the upper end of the spindle 120 is configured to receive a package tube or core 126.

- a ring 128 is mounted on a vertically movable support 130.

- a traveler 132 operates in grooves formed in ring 128.

- the ring and traveler 128, 132 reciprocate along the axis of the package core 126, while the strand 66 is fed through the guide loop 112 and then through the traveler 132 onto the core to produce the package 102 by rotation of the core.

- Rotation of the package 102 causes the traveler 132 to whirl on ring 128 with the rotation of the package and impart turns per inch in accordance with the lineal speed of the strand onto the package and the rotational speed of the package.

- Regulated axial movement of the ring and traveler 128, 132 builds the package 102 to suitable external profile.

- Twist is imparted to the strand at three zones.

- the first twist is given to the strand as the strand speeds through strand guide tube and turns to enter the outlet passage or region.

- the second twist is applied.

- the twisted strand moves through the nip rolls 114 and onto the package 102 a third twist is applied.

- the triple twist approximately triples the rate of production as compared to the prior art tube drive twist frames.

- FIGURE 1 This application of the invention actually highlights the invention as shown in FIGURE 1, by showing the milk bottle serving package that was formerly produced to then be fed to a beamer. This was the old 2-step operation.

- FIGURE 5 illustrates one such system where a strand 131 is withdrawn from the inside of the forming package submerged in a fluid 152 and processed into a strand 137, which is twisted and has fluid applied, by a twister 140', the strand 137 passes through a drying or curing zone 185 and collects as a wound package 191 by a constant strand tension take-up unit 190.

- the twister 140 is a suitably supported unit that includes two main components, a package support unit 142 and a spindle unit 160.

- the twister 140 may include a twister cover 170.

- the spindle 160 as illustrated is a one-piece unit mounted for rotation about its longitudinal axis.

- the upper portion of the spindle 160 includes a strand guide tube 162 having a cylindrical strand guide passageway 163.

- the lower portion of the spindle 160 comprises a solid shaft 164.

- Intermediate the ends of the spindle 160 is a laterally extending circular flange portion 165.

- the strand guide passageway 163 opens at the upper end of the spindle 160, i.e. strand guide tube 162, and extends the midportion of the spindle 160.

- the passageway 163 extends along the axis of rotation of the spindle 160 to a point near its end to where it turns to terminate as a strand outlet region on the surface of the spindle 160 just above the circular flange portion 165.

- a small rotatably mounted sheave or roller 166 At the exit or outlet region of the strand guide passageway 163 is a small rotatably mounted sheave or roller 166 to guide the exit of the strand that passes through the passageway 163.

- An outlet arrangement such as outlet passage 40 shown in FIGURES 1 through 4 or the like may be used.

- the spindle 160 is mounted for rotation about its longitudinal axis, i.e. axis of rotation, by a mounting that includes a bracket 172 and a tubular member 173.

- the solid shaft 164 extends through the tubular member 173 and turns in the bearings 175 and 176 located at the ends of the tubular member 173.

- the mounting arrangement as shown is disposed to support the spindle 160 at a vertical inclination, e.g. degrees.

- the spindle 160 is driven in rotation.

- a whirl 177 is appropriately secured to the end of the solid shaft 164.

- a belt 178 laps the whirl 177.

- Suitable means such as an electric motor moves the belt 178 and whirl 177 to drive the shaft 164, i.e. the spindle 160.

- the forming package support unit 142 is substantially a cylindrical container with a cover 143 that fits across its open end.

- the package support unit 142 includes two compartments or chambers, a package support basket or container 145 and a weight chamber 147.

- the package support basket or container 145 is located above the weight chamber 147 and is separated therefrom by a transverse wall 146 forming the bottom for the package support basket 145.

- a tubular portion 148 extends up from the base of the package support unit 142 through the weight chamber 147 and into the package support basket 145. As shown,

- the tubular portion 148 extending into the support basket 145 has along its length a laterally extending circular flange 149.

- the flange 149 is fashioned with grooves 153 about its periphery to slideably receive a traveler 154, the arrangement being a strand guide.

- the traveler 154 is normally a loop-like structure of highly polished metal for low friction. Other suitable strand guide arrangements may be employed.

- the package support unit 142 is mounted on the spindle 160 over the strand guide tube 162.

- the guide tube 162 extends into the tubular portion 148. Because the strand guide tube 162 and the tubular portion 148 turn on bearings 156 and 157, the package support unit 142 is rotatable on the spindle 160.

- the package support unit 142 is kept steady and is not rotated.

- the package support unit 142 is kept from rotating by a weight 158 that is secured within the chamber 147

- Secured to the upper end of the tubular portion 148 of the package support unit 142 is a die 180 for removing excess fluid from the strand. While the die 180 is shown in the preferred arrangement secured to the end of the tubular portion 148, other suitable arrangements may be employed such as having the die 180 rotate with the spindle 160 by mounting it to the upper end of the strand guide tube 162.

- the die 180 has a passageway 181 through which strand is passed and that is aligned with and communicates with the strand outlet passageway 163.

- the surface of the die 180 is curved and smooth such as a highly polished metal or the like for low friction.

- the package support basket 145 of the package support unit 142 is adapted to hold the fluid 152 such as an impregnant or coating that is to be applied to the textile material, e.g. strand. Enough fluid is kept in the support unit 142 to submerge the package 10 in the fluid when the package 10 is in proper position in the unit 142. It is preferable to maintain the level of the fluid 152 below the entrance of the passageway 181 of the die 180.

- the fluid 152 such as an impregnant or coating that is to be applied to the textile material, e.g. strand.

- Enough fluid is kept in the support unit 142 to submerge the package 10 in the fluid when the package 10 is in proper position in the unit 142. It is preferable to maintain the level of the fluid 152 below the entrance of the passageway 181 of the die 180.

- the embodiment illustrated in FIGURE 5 provides preferably that the tubular portion 148 and strand guide tube 162 extend upwardly enough to position the die 180 above the upper end surface of the positioned package 10. In this manner the package 10 may be submerged in the fluid 152 and the entrance to the die passageway 181 may be positioned above the fluid level.

- the cover 143 fits over the open end of the support unit 142 to close that end and keep the fluid 152 within the support basket 145.

- the package support basket 145 may be loaded and threaded on or off the spindle 160.

- the package 10 when the illustrated twister operates, the package 10 is in the fluid 152 within the support basket and the strand 131 is withdrawn from the inside of the package.

- the strand is directed through the traveler 154 and thence through the passageway 181 of the die 180 into the strand guide passageway 163.

- the spindle is rotating and the basket 145 is stationary.

- the strand is turned on the small roller 166 and subsequently proceeds to a second small roller or sheave 168, which is illustrated appropriately secured to the upper surface of the flange 165.

- the roller 168 rotates on the flange with the spindle 160.

- the path of the strand exiting the outlet region of the strand guide passageway 163 is in a direction reverse to the strand path in the passageway 163.

- twister cover 170 When the twister 140 is covered as by twister cover 170, the strand leaves the apparatus via an opening 183 located at the top of the cover 170. If the twister 140 is not covered,

- the strand may be passed through a guide such as the guide eye 68 illustrated in FIGURES 1 and 2.

- the strand 137 has had the fluid 152 applied to it and is twisted. A two for one twist is imparted to the strand as hereinbefore described where the package support unit 142 is maintained stationary and the spindle 160 rotates. Because the package is in the fluid 152, the strand has the fluid applied to it within the package support basket 145. Any excess fluid applied to the strand is removed as the strand passes through the die 180.

- the strand 137 is passed through a drying or curing zone 185. As illustrated, the strand 137 is turned over a roller or sheave 186 prior to entering the Zone 185.

- the zone 185 may be a conventional thermal oven, a dielectric oven or the like to suitably dry the fluid 152, or, in the case of a resin, cure the fluid resin 152.

- the strand 137 is withdrawn from the zone 185 by cooperating rollers 187 and 188 that are driven by apparatus (not shown) at a substantially constant rpm.

- the rollers 187 and 188 feed the winding apparatus.

- the strand 137 is collected as a wound package 191 on a suitable take-up or winder unit such as a constant strand tension take-up unit 190 known in the textile art.

- a suitable take-up or winder unit such as a constant strand tension take-up unit 190 known in the textile art.

- the strand 137 passes across a sheave 192 on the end of a pivotly mounted tension arm 193.

- the tension arm 193 is operably connected to apparatus within the unit 190 that is responsive to variations instrand tension to control the rotational speed of the package 191 to maintain a substantially unifirm strand tension feed to the take-up unit.

- the strand of the package 10 may be presaturated with fluid which may be in addition to normal size material, may be applied to the individual fibers of the strand or to the strand itself at the fiber-forming position to permeate the strand with the fluid prior to winding the strand as a package.

- the package 10, which may comprise either fluid saturated or nonsaturated strand may be put into a fluid for a period of time as in the support basket 145 and allowed to soak.

- the fluid into which the package is introduced may be the same or a different fluid. This soaking provides prolonged exposure to the fluid.

- the dried package may be subsequently placed in the same type or a type of diflferent fluid, i.e. impregnant or coating.

- the strand of the dried package may be initially impregnated at a fiber forming position or perhaps soaked in a fluid. Further, the second fluid may be a top coating for the strand.

- the twister cover 170 employed with the twister 140 controls the ballooning of the strand withdrawn from the rotating portion of the apparatus, especially at high twister r.p.m.s and high linear strand speeds.

- the cover 170 restrains the path of the strand to its inside surface.

- the cover 170 may be made of any suitable nonporous material such as a light metal, it may be foraminous and further may merely be a series of segments such as wire members spaced from each other that are close enough to provide control or regulation of the strand path forming the balloon. In the latter instance, because air passes over the wet strand as the twister 140 rotates, the fluid is assisted to dry on the strand more rapidly. Further, heat might be imparted to the wire members such as by resistance heating to assist drying or curing of the fluid on the strand.

- the cover 170 may be held on the spindle 160 in any suitable manner. As illustrated in FIGURE 5, a ring 171 is positioned about the periphery of the flange portion 165. The outer peripheral surface of the ring 171 has a groove 174 into which a raised head portion 179 fits to hold the cover 170 securely on the spindle 160.

- FIGURE 6 illustrates an embodiment of apparatus that applies fluid to a strand without imparting twist to it.

- the strand is Withdrawn from the inside of a forming package or the like and the package is submerged in a fluid, e.g. impregnant or coating, that is held in a container 200.

- a fluid e.g. impregnant or coating

- the strand with the fluid applied to it passes through a drying zone and wound onto a take-up unit as a wound package 191 as illustrated in the apparatus of FIGURE 5.

- the container 200 holds the forming package 10 and the fluid 152.

- the container 200 is substantially tubular and has a bottom 202 and is adapted to receive a cap or cover 201.

- the cover 201 fits over the open end of the container 200.

- the container 200 is stationarily mounted and does not rotate. As shown, the container 200 may be mounted vertically; the container 200 may be mounted with a vertical inclination, e. g. 20 degrees.

- a strand guide arrangement is mounted in the container 200 and assists removal of the strand from the inside of the package 10.

- the arrangement as illustrated includes an upper ring 206 and a somewhat smaller lower ring 208.

- the upper ring 206 is supported by a support member including rigid rods 208 that extend upwardly from the bottom 202.

- the lower ring 207 is supported from above by support member including rods 209 that extend below the ring 206.

- the upper ring 206 is located about the middle of the forming package 10.

- the container 200 holds the fluid 152, which may be of any suitable character.

- the level of the fluid is preferably above its upper surface.

- the cap or cover 201 includes a die 211 for removing excess fluid and has a die passageway 212.

- the die 211 is preferably positioned in the cover 201 on the longitudinal axis of the container 200. When the cap is so positioned, the strand is more easily withdrawn from the container 200.

- the strand 131 is withdrawn from the inside surface of the package 10 through the fluid 152 to pass over the top of the upper ring 206 and thence vertically downwardly outside and under the lower ring 208.

- the strand 131 is drawn under the ring 208 upwardly and out of the fluid 152 and thence through the die passageway 212, excess fluid being removed from the strand 131.

- the strand 131 may have a somewhat oval or flat cross section.

- the strand 131 with fluid applied to it passes through a drying or curing zone 185 and collects on a constant strand tension take-up unit 190 as a wound package 191 in a manner that has been discussed in relation to the apparatus shown in FIGURE 5.

- a false twister 214 of conventional construction may be positioned before or after the drying zone 185. When a false twister 214 is employed, the strand 131 is rounded up, eliminating any oval or flat cross section the strand may have.

- the apparatus as disclosed herein may be used with all types of fluids, e.g. impregnants and coatings. These may include, but are not limited to, lattices, e.g. resorcinol formaldehyde latex, neoprene based rubbers, polyvinyl chloride, waxes and the like.

- fluids e.g. impregnants and coatings.

- coatings may include, but are not limited to, lattices, e.g. resorcinol formaldehyde latex, neoprene based rubbers, polyvinyl chloride, waxes and the like.

- the spindle of all embodiments shown has been illustrated as being power driven. This imparts uniform twist through the running length of the strand. Within the scope of the invention, however, the spindle can be free running. This will produce reinforcement-type strands where uniformity of twist along the length of the strand is of lesser consequence and where strand integrity is a more important factor.

- the spindle can be driven or free running.

- Constant strand pull overcomes loping, looping and strand breakage inherent in rotating forming package processing. The package is held still.

- Apparatus for producing a twisted textile product with fluid applied to it comprising:

- container adapted to support the outer peripheral surface of a package placed therein for removal of the textile material from the inside of the package

- a rotatably mounted spindle having a passageway therein for directing the textile material withdrawn from such package to an outlet region laterally disposed from the axis of rotation of the spindle outside the container;

- a die member for removing excess fluid from the textile material having a passageway communicating with the passageway of the spindle;

- Apparatus for producing a twisted textile product with fluid applied to it comprising:

- container adapted to support the outer peripheral surface of a package placed therein for removal of the textile material from the inside of the package

- a rotatably mounted spindle the container rotatably mounted on the spindle, the spindle having a passageway therein for directing the textile material withdrawn from such package to an outlet region laterally disposed from the axis of rotation of the spindle outside the container;

- die member for removing excess fluid from the textile material having a passageway communicating with the passageway of the spindle;

- Apparatus for producing a twisted textile product with fluid applied to it comprising:

- a container for holding a tubular strand package in a fluid the container adapted to support the outer peripheral surface of the package placed therein for removal of the strand from the inside surface of the package, the container including a hollow projection portion extending lengthwise therein;

- a rotatably mounted spindle the container rotatably mounted on the spindle wtih a portion of the spindle extending into the hollow projection portion, the spindle having a passageway therein for the strand withdrawn from such package, the passageway terminating at an outlet region on the surface of the spindle laterally disposed from the axis of rotation of the spindle outside the container;

- the die member at the end of the hollow projection portion in the container for removing excess fluid from the strand, the die member having a die passageway communicating with the passageway of the spindle;

- Apparatus as recited in claim 4 including means for drying the fluid on the strand after the strand leaves the outlet region.

- Apparatus as recited in claim 4 including means rotating with the spindle enclosing the container and outlet region and having an opening for withdrawal of the strand.

- Apparatus for producing a twisted textile product with fluid applied to it comprising:

- a container for holding a tubular strand package in a fluid the container adapted to support the outer peripheral surface of a package held therein for removal of the strand from the inside surface of the package; the container including a tubular portion extending lengthwise therein;

- a rotatably mounted spindle the container rotatably mounted on the spindle with a portion of the spindle extending into the tubular portion, the spindle having a passageway therein for the strand withdrawn from such package, the passageway extending lengthwise in the spindle and turning to terminate at an outlet region on the surface of the spindle laterally disposed from the axis of rotation of the spindle outside the container;

- a die member for removing excess fluid from the strand disposed at the end of the tubular portion in the container, the die member having a passageway communicating with the passageway of the spindle;

- a method of producing a twisted textile product with fluid applied to it comprising:

- a method of producing a twisted textile product with fluid applied to it comprising:

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Spinning Or Twisting Of Yarns (AREA)

Description

Jan. 28, 1969 R. E. SMITH TWISTING FIBROUS STRANDS Sheet Filed June 19, 1967 INVENTOR, For E 5M/7'h 2 BY 2 2 )6 ,4

Jan. 28, 1969 R. E. SMITH 3,423,922

TWISTING FIBROUS STRANDS Filed June 19, 1967 Sheet 2 of 5 Willi/Z414 INVENTOR. Roy E 5M/7'H W QMJM,

Jan. 28, 1969 R. E. SMITH TWISTING FIBROUS STRANDS Sheet Filed June 19, 1967 INVENTOR. A L. SM/fi/ ATTORNEYS United States Patent 3,423,922 TWISTING FIBROUS STRANDS Roy E. Smith, Toledo, Ohio, assignor to Owens-Corning Fiherglas Corporation, a corporation of Delaware Continuation-impart of application Ser. No. 427,051, Jan. 21, 1965. This application June 19, 1967, Ser. No. 651,092 U.S. CI. 5735 12 Claims Int. Cl. D01h 1/10, 13/30 ABSTRACT OF THE DISCLOSURE A method and apparatus producing a twisted textile material that gives two twists to the material for every revolution of the rotating portion of the apparatus. The material is withdrawn from the inside of a stationarily held package and is first twisted along a given path and then reversed to a zone beyond the zone of withdrawal of the material. In the reverse path, the material is rotated about the zone of material withdrawal to impart the second twist.

This application is a continuation-in-part, of my copending application Ser. No. 427,051, filed Jan. 21, 1965, now abandoned.

This invention relates to method and apparatus for twisting strands or yarns made up of a plurality of fibers.

More particularly, this invention relates to twisting strands of continuous glass fibers wherein the strand is removed from the forming cake or package and twisted and then placed directly onto a serving package in a continuous operation without intermediate processing steps or handling as has been the case in the prior art.

THE PROBLEM A beamer package is a very large serving package containing as many as 1,000 separate strands wound in parallel, side-by-side relationship onto a support core about 12 inches in diameter by about 54 inches long. A finished beamer package is about 32 inches in diameter and contains a great quantity of strands.

Due to its size it will be evident that this is a high cost item.

In the prior art, beamer packages of strands of continuous glass fibers have been made by a two-step process that has contributed substantially to the cost.

In a first step, a strand from a fiber forming package, wherein the strand has no twist, is twisted, for strand coherency, and rewound from the forming package onto a serving package of, for example, a milk bottle-like shape.

Then in a second step the coherent serving package strand is rewound onto the beamer package. It has not been possible to wind from the forming package directly to the beamer package and twist at the same time for necessary strand coherency.

The first step, for imparting twist, is a simple sounding operation. However, it involves an expensive tube drive twist frame wherein a plurality of packages are rotatably supported. Additionally, the tube drive twist frame contains an equivalent plurality of milk bottle build serving package spindles upon which tube cores are mounted to be rotatably driven while surrounded by an axially reciprocated ring and traveler mechanism to impart twist for coherency as the strand passes onto the core to produce the serving package.

The tube drive twist frame suitably supports the forming package at the top on rotatable, cage-like cores that are individually driven. Each strand is passed tangentially off the rotating forming package and downwardly through a suitable tension device and then through the traveler of the ring and traveler device where twist is imparted 3,423,922 Patented Jan. 28, 1969 and thence onto the milk bottle build package core which is rapidly rotated.

Prior to the strand passing through the traveler, one or more turns per inch have been put into it for the coherency mentioned.

This rounds up the strand to hold all of the fibers in the strand in coherent form. The twist is elfective to pull in fibers that would otherwise protrude and form loops or ringers. These loops and ringers would otherwise cause entanglements and lost fibers and often strand breakage during passage of the strand through tension devices, guide eyes and the like used in rewind equipment for processing the strands as in a beamer operation, ply and rewind operations and the like.

NECESSITY FOR PACKAGE ROTATION: STRAND COHERENCY Due to the fact that a strand comprises 102 or more very fine fibers very delicately held together by the size, and without twist, coherency maintenance is a diflicult task in any rewinding operation.

By the prior art, this has been most successfully preserved by rotating the forming package and taking the strand ofi tangentially. Over end take oif from a stationary package has not been commercially successful.

It will be evident that the speed at which the forming package can be rotated on the tube drive twist frame is limited. The forming package is a dynamically unstable mass and this prevents fast rotation and high speed strand pay out.

Other factors are also involved. Thus, the moisture content of the forming package, the strand-to-strand adherence and so forth, also tend to limit the speed of strand pay off from the forming package.

The above discussion has related to twist frames of the tube-drive type which of course are more expensive than the free run tube type, because a separate drive mechanism is required to rotate each of the forming packages at a controlled rate of speed for uniformity of twist along the strand.

Both types of twist frames, however, provide essentially the same problems as regards tangential take-01f of the strand from the forming package. Thus the dynamic unbalance of the package produces vibration, strand breakage and so forth even at rather low rotational speeds of the package.

Due to the unbalance of the package, strand will feed from one side more rapidly than from the other because of varying speeds of rotation between one side and the other caused by the unbalanced or heavier weight on the one side of the package. This causes loping or over run of the strand, producing slack. When the package slows down, the slack will be taken up suddenly and snap taut and often break. Also, loping often produces slack in the serving package and this develops loops in the finally plied yarn. At the point of the loop, within the yarn, the yarn strength is substantially nil.

Thus, rotation of the forming package for tangential strand take-off presents difficulties due to the unbalanced nature of the package.

It might seem simple to hold the forming cake or package fixed and feed ofi over end and thus avoid all of the problems of package rotation and dynamic unbalance. However, the nature of the forming package itself hinders over-end processing.

Thus, a forming package, as freshly made, is wet or saturated with liquid size and contains a high moisture content. The size is required to hold the fibers of the strand together for enough coherency for the rewind and twist operation. To be elfective, however, the size must be dried to a degree to bring out its adhesive character to very lightly bond the fibers together, else there will be no strand form, and just a mass of fibers.

The drying that is necessary to produce the strand coherency, however, causes bonding of the strands to one another at least to a degree. Since the strand is laid on in nearly side-by-side turns, the turns tend to adhere to one another. Over end take-oif abrasion pulls the strands apart.

Also, the forming cake is a compact mass, inherent in the fact that it is formed of fibers that are under attenuating tension. This factor also contributes substantially to strand-to-strand adherence. Over end take-off abrasion thus pulls the strands apart.

Also, a forming cake has either a cylindrical or barrel build exterior that adds difficulty as regards over end take-off. In flat build packages, the exterior is cylindrical and this inhibits over end take-off because the strand will rub over the surface. In barrel build packages, the outside surface is of generally arcuate axial contour and the strand will rub over the surface even more severely than encountered with fiat build packages.

It will be evident from the foregoing that substantial difficulties are encountered in processing forming cakes.

The prior art has disclosed over end take-off from a previously processed conventional serving package, Such package is built to a tapered configuration, and the strand is crisscrossed. These factors make over end feed-off possible. Attention is called to German Patent 572,050 dated Mar. 10, 1933, FIGURE 2 of the drawings. It will be noted that the German patent spins the package. This is possible because that package is a dynamically balanced mass, as distinguished from a glass fiber forming cake, and also is tapered so that both over end feed-off and inside-out feed are apparently possible.

Note, however, that this art clearly does not show a stationary forming cake and its problems as contemplated and solved by this invention.

From the foregoing it will be evident that a substantial advance would be provided to the art by method and apparatus for very rapidly removing continuous fibrous strands from a forming cake of essentially cylindrical configuration which naturally resists fast strand removal, and having fiber-to-fiber adhesion which still further resists strand removal; wherein the forming cake is held stationary during movement; and wherein processing from forming cake to beamer package is continuous, and without intermediate manual handling.

Further, a substantial advance would be provided to the art by method and apparatus for imparting high twist to continuous fibrous strands at high processing speeds to form milk bottle build and other types of serving packages.

It is therefore an important object of the present invention to provide a method of processing continuous glass fiber strands directly from a forming cake to a beamer package in a continuous operation.

A further object is to provide a method of processing continuous glass fiber strand from a forming cake to a serving package such as milk bottle package with a greater amount of twist and at greater processing speeds on a more economical basis.

A further object is to provide apparatus for rewinding and twisting strand from glass firber forming packages at high speed, wherein the forming package is retained in a stationary condition, thereby avoiding the defects of lopping, snapping with strand breakage, and looping of the prior art.

A further object is to provide apparatus for rewinding and twisting strands of continuous glass fibers from the forming package directly to a serving package on a continuous basis, where the package is held stationary.

A further object is to provide method and apparatus for rewinding and twisting strands of continuous glass fibers from the forming package by removing the strand from the inside of the package, whereby outside, over-end processing difficulties are avoided by an inside-out takeoff.

A further object is to provide method and apparatus for rewinding from a forming cake, and twisting and plying, all in a continuous manner, and using inside-out takeoff.

A further object is a method and apparatus for producing a twisted textile product with fluid applied to it by withdrawing textile material from the inside of a stationary package through a fluid and subsequently imparting twist to it.

Other objects of this invention will appear in the following description and appended claims, reference being had to the accompanying drawings forming a part of this specification wherein like reference characters designate corresponding parts in the several views.

FIGURE 1 is a vertical sectional view of an inside-out twister of the present invention schematically feeding to a beamer package, using a fiat build forming cake, from a glass fiber forming operation;

FIGURE 2 is a sectional view of an inside-out twister of invention, illustrating use of the twister with a barrel build package from a glass fiber forming operation, and

embodying a smooth orifice cap over the strand outlet tube instead of a traveler as in FIGURE 1;

FIGURE 2a is an enlarged, fragmentary, sectional view more clearly showing the orifice cap;

FIGURE 3 is a sectional view of a third construction of the present invention wherein a vortex-like throat is used for strand take-off from the package to provide smooth, high speed and more straight-line flow to even further facilitate fiber feed-off from the cylindrical interior surface of a glass fiber forming cake;

FIGURE 4 is an elevational view, partly in section, of an inside-out twister as shown in FIGURE 1, feeding strand to a conventional milk bottle build serving package and illustrating substitution of the present invention onto a conventional twister frame in place of the tube drive;

FIGURE 5 is an elevational view, partly in section, of an inside-out twister wherein the package is submerged in a fluid and a twisted strand leaving the twister with fluid applied to it passes through a drying or curing zone prior to winding the strand into a package on a take-up unit; and

FIGURE 6 is an elevational view, partly in section, of apparatus wherein the package is submerged in a fluid and an untwisted strand with the fluid applied to it passes through a drying or curing zone prior to winding the strand into a package on a take-up unit.

Before explaining the present invention in detail it is to be understood that the invention is not limited in its application to the particular construction and arrangement of parts illustrated in the accompanying drawings, since the invention is capable of other embodiments and of being practiced and carried out in various ways. Also, it is to be understood that the phraseology or terminology employed herein is for the purpose of description and not of limitation.

Briefly, the present invention provides novel method and apparatus for high speed processing of continuous glass strands from a forming cake directly onto a serving package with application of suflicient twist for strand coherency, which has not heretofore been done.

In accordance with the invention, two turns of twist are given to the strand for each revolution of the rotating portion of the apparatus. The strand is withdrawn from the inside of a stationary package, e.g. forming package, and passed through a passageway in a whirling spindle to an outlet region whirling with the spindle to impart one turn of twist for each spindle revolution. The second turn is added by directing the strand to follow a path in the reverse direction upon its exit from the outlet region to a point beyond the zone of strand withdrawal and rotating the reverse direction path of the traveling strand in balloon fashion about the zone of strand withdrawal, viz. the package. Subsequent operations may include the application of the so twisted strand directly onto a beamer package along with up to 1,000 other similarly processed and twisted strands; or alternately the passing of the so twisted strand to a second twisting operation such as a conventional ring and traveler mechanism for producing a serving package of the milk bottle build type or other.

In accordance with the present invention, high speed strand processing is provided with a simplified mechanism by virtue of the fact that the forming cake remains stationary and thus the dynamic unbalanced forces inherent therein are nullified and effectively removed from the system. Further, over end strand abrasion and take-off problems are avoided.

Further, strand coherence, forming package compactness and density are factors which have been effectively nullified and effectively removed from the system by the manner in which the fibers are taken out of the forming package by a novel inside-out feed.

THE DIRECT BEAMER PACKAGE FORMING EMBODIMENT FIGURE 1, The traveler embodiment In this embodiment of the invention, strand is taken from a forming cake by an inside-out route and a twofor-one twist is applied; and thereafter the twisted strand is taken directly to the beamer package in a continuous and high speed operation.

In this operation the strand is given suflicient twist for coherency. Thus it is rounded up and all fibers are pulled into it to avoid ringers and lost ends.

In the present embodiment of the invention, the strand after first being removed from the inside of the forming cake or package is directed in a reverse manner around the package as a balloon to provide the Second of the two twists.

It is to be understood that other types of serving packages could equally well be produced within the scope of the invention.

In other embodiments of the invention, as will become apparent hereafter, the twisted strand can be alternately followed, without interruption, by subsequent twisting as by a ring and traveler mechanism, giving added twist in a single pass through rewinding equipment.

It is an unusual aspect of the inside-out removal of the present invention that problems of over end take-off of both flat and barrel build packages are avoided. Thus, the strand is not taken off over end in the present invention. Instead, it is taken off inside and moved axially out of the end of the package; and a forming package at that. Substantial novelty exists at this point.

Therefore, as shown in FIGURES 1 and 2, very rapid take-out from both flat and barrel build forming packages is provided which has not heretofore been done. This is made possible by shorter strand travel and less ballooning; and thus there is less fiber fly and less fiber loss as by ringers.

As shown in FIGURE 1, the numeral represents a flat build forming package typical of the glass fiber forming art. This is made by attenuating a plurality of streams of molten glass that exude from a heated b ushing. Attenfllation of the streams produces fibers of filaments that are gathered together, just after application of a liquid binder and size, into a single strand.

The strand is wound wet and at high speed upon a rapidly rotated, moisture-resistant forming tube. The rotated forming tube provides the force for attenuation of the glass streams into the very small diameter fibers making up the strand.

The flat build is effected by a constant traverse the full length of the package.

At this point of production, the so-produced forming package is highly saturated with moisture and is a mobile mass that is not self-supporting. It therefore requires drying to a suflicient degree to render it self-supporting so that the forming tube can be removed for the inside-out processing. The drying process need only be carried just far enough to render the package self-supporting. The residual moisture can be tolerated by the present invention.

In order to preservestrand integrity, the prior art has been forced to remove the strand from the outside of the forming package in a tangential take-off as mentioned above with the associated problems of vibration, strand breakage, over end abrasion and the like.

In accordance with this invention, as shown in FIG- URE 1, however, the forming package 10 is held stationary within the novel twister 12 of the present invention.

The twister 12 is suitably supported at the creel height position of a rewinding frame. Any suitable support can be used.

The numeral 14 represents a suitable support member to which a bracket 16 is fastened as by welds 18. The twister 12 is mounted to the top of bracket 16 by bolts 20.

The bolts 20 are passed through the foot of the base member 22 to attach the twister 12 to the bracket 16.

A spindle 30 is rotatably mounted on the base member 22. The spindle 30 includes a shaft 32 coaxial within a tubular drive whorl 34. The shaft 32 turns in the bearings 24 and 26. A belt 36 wraps the whorl 34 in driving relationship.

The bottom of the whorl 34 has a retainer flange 35 to hold the belt 36 in driving relationship.

The upper part of the spindle 30 includes a coaxial strand guide tube 38. A strand outlet passage or region 40 extends between the bottom of the strand guide tube 38 and the periphery of the spindle 30, terminating beneath the peripheral, upturned, highly polished flange 42 which serves as a strand feed-off lip.

The strand guide tube 38 has a smooth outside contour and serves to journal a package support 44.

The package support 44 is of annular construction and includes a fiber forming package support basket 46 and a weight chamber 48. The outer wall 50 is cylindrical at the top at the basket 46 portion, and tapers inwardly around the weight chamber 48 to cradle within the flange 42 of spindle 30.

A weight 52 is secured within the Weight chamber 48. This keeps the forming package 10 stationary. The spindle 30 is mounted at a vertical inclination of about 20 or so to make this possible.

A transverse wall 54 separates the weight chamber 48 from the package support basket 46 and forms a bottom upon which the package 10 rests.

Up through the center of the package support 44 there extends coaxially a tubular wall 56 that comprises spaced bearings 58 whereby the package support 44 is rotatably mounted upon the strand guide tube 38.

By means of the weight 52 and the rotatable relationship betwen the tube 38 and the bearings 58, the package support 44 stands still while the tube 38 and spindle 30 rotate to balloon the strand as indicated at 69.

It is to be understood that a conventional tensioning device is positioned either within the strand guide tube 38 or within the outlet passage 40, in this and subsequent embodiments of the invention.

The package 10 is simply lowered by gravity into the support basket 46 to load the device.

A disc 60 is formed around the top of the tubular wall 56 of the package support 44. The disc 60 has grooves 62 provided around the periphery to slidably receive a traveler 64. The traveler is of loop-like structure of highly polished metal for low friction. Enough clearance is provided between the inside of the traveler and the disc 60 to freely pass the strand 66 in guiding relationship.

With the package 10 in position in basket 46 a strand 66 is found on the inside of the package and threaded through the traveler 64 and then downwardly through the strand guide tube 38 as by a small feed tube with air or using other probe device. This strand 66 is pulled out through the strand outlet passage 40 and its direction is reversed to proceed upwardly by balloon 69 to guide eye 68.

Twist is imparted to the strand at two zones. One twist for each revolution of the spindle 30 is given to the strand between its entrance into the strand guide tube 38 and the strand outlet passage 40. The second twist for each revolution of the spindle is imparted as the strand is rotated with the spindle 30 in balloon fashion about the zone of strand withdrawal from the package 10, viz. the package 10. A twisted strand 67 is thus formed having two turns imparted to it for each revolution of the spindle 30. The number of twists-per-inch can be controlled by the linear speed of the strand in relation to the r.p.m. of the spindle, e.g. the slower the linear strand speed for a given spindle r.p.m. the greater the number of twists-per-inch given to the strand. I

From the guide eye 68, the twisted strand 67 is directed to a tension disc 70, from which it passes to a beamer pressure roll 72. By means of a suitable guide, not shown, the twisted strand is directed over the pressure roll 72 and thence onto the beamer package 74. The beamer package 74 includes a beam tube 76 that is carried upon the beam 78 of a collet 80. The collet 80 is connected to a gear motor or the like for rotation.

The showing of FIGURE 1 regarding the beamer package is somewhat schematic for clarity. A beamer package is normally held on gudgeons or sub-shafts which fit on the driving head of the beamer frame, and either one or both ends of the beamer may be power driven. In the event only one end is driven, the other end is supported in a suitable anti-friction bearing.

SUMMARY OF THE EMBODIMENT OF FIGURE 1 In the present description of the beamer operation, it is to be understood that only one twister 12 is shown. In actual production of a beamer package, up to 1,000 strands 66 would be supplied. Also, as many twisters 12 would be used, one for each strand 66. These are necessary to fill a typical beamer package because the core is about 54 inches long and a finished package size could have an outside diameter of about 32 inches.

From the foregoing description it will be evident that a suflicient twist is provided to the strand to round up the multiple fibers forming the strand. The strand is properly tensioned at 70 as it passes from the balloon 69 to the beamer package 74.