US3375813A - Side-mounted internal combustion engine starter - Google Patents

Side-mounted internal combustion engine starter Download PDFInfo

- Publication number

- US3375813A US3375813A US519694A US51969466A US3375813A US 3375813 A US3375813 A US 3375813A US 519694 A US519694 A US 519694A US 51969466 A US51969466 A US 51969466A US 3375813 A US3375813 A US 3375813A

- Authority

- US

- United States

- Prior art keywords

- rope

- starter

- pulley

- wheel

- engine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000007858 starting material Substances 0.000 title description 113

- 238000002485 combustion reaction Methods 0.000 title description 22

- 239000000463 material Substances 0.000 description 11

- 238000006073 displacement reaction Methods 0.000 description 9

- 235000019755 Starter Diet Nutrition 0.000 description 7

- 239000004677 Nylon Substances 0.000 description 6

- 229920001778 nylon Polymers 0.000 description 6

- 239000004033 plastic Substances 0.000 description 5

- 229920004943 Delrin® Polymers 0.000 description 4

- 238000010276 construction Methods 0.000 description 4

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 244000025254 Cannabis sativa Species 0.000 description 1

- 241000656145 Thyrsites atun Species 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000012858 resilient material Substances 0.000 description 1

- 238000010079 rubber tapping Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02N—STARTING OF COMBUSTION ENGINES; STARTING AIDS FOR SUCH ENGINES, NOT OTHERWISE PROVIDED FOR

- F02N3/00—Other muscle-operated starting apparatus

- F02N3/02—Other muscle-operated starting apparatus having pull-cords

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/39—Cord and rope holders

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T24/00—Buckles, buttons, clasps, etc.

- Y10T24/39—Cord and rope holders

- Y10T24/3913—Knot engaging

Definitions

- Rope starters for small internal combustion engines such as the type used on lawn mowers, pumps, generators, garden equipment and the like often employ recoil starters wherein a spiral spring is used to recoil the starter rope upon a ropereceiving pulley.

- recoil starters engage clutching means mounted upon the engine liywheel adjacent the flywheel axis, and the axis of the starter rope pulley is concentrically related to the iiywheel axis.

- each rotation of the rope pulley produces a complete rotation of the engine flywheel.

- the invention is directed to a side-mounted recoil rope starter for internal combustion engines, wherein the starter is mounted upon the side of the engine and the rope pulley axis is transversely disposed to the engine crankshaft and flywheel axis.

- gear teeth are defined upon the flywheel at a distance which is several inches from the flywheel axis and, thereby, provide a mechanical advantage arising from the existing torque arm produced.

- the starter includes a cranking wheel having gear teeth defined thereon which selectively engage with the flywheel gear teeth. Initial rotation of the rope pulley by pulling on the starter rope engages the teeth of the cranking wheel with the fiyw-heel teeth and further rotation of the rope pulley rotates the flywheel to crank and start the engine.

- a basic object of the invention is to provide a recoil starter for internal combustion engines wherein the forces required to crank the engine are reduced from those required with more conventional recoil starters.

- Another object of the invention is to provide a recoil ice rope starter for an internal combustion engine whereby the starter may be mounted upon the side of the engine out of coaxial alignment with the engine crankshaft and the starter does not add to the overall length of the engine in the axial direction of the crankshaft.

- a further object of the invention is to provide a recoil rope starter for internal combustion engines wherein the mounting means for the starter can be readily modified and a given starter construction may be easily adapted for use with a wide variety of engine constructions.

- An additional object of the invention is to provide a recoil rope starter for internal combustion engines wherein the starter includes an engine cranking wheel adapted to be selectively moved toward and away from the engine flywheel, and wherein the rope pulley and engine cranking wheel are formed of synthetic plastic materials.

- Yet another object of the invention is to provide a recoil rope starter for internal combustion engines wherein the recoil spring for rewinding the starter rope pulley is protected from dirt and foreign matter.

- a further object of the invention is to provide a recoil rope starter for internal combustion engines wherein the starter includes a spiral recoil spring having an inner endV adapted to be anchored to the starter support and having an outer end anchored to the rope pulley, the inner spring end anchor being adapted to automatically release the spring inner end should the spring inner end attempt to rotate in a spring-unwinding direction.

- Another object of the invention is to provide a recoil rope starter for internal combustion engines utilizing a spiral recoiling spring wherein the spring; may be prewound and rope retaining means are mountedupon the starter support bracket for maintaining the starter in the prewound condition prior to assembly upon an engine.

- An additional object of the invention is to provide a handle for an internal combustion engine rope starter wherein the starter rope is provided with a knot or other abutment defined thereon wherein the handle may be assembled to the starter rope without removing the starter rope knot or abutment.

- Another object of the invention is to provide a handle for an internal combustion engine starter rope wherein the handle may be easily assembled to the starter rope and consists of a relatively rigid element and a resilient element, the resilient element functioning to increase the comfort aspects of the handle and, also, serving to retain the assembly of the starter rope -with the rigid element.

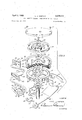

- FIG. 1 is an elevational view of a starter in accord with the invention as assembled upon an engine, the engine shroud being shown in section,

- FIG. 2 is a plan, sectional view of a starter in accord with the invention, the cranking wheel being shown in the operative position, as taken along section II-II of FIG. 1,

- FIG. 3 is an exploded perspective view ⁇ of the components constituting a recoil starter in accord with the invention

- FIG. 4 is an elevational, diametrical, sectional view of the assembled starter rope handle in accord with the invention, as taken along section IV-lV of FIG. 5, and

- FIG. 5 is an elevational, sectional view as taken along section V-V of FIG. 4, the inner handle element being shown in elevation for purposes of illustration.

- FIG. l The environment in which the starter of the invention is employed is shown in FIG. l, wherein an internal combustion engine is represented at 10.

- the engine 10 is of the vertical crankshaft type such as used in rotary lawn mowers, and includes a flywheel 12 having a plurality of gear teeth 14 defined in the periphery thereof.

- a shroud 16 is disposed in a horizontal manner over the engine 10, and is fastened to the engine by suitable brackets, not shown.

- the shroud 16 may completely encompass the entire upper region of the engine and hidethe same from view, improving the aesthetic value of the lawnmower and also protecting the engine from grass clippings, dirt, etc.

- the starter is mounted to the vertical side 18 of the engine V by means of a bracket 20 which may be formed of sheet metal.

- the bracket 20 is provided with formed leg portions 22 having lbolt-receiving holes 24 defined therein, whereby the bracket may be bolted to the engine side by bolts 26.

- the bracket 20 includes a rope retaining portion 28 defined thereon which extends at substantially right angles to the general configuration of the bracket, and a 'brake rotation limiting stud 30 is defined from the material of the bracket extending from the bracket in the same d-irection as the retainer portion 28.

- a headed cylindrical shaft 32 is welded on the bracket 20 adjacent the stud 30 and includes an outer end 34.

- the shaft is recessed at 36 adjacent its outer end, and is centrally provided with a bore 38.

- a rope pulley 40 is rotatably mounted upon the shaft 32.

- the rope pulley 40 is provided with a cylindrical bore adapted to be rotatably received upon the shaft, and the pulley includes a starter rope receiving groove 42 defined therein.

- a radial hole 44 is defined in the groove 42 whereby the inner end 46 of a starter rope 48 coiled within the groove maybe inserted and knotted for afiixing the rope inner end to the pulley 40.

- the pulley 40 is provided with an axially extending annular portion adjacent the pulley surface 52, defines a recess 54 concentric to the axis of rotation of the pulley.

- the pulley 40 also includes ⁇ an axiallyl extending hub project-ion 56 having a plurality of spirally disposed ribs 58 formed thereon.

- the ribs 58 each include spaced parallel edges 60 disposed in a spiral manner for cooperating with the engine cranking wheel, as will be later described.

- the hub projection 56 is grooved at 62 to receive a stop washer 64 and snap ring assembly.

- the rope pulley 40 is formed of a synthetic plastic material having a hardness or durometer reading similar to that of the material of the starter rope.

- the starter rope 48 preferably, is formed of braided nylon filaments and, for instance, the pulley may be formed of nylon or Delrin, a synthetic product manufactured by the Dow Chemical Company.

- An engine cranking wheel 66 is mounted u-pon the pulley hub projection 56 and is axially movable thereon.

- the wheel 66 includes a hub 68 having a shaped bore 70 defined therein.

- the bore 70 includes a plurality of spirally disposed recesses or grooves 72 adapted to closely, yet slidably, receive the ribs 58 defined upon the pulley projection 56.

- the recesses 72 include opposed, spaced, spirally disposed edges 74 adapted to cooperate with the edges 60 of the ribs 58.

- the hub 68 is provided with a concentric recess 7'6 including a radially extending shoulder.

- the recess 76 is of suliicient dimension as to receive the stop washer 64 as shown in FIG. 2.

- the outer periphery of the cranking wheel 66 is provided with gear teeth 78 adapted to cooperate with the fiywheel gear teeth 14.

- the gear teeth 78 may be slightly bevelled on their right edges, FIG. 2, to facilitate engagement of the teeth 78 with the flywheel teeth 14.

- the Wheel 66 be formed of a synthetic plastic material such as nylon or Delrin,

- the rope pulley 40 and wheel 66 are formed of dissimilar materials to prevent galling and adverse wear conditions between these components.

- the pulley 90 is formed of Delrin, the wheel 66 will be formed of nylon.

- The' self-lu ⁇ briicating qualities of nylon are of advantage, due to the axial4 sliding movement of the wheel 66 upon the projection '56.

- the crank wheel hub 68 is provided with an annular groove 80 which is adapted to cooperate with a friction brake clip 82, FIG. 3.

- the brake clip 82 includes a pair of V-shaped hub-embracing portions 84 and a tail portion 86 adapted to receive the bracket stud 30, FIG. 2.

- the portions 84 will resiliently embrace the wheel hub groove 80 and' the stud '30 is of sufficient length to maintain engagement between the stud and the clip tail at all axial positions of the wheel 66.

- the axial direction of movement of the wheel 66 upon the hub projection will depend upon the direction of rotation of the rope pulley.

- a spring anchor 88 is affixed to the end 34 of the shaft 32.

- the anchor 88 is in the form of a cup having a base portion 90 and an axial wall portion 92.

- a hole is centrally defined in the base portion 90 for permitting the anchor to be a valveived in recess 36 and for receiving a screw 94 which may be of the self-tapping type.

- the spring anchor is affixed to the end of the shaft and concentric therewith by threading screw 94 into bore 38.

- the anchor axial wall 92 is lanced at 96 and deiiected inwardly at 98 to define an edge at 96 for cooperation with the inner end of the rope pulley recoil spring.

- the inward deflection of the portion 98 will deflect the inner end of the recoil spring from an operative engagement with the spring anchor if there is a tendency for the inner end of the recoil spring to rotate in a spring-unwinding ⁇ direction relative to the spring anchor, such as would occur if the starter rope broke.

- the recoil spiral spring 100 is received within the rope pulley recess 54, FIG. 2, and includes a hooked inner end 102 and a looped outer end 104.

- the inner end 102 is adapted to cooperate with the spring anchor edge 96 and the loop end 104 fits over a stud 106 molded into the pulley 40.

- the inertia of the rope pulley caused by the very rapid unwinding of the spiral spring 100 will not damage the recoil spring, in that as soon as the tension in the spring is such as to prevent an operative engagement between the hooked inner end 102 and the spring anchor edge 96, the spring inner end will be engaged by the anchor deflected portion 98l and held out of an operative relationship with the spring anchor until the pulley is again wound in the spring-winding direction, wherein the hooked end may again engage the anchor edge 96.

- the cover 108 includes a base portion and an axially extending wall portion, whereby the wall portion will fit over the rope pulley annular portion 50 in the manner shown in FIG. 2. Screw fasteners 110 extending through holes defined in the cover afiix the cover 108 upon the rope pulley.

- the cover 108 and the recess 54 therefore, form a dust-free chamber, in which the recoil spring 100 and the spring anchor 488 are received.

- the bracket portion 28 includes a tapered rope-retaining slot 112 defined therein. As will be apparent from FIG. l, the slot 112 is aligned with the pulley rope groove 42. The purpose of the slot 112 is to retain the outer end of the starter rope after the starter has been assembled and the spiral recoil spring 100 prewound a turn or two. Prewinding of the recoil spring 100 is desirable to insure that the starter rope will be fully wound upon the pulley when the starter is not being operated.

- the free end of the starter rope is inserted into the slot 112 and due to the V-configuration of the slot, the rope may be tightly pulled into the slot to prevent the tension being applied on the 'rope by the spiral spring from pulling the rope out of the slot.

- a 'rope guide clip 114 is fastened to the rope retainer portion 28 and is in axial alignment with the pulley groove 42, as will be apparent from FIG. 1.

- the purpose of the guide 114 is to insure that the starter rope will be rewound in the pulley groove even though the tension in the starter rope, once the starter rope has been eX- tended, is released at a faster rate than the rope is rewound upon the pulley.

- a rope bushing plate 118 Prior to the knot 116 being tied in the outer end of the starter rope 48, a rope bushing plate 118 is placed upon the starter rope outer end.

- the plate 118 includes a pair of mounting holes 120 and a starter rope bushing 122 is affixed to the plate.

- the bushing 122 includes a bore through which the [rope may freely slide and the bushing is free of any sharp edges which may ⁇ tend to fray the rope.

- the recoil starter in accord with the invention, is mounted to the side 18 of the engine 10 by bolts 26 extending through the holes 24 defined in the support bracket.

- the starter is mounted upon the engine so that axial movement of the cranking Wheel 66 on the pulley hub projection 56 selectively engages and disengages the wheel gear teeth 78 with the liywheel ⁇ gear teeth 14.

- the disengaged position of the cranking wheel 66 is shown in full lines and the engaged position of the flywheel is shown in dotted lines.

- the engine shroud 16 is provided with an opening 124 ofsufiicient dimension to permit the bushing plate 118 to be inserted upwardly therethrough.

- the plate 118 is attached to the shroud 16 by fasteners 126 extending through holes 120.

- the plate 118 is attached to the shroud in alignment with the rope pulley groove 42 wherein the rope portion 128 is substantially tangential to the rope coiled upon the rope pulley.

- a sufiicient amount of starter rope may be uncoiled from the pulley 40 and located between slot 112 and knot 116 to permit the above assembly procedure and, thus, the operator does not have to fight the tendency for the rope to recoil on the pulley during assembly to the starter to the engine and shroud.

- the rope handle 130 may be attached to the rope end.

- the rope handle 130 consists of two elements.

- the inner element 132 preferably, is formed of a rigid material, such as a synthetic plastic material as nylon or Delrin, and includes a substantially cylindrical body portion 124 having an exterior surface 136 and a bottom surface 138.

- a gripping portion 146 ⁇ is delinedon the body portion and extends transversely thereof.

- the body portion 134 is formed with an internal chamber 142 which is of sufiicient dimension to receive the knot 116.

- a rope outlet slot 144 is dened in the bottom of the body portion and intersects the bottom surface 138 and the exterior surface 136. The width of the slot 144 is such as Y to substantially equal the width of the starter rope, and is less than the transverse dimension of the knot.

- An opening 146 is formed in the exterior surface of the body portion 134 intersecting the chamber 142 and the slot 144.

- the opening 146 is substantially perpendicularly related to the rope outlet slot and the portion of the rope to be received therein.

- the lower surface of the chamber 142 forms an abutment surface on which the knot will bear.

- the element 148 includes an ⁇ annular collar 150 having a bore defined therein which is of a diameter substantially equal to that of the body portion 134.

- the element 148 is formed with a transversally extending portion 152 in which a recess 154 is defined corresponding to the gripping portion 140 of the inner handle element 132.

- the outer element 148 of the handle 130 is preferably through the bore of collar 158, as shown in FIG. 3L

- the :knot 116 is placed within the chamber 142 defined in bodyportion 134 through opening 146.

- the intersection of the slot 144 with the opening 146 and chamber 142 permits the rope to pass into the body portion in alignment with the axis thereof.

- the elements 132 and 148 are assembled, as will be apparent from FIGS. 4 and 5.

- the 4collar portion 1&5() closely receives the ⁇ body portion 134

- the collar portion functions as a retainer to maintain the knot 116 within the chamber 142, and an attractive, functional and comfortable pull handle for the starter rope 48 is provided.

- the assembly of the starter to the engine and shroud is substantially simplified, as compared to the case if a more conventional handle construction wereutilized. After the handle is assembled to the starter rope, the operator will release the rope from the retainer slot 112 and the starter is now ready for use.

- the normal position of the starter component is that shown in FIG. 1. Due to the pretension placed on the recoil spring 100, the recoil spring will tend to ⁇ wind the rope pulley 40 ina rope-recoiling direction. This biasing force will maintain the handle in engagement with the bushing 122, and due to the previous recoiling operation, the cranking wheel 66 will -be adjacently disposed to the rope pulley 4t). Upon the operator grasping the handle 130 and pulling upwardly to uncoil the rope 48 from the rope pulley, the initial rotation of the rope pulley will cause the cranking wheel 66 to move axially on the hub projection 56.

- This axial movement of the engine cranking wheel 66 is due to the resistance of rotation of the wheel produced by the frictional engagement with the brake clip 82 in the groove 80.

- the axial movement of the wheel 66 causes the Wheel to move into a driving engagement with the ywheel 12.

- Axial movement of the wheel l66 toward the flywheel is limited by engagement of the stop washer 64 with the ⁇ groove 76.

- the starter of the invention can be readily employed with a wide variety of motor constructions as it is only necessary to make modifications in the configuration of the support bracket 20'and the location of the mounting holes 24 to accommodate many engines.

- a rope pulley having a hardness substantially equal to that of the rope 48 fraying of the rope due to engagement with the pulley, particularly in the area of the hole 44, is prevented.

- a self-lubricating, easily sliding operation is assured.

- a recoil starter for internal combustion engines particularly adapted for mounting upon the side of an engine comprising, in combination,

- said pulley includes a recess delined therein having a closed ybottom surface and a continuous annular wall

- a handle for a starter rope having an abutment defined thereon of greater transverse dimension than the rope diameter comprising, in combination,

- a rst handle element including a body portion having an exterior surface and a bottom surface

- said retainer means comprises an annular collar circumscribing said body portion exterior surface.

- said first handle element includes a gripping portion affixed to said body portion and transversely related thereto,

- said first handle element is formed of a su-bstantially rigid material

- said second handle element is formed of a resilient material.

- a recoil sta-rter for internal combustion engines particularly adapted for mounting upon the side of an engine comprising, in combination,

- (d) means ⁇ interconnecting said hub projection and wheel producing axial displacement of said wheel on said projection during initial angular displacement of said pulley with respect to said wheel and causing said wheel to be angularly locked with respect to said pulley at a predetermined axial position of said wheel upon said projection,

- a spring anchor defined at the free end of said shaft, said spring anchor comprising a cup affixed to the free end of said shaft, said cup including an axially extending wall portion extending in the axial direction of said shaft, a lportion of said wall portion being lanced and deflected radially inwardly to define an axially extending edge in said cup wall portion adapted to Ibe engaged by said recoil spiral spring inner end, said inwardly deflected portion preventing retaining engagement of said spring inner end ⁇ with said cup upon said spring being unwound a predetermined degree,

- a recoil starter for internal combustion engines particularly adapted for mounting upon the side of an engine comprising, in combination,

- a recoil starter for internal combustion engines particularly adapted for mounting upon the side of an engine comp-rising, in combination,

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Pulleys (AREA)

Description

April 2, 1968 l.. J. HAMMAN 3,375,813

SIDE-MOUNTED INTERNAL COMBUSTION ENGlNE STARTER Filed Jan. lO, 1966 2 Sheets-5heet l nvvENToRA LYLE .HAMMAN ATTORNEYS L. J.4 HAMMAN April 2, 196s SIDEVMOUNTED INTERNAL COMBUSTION ENGINE STARTER E Sheets-Sheet 2 Filed Jan. lO, 1966 INVENTOR LY LE J. HAMMAN ATTORNEYS United States Patent C 3,375,813 SIDE-MOUNTED INTERNAL COMBUSTION ENGINE STARTER Lyle J. Hamman, Eaton Rapids, Mich., assignor t Eaton Stamping Company, Eaton Rapids, Mich.,

a corporation of Michigan Filed Jan. 10, 1966, Ser. No. 519,694 9 Claims. (Cl. 12S-185) ABSTRACT OF THE DISCLOSURE A manual recoil starter for starting internal combustion engines particularly adapted for mounting upon the side of an engine wherein the starter is characterized by ease of assembly to the engine, accessibility for maintenance purposes and concise configuration. Additionally, novel handle means are employed with the starter rope associated therewith.

Rope starters for small internal combustion engines such as the type used on lawn mowers, pumps, generators, garden equipment and the like often employ recoil starters wherein a spiral spring is used to recoil the starter rope upon a ropereceiving pulley. Normally, such recoil starters engage clutching means mounted upon the engine liywheel adjacent the flywheel axis, and the axis of the starter rope pulley is concentrically related to the iiywheel axis. Thus, each rotation of the rope pulley produces a complete rotation of the engine flywheel. While this arrangement permits a recoil starter to crank the engine through several rotations during the starting operation, the starter is directly subjected to the forces resisting cranking, namely, the engine friction and compression during the compression stroke of the piston. Also, as the conventional rope recoil rope starter is mounted concentric to the engine flywheel axis, the starter dimension increases the overall length of the engine components in the axial direction of the crankshaft axis.

The invention is directed to a side-mounted recoil rope starter for internal combustion engines, wherein the starter is mounted upon the side of the engine and the rope pulley axis is transversely disposed to the engine crankshaft and flywheel axis. With this type of starter, gear teeth are defined upon the flywheel at a distance which is several inches from the flywheel axis and, thereby, provide a mechanical advantage arising from the existing torque arm produced. The starter includes a cranking wheel having gear teeth defined thereon which selectively engage with the flywheel gear teeth. Initial rotation of the rope pulley by pulling on the starter rope engages the teeth of the cranking wheel with the fiyw-heel teeth and further rotation of the rope pulley rotates the flywheel to crank and start the engine. While this type of side-mounted starter will not rotate the flywheel through as great a number of rotations for a given extension of the rope starter as the more conventional recoil starters described above, considerably less force is required to rotate the engine fiywheel, due to the distance separating the flywheel gear teeth and lits axis, which functions as a lever arm. Thus, this type of side-mounted starter permits an engine to `be cranked while exerting considerably less tension on the starter rope than with the more conventional rope starters mounted coaxially with the flywheel axis. With this type of starter, women and children are able to start internal combustion engines which they were not previously able to crank. Thus, a basic object of the invention is to provide a recoil starter for internal combustion engines wherein the forces required to crank the engine are reduced from those required with more conventional recoil starters.

Another object of the invention is to provide a recoil ice rope starter for an internal combustion engine whereby the starter may be mounted upon the side of the engine out of coaxial alignment with the engine crankshaft and the starter does not add to the overall length of the engine in the axial direction of the crankshaft.

A further object of the invention is to provide a recoil rope starter for internal combustion engines wherein the mounting means for the starter can be readily modified and a given starter construction may be easily adapted for use with a wide variety of engine constructions.

An additional object of the invention .is to provide a recoil rope starter for internal combustion engines wherein the starter includes an engine cranking wheel adapted to be selectively moved toward and away from the engine flywheel, and wherein the rope pulley and engine cranking wheel are formed of synthetic plastic materials.

Yet another object of the invention is to provide a recoil rope starter for internal combustion engines wherein the recoil spring for rewinding the starter rope pulley is protected from dirt and foreign matter.

A further object of the invention is to provide a recoil rope starter for internal combustion engines wherein the starter includes a spiral recoil spring having an inner endV adapted to be anchored to the starter support and having an outer end anchored to the rope pulley, the inner spring end anchor being adapted to automatically release the spring inner end should the spring inner end attempt to rotate in a spring-unwinding direction.

Another object of the invention is to provide a recoil rope starter for internal combustion engines utilizing a spiral recoiling spring wherein the spring; may be prewound and rope retaining means are mountedupon the starter support bracket for maintaining the starter in the prewound condition prior to assembly upon an engine.

An additional object of the invention is to provide a handle for an internal combustion engine rope starter wherein the starter rope is provided with a knot or other abutment defined thereon wherein the handle may be assembled to the starter rope without removing the starter rope knot or abutment.

Another object of the invention is to provide a handle for an internal combustion engine starter rope wherein the handle may be easily assembled to the starter rope and consists of a relatively rigid element and a resilient element, the resilient element functioning to increase the comfort aspects of the handle and, also, serving to retain the assembly of the starter rope -with the rigid element.

These and other objects of the invention arising from the details and relationships of the components of an ernbodiment thereof will be apparent from the following description and accompanying drawings wherein:

FIG. 1 is an elevational view of a starter in accord with the invention as assembled upon an engine, the engine shroud being shown in section,

FIG. 2 is a plan, sectional view of a starter in accord with the invention, the cranking wheel being shown in the operative position, as taken along section II-II of FIG. 1,

FIG. 3 is an exploded perspective view `of the components constituting a recoil starter in accord with the invention,

FIG. 4 is an elevational, diametrical, sectional view of the assembled starter rope handle in accord with the invention, as taken along section IV-lV of FIG. 5, and

FIG. 5 is an elevational, sectional view as taken along section V-V of FIG. 4, the inner handle element being shown in elevation for purposes of illustration.

The environment in which the starter of the invention is employed is shown in FIG. l, wherein an internal combustion engine is represented at 10. In the disclosed arrangement, the engine 10 is of the vertical crankshaft type such as used in rotary lawn mowers, and includes a flywheel 12 having a plurality of gear teeth 14 defined in the periphery thereof. A shroud 16 is disposed in a horizontal manner over the engine 10, and is fastened to the engine by suitable brackets, not shown. The shroud 16 may completely encompass the entire upper region of the engine and hidethe same from view, improving the aesthetic value of the lawnmower and also protecting the engine from grass clippings, dirt, etc.

4 The starter is mounted to the vertical side 18 of the engine V by means of a bracket 20 which may be formed of sheet metal. The bracket 20 is provided with formed leg portions 22 having lbolt-receiving holes 24 defined therein, whereby the bracket may be bolted to the engine side by bolts 26. The bracket 20 includes a rope retaining portion 28 defined thereon which extends at substantially right angles to the general configuration of the bracket, and a 'brake rotation limiting stud 30 is defined from the material of the bracket extending from the bracket in the same d-irection as the retainer portion 28.

A headed cylindrical shaft 32 is welded on the bracket 20 adjacent the stud 30 and includes an outer end 34. The shaft is recessed at 36 adjacent its outer end, and is centrally provided with a bore 38.

A rope pulley 40 is rotatably mounted upon the shaft 32. The rope pulley 40 is provided with a cylindrical bore adapted to be rotatably received upon the shaft, and the pulley includes a starter rope receiving groove 42 defined therein. A radial hole 44 is defined in the groove 42 whereby the inner end 46 of a starter rope 48 coiled within the groove maybe inserted and knotted for afiixing the rope inner end to the pulley 40. The pulley 40 is provided with an axially extending annular portion adjacent the pulley surface 52, defines a recess 54 concentric to the axis of rotation of the pulley. The pulley 40 also includes `an axiallyl extending hub project-ion 56 having a plurality of spirally disposed ribs 58 formed thereon. The ribs 58 each include spaced parallel edges 60 disposed in a spiral manner for cooperating with the engine cranking wheel, as will be later described. The hub projection 56 is grooved at 62 to receive a stop washer 64 and snap ring assembly.

Preferably, the rope pulley 40 is formed of a synthetic plastic material having a hardness or durometer reading similar to that of the material of the starter rope. The starter rope 48, preferably, is formed of braided nylon filaments and, for instance, the pulley may be formed of nylon or Delrin, a synthetic product manufactured by the Dow Chemical Company.

An engine cranking wheel 66 is mounted u-pon the pulley hub projection 56 and is axially movable thereon.

The wheel 66 includes a hub 68 having a shaped bore 70 defined therein. The bore 70 includes a plurality of spirally disposed recesses or grooves 72 adapted to closely, yet slidably, receive the ribs 58 defined upon the pulley projection 56.

The recesses 72 include opposed, spaced, spirally disposed edges 74 adapted to cooperate with the edges 60 of the ribs 58. The hub 68 is provided with a concentric recess 7'6 including a radially extending shoulder. The recess 76 is of suliicient dimension as to receive the stop washer 64 as shown in FIG. 2.

The outer periphery of the cranking wheel 66 is provided with gear teeth 78 adapted to cooperate with the fiywheel gear teeth 14. The gear teeth 78 may be slightly bevelled on their right edges, FIG. 2, to facilitate engagement of the teeth 78 with the flywheel teeth 14.

It is also desirable that the Wheel 66 be formed of a synthetic plastic material such as nylon or Delrin, Preferably, the rope pulley 40 and wheel 66 are formed of dissimilar materials to prevent galling and adverse wear conditions between these components. Thus, if the pulley 90 is formed of Delrin, the wheel 66 will be formed of nylon. The' self-lu`briicating qualities of nylon are of advantage, due to the axial4 sliding movement of the wheel 66 upon the projection '56.

The crank wheel hub 68 is provided with an annular groove 80 which is adapted to cooperate with a friction brake clip 82, FIG. 3. The brake clip 82 includes a pair of V-shaped hub-embracing portions 84 and a tail portion 86 adapted to receive the bracket stud 30, FIG. 2. As the brake clip 82 is formed of a resilient wire, the portions 84 will resiliently embrace the wheel hub groove 80 and' the stud '30 is of sufficient length to maintain engagement between the stud and the clip tail at all axial positions of the wheel 66. The stud 30, of course, prevents rotation of the brake clip 82 and the brake clip provides sufiicient resistance to rotation of the cranking wheel 66 to produce axial displacement of the wheel upon the hub projection 56 as the rope pulley 40 rotates. The axial direction of movement of the wheel 66 upon the hub projection will depend upon the direction of rotation of the rope pulley.

A spring anchor 88 is affixed to the end 34 of the shaft 32. The anchor 88 is in the form of a cup having a base portion 90 and an axial wall portion 92. A hole is centrally defined in the base portion 90 for permitting the anchor to be treceived in recess 36 and for receiving a screw 94 which may be of the self-tapping type. The spring anchor is affixed to the end of the shaft and concentric therewith by threading screw 94 into bore 38. The anchor axial wall 92 is lanced at 96 and deiiected inwardly at 98 to define an edge at 96 for cooperation with the inner end of the rope pulley recoil spring. The inward deflection of the portion 98 will deflect the inner end of the recoil spring from an operative engagement with the spring anchor if there is a tendency for the inner end of the recoil spring to rotate in a spring-unwinding `direction relative to the spring anchor, such as would occur if the starter rope broke.

The recoil spiral spring 100 is received within the rope pulley recess 54, FIG. 2, and includes a hooked inner end 102 and a looped outer end 104. The inner end 102 is adapted to cooperate with the spring anchor edge 96 and the loop end 104 fits over a stud 106 molded into the pulley 40. In the event that the starter rope breaks, the inertia of the rope pulley caused by the very rapid unwinding of the spiral spring 100 will not damage the recoil spring, in that as soon as the tension in the spring is such as to prevent an operative engagement between the hooked inner end 102 and the spring anchor edge 96, the spring inner end will be engaged by the anchor deflected portion 98l and held out of an operative relationship with the spring anchor until the pulley is again wound in the spring-winding direction, wherein the hooked end may again engage the anchor edge 96.

The cover 108 includes a base portion and an axially extending wall portion, whereby the wall portion will fit over the rope pulley annular portion 50 in the manner shown in FIG. 2. Screw fasteners 110 extending through holes defined in the cover afiix the cover 108 upon the rope pulley. The cover 108 and the recess 54, therefore, form a dust-free chamber, in which the recoil spring 100 and the spring anchor 488 are received.

The bracket portion 28 includes a tapered rope-retaining slot 112 defined therein. As will be apparent from FIG. l, the slot 112 is aligned with the pulley rope groove 42. The purpose of the slot 112 is to retain the outer end of the starter rope after the starter has been assembled and the spiral recoil spring 100 prewound a turn or two. Prewinding of the recoil spring 100 is desirable to insure that the starter rope will be fully wound upon the pulley when the starter is not being operated. After the spring 100k has been prewound, the free end of the starter rope is inserted into the slot 112 and due to the V-configuration of the slot, the rope may be tightly pulled into the slot to prevent the tension being applied on the 'rope by the spiral spring from pulling the rope out of the slot.

A 'rope guide clip 114 is fastened to the rope retainer portion 28 and is in axial alignment with the pulley groove 42, as will be apparent from FIG. 1. The purpose of the guide 114 is to insure that the starter rope will be rewound in the pulley groove even though the tension in the starter rope, once the starter rope has been eX- tended, is released at a faster rate than the rope is rewound upon the pulley.

Prior to the knot 116 being tied in the outer end of the starter rope 48, a rope bushing plate 118 is placed upon the starter rope outer end. The plate 118 includes a pair of mounting holes 120 and a starter rope bushing 122 is affixed to the plate. The bushing 122 includes a bore through which the [rope may freely slide and the bushing is free of any sharp edges which may `tend to fray the rope. After the bushing plate is placed upon the rope, the rope is tied with the knot 116 at the outer end.`

The recoil starter, in accord with the invention, is mounted to the side 18 of the engine 10 by bolts 26 extending through the holes 24 defined in the support bracket. The starter is mounted upon the engine so that axial movement of the cranking Wheel 66 on the pulley hub projection 56 selectively engages and disengages the wheel gear teeth 78 with the liywheel` gear teeth 14. In FIG. 1, the disengaged position of the cranking wheel 66 is shown in full lines and the engaged position of the flywheel is shown in dotted lines.

The engine shroud 16 is provided with an opening 124 ofsufiicient dimension to permit the bushing plate 118 to be inserted upwardly therethrough. Thereupon, the plate 118 is attached to the shroud 16 by fasteners 126 extending through holes 120. Of course, the plate 118 is attached to the shroud in alignment with the rope pulley groove 42 wherein the rope portion 128 is substantially tangential to the rope coiled upon the rope pulley. During mounting of the starter upon the engine, the outer end of the starter rope will be held in the retainer slot 112. A sufiicient amount of starter rope may be uncoiled from the pulley 40 and located between slot 112 and knot 116 to permit the above assembly procedure and, thus, the operator does not have to fight the tendency for the rope to recoil on the pulley during assembly to the starter to the engine and shroud.

When the plate 118 is fastened to the shroud, the rope handle 130 may be attached to the rope end.

The rope handle 130 consists of two elements. The inner element 132, preferably, is formed of a rigid material, such as a synthetic plastic material as nylon or Delrin, and includes a substantially cylindrical body portion 124 having an exterior surface 136 and a bottom surface 138. A gripping portion 146` is delinedon the body portion and extends transversely thereof. The body portion 134 is formed with an internal chamber 142 which is of sufiicient dimension to receive the knot 116. A rope outlet slot 144 is dened in the bottom of the body portion and intersects the bottom surface 138 and the exterior surface 136. The width of the slot 144 is such as Y to substantially equal the width of the starter rope, and is less than the transverse dimension of the knot. An opening 146 is formed in the exterior surface of the body portion 134 intersecting the chamber 142 and the slot 144. The opening 146 is substantially perpendicularly related to the rope outlet slot and the portion of the rope to be received therein. The lower surface of the chamber 142 forms an abutment surface on which the knot will bear.

formed of a resilient molded material such as rubber, or the like. The element 148 includes an `annular collar 150 having a bore defined therein which is of a diameter substantially equal to that of the body portion 134. The element 148 is formed with a transversally extending portion 152 in which a recess 154 is defined corresponding to the gripping portion 140 of the inner handle element 132.

To assemble the handle 130 to the end of the starter rope, the knotted end of the starter rope .is` inserted The outer element 148 of the handle 130 is preferably through the bore of collar 158, as shown in FIG. 3L Thereupon, the :knot 116 is placed within the chamber 142 defined in bodyportion 134 through opening 146. The intersection of the slot 144 with the opening 146 and chamber 142 permits the rope to pass into the body portion in alignment with the axis thereof. Thereupon, the elements 132 and 148 are assembled, as will be apparent from FIGS. 4 and 5. In that the 4collar portion 1&5() closely receives the `body portion 134, the collar portion functions as a retainer to maintain the knot 116 within the chamber 142, and an attractive, functional and comfortable pull handle for the starter rope 48 is provided.

As the aforedescribed assembly of the starter rope to the handle does not require that the knot 116 be untied, the assembly of the starter to the engine and shroud is substantially simplified, as compared to the case if a more conventional handle construction wereutilized. After the handle is assembled to the starter rope, the operator will release the rope from the retainer slot 112 and the starter is now ready for use.

The normal position of the starter component is that shown in FIG. 1. Due to the pretension placed on the recoil spring 100, the recoil spring will tend to` wind the rope pulley 40 ina rope-recoiling direction. This biasing force will maintain the handle in engagement with the bushing 122, and due to the previous recoiling operation, the cranking wheel 66 will -be adjacently disposed to the rope pulley 4t). Upon the operator grasping the handle 130 and pulling upwardly to uncoil the rope 48 from the rope pulley, the initial rotation of the rope pulley will cause the cranking wheel 66 to move axially on the hub projection 56. This axial movement of the engine cranking wheel 66 is due to the resistance of rotation of the wheel produced by the frictional engagement with the brake clip 82 in the groove 80. The axial movement of the wheel 66 causes the Wheel to move into a driving engagement with the ywheel 12. Axial movement of the wheel l66 toward the flywheel is limited by engagement of the stop washer 64 with the `groove 76. Once the cranking wheel gear teeth 78 are in mating engagement with the flywheel gear teeth 14, rotation of the rope pulley 40 will rotate the cranking Wheel 66 and flywheel to cause the engine to start. When the engine starts, the `liywheel will tend to rotate the wheel 66 faster than the rotation of the rope pulley. This acceleration in the rotation of the cranking wheel will axially translate the Wheel 66 on the hub projection 56 toward the rope pulley groove 42 and disengage the wheel 466 from the ywheel gear teeth. The operator will permit the starter rope 48 to retract into the rope groove 42 and if the Wheel 66 is not directly disposed adjacent the rope pulley at this time, the frictional resistance to rotation of the wheel will cause the `wheel to move adjacent the rope pulley to the position shown` in full lines in FIG. 1. As the rope is wound on the pulley 40, the guide 114 will insure that the rope enters the pulley groove. The starter components are now related as shown in FIG. 1 and ready for the next starting cycle.

The starter of the invention can be readily employed with a wide variety of motor constructions as it is only necessary to make modifications in the configuration of the support bracket 20'and the location of the mounting holes 24 to accommodate many engines. By employing a rope pulley having a hardness substantially equal to that of the rope 48, fraying of the rope due to engagement with the pulley, particularly in the area of the hole 44, is prevented. Also, -by using dissimilar synthetic plastic materials for the rope pulley and the cranking wheel 66, a self-lubricating, easily sliding operation is assured.

It is appreciated that various modifications to the invention may be apparent to those skilled in the art without departing from the Ispirit and scope thereof, and it is intended that the invention be defined only by the scope of the following claims.

I claim:

1. A recoil starter for internal combustion engines particularly adapted for mounting upon the side of an engine comprising, in combination,

(a) a support bracket having a cylindrical cantilever supported shaft extending therefrom, said shaft having a free end,

(b) a pulley rotatably mounted on said shaft having a starter rope-receiving groove defined therein, an outer radially extending face disposed remote from said bracket and an axially extending hub projection extending toward said bracket,

(c) an engine cranking wheel having engine engageable means defined thereon axially movably mounted upon said hub projection concentric to the axis of pulley rotation,

(d) means interconnecting said hub projection and wheel producing axial displacement of said wheel on said projection during initial angular displacement of said pulley with respect to said wheel and causing said Wheel to be angularly locked with respect to said pulley at a predetermined axial position of said wheel upon said projection,

(e) a spring anchor dened at the free end of said shaft,

(f) a spiral recoil spring mounted adjacent said pulley outer face and having an inner end andan outer end, said spring inner end being connectible to said spring anchor and said outer end being connected to said pulley,

(g) brake means resisting rotation of said wheel, and

(h) a starter rope having an inner end connected to said pulley adapted to be wound within said pulley groove.

2. In a recoil starter as in claim 1 wherein:

(a) said pulley includes a recess delined therein having a closed ybottom surface and a continuous annular wall,

(b) said recoil spring being received within said pulley recess, and

(c) a cover afxed to said pulley engaging said continuous wall and enclosing said recess whereby said recess and cover form a relatively dirt-free chamber for said recoil spring.

3. A handle for a starter rope having an abutment defined thereon of greater transverse dimension than the rope diameter comprising, in combination,

(a) a rst handle element including a body portion having an exterior surface and a bottom surface,

(b) a chamber defined in said body portion of sufficient dimension to contain the rope abutment,

(c) a rope outlet slot dened in said body portion of a transverse dimension substantially equal to said rope diameter and less than that of the rope abutment, said slot intersecting said -body portion exterior and bottom surface and communicating with said chamber (d) said body portion including an opening defined therein intersecting said exterior surface and said slot and communicating with said chamber and of sufficient dimension to receive the rope abutment whereby placing of the lrope abutment in said chamber ythrough said opening permits said rope to extend from said chamber through said outlet slot, said opening being transversely disposed to the longitudinal length of the .rope received within said slot, and

(e) retainer means mounted on said body portion retaining the rope abutment within said chamber.

4. In a handle for a rope starter as in claim 3 wherein: (a) said retainer means comprises an annular collar circumscribing said body portion exterior surface. 5. In a handle for a starter rope as in claim 3 wherein: (a) said first handle element includes a gripping portion affixed to said body portion and transversely related thereto,

(b) a second handle element having a recess dened therein adapted to receive said rst handle element gripping portion, and

(c) a bore defined in said second handle element intersecting said recess defined therein, said first handle element body portion being received within said bore whereby said second handle element comprises the retainer means retaining the rope abutment within said chamber.

6. In a handle for a starter rope as in claim 5 wherein:

(a) said first handle element is formed of a su-bstantially rigid material, and

(b) said second handle element is formed of a resilient material.

7. A recoil sta-rter for internal combustion engines particularly adapted for mounting upon the side of an engine comprising, in combination,

(a) a support bracket having a cylindrical shaft extending there-from, said shaft having a free end,

(b) a pulley rotatably mounted on said shaft having a starter rope receiving groove defined therein and an axially extending hub projection,

(c) an engine cranking wheel having engine engageable means defined thereon axially movably mounted upon said hub projection concentric to the axis cf pulley rotation,

(d) means` interconnecting said hub projection and wheel producing axial displacement of said wheel on said projection during initial angular displacement of said pulley with respect to said wheel and causing said wheel to be angularly locked with respect to said pulley at a predetermined axial position of said wheel upon said projection,

(e) a spiral recoil spring having an inner end and an outer end, said outer end being connected to said pulley,

(f) a spring anchor defined at the free end of said shaft, said spring anchor comprising a cup affixed to the free end of said shaft, said cup including an axially extending wall portion extending in the axial direction of said shaft, a lportion of said wall portion being lanced and deflected radially inwardly to define an axially extending edge in said cup wall portion adapted to Ibe engaged by said recoil spiral spring inner end, said inwardly deflected portion preventing retaining engagement of said spring inner end `with said cup upon said spring being unwound a predetermined degree,

(g) brake means resisting rotation of said wheel, and,

(h) a starter rope having an inner end connected to said pulley adapted to be wound within said pulley groove.

8. A recoil starter for internal combustion engines particularly adapted for mounting upon the side of an engine comprising, in combination,

(a) a support bracket having a cylindrical shaft extending therefrom, said shaft having a free end,

(b) a pulley rotatably mounted on said shaft having a starter rope receiving groove defined therein and an axially extending hub projection,

(c) an engine cranking wheel having engine engageable means defined thereon axially movably mounted upon said hub projection concentric to the laxis of pulley rotation,

(d) means interconnecting said hub projection and wheel producing axial displacement of said wheel on said projection during initial angular displacement of said pulley with respect to said wheel and causing said wheel to -be angularly locked with respect to said pulley at a predetermined axial position of said wheel upon said projection, said means comprising a spiral rib defined on said projection concentric with the axis of rotation of said pulley and extending substantially the `axial length of said projection,

(e) a spiral groove defined in said wheel adapted to receive said rib,

(f) a spring anchor dened at the free end of said shaft,

(g) a spiral recoil spring having an inner end and an outer end, said spring inner end being connectible to said spring anchor and said outer end being connected to said pulley,

(h) brake means resisting rotation of said wheel, and,

(i) a starter rope having an inner end connected to said pulley adapted to be wound Within said pulley groove.

9. A recoil starter for internal combustion engines particularly adapted for mounting upon the side of an engine comp-rising, in combination,

(a) a support bracket having a cylindrical shaft extending therefrom, said shaft having a free end,

(-b) a pulley rotatably mounted on said shaft having a starter rope receiving groove defined therein and an axially extending hub projection,

(c) an engine cranking Wheel having engine engageable means defined thereon axially movably mounted upon said hub projection concentric to the axis of pulley rotation,

(d) means interconnecting said hub projection and Wheel producing axial displacement of said wheel on said projection during initial angular displacement of said pulley with respect to said Wheel and causing said Wheel to be angularly locked with respect to said pulley at a predetermined axial position of said Wheel upon said projection,

(e) a spring anchor dened at the free end of said shaft,

(f) a spiral recoil spring having an inner end and an Outer end, said spring inner end being connectible to said spring anchor and said outer end being connected to said pulley,

(g) brake means resisting rotation of said wheel,

(h) a starter rope having an inner end connected to said pulley adapted to be wound within said pulley groove, and

(i) a rope retainer dened on said bracket, said rope retainer adapted to hold said starter rope to prevent unwinding of said pulley after said spiral spring has been partially Wound and prior to said starter being completely installed upon an engine..

References Cited UNITED STATES PATENTS 2,348,547 5/1944 Kissel 123-185 2,722,209 11/1955 Pillow 123-185 2,938,511 S/l960 Pike 123-185 25 RALPH D. BLAKESLEE, Primary Examiner.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US519694A US3375813A (en) | 1966-01-10 | 1966-01-10 | Side-mounted internal combustion engine starter |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US519694A US3375813A (en) | 1966-01-10 | 1966-01-10 | Side-mounted internal combustion engine starter |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3375813A true US3375813A (en) | 1968-04-02 |

Family

ID=24069380

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US519694A Expired - Lifetime US3375813A (en) | 1966-01-10 | 1966-01-10 | Side-mounted internal combustion engine starter |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3375813A (en) |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3465740A (en) * | 1968-02-13 | 1969-09-09 | Briggs & Stratton Corp | Pull rope type starter for vertical shaft engines |

| US3827307A (en) * | 1973-07-12 | 1974-08-06 | Briggs & Stratton Corp | Drag device for bendix-type rope starters |

| US4019490A (en) * | 1975-05-09 | 1977-04-26 | Tecumseh Products Company | Pull-rope recoil starter |

| JPS54158930U (en) * | 1978-04-27 | 1979-11-06 | ||

| EP0048183A3 (en) * | 1980-09-17 | 1982-06-23 | Tecumseh Products Company | Internal combustion engines |

| US4507917A (en) * | 1980-09-17 | 1985-04-02 | Tecumseh Products Company | Economical engine construction having integrally cast muffler |

| US4582030A (en) * | 1984-03-02 | 1986-04-15 | Tecumseh Products Company | Mounting recoil starter |

| US4658775A (en) * | 1985-12-23 | 1987-04-21 | Eaton Stamping Company | Rope starter for engines |

| US5237722A (en) * | 1992-04-09 | 1993-08-24 | Ott David L | Rope pulling device |

| US6026695A (en) * | 1998-06-16 | 2000-02-22 | Ingersoll-Rand Company | Engine starter housing and an annular housing extension therefor |

| US6792908B1 (en) | 2003-06-25 | 2004-09-21 | Starting Industrial Co., Ltd. | Recoil assembly for a pull starter |

| US20080016654A1 (en) * | 2006-07-21 | 2008-01-24 | M Group, Inc. | Engine pull start handle |

| US20090301424A1 (en) * | 2007-01-23 | 2009-12-10 | 0813446 B.C. Ltd. | Starter pull cords for internal combustion engines |

| WO2010060900A1 (en) * | 2008-11-26 | 2010-06-03 | Dsm Ip Assets B.V. | Automotive flywheels |

| US11428198B2 (en) * | 2020-06-29 | 2022-08-30 | Starting Industrial Co., Ltd. | Engine starting device |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2348547A (en) * | 1941-01-09 | 1944-05-09 | B M Kissel | Starting device |

| US2722209A (en) * | 1954-02-26 | 1955-11-01 | Benjamin M Pillow | Starter rope handle |

| US2938511A (en) * | 1955-12-06 | 1960-05-31 | West Bend Aluminum Co | Rewind starting device for outboard motors |

-

1966

- 1966-01-10 US US519694A patent/US3375813A/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2348547A (en) * | 1941-01-09 | 1944-05-09 | B M Kissel | Starting device |

| US2722209A (en) * | 1954-02-26 | 1955-11-01 | Benjamin M Pillow | Starter rope handle |

| US2938511A (en) * | 1955-12-06 | 1960-05-31 | West Bend Aluminum Co | Rewind starting device for outboard motors |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3465740A (en) * | 1968-02-13 | 1969-09-09 | Briggs & Stratton Corp | Pull rope type starter for vertical shaft engines |

| US3827307A (en) * | 1973-07-12 | 1974-08-06 | Briggs & Stratton Corp | Drag device for bendix-type rope starters |

| US4019490A (en) * | 1975-05-09 | 1977-04-26 | Tecumseh Products Company | Pull-rope recoil starter |

| JPS54158930U (en) * | 1978-04-27 | 1979-11-06 | ||

| EP0048183A3 (en) * | 1980-09-17 | 1982-06-23 | Tecumseh Products Company | Internal combustion engines |

| US4507917A (en) * | 1980-09-17 | 1985-04-02 | Tecumseh Products Company | Economical engine construction having integrally cast muffler |

| US4582030A (en) * | 1984-03-02 | 1986-04-15 | Tecumseh Products Company | Mounting recoil starter |

| US4658775A (en) * | 1985-12-23 | 1987-04-21 | Eaton Stamping Company | Rope starter for engines |

| US5237722A (en) * | 1992-04-09 | 1993-08-24 | Ott David L | Rope pulling device |

| US6026695A (en) * | 1998-06-16 | 2000-02-22 | Ingersoll-Rand Company | Engine starter housing and an annular housing extension therefor |

| US6792908B1 (en) | 2003-06-25 | 2004-09-21 | Starting Industrial Co., Ltd. | Recoil assembly for a pull starter |

| US20080016654A1 (en) * | 2006-07-21 | 2008-01-24 | M Group, Inc. | Engine pull start handle |

| US8020257B2 (en) * | 2006-07-21 | 2011-09-20 | M Group, Inc. | Engine pull start handle |

| US20090301424A1 (en) * | 2007-01-23 | 2009-12-10 | 0813446 B.C. Ltd. | Starter pull cords for internal combustion engines |

| WO2010060900A1 (en) * | 2008-11-26 | 2010-06-03 | Dsm Ip Assets B.V. | Automotive flywheels |

| US11428198B2 (en) * | 2020-06-29 | 2022-08-30 | Starting Industrial Co., Ltd. | Engine starting device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3375813A (en) | Side-mounted internal combustion engine starter | |

| US3375814A (en) | Pulley construction for recoil starter | |

| US6230678B1 (en) | Starting and stopping device for internal combustion engine | |

| US4019490A (en) | Pull-rope recoil starter | |

| US4582030A (en) | Mounting recoil starter | |

| US5431135A (en) | Starter assembly | |

| US4658775A (en) | Rope starter for engines | |

| US6679216B2 (en) | Starters for internal combustion engine | |

| US2804173A (en) | Turning device for rotatable body | |

| US3024780A (en) | Side mounted starter | |

| US3827307A (en) | Drag device for bendix-type rope starters | |

| US2875851A (en) | Vakos | |

| US3744468A (en) | Combined rope starter and guard for gasoline engines | |

| US4068644A (en) | Rewind starter pulley assembly | |

| US4149510A (en) | Recoil type starter for internal-combustion engine | |

| US3465740A (en) | Pull rope type starter for vertical shaft engines | |

| US3081760A (en) | Spring starter | |

| US2386703A (en) | Starting device for outboard motors | |

| US2955584A (en) | Engaging means of starter to gasoline engine | |

| US2999490A (en) | Spring starter | |

| DE581477C (en) | Starter device | |

| JP3820140B2 (en) | Internal combustion engine starter | |

| US3267922A (en) | Release mechanism for starter | |

| US3000471A (en) | Spring brake for gasoline engine starter | |

| US6581562B2 (en) | Open center recoil starter |