US3290549A - Electroluminescent display device with piezoelectrical scanning and gating means - Google Patents

Electroluminescent display device with piezoelectrical scanning and gating means Download PDFInfo

- Publication number

- US3290549A US3290549A US47989A US4798960A US3290549A US 3290549 A US3290549 A US 3290549A US 47989 A US47989 A US 47989A US 4798960 A US4798960 A US 4798960A US 3290549 A US3290549 A US 3290549A

- Authority

- US

- United States

- Prior art keywords

- electroluminescent

- phosphor

- frequency

- display device

- generator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 claims description 33

- 239000013078 crystal Substances 0.000 claims description 16

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 44

- 238000000576 coating method Methods 0.000 description 23

- 239000011248 coating agent Substances 0.000 description 18

- 230000005684 electric field Effects 0.000 description 17

- 239000004020 conductor Substances 0.000 description 14

- 239000012799 electrically-conductive coating Substances 0.000 description 11

- 230000010287 polarization Effects 0.000 description 5

- 239000002178 crystalline material Substances 0.000 description 3

- 230000001419 dependent effect Effects 0.000 description 3

- 239000010453 quartz Substances 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- 241001247986 Calotropis procera Species 0.000 description 2

- 229910021627 Tin(IV) chloride Inorganic materials 0.000 description 2

- 230000003321 amplification Effects 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005401 electroluminescence Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 238000003199 nucleic acid amplification method Methods 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 238000010408 sweeping Methods 0.000 description 2

- 230000001360 synchronised effect Effects 0.000 description 2

- HPGGPRDJHPYFRM-UHFFFAOYSA-J tin(iv) chloride Chemical compound Cl[Sn](Cl)(Cl)Cl HPGGPRDJHPYFRM-UHFFFAOYSA-J 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910005540 GaP Inorganic materials 0.000 description 1

- 239000005083 Zinc sulfide Substances 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- LFVGISIMTYGQHF-UHFFFAOYSA-N ammonium dihydrogen phosphate Chemical compound [NH4+].OP(O)([O-])=O LFVGISIMTYGQHF-UHFFFAOYSA-N 0.000 description 1

- 229910000387 ammonium dihydrogen phosphate Inorganic materials 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- DSAJWYNOEDNPEQ-UHFFFAOYSA-N barium atom Chemical compound [Ba] DSAJWYNOEDNPEQ-UHFFFAOYSA-N 0.000 description 1

- JRPBQTZRNDNNOP-UHFFFAOYSA-N barium titanate Chemical compound [Ba+2].[Ba+2].[O-][Ti]([O-])([O-])[O-] JRPBQTZRNDNNOP-UHFFFAOYSA-N 0.000 description 1

- 229910002113 barium titanate Inorganic materials 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- NKZSPGSOXYXWQA-UHFFFAOYSA-N dioxido(oxo)titanium;lead(2+) Chemical compound [Pb+2].[O-][Ti]([O-])=O NKZSPGSOXYXWQA-UHFFFAOYSA-N 0.000 description 1

- HZXMRANICFIONG-UHFFFAOYSA-N gallium phosphide Chemical compound [Ga]#P HZXMRANICFIONG-UHFFFAOYSA-N 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 235000019837 monoammonium phosphate Nutrition 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- LJCNRYVRMXRIQR-OLXYHTOASA-L potassium sodium L-tartrate Chemical compound [Na+].[K+].[O-]C(=O)[C@H](O)[C@@H](O)C([O-])=O LJCNRYVRMXRIQR-OLXYHTOASA-L 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 235000011006 sodium potassium tartrate Nutrition 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

- 229910052984 zinc sulfide Inorganic materials 0.000 description 1

- DRDVZXDWVBGGMH-UHFFFAOYSA-N zinc;sulfide Chemical compound [S-2].[Zn+2] DRDVZXDWVBGGMH-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

- H05B33/12—Light sources with substantially two-dimensional radiating surfaces

- H05B33/22—Light sources with substantially two-dimensional radiating surfaces characterised by the chemical or physical composition or the arrangement of auxiliary dielectric or reflective layers

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

Definitions

- the present invention relates to display devices and, more particularly, to a display device employing an electroluminescent light emitting phosphor of which selective areas may be energized by an electric field established by one or more piezoelectric crystal elements.

- the conventional electroluminescent display devices which are capable of effecting energization of selected areas of the light-emitting phosphor material typically comprise a first grid of spaced parallel conductors, a second grid of spaced parallel conductors spaced in electrically insulated relationship with the first grid, the conductors of the second grid running at substantially a right angle to the conductors of the first grid, and a phosphor layer positioned between the grids.

- the phosphor layer is composed of an electroluminescent phosphor emitting light phased with the applied voltage.

- a switching arrangement is employed to simultaneously energize selective ones of the conductors of the first and second grids to generate an intense electric field in localized regions of the device where the conductors cross one another.

- the electric field causes the phosphor to luminesce as a spot and by proper synchronization of the switching arrangement, a spot can be made to traverse the phosphor layer and thereby create a, raster.

- modulation of the applied voltage it is possible to vary the intensity of the emitted light and thereby display information much in the same manner as in conventional television receiver systems.

- the conventional crossed grid type of electroluminescent display devices have certain disadvantages which the present invention overcomes.

- Among these disadvantages is t-he necessity tor the use of a high-speed precision switch with which it is difficult to obtain high resolution.

- Colored displays are impractical as it is necessary in order to obtain color displays to use a plurality of superposed layers of diiferent color light emitting phosphors, each layer having its own crossed grid network.

- control requirement on the phosphor Circuitry, and voltages are severe in order to avoid electroluminescence by sufficiently high electric field being developed in areas other than the cross-over points of the conductors, causing a background problem.

- a further object of the invention is to produce an electroluminescent display device capable of exceedingly good resolution, definition, and brightness characteristics.

- the invention typically may be defined as an electroluminescent display devi-ce comprising a piezoelectric crystal structure shaped to provide zones of differential response to oscillating potentials, electroluminescent means responsive to an electric field positioned as a coating on the surface of the crystal structure, and means for applying an oscillating potential to the structure to create an electric field at a surface zone of the structure; which zone is determined by the frequency of the applied potential.

- FIG. 1 is a diagrammatic illustration of a system capable of employing and energizing the invention

- FIG. 2 is a diagrammatic illustration of a basic principle of the invention wherein a plurality of discrete crystalline elements are adapted to energize the associated phosphor coatings;

- FIG. 3 is a diagrammatic illustration of another embodiment of the invention wherein a single wedge-shaped crystalline element is employed to energize selected areas of an associated phosphor coating;

- FIG. 4 is a diagrammatic illustration of an alternative arrangement for energizing an electroluminescent display device in accordance with the present invention

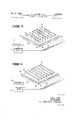

- FIG. 5 is a perspective view of a modification of the invention which is capable of displaying conventional video television signals wherein each scanning line of the device is similar to the arrangement shown in FIG. 2 being comprised of a plurality of individual crystalline cylinders, each provided with a coating of electroluminescent phosphor material on one surface thereof;

- FIG. 6 is a perspective view of another modification of the invention which is capable of displaying conventional video television signals wherein each scanning line of the device is similar to the arrangement shown in FIG. 3 being comprised of a single wedge-shaped crystalline elementbeing provided with a coating of electroluminescent phosphor material on one surface thereof; and

- FIG. 7 is a diagrammatic illustration of an embodiment of the invention 'for use as an aircraft altitude meter.

- the underlying principle of the present invention is that a luminescent light spot can be created and caused to move about on a panel surface of electroluminescent material by varying the frequency of the driving voltage applied to the means tor establishing the electric field applied to the phosphor material.

- the intensity of the light output will depend upon the magnitude of the driving voltage, since this voltage, in turn, is responsible for the electric field strength applied to the phosphor.

- an electronic sweep frequency oscillator 10 is actually all that is necessary to achieve a light spot movement on the display panel 12, while a video input 14 is fed to a modulator 16 to provide :for amplitude modulation of the driving voltage and thereby effect an intensity modulation of the resultant luminescent spot.

- the output of the modulator may be fed through a driver amplifier network 18.

- FIG. 2 illustrates one simple embodiment of a display device incorporating the principles of the invention.

- a plurality of piezoelectric cylinders 20 each being provided with an electrically conductive coating 22 disposed on the bottom thereof.

- the top of each of the cylinders 20 is provided with an electroluminescent phosphor coating 24 and an electrically conductive coating 26. It may .be desirable in certain applications of the invention to insulatingly separate the coatings 24- and 26 by slight spacing therebetween or alternatively by disposing a dielectric material therebetween.

- the phosphor coating 24 consumes the majority of the area of the top of the cylinders 20, while the electrically conductive coating 26 consumes only a small portion of the area of the top.

- the plurality of cylinders 20 is connected in electrically parallel relationship across a variable frequency generator 28 by electrically conductive leads 3% and 32.

- the lead 30 is connected to the electrically conductive coating 22, on the bottom of the cylinders 20, while the lead 32 is connected to the electrically conductive coating 26 on the top of the cylinders 20.

- Each of the cylinders is formed of a crystalline material such as barium titanate and has its own resonating frequency, each differing from the other.

- the phosphor layers 24 give off light through a phenomenon of electroluminescence which is a process by which certain semiconducting materials known as phosphors, emit radiant energy at room temperature under the primary stimulus of a varying electrical potential, which generates a varying electric field.

- phosphors include, for example, gallium phosphide and zinc sulfide activated with copper. While there are several scientific theories presently advanced to explain the mechanism by which electnoluminescence occurs, a discussion of these theories is not essential in this description.

- the material which is used to fabricate the crystalline cylinders 20 is a piezoelectric material and may be defined as one which exhibits a phenomenon of expansion along one axis and contracts on another axis when subjected to an applied voltage and in response thereto a strong polarization (electric) field is generated :across its end surfaces. The intensity of the generated field is dependent upon the applied voltage.

- piezoelectric materials may be either single crystals as quartz, Rochelle salt, or ammonium dihydrogen phosphate; or they may be polycrystalline material such as ferroelectric barium or lead titanate ceramics which have been polarized.

- a generator 28 when a generator 28 is energized to produce a voltage of a frequency equal to the resonant frequency of one of the cylinders 20, that cylinder will respond in its vibrational mode and a strong polarization (electric) field will be generated across its end surfaces.

- the generator 28 is producing a voltage of a frequency equal to the resonant frequency of the centermost cylinder 20 of the plurality illustrated in FIG. 2.

- the intensity of the field produced or developed by the resonating cylinder is dependent upon the voltage output of the generator 28.

- the electric field established across the end surface of the resonating cylinder is sufficient to energize the electroluminescent coating 24 and thereby cause light to be emitted therefrom.

- the different cylinders 20 can be made to respond selectively, with the light output following the tuned cylinder 20 and the light modulation being achieved by modulating the amplitude of the voltage output of the. generator 28.

- FIG. 3 Similar results, that is, the ability to effect selective area energization of an electroluminescent coating, may likewise be achieved by the structures shown in FIG. 3.

- a crystalline wedge 20' similar to the cylinders 20 of FIG. 2, made of quartz or the like material, and is provided with an electrically conductive coating 22' on the bottom surface thereof.

- An electroluminescent phosphor layer 24 is coated on the major portion of the top of the wedge 26) and an electrically conductive coating 26 on the remaining portion of the top thereof.

- the wedge is electrically connected to frequency generator 28 through conductors 30 and 32. Localized resonance of the wedge 20' is obtained by varying the frequency of the generator 28' which will accordingly enengize selective areas of the electroluminescent phosphor coating 24'. Since the resonant frequency of the crystalline material of the wedge 30 is a sharp function of the geometry of the wedge, localized resonance may be readily attained.

- the movement of the light spot or energized area of the phosphor coating may be generated without the need for electrodes other than the conductive coatings on the top and bottom of piezoelectric material to be placed in close proximity to the display device.

- the electric field which is effective to energize the phosphor material is generated by polarization charges appearing at the surface of the crystal. These changes can be made to appear at surfaces to which no electrical connections are made. If the crystalline elements are properly shaped, the vibrational polarization fields can be inducedwith the electrodes placed a significant distance along the crystal away from the surface thereof which is coated with the phosphor layer.

- FIG. 4 It has been found advantageous in certain applications where it is desirable to obtain a maximum field across the surface of the energizing crystal to employ a structure such as shown in FIG. 4.

- a crystalline element 40 provided with an electroluminescent phosphor coating 42 on the upper surface thereof.

- a transparent electrically conducting coating 43 such as stannic chloride on a sheet of glass 44, is disposed over the entire uppermost surface of the phosphor coating 42.

- the base of the element 40 is provided with an electrically conductive coating 46 which may in certain applications be transparent to thereby allow the light emitted from the phosphor coating 42 to be viewed from both sides, the crystalline material of the element 40 must either be transparent or translucent.

- Both the electrically conductive coatings, 43 and 46 are coupled together through an electrically conducting wire 48.

- a generator 50 capable of producing a variable frequency voltage, has one of its output terminals connected to an electrically conductive strip 54 through an electrically conducting wire 52.

- the strip 54 is adapted to be in intimate contact with the side walls of the crystalline element 40.

- the other output terminal of the generator 50 is connected to the electrically conductive coating 46 through an electrically conducting wire 56.

- the generator 50 is effective, when operated at the resonant frequency of the crystalline element 40, to create :an electric field across the surface thereof.

- the conducting coatings 43 and 46 provide a minimum path length for the electric field and, therefore, achieves maximum therein. This action is similar and can be compared to moving the plates of a parallel plate condenser closer to one another, while maintaining the same potention difference across the plates. Since the field intensity is given by the following relation:

- the arrang ment illustrated in FIG. 4 has an advantage in that the voltage applied directly to the electrode strip 54 also contributes a field across the electroluminescent phosphor layer 42 in addition to the polarization field created by the piezoelectric material of the crystal 40.

- This device also provides significant voltage amplification.

- the potential difference across the phosphor has been found to be three to four times the voltage driving the piezoelectric element (at resonance operation). Using a driving voltage of about v. light output comparable to the TV type displays has been obtained.

- FIGS. 5 and 6 In an application where the device is employed as a TV type display, for example, arrangements such as illustrated in FIGS. 5 and 6 may be used.

- FIG. 5 an arrangement of piezoelectric cylinders 60 are disposed in a predetermined pattern on a layer 62 of an electroluminescent phosphor which, in turn, is desposited on a transparent supporting panel 66 formed of glass or the like material.

- the supporting panel 66 is provided with the transparent conductive coating 68.

- the opposite end of the cylinders 60 are coated with an electrically conductive material 64.

- the various groups of cylinders 60 are connected together in rows in parallel by Wires 69 and 70 to a switching device 72 which, in turn, is connected to a generator 74 capable of producing variable frequency signals.

- a generator 74 capable of producing variable frequency signals.

- the cylinders 60 of each row vary in length from one side to another in an arrangement similar to that illustrated in FIGURE 22, therefore, each cylinder will resonate and establish an energizing field for the phosphor layer at a different frequency.

- the generator 74 is tuned to a frequency at which one of the cylinders 60 will resonate, that cylinder will create an electric field at the end thereof in contact with the electroluminescent layer 62 and cause a localized zone thereof to fluoresce.

- the intensity of the field created by the individual cylinders 60 is a function of the voltage output of the generator 74; the higher the voltage, the higher the intensity of the field and the resultant emitted light.

- the various cylinders 60 of a single row may be made to respond one at a time, with the light output following the tuned cylinder, and the light modulated in accordance with the modulation of the generator voltage.

- the switching circuit 72 may be caused to switch the voltage signal produced by the generator 74, to selectively energize adjacent rows of cylinders. It will be appreciated by those skilled in the art that by proper synchronization the cylinders 60 can be energized in such a manner as to produce a raster much in the same way a raster is produced in the conventional cathode ray tubes used in television reception.

- FIG. 6 Another embodiment of the invention is illustrated in FIG. 6 wherein an arrangement of piezoelectric wedges 80, each being of the type illustrated in FIG. 3, is disposed on a layer 82 of an electroluminescent phosphor which, in turn, is deposited on a transparent electrically conductive coating 84, of a supporting panel 86.

- the opposite side of the wedges 80 from that in contact with the phosphor is provided with an electrically conductive coating 88.

- Each wedge 80 is connected to a variable frequency generator 90 through a switching circuit 92 by an electrically conducting wire 89.

- the wires 89 may be cabled together as shown.

- the conductive coating 84 is likewise connected to the switching device 92 through an electrically conducting wire 91.

- the generator 90 is capable of producing variable frequency signals to cause various zones of the wedges 80 to resonate and thereby create associated electric fields to excite the electroluminescent phosphor 82. Thereby a light spot can be produced and caused to move along a wedge 80 by merely varying the frequency of the generator 90. Then, as in the embodiment illustrated in FIG. 5, the adjacent wedges 80 may be selectively energized by the switching circuit 92.

- the resolution available with a wedge is determined mainly by the piezoelectric material from which the wedges are made and geometry of the wedge. For all intents and purposes, the embodiment illustrated in FIG. 6 is operated in the same manner as the embodiment of FIG. 5.

- the generator 90 is operating to produce a voltage signal of a given frequency, only one spot on the energized wedge will establish a field of the proper intensity to cause light to be emitted from a single zone of the phosphor layer 82. A change in the frequency of the applied voltage causes the light spot to move.

- all of the wedges 80 can be placed electrically in parallel and by a single traversal through the frequency range, the spot would move over the entire panel.

- the wedges 80 are connected as shown in FIG. 6 and are, in operation, frequency scanned one at a time in any desired sequence 'by the switching device 92 and will display video information by amplitude modulation of the electric field generator 90.

- the wedge element 100 is formed of quartz or other suitable material which is substantially transparent to the light emitted from an associated electroluminescent phosphor material layer 102 coated on one side of the element.

- a conductive coating 104 is applied to the outer surface of the phosphor layer 102 and may be a light transparent material such as stannic chloride in which case the light emitted from the phosphor coating may be viewed from two sides of the wedge element 100, or may be formed of an opaque conducting material which would obviously permit viewing of the light emitted from the phosphor layer 102 only through the material of the element 100.

- the conductive layer 104 may cover the entire exposed surface of the phosphor layer 102 as illustrated in FIG. 4 or may be applied in the manner illustrated in FIGS. 2 and 3.

- the conductive layer 104 is shown as being connected to ground potential through a conductive wire 106.

- a strip 108 of electrically conductive material is applied to the side walls of the element 100 and is, in turn, connected to the energizing circuit through a conductive wire 110.

- the surface of the element 100 which is opposed to the surface on which the phosphor layer 102 is applied is provided with indicia indicating various altitudes. If wedge 100 is formed of non-transparent piezoelectric material, the phosphor layer should be positioned between the wedge and an indicia bearing member.

- the energizing circuit comprises an altitude sensing device 112 which is capable of producing a DC. output signal proportional in strength to the sensed altitude. Conventional radar systems may be satisfactorily employed for this purpose.

- the output signal produced by the altitude sensing device 112 is fed to a comparisongating circuit 114.

- the comparison-gating circuit 114 is capable of producing a saw-tooth reference signal.

- the comparator portion of the circuit 114 compares the DC. signal received from the sensing device 112 with the saw tooth reference signal.

- the slope of the saw tooth signal is set to correspond to the altituderange required for the sensing device 112.

- the DC signal from the sensing device 112 will then exceed the saw tooth signal up to an altitude match.

- the saw tooth reference signal of the comparison-gating circuit is synchronized with a sweep frequency signal fed thereto by a sweep frequency generator 115. Thereby, the saw tooth reference signal commences when the sweep frequency generator 116 starts its frequency scan. For all levels of the DC. signal from the sensing device 112 which exceed the reference signal, a gate is opened and the output of the sweep frequency generator 116 is passed to an amplifier 118 and to the altitude display device through the conductor 110.

- the altitude sensing device 112 senses a signal corresponding to 11,000 feet, for example, a DC. signal is fed to the comparison-gating circuit 114 which is operative to open a gate and allow only that frequency signal of the generator 116 effective to energize the top portion of the wedge element 100 to pass to the amplifier 118 and thence to the conductive strip 108 of the wedge element 100 through the conductor 110.

- the electroluminescent phosphor material 102 adjacent the upper portion of the wedge element 100 is excited to give off visible light indicating an altitude of 11,000 feet.

- the altitude meter piezoelectric crystal display element 100 provides significant voltage amplification.

- the potential difference across the phosphor 102 will be found to exceed the driving voltage applied between str-ip 108 and ground return wire 106.

- electroluminescent material is phosphor

- electroluminescent materials include electric field sensitive fluorescent liquids and jells, or gases with suitable discharge characteristics. In use, these materials are contained in a thin panel, one surface of which is in contact with the piezoelectric material.

- Display devices such as those hereinabove described and illustrated in the drawings also may be employed as frequency spectrum analyzers.

- the signal to be examined is fed into a variable, sharply tuned, resonant circuit synchronized to the sweeping oscillation.

- the tuned circuit employs a voltage dependent capacitor to vary the resonant frequency of the circuit.

- the output of the tuned circuit is rectified and filtered to eliminate the carrier.

- This video signal is then fed to the modulator 16 of FIG. 1 and thence to the display device 12 through an amplifier 18 and thereby cause the display panel 12 to exhibit visibly the frequency characteristics of the incoming signal.

- An electroluminescent display device comprising a Wedge shaped piezoelectric crystal element, an electroluminescent material disposed on a tapering longitudinal surface of said crystal element, an electrode disposed on the same surface as said material, said electrode and said material extending along the entire length of said surface, the widthwise dimension of said electrode, with respect to the width of said tapering longitudinal surface, being less than the widthwise dimension of said electroluminescent material, and a base electrode extending over that surface of said crystal which is opposite to said tapering surface.

Landscapes

- Control Of Indicators Other Than Cathode Ray Tubes (AREA)

Description

Dec. 6, 1966 J J. LAMBE ETAL 3,290,549

ELECTROLUMINESCENT DISPLAY DEVICE WITH PIEZOELECTRICAL SCANNING AND GATING MEANS Filed Au 8, 1960 5 Sheets-Sheet 1 E z: 1.. VIDEO l6 l8 l2 fi K ELECTRON/C DRIVER FLAT PANEL SWEEP/N6 MODULATOR 056, OR AMPL/F/ER DISPLAY 1 I l 1 22 20 30 2o 2 1NVENTOR JOHN J. LAMBE JOSEPH MUDAR SOL NUDELMAN BY 5% -r 5M ATTORNEYS Dec. 6, 1966 J. J. LAMBE ETAL 3,290,549

ELECTROLUMINESCENT ELECTRICAL DISPLAY DEVICE WITH PIEZO SCANNING AND GATING MEANS 3 Sheets-Sheet 2 Filed Aug. 8, 1960 SWITCHING DEVICE SWITCHING DEVICE INVENTORS JOHN J. LAMBE JOSEPH MUDAR SOL NUDELMAN BY 5M? 8M ATTORNEYS 3,290,549 TRICAL Dec. 6, 1966 J. J. LAMBE ETAL ELECTROLUMINESCENT DISPLAY DEVICE WITH PIEZOELEC SCANNING AND GATING MEANS 5 Sheets-Sheet 5 Filed Aug. 8, 1960 lOO ELECTRONIC SWEEPING OSCILLATOR COMPARISON GATING r-IIB CIRCUIT AMPLIFIER D QQ Off.

I NVEN TOR 5 United States Patent Ofiice 3,290,549 Patented Dec. 6, 1966 3,290,549 ELECTROLUMINESCENT DISPLAY DEVICE WITH PIEZOELECTRICAL SCANNING AND GATING MEANS John J. Lambe, Wayne, Joseph Mudar, Whitrnore Lake,

and Sol Nudelmau, Ann Arbor, Mich, assignors to Research Corporation, New York, N.Y., a corporation of New York Filed Aug. 8, 1960, Ser. No. 47,989 2 Claims. (Cl. 31555) The present invention relates to display devices and, more particularly, to a display device employing an electroluminescent light emitting phosphor of which selective areas may be energized by an electric field established by one or more piezoelectric crystal elements.

The conventional electroluminescent display devices which are capable of effecting energization of selected areas of the light-emitting phosphor material typically comprise a first grid of spaced parallel conductors, a second grid of spaced parallel conductors spaced in electrically insulated relationship with the first grid, the conductors of the second grid running at substantially a right angle to the conductors of the first grid, and a phosphor layer positioned between the grids. The phosphor layer is composed of an electroluminescent phosphor emitting light phased with the applied voltage. In operation, a switching arrangement is employed to simultaneously energize selective ones of the conductors of the first and second grids to generate an intense electric field in localized regions of the device where the conductors cross one another. The electric field causes the phosphor to luminesce as a spot and by proper synchronization of the switching arrangement, a spot can be made to traverse the phosphor layer and thereby create a, raster. By modulation of the applied voltage, it is possible to vary the intensity of the emitted light and thereby display information much in the same manner as in conventional television receiver systems.

A typical system employing such a device is illustrated and described in US. Patent 2,698,915 entitled Phosphor Screen, William W. Piper.

The conventional crossed grid type of electroluminescent display devices have certain disadvantages which the present invention overcomes. Among these disadvantages is t-he necessity tor the use of a high-speed precision switch with which it is difficult to obtain high resolution. Colored displays are impractical as it is necessary in order to obtain color displays to use a plurality of superposed layers of diiferent color light emitting phosphors, each layer having its own crossed grid network. And, thirdly, control requirement on the phosphor Circuitry, and voltages are severe in order to avoid electroluminescence by sufficiently high electric field being developed in areas other than the cross-over points of the conductors, causing a background problem.

It is an object of the present invention to produce an electroluminescent display device wherein discrete areas thereof may be selectively energized by varying the frequency of the energizing potential.

A further object of the invention is to produce an electroluminescent display device capable of exceedingly good resolution, definition, and brightness characteristics.

. The invention typically may be defined as an electroluminescent display devi-ce comprising a piezoelectric crystal structure shaped to provide zones of differential response to oscillating potentials, electroluminescent means responsive to an electric field positioned as a coating on the surface of the crystal structure, and means for applying an oscillating potential to the structure to create an electric field at a surface zone of the structure; which zone is determined by the frequency of the applied potential.

Other objects and advantages of the invention will be manifested from reading the following detailed description of several embodiments of the invention when considered in light of the accompanying drawings in which:

FIG. 1 is a diagrammatic illustration of a system capable of employing and energizing the invention;

FIG. 2 is a diagrammatic illustration of a basic principle of the invention wherein a plurality of discrete crystalline elements are adapted to energize the associated phosphor coatings;

FIG. 3 is a diagrammatic illustration of another embodiment of the invention wherein a single wedge-shaped crystalline element is employed to energize selected areas of an associated phosphor coating;

FIG. 4 is a diagrammatic illustration of an alternative arrangement for energizing an electroluminescent display device in accordance with the present invention;

FIG. 5 is a perspective view of a modification of the invention which is capable of displaying conventional video television signals wherein each scanning line of the device is similar to the arrangement shown in FIG. 2 being comprised of a plurality of individual crystalline cylinders, each provided with a coating of electroluminescent phosphor material on one surface thereof;

FIG. 6 is a perspective view of another modification of the invention which is capable of displaying conventional video television signals wherein each scanning line of the device is similar to the arrangement shown in FIG. 3 being comprised of a single wedge-shaped crystalline elementbeing provided with a coating of electroluminescent phosphor material on one surface thereof; and

FIG. 7 is a diagrammatic illustration of an embodiment of the invention 'for use as an aircraft altitude meter.

The underlying principle of the present invention is that a luminescent light spot can be created and caused to move about on a panel surface of electroluminescent material by varying the frequency of the driving voltage applied to the means tor establishing the electric field applied to the phosphor material. The intensity of the light output will depend upon the magnitude of the driving voltage, since this voltage, in turn, is responsible for the electric field strength applied to the phosphor. As shown in the schematic diagram of FIG. 1, an electronic sweep frequency oscillator 10 is actually all that is necessary to achieve a light spot movement on the display panel 12, while a video input 14 is fed to a modulator 16 to provide :for amplitude modulation of the driving voltage and thereby effect an intensity modulation of the resultant luminescent spot. The output of the modulator may be fed through a driver amplifier network 18.

FIG. 2 illustrates one simple embodiment of a display device incorporating the principles of the invention. There is shown a plurality of piezoelectric cylinders 20, each being provided with an electrically conductive coating 22 disposed on the bottom thereof. The top of each of the cylinders 20 is provided with an electroluminescent phosphor coating 24 and an electrically conductive coating 26. It may .be desirable in certain applications of the invention to insulatingly separate the coatings 24- and 26 by slight spacing therebetween or alternatively by disposing a dielectric material therebetween. It will be noted that the phosphor coating 24 consumes the majority of the area of the top of the cylinders 20, while the electrically conductive coating 26 consumes only a small portion of the area of the top. The plurality of cylinders 20 is connected in electrically parallel relationship across a variable frequency generator 28 by electrically conductive leads 3% and 32. The lead 30 is connected to the electrically conductive coating 22, on the bottom of the cylinders 20, while the lead 32 is connected to the electrically conductive coating 26 on the top of the cylinders 20. Each of the cylinders is formed of a crystalline material such as barium titanate and has its own resonating frequency, each differing from the other.

The phosphor layers 24 give off light through a phenomenon of electroluminescence which is a process by which certain semiconducting materials known as phosphors, emit radiant energy at room temperature under the primary stimulus of a varying electrical potential, which generates a varying electric field. Such phosphors include, for example, gallium phosphide and zinc sulfide activated with copper. While there are several scientific theories presently advanced to explain the mechanism by which electnoluminescence occurs, a discussion of these theories is not essential in this description.

The material which is used to fabricate the crystalline cylinders 20 is a piezoelectric material and may be defined as one which exhibits a phenomenon of expansion along one axis and contracts on another axis when subjected to an applied voltage and in response thereto a strong polarization (electric) field is generated :across its end surfaces. The intensity of the generated field is dependent upon the applied voltage. Such piezoelectric materials may be either single crystals as quartz, Rochelle salt, or ammonium dihydrogen phosphate; or they may be polycrystalline material such as ferroelectric barium or lead titanate ceramics which have been polarized.

With the above background, it will be appreciated that when a generator 28 is energized to produce a voltage of a frequency equal to the resonant frequency of one of the cylinders 20, that cylinder will respond in its vibrational mode and a strong polarization (electric) field will be generated across its end surfaces. For purposes of illustration, we will assume that the generator 28 is producing a voltage of a frequency equal to the resonant frequency of the centermost cylinder 20 of the plurality illustrated in FIG. 2. The intensity of the field produced or developed by the resonating cylinder is dependent upon the voltage output of the generator 28. The electric field established across the end surface of the resonating cylinder is sufficient to energize the electroluminescent coating 24 and thereby cause light to be emitted therefrom. It will be appreciated that by changing the frequency of the generator 28, the different cylinders 20 can be made to respond selectively, with the light output following the tuned cylinder 20 and the light modulation being achieved by modulating the amplitude of the voltage output of the. generator 28.

Similar results, that is, the ability to effect selective area energization of an electroluminescent coating, may likewise be achieved by the structures shown in FIG. 3. In the structure shown in FIG. 3, a crystalline wedge 20' similar to the cylinders 20 of FIG. 2, made of quartz or the like material, and is provided with an electrically conductive coating 22' on the bottom surface thereof. An electroluminescent phosphor layer 24 is coated on the major portion of the top of the wedge 26) and an electrically conductive coating 26 on the remaining portion of the top thereof. The wedge is electrically connected to frequency generator 28 through conductors 30 and 32. Localized resonance of the wedge 20' is obtained by varying the frequency of the generator 28' which will accordingly enengize selective areas of the electroluminescent phosphor coating 24'. Since the resonant frequency of the crystalline material of the wedge 30 is a sharp function of the geometry of the wedge, localized resonance may be readily attained.

It will be appreciated that of primary importance in the application of device of the type already explained is that the movement of the light spot or energized area of the phosphor coating may be generated without the need for electrodes other than the conductive coatings on the top and bottom of piezoelectric material to be placed in close proximity to the display device. The electric field which is effective to energize the phosphor material is generated by polarization charges appearing at the surface of the crystal. These changes can be made to appear at surfaces to which no electrical connections are made. If the crystalline elements are properly shaped, the vibrational polarization fields can be inducedwith the electrodes placed a significant distance along the crystal away from the surface thereof which is coated with the phosphor layer.

It has been found advantageous in certain applications where it is desirable to obtain a maximum field across the surface of the energizing crystal to employ a structure such as shown in FIG. 4. In the arrangement illustrated in FIG. 4, there is a crystalline element 40 provided with an electroluminescent phosphor coating 42 on the upper surface thereof. A transparent electrically conducting coating 43, such as stannic chloride on a sheet of glass 44, is disposed over the entire uppermost surface of the phosphor coating 42. The base of the element 40 is provided with an electrically conductive coating 46 which may in certain applications be transparent to thereby allow the light emitted from the phosphor coating 42 to be viewed from both sides, the crystalline material of the element 40 must either be transparent or translucent. Both the electrically conductive coatings, 43 and 46 are coupled together through an electrically conducting wire 48. A generator 50, capable of producing a variable frequency voltage, has one of its output terminals connected to an electrically conductive strip 54 through an electrically conducting wire 52. The strip 54 is adapted to be in intimate contact with the side walls of the crystalline element 40. The other output terminal of the generator 50 is connected to the electrically conductive coating 46 through an electrically conducting wire 56.

In operation, the generator 50 is effective, when operated at the resonant frequency of the crystalline element 40, to create :an electric field across the surface thereof. The conducting coatings 43 and 46 provide a minimum path length for the electric field and, therefore, achieves maximum therein. This action is similar and can be compared to moving the plates of a parallel plate condenser closer to one another, while maintaining the same potention difference across the plates. Since the field intensity is given by the following relation:

where d is the distance between the plates and v is the voltage acnoss the plates. Therefore, by maintaining a given applied voltage, the field intensity E may be increased by making the distance d between the plates smaller. It is also to be understood that the arrang ment illustrated in FIG. 4 has an advantage in that the voltage applied directly to the electrode strip 54 also contributes a field across the electroluminescent phosphor layer 42 in addition to the polarization field created by the piezoelectric material of the crystal 40.

This device also provides significant voltage amplification. The potential difference across the phosphor has been found to be three to four times the voltage driving the piezoelectric element (at resonance operation). Using a driving voltage of about v. light output comparable to the TV type displays has been obtained.

In an application where the device is employed as a TV type display, for example, arrangements such as illustrated in FIGS. 5 and 6 may be used. In FIG. 5 an arrangement of piezoelectric cylinders 60 are disposed in a predetermined pattern on a layer 62 of an electroluminescent phosphor which, in turn, is desposited on a transparent supporting panel 66 formed of glass or the like material. The supporting panel 66 is provided with the transparent conductive coating 68. The opposite end of the cylinders 60 are coated with an electrically conductive material 64.

The various groups of cylinders 60 are connected together in rows in parallel by Wires 69 and 70 to a switching device 72 which, in turn, is connected to a generator 74 capable of producing variable frequency signals. It will be noted that the cylinders 60 of each row vary in length from one side to another in an arrangement similar to that illustrated in FIGURE 22, therefore, each cylinder will resonate and establish an energizing field for the phosphor layer at a different frequency. When the generator 74 is tuned to a frequency at which one of the cylinders 60 will resonate, that cylinder will create an electric field at the end thereof in contact with the electroluminescent layer 62 and cause a localized zone thereof to fluoresce. The intensity of the field created by the individual cylinders 60 is a function of the voltage output of the generator 74; the higher the voltage, the higher the intensity of the field and the resultant emitted light.

By varying the generator frequency, the various cylinders 60 of a single row may be made to respond one at a time, with the light output following the tuned cylinder, and the light modulated in accordance with the modulation of the generator voltage. At the completion of the energization of .an entire row of cylinders 60, the switching circuit 72 may be caused to switch the voltage signal produced by the generator 74, to selectively energize adjacent rows of cylinders. It will be appreciated by those skilled in the art that by proper synchronization the cylinders 60 can be energized in such a manner as to produce a raster much in the same way a raster is produced in the conventional cathode ray tubes used in television reception.

Another embodiment of the invention is illustrated in FIG. 6 wherein an arrangement of piezoelectric wedges 80, each being of the type illustrated in FIG. 3, is disposed on a layer 82 of an electroluminescent phosphor which, in turn, is deposited on a transparent electrically conductive coating 84, of a supporting panel 86. The opposite side of the wedges 80 from that in contact with the phosphor is provided with an electrically conductive coating 88. Each wedge 80 is connected to a variable frequency generator 90 through a switching circuit 92 by an electrically conducting wire 89. The wires 89 may be cabled together as shown. The conductive coating 84 is likewise connected to the switching device 92 through an electrically conducting wire 91. The generator 90 is capable of producing variable frequency signals to cause various zones of the wedges 80 to resonate and thereby create associated electric fields to excite the electroluminescent phosphor 82. Thereby a light spot can be produced and caused to move along a wedge 80 by merely varying the frequency of the generator 90. Then, as in the embodiment illustrated in FIG. 5, the adjacent wedges 80 may be selectively energized by the switching circuit 92. The resolution available with a wedge is determined mainly by the piezoelectric material from which the wedges are made and geometry of the wedge. For all intents and purposes, the embodiment illustrated in FIG. 6 is operated in the same manner as the embodiment of FIG. 5. Accordingly, if the generator 90 is operating to produce a voltage signal of a given frequency, only one spot on the energized wedge will establish a field of the proper intensity to cause light to be emitted from a single zone of the phosphor layer 82. A change in the frequency of the applied voltage causes the light spot to move.

If bandwidth requirements permit, all of the wedges 80 can be placed electrically in parallel and by a single traversal through the frequency range, the spot would move over the entire panel.

With limited bandwidth requirements, the wedges 80 are connected as shown in FIG. 6 and are, in operation, frequency scanned one at a time in any desired sequence 'by the switching device 92 and will display video information by amplitude modulation of the electric field generator 90.

With reference to FIG. 7, there is shown a system embodying the principles of the invention in an aircraft attitude meter. The system employs a single wedge-shaped crystalline element similar to that illustrated in FIG. 3. The wedge element 100 is formed of quartz or other suitable material which is substantially transparent to the light emitted from an associated electroluminescent phosphor material layer 102 coated on one side of the element. A conductive coating 104 is applied to the outer surface of the phosphor layer 102 and may be a light transparent material such as stannic chloride in which case the light emitted from the phosphor coating may be viewed from two sides of the wedge element 100, or may be formed of an opaque conducting material which would obviously permit viewing of the light emitted from the phosphor layer 102 only through the material of the element 100. The conductive layer 104 may cover the entire exposed surface of the phosphor layer 102 as illustrated in FIG. 4 or may be applied in the manner illustrated in FIGS. 2 and 3. The conductive layer 104 is shown as being connected to ground potential through a conductive wire 106.

A strip 108 of electrically conductive material, similar to the strip 54 of FIGURE 4, is applied to the side walls of the element 100 and is, in turn, connected to the energizing circuit through a conductive wire 110.

The surface of the element 100 which is opposed to the surface on which the phosphor layer 102 is applied is provided with indicia indicating various altitudes. If wedge 100 is formed of non-transparent piezoelectric material, the phosphor layer should be positioned between the wedge and an indicia bearing member.

The energizing circuit comprises an altitude sensing device 112 which is capable of producing a DC. output signal proportional in strength to the sensed altitude. Conventional radar systems may be satisfactorily employed for this purpose. The output signal produced by the altitude sensing device 112 is fed to a comparisongating circuit 114. The comparison-gating circuit 114 is capable of producing a saw-tooth reference signal. The comparator portion of the circuit 114 compares the DC. signal received from the sensing device 112 with the saw tooth reference signal. The slope of the saw tooth signal is set to correspond to the altituderange required for the sensing device 112. The DC signal from the sensing device 112 will then exceed the saw tooth signal up to an altitude match. The saw tooth reference signal of the comparison-gating circuit is synchronized with a sweep frequency signal fed thereto by a sweep frequency generator 115. Thereby, the saw tooth reference signal commences when the sweep frequency generator 116 starts its frequency scan. For all levels of the DC. signal from the sensing device 112 which exceed the reference signal, a gate is opened and the output of the sweep frequency generator 116 is passed to an amplifier 118 and to the altitude display device through the conductor 110.

In operation, therefore, when the altitude sensing device 112 senses a signal corresponding to 11,000 feet, for example, a DC. signal is fed to the comparison-gating circuit 114 which is operative to open a gate and allow only that frequency signal of the generator 116 effective to energize the top portion of the wedge element 100 to pass to the amplifier 118 and thence to the conductive strip 108 of the wedge element 100 through the conductor 110. Whereupon the electroluminescent phosphor material 102 adjacent the upper portion of the wedge element 100 is excited to give off visible light indicating an altitude of 11,000 feet.

As in the embodiment of FIGURE 4 the altitude meter piezoelectric crystal display element 100 provides significant voltage amplification. Thus, at any resonant frequency applied to the crystal wedge 100 through conduc tor 110, the potential difference across the phosphor 102 will be found to exceed the driving voltage applied between str-ip 108 and ground return wire 106.

Other satisfactory systems employing the concepts of the invention include the use of a sweep frequency oscillator with a voltage tuneable bandwidth. Thus, as the voltage increases with altitude, so will the bandwidth of the sweep frequency oscillator and the display will light up accordingly.

Although the description of the devices has made reference to the electroluminescent material as being phosphor, it must be understood that satisfactory results could be obtained by employing other materials which are electroluminescent. These materials include electric field sensitive fluorescent liquids and jells, or gases with suitable discharge characteristics. In use, these materials are contained in a thin panel, one surface of which is in contact with the piezoelectric material.

Display devices such as those hereinabove described and illustrated in the drawings also may be employed as frequency spectrum analyzers. In such an application, the signal to be examined is fed into a variable, sharply tuned, resonant circuit synchronized to the sweeping oscillation. The tuned circuit employs a voltage dependent capacitor to vary the resonant frequency of the circuit. The output of the tuned circuit is rectified and filtered to eliminate the carrier. This video signal is then fed to the modulator 16 of FIG. 1 and thence to the display device 12 through an amplifier 18 and thereby cause the display panel 12 to exhibit visibly the frequency characteristics of the incoming signal.

In accordance with the provisions of the patent statutes, we have explained the principle and mode of operation of our invention and have illustrated and described what we now consider to represent its best embodiments. However, we desire to have it understood that, within the scope of the appended claims, the invention may be practiced otherwise than as specifically illustrated and described.

We claim:

1. An electroluminescent display device comprising a Wedge shaped piezoelectric crystal element, an electroluminescent material disposed on a tapering longitudinal surface of said crystal element, an electrode disposed on the same surface as said material, said electrode and said material extending along the entire length of said surface, the widthwise dimension of said electrode, with respect to the width of said tapering longitudinal surface, being less than the widthwise dimension of said electroluminescent material, and a base electrode extending over that surface of said crystal which is opposite to said tapering surface.

2. The display device of claim 1 wherein said electrode on said tapering surface is positioned along one longitudinal edge thereof.

References Cited by the Examiner UNITED STATES PATENTS 2,159,891 5/1939 Guerbilsky 32456 X 2,779,191 1/1957 Willard 3l08.1 X 2,796,584 6/1957 Hurvitz 313108 2,810,883 10/1957 Carnine 32478 2,877,371 3/1959 Orthuber 315-169 2,951,168 8/1960 Yando 3l5-55 X 3,235,799 2/1966 Hurvitz 324-78 JAMES W. LAWRENCE, Primary Examiner.

RALPH G. NILSON, ARTHUR GAUSS,

GEORGE N. WESTBY, Examiners.

o C. R. CAMPBELL, Assistant Examiner.

Claims (1)

1. AN ELECTROLUMINESCENT DISPLAY DEVICE COMPRISING A WEDGE SHAPED PIEZOELECTRIC CRYSTAL ELEMENT, AN ELECTROLUMINESCENT MATERIAL DISPOSED ON A TAPERING LONGITUDINAL SURFACE OF SAID CRYSTAL ELEMENT, AN ELECTRODE DISPOSED ON THE SAME SURFACE AS SAID MATERIAL, SAID ELECTRODE AND SAID MATERIAL EXTENDING ALONG THE ENTIRE LENGTH OF SAID SURFACE, THE WIDTHWISE DIMENSION OF SAID ELECTRODE, WITH RESPECT TO THE WIDTH OF SAID TAPERING LONGITUDINAL SURFACE, BEING LESS THAN THE WIDTHWISE DIMENSION OF SAID ELECTROLUMINESCENT MATERIAL, AND A BASE ELECTRODE EXTENDING OVER THAT SURFACE OF SAID CRYSTAL WHICH IS OPPOSITE TO SAID TAPERING SURFACE.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US47989A US3290549A (en) | 1960-08-08 | 1960-08-08 | Electroluminescent display device with piezoelectrical scanning and gating means |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US47989A US3290549A (en) | 1960-08-08 | 1960-08-08 | Electroluminescent display device with piezoelectrical scanning and gating means |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3290549A true US3290549A (en) | 1966-12-06 |

Family

ID=21952164

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US47989A Expired - Lifetime US3290549A (en) | 1960-08-08 | 1960-08-08 | Electroluminescent display device with piezoelectrical scanning and gating means |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3290549A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3621328A (en) * | 1969-05-13 | 1971-11-16 | Iit Res Inst | Information display system |

| US20030231370A1 (en) * | 2002-03-26 | 2003-12-18 | Hiroyuki Fujii | Wavelength variable light source |

| US20100164378A1 (en) * | 2008-12-31 | 2010-07-01 | Nokia Corporation | Electroluminescent device |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2159891A (en) * | 1934-06-22 | 1939-05-23 | Guerbilsky Alexis | Electromechanical resonator |

| US2779191A (en) * | 1950-10-28 | 1957-01-29 | Bell Telephone Labor Inc | Frequency discriminator employing multiply resonant piezoelectric vibrator |

| US2796584A (en) * | 1955-03-21 | 1957-06-18 | Hurvitz Hyman | Two dimensional electroluminescent display |

| US2810883A (en) * | 1955-04-18 | 1957-10-22 | Raymond M Wilmotte Inc | Frequency sensitive visual indicator |

| US2877371A (en) * | 1955-08-16 | 1959-03-10 | Itt | Information display device |

| US2951168A (en) * | 1958-11-28 | 1960-08-30 | Sylvania Electric Prod | Electroluminescent device |

| US3235799A (en) * | 1954-12-27 | 1966-02-15 | Hurvitz Hyman | Electroluminescent frequency sensitive visual indicator |

-

1960

- 1960-08-08 US US47989A patent/US3290549A/en not_active Expired - Lifetime

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2159891A (en) * | 1934-06-22 | 1939-05-23 | Guerbilsky Alexis | Electromechanical resonator |

| US2779191A (en) * | 1950-10-28 | 1957-01-29 | Bell Telephone Labor Inc | Frequency discriminator employing multiply resonant piezoelectric vibrator |

| US3235799A (en) * | 1954-12-27 | 1966-02-15 | Hurvitz Hyman | Electroluminescent frequency sensitive visual indicator |

| US2796584A (en) * | 1955-03-21 | 1957-06-18 | Hurvitz Hyman | Two dimensional electroluminescent display |

| US2810883A (en) * | 1955-04-18 | 1957-10-22 | Raymond M Wilmotte Inc | Frequency sensitive visual indicator |

| US2877371A (en) * | 1955-08-16 | 1959-03-10 | Itt | Information display device |

| US2951168A (en) * | 1958-11-28 | 1960-08-30 | Sylvania Electric Prod | Electroluminescent device |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3621328A (en) * | 1969-05-13 | 1971-11-16 | Iit Res Inst | Information display system |

| US20030231370A1 (en) * | 2002-03-26 | 2003-12-18 | Hiroyuki Fujii | Wavelength variable light source |

| US7078856B2 (en) * | 2002-03-26 | 2006-07-18 | Sanyo Electric Co., Ltd. | Wavelength variable light source |

| US20100164378A1 (en) * | 2008-12-31 | 2010-07-01 | Nokia Corporation | Electroluminescent device |

| US8513883B2 (en) * | 2008-12-31 | 2013-08-20 | Nokia Corporation | Electroluminescent device having piezoelectric component |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2663083B2 (en) | Address device | |

| US4575765A (en) | Method and apparatus for transmitting images to a viewing screen | |

| US2877371A (en) | Information display device | |

| US2922076A (en) | Display device | |

| US3154720A (en) | Solid state display device | |

| US3246162A (en) | Electroluminescent device having a field-effect transistor addressing system | |

| US2875380A (en) | Display systems | |

| US3042834A (en) | Electroluminescent device | |

| US2877376A (en) | Phosphor screen device | |

| US2900574A (en) | Electroluminescent device | |

| US3290549A (en) | Electroluminescent display device with piezoelectrical scanning and gating means | |

| US2951168A (en) | Electroluminescent device | |

| US2969481A (en) | Display device | |

| US3249804A (en) | System for effecting selective energization of a display device with coincident waves | |

| US3356850A (en) | Frequency-sensitive and photo-sensitive device | |

| US2888593A (en) | Cathode ray tube | |

| US3225253A (en) | Electroluminescent photoconductive display device | |

| US3202868A (en) | Electroluminescent-piezoelectric bar graph display system | |

| US3566014A (en) | Electroluminescent display systems | |

| US3065378A (en) | Visual display and readout systems | |

| US3069596A (en) | Electroluminescent screen and device | |

| US3235799A (en) | Electroluminescent frequency sensitive visual indicator | |

| US3387271A (en) | Signal distribution system having a voltage variable capacitive distribution layer | |

| US4801850A (en) | High brightness vacuum fluorescent display (VFD) devices | |

| US3086143A (en) | Display device |