US2879110A - Scaffolding - Google Patents

Scaffolding Download PDFInfo

- Publication number

- US2879110A US2879110A US499091A US49909155A US2879110A US 2879110 A US2879110 A US 2879110A US 499091 A US499091 A US 499091A US 49909155 A US49909155 A US 49909155A US 2879110 A US2879110 A US 2879110A

- Authority

- US

- United States

- Prior art keywords

- members

- spokes

- scaffolding

- scaffold

- pair

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010276 construction Methods 0.000 description 4

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 241000212384 Bifora Species 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G7/00—Connections between parts of the scaffold

- E04G7/02—Connections between parts of the scaffold with separate coupling elements

- E04G7/06—Stiff scaffolding clamps for connecting scaffold members of common shape

- E04G7/24—Couplings involving arrangements covered by more than one of the subgroups E04G7/08, E04G7/12, E04G7/20, E04G7/22

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/34—Branched

- Y10T403/341—Three or more radiating members

- Y10T403/344—Plural pairs of axially aligned members

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/47—Molded joint

- Y10T403/477—Fusion bond, e.g., weld, etc.

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T403/00—Joints and connections

- Y10T403/70—Interfitted members

- Y10T403/7062—Clamped members

Definitions

- Each connector means 12 comprises a metal plate 16 which may be square in shape and of the order of about six inches on a side and about /2 inch in thickness.

- a pair of horizontally aligned tubular spokes 17, 18 extend from the vertical edges of plate 16, such edges being recessed as at 19 to receive the inner ends of the spokes which are welded in place.

- a pair of vertically aligned V tubular spokes 20, 21 extend from the recessed horizontal scaffolding adapted for use with the exterior or interior portions of a building.

- An object of this invention' is to provide, improved scaffolding comprising scaffold members and connectors therefor which may be rapidly assembled for use and quickly disassembledfor storage when not in use, yet being adapted to sustain while in assembled and erected form, unusually large loads.

- Another object'of this i vention is to provide in a scaffolding construction of the character described, im- 1 proved connector means for the horizontal and vertical scaffold members and including improved clamping means for retaining the interconnected members and to withstand unusually large loads which may be applied to the scaffolding.

- a further object of this invention is to provide in a I scaffolding construction ofvthe character described, improved connector means and horizontal scaffold members so interrelated as to permit the initial assembly of the connector means and the vertical scafiold members, positioning such assemblies at fixed distances from each other in both longitudinal and transverse directions, and finally interconnecting such assemblie'sby horizontal and transverse scaifold members.

- Another object of this invention is to provide an improved connector for scaifolding which includes projecting spoke members adapted for telescopic engagement with horizontal and vertically disposed tubular scaffold members, together with quick release clamping means for gripping the end portions of the scaffold members.

- Still a further object of this invention is to provide an improved scaffolding construction including a pair of scaffold frames in parallel relation and including horizontally aligned connector means provided with open supporting means extending toward each other for receiving a transverse scaffolding member for interconnecting the frames, together with clamping means for gripping end portions of the transverse member and retaining the same on the supporting means.

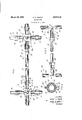

- Fig. l is a front elevational view showing the interconnected elements of a scaffolding construction embodying the invention.

- Fig. 2 is a transverse sectional view taken on the line 2---2 of Fig. 1;

- Fig. 3 is a front elevational view of a portion of a pair of scaifolding frames and the transverse interconnection thereof.

- frame 10 includes connector means generally indicated 12 for interconnecting elongated, horizontally extending tubular members 13 and elongated, vertically extending tubular members edges of plate 16.

- spokes 17, 18, 20, 21 is proportioned to the inner diameter of tubular members 13, 14 to allow telescopic engagement thereof while erecting the frames and quick disassembly of the same to allow transportation or storage of the scaffolding elements.

- hinge pins 22 are as sociated with each spoke, said pins extending parallel to the axis of the spokes and including a rear portion 23 welded to the outer surface of the spoke and a forwardly extending portion 24 displaced from said outer surface.

- a pair of semi-cylindrical clamping members 25, 26 are provided.

- Members 25, 26 also include radially extending flanges 29, 30 having transverse openings which may be aligned when said flangesare brought into registration.

- a bolt 31 and nut 32 holds members 25, 26 in clamped relation to the end'portions of the tubular member engaged with the spoke, as shown in Fig. 2.

- the clamping members 25, 26 have a longitudinal extent sufficient to firmly grip the ends of the tubular scaffold members 13, 14 while the same are in telescoped relation to the spokes of the connector means 12. Accordingly, the connector means makes possible the application of very substantial loads to the scaffolding without danger of collapse of the interconnected scaffold elements.

- the vertical tubular members 14 would initially be connected to connector plates 16 and the vertical assemblies thus produced would be located at fixed distances from each other with the horizontal spokes 17, 18 of successive, longitudinally spaced connector plates, extending toward each other.

- the horizontal tubular scaffold members 13 are provided with extensions 33 on one end thereof, on which a tubular sleeve 34 is mounted for slidable movement thereon.

- the extension 33 is formed with a transverse opening 35 and sleeve 34 is formed with aligned openings 36 adapted to register with opening 35 when sleeve 34 is in its retracted position and may be retained in such position by a 'bolt 37. While in such retracted position, the member 13 may be located between spokes 17, 18 and in alignment therewith, and then the sleeve 34 may be extended so that the opposite ends of member 13 may telescopically engage the spokes 17, 18.

- a second transverse opening 35a forwardly of opening 35 in extension 33, allows the bolt 37 to retain the sleeve 34 in such extended position.

- a semi-cylindrical support member 38 has its inner end welded to one face of plate 16, the member 38 extending at right angles to the plane including spokes 17, 18, 20, 21.

- Clamping means generally indicated at 39 and including a hinge pin with a rear portion 40 welded to the 3 bottom of support member 38; an off set forwardly extending portion 41 on which are hinged semi-circular clamping members 25, 26, is adapted to clamp end portions of the transverse tubular member 15.

- the support members 38 extend toward each other and open upwardly so that the transverse members 15 may be dropped in place and the clamping members 25, 26, which are disposed forwardly of the outer ends of support members 38, may be brought into direct clamping en gagement with member 15.

- the members 25, 26 are similar to those previously described and bolt 31 draws the members together to achieve maximum clamping effect.

- a scaffold connector comprising a rectangular plate, a plurality of spokes respectively extending radially from the edges of said plateya hinge pin disposed axially of each spoke, each pin including an offset portion in welded engagement to a surface portion of the pin, and a pair of stantial loads which may be applied to the scaffolding,

- the erected scaffolding may be quickly disassembled as required.

- a scalfold connector means comprising a plate, a pair of horizontally aligned spokes and a pair of vertically aligned spokes projecting radially from the edges of said plate, a hinge pin associated with each spoke, each pin having a forwardly extending portion extending parallel With the axis of said spoke and spaced from the outer surface thereof, a pair of semi-cylindrical clamping members having interfitting ear portions pivotally mounted on the forwardly extending portion of said pin, said clamping members being coaxially related to said spoke.

- a scalfold connector means comprising a plate, a pair of horizontally aligned spokes and a pair of vertically aligned spokes projecting radially from the edges of said semi-cylindrical clamping members coaxially related to each spoke, said clamping members being pivotally mounted on another portion of said hinge pin.

- a scaffold connector comprising a plate, a semi-cylindrical, support member extending from one face of said plate and at right angles thereto, a hinge pin disposed axially of said support and including one end portion in welded engagement to an outer surface portion of said support and another end portion projecting beyond the end of said support, and a pair of semi-cylindrical clamping members coaxially related to said support, said clamping members being pivotally mounted on the projecting end portion of said hinge pin.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mutual Connection Of Rods And Tubes (AREA)

Description

March 24, 1959 G. "c. HARDlE SCAFFOLDING Filed April 4, 1955 BY GEORGE C. HARDIE- ATTORNEY United States Patent O 2,879,110- scAEFoLDnsG George C. Hardie, Brooklyn, N.Y. Application April 4, 1955, Serial N... 499,091

4 Claims. (Cl. 304-40 This invention relates to scaffolding and scaffold connector means. More specifically, the invention concerns 14. The horizontally aligned connector means 12 of frames 10, 11, are interconnected by transversely extending tubular members 15, as shown in Fig. 3.

Each connector means 12 comprises a metal plate 16 which may be square in shape and of the order of about six inches on a side and about /2 inch in thickness. Ob

i viously these dimensions may be varied. A pair of horizontally aligned tubular spokes 17, 18 extend from the vertical edges of plate 16, such edges being recessed as at 19 to receive the inner ends of the spokes which are welded in place. Similarly, a pair of vertically aligned V tubular spokes 20, 21 extend from the recessed horizontal scaffolding adapted for use with the exterior or interior portions of a building.

An object of this invention'is to provide, improved scaffolding comprising scaffold members and connectors therefor which may be rapidly assembled for use and quickly disassembledfor storage when not in use, yet being adapted to sustain while in assembled and erected form, unusually large loads.

Another object'of this i vention is to provide in a scaffolding construction of the character described, im- 1 proved connector means for the horizontal and vertical scaffold members and including improved clamping means for retaining the interconnected members and to withstand unusually large loads which may be applied to the scaffolding.

A further object of this invention is to provide in a I scaffolding construction ofvthe character described, improved connector means and horizontal scaffold members so interrelated as to permit the initial assembly of the connector means and the vertical scafiold members, positioning such assemblies at fixed distances from each other in both longitudinal and transverse directions, and finally interconnecting such assemblie'sby horizontal and transverse scaifold members.

Another object of this invention is to provide an improved connector for scaifolding which includes projecting spoke members adapted for telescopic engagement with horizontal and vertically disposed tubular scaffold members, together with quick release clamping means for gripping the end portions of the scaffold members.

Still a further object of this invention is to provide an improved scaffolding construction including a pair of scaffold frames in parallel relation and including horizontally aligned connector means provided with open supporting means extending toward each other for receiving a transverse scaffolding member for interconnecting the frames, together with clamping means for gripping end portions of the transverse member and retaining the same on the supporting means.

Other objects of this invention will in part be obvious and in part hereinafter disclosed.

In the drawing,

Fig. l is a front elevational view showing the interconnected elements of a scaffolding construction embodying the invention;

Fig. 2 is a transverse sectional view taken on the line 2---2 of Fig. 1; and

Fig. 3 is a front elevational view of a portion of a pair of scaifolding frames and the transverse interconnection thereof.

Referring in detail to the drawing, 10, 11 gnemi indicate similar scaffold frames arranged in opposed, parallel relation. As shown in Fig. 1, frame 10 includes connector means generally indicated 12 for interconnecting elongated, horizontally extending tubular members 13 and elongated, vertically extending tubular members edges of plate 16.

The outer diameter of spokes 17, 18, 20, 21 is proportioned to the inner diameter of tubular members 13, 14 to allow telescopic engagement thereof while erecting the frames and quick disassembly of the same to allow transportation or storage of the scaffolding elements.

Means is provided for tightly gripping the telescoped end portions of said members 13, 14 in relation to the respective spokes. Accordingly, hinge pins 22 are as sociated with each spoke, said pins extending parallel to the axis of the spokes and including a rear portion 23 welded to the outer surface of the spoke and a forwardly extending portion 24 displaced from said outer surface.

A pair of semi-cylindrical clamping members 25, 26

: having radially extending, interfitting ear portions 27,

28 are pivotally mounted on pin portions 24, said clamping members being coaxially related to the spoke with which the same is associated. Members 25, 26 also include radially extending flanges 29, 30 having transverse openings which may be aligned when said flangesare brought into registration. A bolt 31 and nut 32 holds members 25, 26 in clamped relation to the end'portions of the tubular member engaged with the spoke, as shown in Fig. 2.

' The clamping members 25, 26 have a longitudinal extent sufficient to firmly grip the ends of the tubular scaffold members 13, 14 while the same are in telescoped relation to the spokes of the connector means 12. Accordingly, the connector means makes possible the application of very substantial loads to the scaffolding without danger of collapse of the interconnected scaffold elements.

In the conventional manner of erecting scaffold frames, the vertical tubular members 14 would initially be connected to connector plates 16 and the vertical assemblies thus produced would be located at fixed distances from each other with the horizontal spokes 17, 18 of successive, longitudinally spaced connector plates, extending toward each other.

The horizontal tubular scaffold members 13 are provided with extensions 33 on one end thereof, on which a tubular sleeve 34 is mounted for slidable movement thereon. The extension 33 is formed with a transverse opening 35 and sleeve 34 is formed with aligned openings 36 adapted to register with opening 35 when sleeve 34 is in its retracted position and may be retained in such position by a 'bolt 37. While in such retracted position, the member 13 may be located between spokes 17, 18 and in alignment therewith, and then the sleeve 34 may be extended so that the opposite ends of member 13 may telescopically engage the spokes 17, 18. A second transverse opening 35a, forwardly of opening 35 in extension 33, allows the bolt 37 to retain the sleeve 34 in such extended position.

Means is provided for interconnecting the horizontally aligned connector plates 16 of frames 10, 11. To this end, a semi-cylindrical support member 38 has its inner end welded to one face of plate 16, the member 38 extending at right angles to the plane including spokes 17, 18, 20, 21. Clamping means generally indicated at 39 and including a hinge pin with a rear portion 40 welded to the 3 bottom of support member 38; an off set forwardly extending portion 41 on which are hinged semi-circular clamping members 25, 26, is adapted to clamp end portions of the transverse tubular member 15.

The support members 38 extend toward each other and open upwardly so that the transverse members 15 may be dropped in place and the clamping members 25, 26, which are disposed forwardly of the outer ends of support members 38, may be brought into direct clamping en gagement with member 15. The members 25, 26 are similar to those previously described and bolt 31 draws the members together to achieve maximum clamping effect.

It will be apparent that the arrangement of parts as described, allows rapid assembly of the connector means and scaffold members and that the clamping means can be quickly adjusted to effect maximum resistance to subplate, releasable clamping means associated with each spoke and including a pair of semi-cylindrical clamping members coaxially related tolsaid spoke, a semi-cylindrical support member extending from one face of said plate and at right angles to said spokes, releasable clamping means associated with said support member and including a pair of semi-cylindrical clamping members coaxially related to said support member;

3. A scaffold connector; comprising a rectangular plate, a plurality of spokes respectively extending radially from the edges of said plateya hinge pin disposed axially of each spoke, each pin including an offset portion in welded engagement to a surface portion of the pin, and a pair of stantial loads which may be applied to the scaffolding,

Furthermore, the erected scaffolding may be quickly disassembled as required.

This application is a continuation in part of application Ser. No. 239,234, filed July 30, 1951 now abandoned.

As various changes might be made in the embodiment of the invention herein shown and described without departing from the spirit thereof, it is understood that all matter herein shown and described is to be interpreted in an illustrative sense and not by Way of limitation.

Having thus disclosed my invention, I claim as new and desire to protect by Letters Patent:

1. A scalfold connector means comprising a plate, a pair of horizontally aligned spokes and a pair of vertically aligned spokes projecting radially from the edges of said plate, a hinge pin associated with each spoke, each pin having a forwardly extending portion extending parallel With the axis of said spoke and spaced from the outer surface thereof, a pair of semi-cylindrical clamping members having interfitting ear portions pivotally mounted on the forwardly extending portion of said pin, said clamping members being coaxially related to said spoke.

2. A scalfold connector means comprising a plate, a pair of horizontally aligned spokes and a pair of vertically aligned spokes projecting radially from the edges of said semi-cylindrical clamping members coaxially related to each spoke, said clamping members being pivotally mounted on another portion of said hinge pin.

4. A scaffold connector comprising a plate, a semi-cylindrical, support member extending from one face of said plate and at right angles thereto, a hinge pin disposed axially of said support and including one end portion in welded engagement to an outer surface portion of said support and another end portion projecting beyond the end of said support, and a pair of semi-cylindrical clamping members coaxially related to said support, said clamping members being pivotally mounted on the projecting end portion of said hinge pin.

References Cited in the file of this patent UNITED STATES PATENTS 346,466 Corbett Aug. 3, 1886 885,992 Graham Apr. 28, 1908 1,026,845 Bishop May 21', 1912- 1,273,143 Bryan July 23, 1918 2,383,163 Roten Aug. 21, 1945 2,445,453 Pennington July 20, 1948 FOREIGN PATENTS 18,532 France May 13, 1914' 793,017 France Jan. 15, 1936 412,073 Italy Oct. 13, 1945: 653,861 Great Britain May 30, 1951 301,370 Switzerland Sept. 15, 1954-

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US499091A US2879110A (en) | 1955-04-04 | 1955-04-04 | Scaffolding |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US499091A US2879110A (en) | 1955-04-04 | 1955-04-04 | Scaffolding |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2879110A true US2879110A (en) | 1959-03-24 |

Family

ID=23983777

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US499091A Expired - Lifetime US2879110A (en) | 1955-04-04 | 1955-04-04 | Scaffolding |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US2879110A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5013176A (en) * | 1989-04-20 | 1991-05-07 | Orbom Eric W | Continuous connector |

| US5127759A (en) * | 1989-04-20 | 1992-07-07 | Orbom Eric W | Continuous connector |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US346466A (en) * | 1886-08-03 | Pipe-derrick | ||

| US885992A (en) * | 1908-04-28 | G A Edward Kohler | Fitting for reinforced concrete structures. | |

| US1026845A (en) * | 1911-07-31 | 1912-05-21 | William Bishop | Derrick connection. |

| FR18532E (en) * | 1913-10-16 | 1914-05-13 | Marie Jules Andre Gueury | Removable cabin |

| US1273143A (en) * | 1916-11-20 | 1918-07-23 | Cecil E Bryan | Coffin-elevator for mausoleums. |

| FR793017A (en) * | 1934-10-17 | 1936-01-15 | A Teste & Cie Ets | Removable and transformable support for display cases, tents and others |

| US2383163A (en) * | 1944-05-05 | 1945-08-21 | Henry G Roten | Scaffold |

| US2445453A (en) * | 1946-04-05 | 1948-07-20 | Lacy K Pennington | Portable scaffold |

| GB653861A (en) * | 1948-05-24 | 1951-05-30 | Ernest Goodall Malthouse | Improvements in or relating to tubular scaffolding |

| CH301370A (en) * | 1951-07-23 | 1954-09-15 | Schwarz Bernhard | Tube connection for scaffolding tubes. |

-

1955

- 1955-04-04 US US499091A patent/US2879110A/en not_active Expired - Lifetime

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US346466A (en) * | 1886-08-03 | Pipe-derrick | ||

| US885992A (en) * | 1908-04-28 | G A Edward Kohler | Fitting for reinforced concrete structures. | |

| US1026845A (en) * | 1911-07-31 | 1912-05-21 | William Bishop | Derrick connection. |

| FR18532E (en) * | 1913-10-16 | 1914-05-13 | Marie Jules Andre Gueury | Removable cabin |

| US1273143A (en) * | 1916-11-20 | 1918-07-23 | Cecil E Bryan | Coffin-elevator for mausoleums. |

| FR793017A (en) * | 1934-10-17 | 1936-01-15 | A Teste & Cie Ets | Removable and transformable support for display cases, tents and others |

| US2383163A (en) * | 1944-05-05 | 1945-08-21 | Henry G Roten | Scaffold |

| US2445453A (en) * | 1946-04-05 | 1948-07-20 | Lacy K Pennington | Portable scaffold |

| GB653861A (en) * | 1948-05-24 | 1951-05-30 | Ernest Goodall Malthouse | Improvements in or relating to tubular scaffolding |

| CH301370A (en) * | 1951-07-23 | 1954-09-15 | Schwarz Bernhard | Tube connection for scaffolding tubes. |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5013176A (en) * | 1989-04-20 | 1991-05-07 | Orbom Eric W | Continuous connector |

| US5127759A (en) * | 1989-04-20 | 1992-07-07 | Orbom Eric W | Continuous connector |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100203520B1 (en) | Jiboong | |

| US3995843A (en) | Apparatus for supporting a window buck frame | |

| US3656269A (en) | Support structure of frame work construction | |

| US3564803A (en) | Extensible scaffold and other load supporting elements | |

| US3367080A (en) | Adjustable cross brace | |

| NO117502B (en) | ||

| US2435171A (en) | Scaffold | |

| NO167908B (en) | SAFETY BRAKING SYSTEM FOR A LIFTING GAME | |

| WO1996041928A1 (en) | Collapsible display framework for indoor or outdoor use | |

| US2555782A (en) | Scaffold structure | |

| US4015395A (en) | Puncheon unit for builders scaffolding | |

| US2583368A (en) | Coupling means for scaffolding bars | |

| US2478088A (en) | Scaffolding | |

| US2982572A (en) | Interlocking sectional units | |

| US2879110A (en) | Scaffolding | |

| US4179090A (en) | Scaffolding | |

| US3000466A (en) | Folding scaffold | |

| US2181784A (en) | Scaffold | |

| US2046123A (en) | Mold form for circular concrete walls | |

| US2468186A (en) | Scaffold | |

| US2891819A (en) | Scaffolding jack | |

| US1442582A (en) | Scaffolding | |

| US3053356A (en) | Connecting element for assembling horizontal and vertical ladder sections to form a scaffold | |

| US2631900A (en) | Sectional scaffold frame | |

| US2467688A (en) | Scaffold |