US2829216A - Electric switch units - Google Patents

Electric switch units Download PDFInfo

- Publication number

- US2829216A US2829216A US391398A US39139853A US2829216A US 2829216 A US2829216 A US 2829216A US 391398 A US391398 A US 391398A US 39139853 A US39139853 A US 39139853A US 2829216 A US2829216 A US 2829216A

- Authority

- US

- United States

- Prior art keywords

- armature

- assembly

- base

- contact

- electromagnet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000000712 assembly Effects 0.000 description 20

- 238000000429 assembly Methods 0.000 description 20

- 230000005484 gravity Effects 0.000 description 4

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000007689 inspection Methods 0.000 description 3

- 125000006850 spacer group Chemical group 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 230000003137 locomotive effect Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/02—Bases; Casings; Covers

Definitions

- a primary object of the invention is to provide rugged and dependable switch units having large electrical capacity in relation to their size, weight and cost.

- Another object is to provide switch units which may be easily and safely inspected.

- Another object is to provide switch units of the aforedescribed character which consists primarily of standard parts and require only a minimum number of specially formed parts, thus to facilitate repair in the field with ordinary tools and with a minimum number of different spare parts.

- Another object is to provide electromagnetically operated switch units having improved mounting means for the movable parts thereof.

- a further object is to provide switch units which may be readily adapted for various applications.

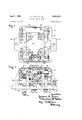

- Figure 1 is a plan view of a base assembly

- Fig. 2 is a plan view of a cover assembly

- Figs. 3 and 4 are partly cross sectional, partly elevational views of the opposite ends, respectively, of a switch unit embodying the invention and in which the main contacts are shown to be open and closed, respectively;

- Fig. 5 is a partly fragmentary, partly crosssectional, and partly side elevational view of the switch unit shown in Figs. 3 and 4.

- the switch unit consists generally of a panel assembly 12 (Fig. l) and a cover assembly 14 (Fig. 2).

- the panel assembly 12 includes a panel or base 16, an electromagnet 18 centrally located on the front face of the base 16, and a row of fixed main contact assemblies 20 on opposite sides of the electromagnet 18.

- Said panel assembly 12 further includes an auxiliary interlock assembly 22 located at one end, and a fixed auxiliary contact assembly 24 located at the other end of the electromagnet 18.

- the electromagnet 18 comprises an E-shaped magnet frame 26, the E-shape being a preferred form, and an operating coil 28 placed around the central pole 30 of the magnet frame 26.

- the ends of the coil 28 are secured to appropriate terminal assemblies 32, 32.

- Nut and bolt sets 34, 34 secure the magnet frame 26 to the base 16; and bolts 36, 36, which extend through a clamp 38 disposed on top of the coil 28 and into the magnet frame 26, hold the coil in position, as shown.

- the cover assembly 14 consists of a cover 40, an armature assembly 42, and a pair of spring support straps 44,

- the armature assembly 42 includes a magnetic plate 50 on each side edge 52 thereof, parallel insulating bars 53, 54 each of which is secured to a respectively associated side extension 50, an interlock finger operating assembly 56 fastened to one end of the armature 48, and a pair of movable auxiliary contact assemblies 60 and 62 secured to the opposite end of the armature 48.

- the armature assembly 42 also includes four main bridging contact assemblies 63 which are fastened one to each end of each insulating bar 54.

- the armature assembly is suspended from the cover 40 by means of the support straps 44, 44.

- Each strap 44 is bolted at one end thereof to one of a pair of projections 64, 64 on the inner wall at one side of the cover 40.

- the straps 44 extend in like directions toward the opposite side of the cover 40, and each is bolted at its opposite end 44 to the lower side of one bar 54.

- Four posts 66 which are riveted or otherwise secured to the top of cover 40, extend through four respectively associated enlarged holes in the armature 48 located one in each corner portion of the armature.

- a biasing spring 68 surrounds each post 66 and is held in compression against the outer face of the armature 48 by a washer 69 and a cotter pin 70 associated with the outer end of the post 66.

- the springs 68 act to afford a shock-proof character to the switch unit and cooperate with spring straps 44, 44 to bias the armature 48 toward cover 40.

- the cover is provided with mounting lugs 72 and 74 extending outwardly from opposite sides of the cover.

- the lugs 72 and 74 are perforated and are adapted to accommodate bolts 76 and 78 respectively.

- the bolts are each secured by a nut to the base 16.

- One lug '72 is provided with a recess adapted to accommodate a pin or dowel 79 extending from the base 16 so that the cover assembly 14 may not be reversely assembled with respect to the panel assembly 12.

- the central pole 30 of electromagnet 18 is spaced from, and is disposed opposite the central portion of, the armature 48.

- the interlock operating finger 56 and the movable auxiliary contact assemblies 60 and 62 are alined, respectively, with auxiliary interlock assembly 22 and fixed auxiliary contact assembly 24.

- Each bridging contact assembly 63 is alined with two adjacent, or one set of, fixed main contact assemblies 20.

- the interlock operating finger 56 is carried into actuating engagement with the auxiliary interlock assembly 22; the movable auxiliary contact assemblies 60 and 62 are carried into circuit making engagement with the fixed auxiliary contact assembly 24, and each main bridging contact assembly 63 is carried into bridging engagement with its respectively associated set of fixed main contact assemblies 20.

- the straps 44 are arranged in such manner that they bear all of the weight of the armature assembly 42 and also prevent lateral motion of said armature assembly.

- the posts 66 do not cooperate to position the armature, but serve only to retain the bias springs 68.

- the straps 44 are attached to the armature assembly 42 at points in a plane extending substantially through the center of gravity of the armature assembly. Said plane is perpendicular to the line of motion of the armature assembly. Said straps 44 are bolted to opposite ends of the armature assembly 42 at one side of the latter and extend substantially parallel with said armature assembly to the other side of the same two points on projections 64, 64 in the cover 40.

- the aforementioned features permit a generally symmetrical arrangement of the interlock contact assembly 22, main contact assemblies 20, and the auxiliary contact assembly 24 around the electromagnet 18; and such features also permit corresponding symmetrical arrangement of the interlock operating finger 56, movable auxiliary contact assemblies 60 and 62 and the main bridging contact assemblies 63 on the armature assembly 42.

- All the contacts and bridging contacts are arranged in close proximity to the Walls of the cover 40 so that inspection windows 80 may be formed in the cover wall, as shown, for inspection of the switch unit without disconnecting said unit. Also it is possible to interchange or to replace either the interlock assembly 22 or the auxiliary contact assemblies with the other or others.

- the main bridging contact assemblies 63 may be relocated on bars 53 or 54 in such manner that they Cam bridge other sets of the fixed contact assemblies 20, thus to adapt the switch unit for various control schemes without sacrificing balance of the armature assembly 42.

- Another feature of the invention is that all of the main contacts are open and they and their contact tips are accessible for inspection and repair when the cover assembly 14 is removed from the panel assembly 12. Increased safety is provided since the cover must be removed before any other component can be removed.

- circuit ccmmutating components are arranged around the electromagnet 18 in a manner providing maximum spacing between adjacent components and permitting the use of components having common shapes rather than complex formed parts.

- the interlock operating finger 56 consists of a bolt 82 extending through a cutout or hole in the armature 48 and secured to the latter by a nut and a lock washer. At its outer end the bolt 82 is threaded into a cylindrical actuator 84. The latter is prevented from turning on bolt 82 by a nut and a lock washer.

- the auxiliary interlock contact assembly 22 comprises a stand-off block 86 and an overlying insulating strip 88 held by nut and bolt sets 90 to the base 16.

- the strip a 88 extends beyond the block 86 at both ends thereof and a pair of fixed contact assemblies 92 is attached to each end portion of strip 88.

- a bolt 94 secured to the base 16 by nuts, serves as a stop for the movable parts of the assembly 22.

- the latter parts consist of a generally U-shaped channel 27, an insulating block 98 which is riveted or bolted at one end thereof to the end of the outer arm of the channel 97 and extends to one side of the channel.

- An interlock bridging contact assembly 100 is riveted to the other end of the block 98 in bridging alinement with one set of fixed contact assemblies 92.

- Another insulating block 102 is attached at one end thereof to said end of said arm of the channel 97 and extends to the other side of channel 7 at an angle with respect to the block 98.

- a second interlock bridging contact assembly 1% is secured to the other end of block 102 in bridging alinement with the other set of fixed contact assemblies 92.

- the channel 517 is journaied at each of its arms upon a shaft 106 which is threaded at one end 106 thereof into an outer leg of the magnet frame 26.

- the channel 97 is held on the shaft 106 by suitable fastening means, such, for example, as a cotter pin.

- the connecting portion 97* of the channel is elongated and one side thereof 1s adapted to engage stop bolt 94.

- the Other side of said connecting portion 97* is provided with a button 110 on the upper surface thereof in alinement with the actuator 84.

- the lower end of button 110 extends through portion 97 and is disposed within the upper end of a coiled compression spring 114.

- Said spring in turn extends through a hole in the insulating strip Sfi and bears at its opposite end against the bottom of a recess formed in the upper face of the stand-off block 86.

- the movable portions of the auxiliary contact assembly 22 are biased toward the position in which they are shown by spring 114, so that interlock bridging contact assembly bridges its associated contacts 92 and so that the contacts 92 which are associated with auxiliary interlock contact assembly 104, are not bridged by the latter.

- actuator 84 engages button to rotate the moving parts of the interlock contact assembly 22 against the bias of spring 114 to actuate the interlock contacts.

- the fixed auxiliary contact assembly 24 consists of a stand-off block and an overlying insulating strip 122 held by nut and bolt sets 124 to the base 16.

- the strip 122 extends beyond the block 120 at both ends thereof and a pair of fixed contact assemblies 126 is attached to each end portion of the strip 122.

- the movable auxiliary contact assembly 60 includes a strap 13th bolted to and extending outwardly from the armature 48. The lower end of the strap 130 is bent laterally. A first L-shaped, anti-leakage, insulating piece 132, an L-shaped, auxiliary bridging contact block 134, and a second L-shaped, anti-leakage, insulating piece 136 are bolted in the order named to the underside of the end of the strap 130. An auxiliary bridging contact assembly 138 is attached to the L-shaped piece 134 in bridging alinement with one pair of the fixed auxiliary assemblies 126 on an associated end of the strip 122. T he movable auxiliary contact assembly 62 is like movable auxiliary contact assembly 60 except that its strap 139 is adapted for left-hand mounting of assembly 62 whereas strap 136* is adapted for righthand mounting of assembly 60.

- Each main bridging contact assembly 63 includes a generally U-shaped bracket 140 which is held by a rivet 142 and a washer 14 2 to a respectively associated one of the insulating bars 53 or 54 with the open portion of the U facing away from the bar 53 or 54.

- the ends 140 of the arms of the U-shaped bracket 140 are bent inwardly and act to retain a bridging contact LE4.

- the latter is provided with a rivet 146 and a washer 146 at the center thereof.

- a coiled spring 148 is held under compression between the bracket 140 and the bridging contact 144 and is held in place by the washers l t/2 and 146 acting as spring guides.

- the ends of the bridging contact 144 extend beyond the bracket 140 and said ends are provided with non-welding contact tips.

- Each main contact assembly 20 includes a threaded stud bolt 150 secured to the base 16 by suitable lock washers and nuts, a threaded spacer 152 and a non-welding contact tip cap nut 154.

- the cap nut 154 is threaded on post 150 against the spacer 152.

- Washers 156 may be interposed between the spacer 152 and the base 16 to adjust the contact arc gap and wear allowance.

- the switch unit it may be desirable to mount the armature assembly 42 independently of the cover 40, as, for example, from fixed points such as posts connected to the base 16. This may be done Without sacrificing the advantages afforded by the strap, spring mounting of the armature. A most important one of those advantages is that no pivotal or sliding bearing or other connection conducive to wearing of the parts is required.

- an electric switch in combination, a base, an electromagnet carried by said base for energization from a source of electrical power to establish a magnetic attractive force, a plurality of sets of fixed contacts carried by said base and disposed about said electromagnet, a removable cover for fixed mounting on said base to cover said electromagnet and said sets of fixed contacts, an armature assembly comprising an armature for said electromagnet and a plurality of bridging contacts carried by said armature, said armature being attractable in one direction by said electromagnet to effect engagement of each of said plurality of said bridging contacts with a respectively associated set of said fixed contacts, and means resiliently supporting said armature assembly on said cover and having connection with said armature assembly at points on the latter in a plane extending substantially through the center of gravity thereof, said plane being perpendicular to said one direction.

- said means comprises spring means extending substantially the length of said armature assembly and being connected at one end to said armature assembly and at the other end to said cover.

- an electric switch unit in combination, a base, a fixed contact carried by said base, an electromagnet for energization from a source of electrical power and carried by said base, an armature for attraction by said electromagnet, a movable contact member mounted on said armature and engageable with said fixed contact upon attraction of said armature by said electromagnet, and suspension means for said armature comprising a spring connected at one end with one end portion of said armature and connected at its other end at a point fixed relative to said base adjacent the opposite end portion of said armature.

- an electric switch unit in combination, a base, an electromagnet carried by said base and energizable from a source of electrical power to establish a magnetic attractive force, a plurality of fixed contacts carried by said base and disposed about said electromagnet, an armature assembly comprising an armature for said electromagnet and movable contact members disposed about said armature for cooperation with said fixed contacts, supporting means for said armature assembly permitting movement of the latter to effect engagement of said fixed contacts and said movable contact members and comprising a spring connected at one end thereof to one end portion of said armature assembly and connected at its other end at a point fixed relative to said base adjacent the opposite end portion of said armature.

- an electric switch in combination, a base, an electro-magnet carried by said base, a removable cover for fixed mounting on said base to cover said electromagnet, an armature assembly comprising an armature for said electromagnet and being attractable in one direction thereby, resilient means interconnecting said cover and said armature assembly at points on the latter in a plane extending substantially through the center of gravity thereof and perpendicular to said one direction, and switch contacts adapted to be actuated by movement of said armature.

- an electric switch unit in combination, a base, a fixed contact carried by said base, an electromagnet for energization from a source of electrical power and carried by said base, an armature for attraction by said electromagnet, a movable contact member carried by said armature and engageable with said fixed contact upon attraction of said armature by said electromagnet, and suspension means for said armature comprising a spring connected at one end with one end portion of said armature and connected at its other end at a point fixed relative to said base adjacent the opposite end portion of said armature, said spring being connected to said armature at a point on the latter in a plane extending substantially through the center of gravity of said armature, said plane being perpendicular to the line of motion of said armature.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Switch Cases, Indication, And Locking (AREA)

- Push-Button Switches (AREA)

- Magnetic Treatment Devices (AREA)

Description

April 1, 1958 J. F. DRIES ET AL.

ELECTRIC SWITCH UNITS 3 Sheets-Sheet 1 Filed Nov. 12, 1953 I I 97 we 90 86 April 1, 1958 .1. F. DRIES ET AL ELECTRIC SWITCH UNITS 3 Sheets-Sheet 2 Filed Nov. 12, 1953 VJ'II/V/ April 1, 1958 J. F. DRIES ET AL 2,829,216

ELECTRIC SWITCH UNITS Filed Nov. 12, 1955 3 Sheets-Sheet 5 w s w w Mar/1mg.

United States Patent C if ELECTRIC SWITCH UNITS Jerome F. Dries, Milwaukee, and Clarence W. Kuhn, Wauwatosa, Wis., assignors to Cutler-Hammer, Inc., Milwaukee, Wis., a corporation of Delaware Application November 12, 1953, Serial No. 391,398

6 Claims. (Cl. 200-87) This invention relates to improvements in electric switch units; and it relates more particularly to improvements in electromagnetically operated switch units.

A primary object of the invention is to provide rugged and dependable switch units having large electrical capacity in relation to their size, weight and cost.

Another object is to provide switch units which may be easily and safely inspected.

Another object is to provide switch units of the aforedescribed character which consists primarily of standard parts and require only a minimum number of specially formed parts, thus to facilitate repair in the field with ordinary tools and with a minimum number of different spare parts.

Another object is to provide electromagnetically operated switch units having improved mounting means for the movable parts thereof.

A further object is to provide switch units which may be readily adapted for various applications.

Various other objects and advantages of the invention will hereinafter appear.

The accompanying drawings illustrate one embodiment of the invention which will now be described, it being understood that certain modifications may be made in the embodiment shown without departing from the spirit of the invention or the scope of the appended claims.

In the drawings,

Figure 1 is a plan view of a base assembly;

Fig. 2 is a plan view of a cover assembly;

Figs. 3 and 4 are partly cross sectional, partly elevational views of the opposite ends, respectively, of a switch unit embodying the invention and in which the main contacts are shown to be open and closed, respectively; and

Fig. 5 is a partly fragmentary, partly crosssectional, and partly side elevational view of the switch unit shown in Figs. 3 and 4.

Referring to the drawings, the switch unit consists generally of a panel assembly 12 (Fig. l) and a cover assembly 14 (Fig. 2). The panel assembly 12 includes a panel or base 16, an electromagnet 18 centrally located on the front face of the base 16, and a row of fixed main contact assemblies 20 on opposite sides of the electromagnet 18. Said panel assembly 12 further includes an auxiliary interlock assembly 22 located at one end, and a fixed auxiliary contact assembly 24 located at the other end of the electromagnet 18.

The electromagnet 18 comprises an E-shaped magnet frame 26, the E-shape being a preferred form, and an operating coil 28 placed around the central pole 30 of the magnet frame 26. The ends of the coil 28 are secured to appropriate terminal assemblies 32, 32. Nut and bolt sets 34, 34 secure the magnet frame 26 to the base 16; and bolts 36, 36, which extend through a clamp 38 disposed on top of the coil 28 and into the magnet frame 26, hold the coil in position, as shown.

The cover assembly 14 consists of a cover 40, an armature assembly 42, and a pair of spring support straps 44,

, 2,329,216 Patented Apr. 1, 1958 44.- The armature assembly 42 includes a magnetic plate 50 on each side edge 52 thereof, parallel insulating bars 53, 54 each of which is secured to a respectively associated side extension 50, an interlock finger operating assembly 56 fastened to one end of the armature 48, and a pair of movable auxiliary contact assemblies 60 and 62 secured to the opposite end of the armature 48. The armature assembly 42 also includes four main bridging contact assemblies 63 which are fastened one to each end of each insulating bar 54.

The armature assembly is suspended from the cover 40 by means of the support straps 44, 44. Each strap 44 is bolted at one end thereof to one of a pair of projections 64, 64 on the inner wall at one side of the cover 40. The straps 44 extend in like directions toward the opposite side of the cover 40, and each is bolted at its opposite end 44 to the lower side of one bar 54. Four posts 66, which are riveted or otherwise secured to the top of cover 40, extend through four respectively associated enlarged holes in the armature 48 located one in each corner portion of the armature. A biasing spring 68 surrounds each post 66 and is held in compression against the outer face of the armature 48 by a washer 69 and a cotter pin 70 associated with the outer end of the post 66. The springs 68 act to afford a shock-proof character to the switch unit and cooperate with spring straps 44, 44 to bias the armature 48 toward cover 40.

The cover is provided with mounting lugs 72 and 74 extending outwardly from opposite sides of the cover. The lugs 72 and 74 are perforated and are adapted to accommodate bolts 76 and 78 respectively. The bolts are each secured by a nut to the base 16. One lug '72 is provided with a recess adapted to accommodate a pin or dowel 79 extending from the base 16 so that the cover assembly 14 may not be reversely assembled with respect to the panel assembly 12.

When the panel assembly 12 and the cover assembly 14 are secured in assembled relation, the central pole 30 of electromagnet 18 is spaced from, and is disposed opposite the central portion of, the armature 48. The interlock operating finger 56 and the movable auxiliary contact assemblies 60 and 62 are alined, respectively, with auxiliary interlock assembly 22 and fixed auxiliary contact assembly 24. Each bridging contact assembly 63 is alined with two adjacent, or one set of, fixed main contact assemblies 20.

When the electromagnet 18 is energized and the armature is attracted toward the magnet frame 26 the interlock operating finger 56 is carried into actuating engagement with the auxiliary interlock assembly 22; the movable auxiliary contact assemblies 60 and 62 are carried into circuit making engagement with the fixed auxiliary contact assembly 24, and each main bridging contact assembly 63 is carried into bridging engagement with its respectively associated set of fixed main contact assemblies 20. To insure proper alinement of the aforementioned assemblies, the straps 44 are arranged in such manner that they bear all of the weight of the armature assembly 42 and also prevent lateral motion of said armature assembly.

The posts 66 do not cooperate to position the armature, but serve only to retain the bias springs 68. The straps 44 are attached to the armature assembly 42 at points in a plane extending substantially through the center of gravity of the armature assembly. Said plane is perpendicular to the line of motion of the armature assembly. Said straps 44 are bolted to opposite ends of the armature assembly 42 at one side of the latter and extend substantially parallel with said armature assembly to the other side of the same two points on projections 64, 64 in the cover 40. When the armature is attracted toward asaegaie 3 theframe 26 each strap 44 is flexed intoa somewhat S-shape (see Fig. 4). This arrangement insures that the armature assembly 42 will remain substantially parallel with the clectromagnet frame 26 as it moves toward frame 26.

The aforementioned features permit a generally symmetrical arrangement of the interlock contact assembly 22, main contact assemblies 20, and the auxiliary contact assembly 24 around the electromagnet 18; and such features also permit corresponding symmetrical arrangement of the interlock operating finger 56, movable auxiliary contact assemblies 60 and 62 and the main bridging contact assemblies 63 on the armature assembly 42.

This symmetrical arrangement provides other desirable features. All the contacts and bridging contacts are arranged in close proximity to the Walls of the cover 40 so that inspection windows 80 may be formed in the cover wall, as shown, for inspection of the switch unit without disconnecting said unit. Also it is possible to interchange or to replace either the interlock assembly 22 or the auxiliary contact assemblies with the other or others. The main bridging contact assemblies 63 may be relocated on bars 53 or 54 in such manner that they Cam bridge other sets of the fixed contact assemblies 20, thus to adapt the switch unit for various control schemes without sacrificing balance of the armature assembly 42.

Another feature of the invention, and one which is particularly desirable in certain applications (as in electric locomotive service for which the switch unit illustrated is particularly suited), is that all of the main contacts are open and they and their contact tips are accessible for inspection and repair when the cover assembly 14 is removed from the panel assembly 12. Increased safety is provided since the cover must be removed before any other component can be removed.

Maintenance and repair of the unit is facilitated because the circuit ccmmutating components are arranged around the electromagnet 18 in a manner providing maximum spacing between adjacent components and permitting the use of components having common shapes rather than complex formed parts.

The interlock operating finger 56 consists of a bolt 82 extending through a cutout or hole in the armature 48 and secured to the latter by a nut and a lock washer. At its outer end the bolt 82 is threaded into a cylindrical actuator 84. The latter is prevented from turning on bolt 82 by a nut and a lock washer.

The auxiliary interlock contact assembly 22 comprises a stand-off block 86 and an overlying insulating strip 88 held by nut and bolt sets 90 to the base 16. The strip a 88 extends beyond the block 86 at both ends thereof and a pair of fixed contact assemblies 92 is attached to each end portion of strip 88. A bolt 94, secured to the base 16 by nuts, serves as a stop for the movable parts of the assembly 22. The latter parts consist of a generally U-shaped channel 27, an insulating block 98 which is riveted or bolted at one end thereof to the end of the outer arm of the channel 97 and extends to one side of the channel. An interlock bridging contact assembly 100 is riveted to the other end of the block 98 in bridging alinement with one set of fixed contact assemblies 92. Another insulating block 102 is attached at one end thereof to said end of said arm of the channel 97 and extends to the other side of channel 7 at an angle with respect to the block 98. A second interlock bridging contact assembly 1% is secured to the other end of block 102 in bridging alinement with the other set of fixed contact assemblies 92.

The channel 517 is journaied at each of its arms upon a shaft 106 which is threaded at one end 106 thereof into an outer leg of the magnet frame 26. The channel 97 is held on the shaft 106 by suitable fastening means, such, for example, as a cotter pin. The connecting portion 97* of the channel is elongated and one side thereof 1s adapted to engage stop bolt 94. The Other side of said connecting portion 97* is provided with a button 110 on the upper surface thereof in alinement with the actuator 84. The lower end of button 110 extends through portion 97 and is disposed within the upper end of a coiled compression spring 114. Said spring in turn extends through a hole in the insulating strip Sfi and bears at its opposite end against the bottom of a recess formed in the upper face of the stand-off block 86. The movable portions of the auxiliary contact assembly 22 are biased toward the position in which they are shown by spring 114, so that interlock bridging contact assembly bridges its associated contacts 92 and so that the contacts 92 which are associated with auxiliary interlock contact assembly 104, are not bridged by the latter. When the armature 43 is attracted by electromagnet 18, actuator 84 engages button to rotate the moving parts of the interlock contact assembly 22 against the bias of spring 114 to actuate the interlock contacts.

The fixed auxiliary contact assembly 24 consists of a stand-off block and an overlying insulating strip 122 held by nut and bolt sets 124 to the base 16. The strip 122 extends beyond the block 120 at both ends thereof and a pair of fixed contact assemblies 126 is attached to each end portion of the strip 122. These parts may be made interchangeable with the corresponding fixed parts of auxiliary interlock contact assembly 22.

The movable auxiliary contact assembly 60 includes a strap 13th bolted to and extending outwardly from the armature 48. The lower end of the strap 130 is bent laterally. A first L-shaped, anti-leakage, insulating piece 132, an L-shaped, auxiliary bridging contact block 134, and a second L-shaped, anti-leakage, insulating piece 136 are bolted in the order named to the underside of the end of the strap 130. An auxiliary bridging contact assembly 138 is attached to the L-shaped piece 134 in bridging alinement with one pair of the fixed auxiliary assemblies 126 on an associated end of the strip 122. T he movable auxiliary contact assembly 62 is like movable auxiliary contact assembly 60 except that its strap 139 is adapted for left-hand mounting of assembly 62 whereas strap 136* is adapted for righthand mounting of assembly 60.

Each main bridging contact assembly 63 includes a generally U-shaped bracket 140 which is held by a rivet 142 and a washer 14 2 to a respectively associated one of the insulating bars 53 or 54 with the open portion of the U facing away from the bar 53 or 54. The ends 140 of the arms of the U-shaped bracket 140 are bent inwardly and act to retain a bridging contact LE4. The latter is provided with a rivet 146 and a washer 146 at the center thereof. A coiled spring 148 is held under compression between the bracket 140 and the bridging contact 144 and is held in place by the washers l t/2 and 146 acting as spring guides. The ends of the bridging contact 144 extend beyond the bracket 140 and said ends are provided with non-welding contact tips.

Each main contact assembly 20 includes a threaded stud bolt 150 secured to the base 16 by suitable lock washers and nuts, a threaded spacer 152 and a non-welding contact tip cap nut 154. The cap nut 154 is threaded on post 150 against the spacer 152. Washers 156 may be interposed between the spacer 152 and the base 16 to adjust the contact arc gap and wear allowance.

In certain applications of the switch unit it may be desirable to mount the armature assembly 42 independently of the cover 40, as, for example, from fixed points such as posts connected to the base 16. This may be done Without sacrificing the advantages afforded by the strap, spring mounting of the armature. A most important one of those advantages is that no pivotal or sliding bearing or other connection conducive to wearing of the parts is required.

We claim:

1. In an electric switch, in combination, a base, an electromagnet carried by said base for energization from a source of electrical power to establish a magnetic attractive force, a plurality of sets of fixed contacts carried by said base and disposed about said electromagnet, a removable cover for fixed mounting on said base to cover said electromagnet and said sets of fixed contacts, an armature assembly comprising an armature for said electromagnet and a plurality of bridging contacts carried by said armature, said armature being attractable in one direction by said electromagnet to effect engagement of each of said plurality of said bridging contacts with a respectively associated set of said fixed contacts, and means resiliently supporting said armature assembly on said cover and having connection with said armature assembly at points on the latter in a plane extending substantially through the center of gravity thereof, said plane being perpendicular to said one direction.

2. The combination defined in claim 1 in which said means comprises spring means extending substantially the length of said armature assembly and being connected at one end to said armature assembly and at the other end to said cover.

3. In an electric switch unit, in combination, a base, a fixed contact carried by said base, an electromagnet for energization from a source of electrical power and carried by said base, an armature for attraction by said electromagnet, a movable contact member mounted on said armature and engageable with said fixed contact upon attraction of said armature by said electromagnet, and suspension means for said armature comprising a spring connected at one end with one end portion of said armature and connected at its other end at a point fixed relative to said base adjacent the opposite end portion of said armature.

4. In an electric switch unit, in combination, a base, an electromagnet carried by said base and energizable from a source of electrical power to establish a magnetic attractive force, a plurality of fixed contacts carried by said base and disposed about said electromagnet, an armature assembly comprising an armature for said electromagnet and movable contact members disposed about said armature for cooperation with said fixed contacts, supporting means for said armature assembly permitting movement of the latter to effect engagement of said fixed contacts and said movable contact members and comprising a spring connected at one end thereof to one end portion of said armature assembly and connected at its other end at a point fixed relative to said base adjacent the opposite end portion of said armature.

5. In an electric switch, in combination, a base, an electro-magnet carried by said base, a removable cover for fixed mounting on said base to cover said electromagnet, an armature assembly comprising an armature for said electromagnet and being attractable in one direction thereby, resilient means interconnecting said cover and said armature assembly at points on the latter in a plane extending substantially through the center of gravity thereof and perpendicular to said one direction, and switch contacts adapted to be actuated by movement of said armature.

6. In an electric switch unit, in combination, a base, a fixed contact carried by said base, an electromagnet for energization from a source of electrical power and carried by said base, an armature for attraction by said electromagnet, a movable contact member carried by said armature and engageable with said fixed contact upon attraction of said armature by said electromagnet, and suspension means for said armature comprising a spring connected at one end with one end portion of said armature and connected at its other end at a point fixed relative to said base adjacent the opposite end portion of said armature, said spring being connected to said armature at a point on the latter in a plane extending substantially through the center of gravity of said armature, said plane being perpendicular to the line of motion of said armature.

References Cited in the file of this patent UNITED STATES PATENTS 960,440 Thomson June 7, 1910 1,165,098 Herr Dec. 21, 1915 1,187,897 Friedemann June 20, 1916 1,311,459 Patten July 29, 1919 1,534,753 Watson Apr. 21, 1925 1,730,216 Kendall Oct. 1, 1929 1,731,188 Avery Oct. 8, 1929 2,036,295 Pittath Apr. 7, 1936 2,444,198 Hasselhorn June 29, 1948 2,524,257 Harrah Oct. 3, 1950 2,541,778 Rappl Feb. 13, 1951 FOREIGN PATENTS 336,762 France Nov. 17, 1903

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US391398A US2829216A (en) | 1953-11-12 | 1953-11-12 | Electric switch units |

| GB31307/54A GB774012A (en) | 1953-11-12 | 1954-10-29 | Improvements in or relating to electromagnetically operated switch units |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US391398A US2829216A (en) | 1953-11-12 | 1953-11-12 | Electric switch units |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US2829216A true US2829216A (en) | 1958-04-01 |

Family

ID=23546427

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US391398A Expired - Lifetime US2829216A (en) | 1953-11-12 | 1953-11-12 | Electric switch units |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US2829216A (en) |

| GB (1) | GB774012A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11117136B2 (en) * | 2016-06-21 | 2021-09-14 | General Electric Technology Gmbh | System, method and apparatus for upgrading a pulverizer |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR336762A (en) * | 1903-11-17 | 1904-03-17 | Barthelemy Becker | Ruhmkorff coil shaker system |

| US960440A (en) * | 1908-02-10 | 1910-06-07 | Gen Electric | Compensator. |

| US1165098A (en) * | 1915-01-30 | 1915-12-21 | Charles H Herr | Motor control. |

| US1187897A (en) * | 1913-08-09 | 1916-06-20 | Arthur H K Friedemann | Electromagnetic switch. |

| US1311459A (en) * | 1919-07-29 | Francis h | ||

| US1534753A (en) * | 1922-07-25 | 1925-04-21 | C L I Mfg Company Ltd | Electric switch or circuit breaker |

| US1730216A (en) * | 1926-03-01 | 1929-10-01 | Allen B Kendall | Relay |

| US1731188A (en) * | 1921-07-22 | 1929-10-08 | Union Bag & Paper Corp | Electric switch |

| US2036295A (en) * | 1936-04-07 | Circuit breaker | ||

| US2444198A (en) * | 1944-04-01 | 1948-06-29 | Cook Electric Co | Hermetically sealed electromagnetic relay |

| US2524257A (en) * | 1947-07-21 | 1950-10-03 | Charles J Harrah | Engine control for electric welding machine |

| US2541778A (en) * | 1946-10-30 | 1951-02-13 | Trico Products Corp | Magnetically operated switch |

-

1953

- 1953-11-12 US US391398A patent/US2829216A/en not_active Expired - Lifetime

-

1954

- 1954-10-29 GB GB31307/54A patent/GB774012A/en not_active Expired

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1311459A (en) * | 1919-07-29 | Francis h | ||

| US2036295A (en) * | 1936-04-07 | Circuit breaker | ||

| FR336762A (en) * | 1903-11-17 | 1904-03-17 | Barthelemy Becker | Ruhmkorff coil shaker system |

| US960440A (en) * | 1908-02-10 | 1910-06-07 | Gen Electric | Compensator. |

| US1187897A (en) * | 1913-08-09 | 1916-06-20 | Arthur H K Friedemann | Electromagnetic switch. |

| US1165098A (en) * | 1915-01-30 | 1915-12-21 | Charles H Herr | Motor control. |

| US1731188A (en) * | 1921-07-22 | 1929-10-08 | Union Bag & Paper Corp | Electric switch |

| US1534753A (en) * | 1922-07-25 | 1925-04-21 | C L I Mfg Company Ltd | Electric switch or circuit breaker |

| US1730216A (en) * | 1926-03-01 | 1929-10-01 | Allen B Kendall | Relay |

| US2444198A (en) * | 1944-04-01 | 1948-06-29 | Cook Electric Co | Hermetically sealed electromagnetic relay |

| US2541778A (en) * | 1946-10-30 | 1951-02-13 | Trico Products Corp | Magnetically operated switch |

| US2524257A (en) * | 1947-07-21 | 1950-10-03 | Charles J Harrah | Engine control for electric welding machine |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11117136B2 (en) * | 2016-06-21 | 2021-09-14 | General Electric Technology Gmbh | System, method and apparatus for upgrading a pulverizer |

Also Published As

| Publication number | Publication date |

|---|---|

| GB774012A (en) | 1957-05-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3296567A (en) | Electric control device | |

| US2276698A (en) | Contactor | |

| US2929899A (en) | Contactor switch device | |

| US2514913A (en) | Multiple switch | |

| US2036295A (en) | Circuit breaker | |

| US6794968B2 (en) | Magnetic latching contactor | |

| US2414961A (en) | Electromagnetic device | |

| US2946872A (en) | Shock and vibration resistant electromagnetic contactor | |

| US2474742A (en) | Electromagnetic switch | |

| US2829216A (en) | Electric switch units | |

| US2619569A (en) | Electrical contact mounting | |

| US2773948A (en) | Contact arrangement for control relay | |

| US2424308A (en) | Contactor | |

| US2792469A (en) | Multiple electrical contactor | |

| US2235861A (en) | Electromagnetic relay | |

| US2140604A (en) | Electrical relay | |

| US3493903A (en) | Electromagnetic relay with a suspended armature | |

| US2550110A (en) | Magnet assembly for contactors | |

| US1816429A (en) | Electric switch | |

| US2432782A (en) | Electric switch | |

| US3588765A (en) | Electromagnetic relays | |

| US2153402A (en) | Electric switch | |

| US2228069A (en) | Relay | |

| US3187141A (en) | Armature mounting means for electromagnetic relays | |

| US2462482A (en) | Electromagnet with plunger |