US20030194556A1 - Stabilized aqueous polyurethane-polyurea dispersions - Google Patents

Stabilized aqueous polyurethane-polyurea dispersions Download PDFInfo

- Publication number

- US20030194556A1 US20030194556A1 US10/341,880 US34188003A US2003194556A1 US 20030194556 A1 US20030194556 A1 US 20030194556A1 US 34188003 A US34188003 A US 34188003A US 2003194556 A1 US2003194556 A1 US 2003194556A1

- Authority

- US

- United States

- Prior art keywords

- compound

- binder composition

- formula

- weight

- components

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- BIZSJKULZKHUPS-UHFFFAOYSA-N CC1CC(C)(C)NC(C)(C)C1 Chemical compound CC1CC(C)(C)NC(C)(C)C1 BIZSJKULZKHUPS-UHFFFAOYSA-N 0.000 description 9

- 0 [3*]C([1*]O)[2*]O Chemical compound [3*]C([1*]O)[2*]O 0.000 description 8

- JYOXAXRSDUSKFL-UHFFFAOYSA-N [H]N(C(=O)OCC(C)C)N([H])C(=O)OCC(C)O Chemical compound [H]N(C(=O)OCC(C)C)N([H])C(=O)OCC(C)O JYOXAXRSDUSKFL-UHFFFAOYSA-N 0.000 description 6

- SFMFUPJQLLKCHO-UHFFFAOYSA-N [H]N1C(C)(C)CC(OC(=O)CCCCCCCCC(=O)OC2CC(C)(C)N(C)C(C)(C)C2)CC1(C)C Chemical compound [H]N1C(C)(C)CC(OC(=O)CCCCCCCCC(=O)OC2CC(C)(C)N(C)C(C)(C)C2)CC1(C)C SFMFUPJQLLKCHO-UHFFFAOYSA-N 0.000 description 3

- STLLXWLDRUVCHL-UHFFFAOYSA-N C=CC(=O)OC1=C(C(C)C2=CC(C(C)(C)CC)=CC(C(C)(C)CC)=C2O)C=C(C(C)(C)CC)C=C1C(C)(C)CC Chemical compound C=CC(=O)OC1=C(C(C)C2=CC(C(C)(C)CC)=CC(C(C)(C)CC)=C2O)C=C(C(C)(C)CC)C=C1C(C)(C)CC STLLXWLDRUVCHL-UHFFFAOYSA-N 0.000 description 2

- QAMNLGFPMQLFDU-UHFFFAOYSA-N CC(C)(C)C1=CC(C(C)(C)C)=C(OP)C=C1 Chemical compound CC(C)(C)C1=CC(C(C)(C)C)=C(OP)C=C1 QAMNLGFPMQLFDU-UHFFFAOYSA-N 0.000 description 2

- DXGLGDHPHMLXJC-UHFFFAOYSA-N [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OC)=C1 Chemical compound [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OC)=C1 DXGLGDHPHMLXJC-UHFFFAOYSA-N 0.000 description 2

- LHPPDQUVECZQSW-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)C)C=C1C(C)(C)C Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)C)C=C1C(C)(C)C LHPPDQUVECZQSW-UHFFFAOYSA-N 0.000 description 2

- BKCZFJZUDZPQFM-UHFFFAOYSA-N C#CC#CC#CC#CC#CC#CC#CC#CC#COC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#CC#CC#CC#CC#CC#CC#COC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] BKCZFJZUDZPQFM-UHFFFAOYSA-N 0.000 description 1

- XEJUJLRSKOUDIT-UHFFFAOYSA-N C#CC#CC#CC#CC#CC#CC#CC#CC#COC(=O)CCS.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#CC#CC#CC#CC#CC#CC#COC(=O)CCS.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] XEJUJLRSKOUDIT-UHFFFAOYSA-N 0.000 description 1

- ZFRRCVPHSTWSQJ-UHFFFAOYSA-N C#CC#CC#CC#CC#CC#CC#CC#COC(=O)C1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#CC#CC#CC#CC#CC#COC(=O)C1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] ZFRRCVPHSTWSQJ-UHFFFAOYSA-N 0.000 description 1

- KAAOSXYIKCHAMJ-UHFFFAOYSA-N C#CC#CC#CC#CC#CC#CC#COC(=O)CCS.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#CC#CC#CC#CC#COC(=O)CCS.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] KAAOSXYIKCHAMJ-UHFFFAOYSA-N 0.000 description 1

- SBDKVFLSBGSYFI-UHFFFAOYSA-N C#CC#CC#CC#CC#CC#COC(=O)CCS.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#CC#CC#CC#COC(=O)CCS.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] SBDKVFLSBGSYFI-UHFFFAOYSA-N 0.000 description 1

- PCPBEWWDOXULKA-UHFFFAOYSA-N C#CC#CC#CC#CSC1=NC(NC2=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C2)=NC(SCCCCCCCC)=N1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#CC#CSC1=NC(NC2=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C2)=NC(SCCCCCCCC)=N1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] PCPBEWWDOXULKA-UHFFFAOYSA-N 0.000 description 1

- FGDJBWVZYVSJCK-UHFFFAOYSA-N C#CC#CC#COC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound C#CC#CC#COC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] FGDJBWVZYVSJCK-UHFFFAOYSA-N 0.000 description 1

- WTHSHMYXFBCWDI-UHFFFAOYSA-N C.C.[H]N1C(C)(C)CC(OC(=O)CC(=O)OC2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C Chemical compound C.C.[H]N1C(C)(C)CC(OC(=O)CC(=O)OC2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C WTHSHMYXFBCWDI-UHFFFAOYSA-N 0.000 description 1

- KEQFTVQCIQJIQW-UHFFFAOYSA-N C1=CC=C(NC2=CC3=C(C=CC=C3)C=C2)C=C1 Chemical compound C1=CC=C(NC2=CC3=C(C=CC=C3)C=C2)C=C1 KEQFTVQCIQJIQW-UHFFFAOYSA-N 0.000 description 1

- XQVWYOYUZDUNRW-UHFFFAOYSA-N C1=CC=C(NC2=CC=CC3=C2C=CC=C3)C=C1 Chemical compound C1=CC=C(NC2=CC=CC3=C2C=CC=C3)C=C1 XQVWYOYUZDUNRW-UHFFFAOYSA-N 0.000 description 1

- QUVHVAQXNLZPIV-UHFFFAOYSA-N C=C1N(CCN(C2=NC(N(CCC3CC(C)(C)N(C)C(C)(C)C3=O)C3CCCCC3)=NC(N(CCN3CC(C)(C)N(C)C(C)(C)C3=O)C3CCCCC3)=N2)C2CCCCC2)CC(C)(C)N(C)C1(C)C.[HH].[HH].[HH] Chemical compound C=C1N(CCN(C2=NC(N(CCC3CC(C)(C)N(C)C(C)(C)C3=O)C3CCCCC3)=NC(N(CCN3CC(C)(C)N(C)C(C)(C)C3=O)C3CCCCC3)=N2)C2CCCCC2)CC(C)(C)N(C)C1(C)C.[HH].[HH].[HH] QUVHVAQXNLZPIV-UHFFFAOYSA-N 0.000 description 1

- IORUEKDKNHHQAL-UHFFFAOYSA-N C=CC(=O)OC1=C(CC2=CC(C)=CC(C(C)(C)C)=C2O)C=C(C)C=C1C(C)(C)C Chemical compound C=CC(=O)OC1=C(CC2=CC(C)=CC(C(C)(C)C)=C2O)C=C(C)C=C1C(C)(C)C IORUEKDKNHHQAL-UHFFFAOYSA-N 0.000 description 1

- VAOXTGPXYJHNHC-UHFFFAOYSA-N CC#CC#CC#CC#CC#CC#CC#CC#CC(=O)NC1=CC=C(O)C=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] Chemical compound CC#CC#CC#CC#CC#CC#CC#CC#CC(=O)NC1=CC=C(O)C=C1.[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH] VAOXTGPXYJHNHC-UHFFFAOYSA-N 0.000 description 1

- ZNGKFOFTPPPYJK-UHFFFAOYSA-N CC(=O)NCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CC(=O)NCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 ZNGKFOFTPPPYJK-UHFFFAOYSA-N 0.000 description 1

- GPTBUIMZDZKKLE-UHFFFAOYSA-N CC(=O)NN=CC1=CC=CC=C1 Chemical compound CC(=O)NN=CC1=CC=CC=C1 GPTBUIMZDZKKLE-UHFFFAOYSA-N 0.000 description 1

- NHUIRBHYEVBHLF-UHFFFAOYSA-N CC(C)(C)C1=CC(C(C)(C)C)=C(OP2OCCCO2)C=C1 Chemical compound CC(C)(C)C1=CC(C(C)(C)C)=C(OP2OCCCO2)C=C1 NHUIRBHYEVBHLF-UHFFFAOYSA-N 0.000 description 1

- XEZIXFCSVLUXBR-UHFFFAOYSA-N CC(C)(C)C1=CC(CCC(=O)OCCS)=CC(C(C)(C)C)=C1O Chemical compound CC(C)(C)C1=CC(CCC(=O)OCCS)=CC(C(C)(C)C)=C1O XEZIXFCSVLUXBR-UHFFFAOYSA-N 0.000 description 1

- RQQXRISMYXIACK-UHFFFAOYSA-N CC(C)(C)C1=CC(CCC2=CC(C(C)(C)C)=C(OP3OCCCO3)C=C2)=CC(C(C)(C)C)=C1OP1OCCCO1 Chemical compound CC(C)(C)C1=CC(CCC2=CC(C(C)(C)C)=C(OP3OCCCO3)C=C2)=CC(C(C)(C)C)=C1OP1OCCCO1 RQQXRISMYXIACK-UHFFFAOYSA-N 0.000 description 1

- FBVYJGUWIUOVAY-UHFFFAOYSA-N CC(C)(C)C1=CC2=C(OP(OCCN)OC3=C(C(C)(C)C)C=C(C(C)(C)C)C=C23)C(C(C)(C)C)=C1 Chemical compound CC(C)(C)C1=CC2=C(OP(OCCN)OC3=C(C(C)(C)C)C=C(C(C)(C)C)C=C23)C(C(C)(C)C)=C1 FBVYJGUWIUOVAY-UHFFFAOYSA-N 0.000 description 1

- KJYSXRBJOSZLEL-UHFFFAOYSA-N CC(C)(C)C1=CC=C(OC(=O)C2=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C2)C(C(C)(C)C)=C1 Chemical compound CC(C)(C)C1=CC=C(OC(=O)C2=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C2)C(C(C)(C)C)=C1 KJYSXRBJOSZLEL-UHFFFAOYSA-N 0.000 description 1

- GQBHYWDCHSZDQU-UHFFFAOYSA-N CC(C)(C)CC(C)(C)C1=CC=C(NC2=CC=C(C(C)(C)CC(C)(C)C)C=C2)C=C1 Chemical compound CC(C)(C)CC(C)(C)C1=CC=C(NC2=CC=C(C(C)(C)CC(C)(C)C)C=C2)C=C1 GQBHYWDCHSZDQU-UHFFFAOYSA-N 0.000 description 1

- UJAWGGOCYUPCPS-UHFFFAOYSA-N CC(C)(C1=CC=CC=C1)C1=CC=C(NC2=CC=C(C(C)(C)C3=CC=CC=C3)C=C2)C=C1 Chemical compound CC(C)(C1=CC=CC=C1)C1=CC=C(NC2=CC=C(C(C)(C)C3=CC=CC=C3)C=C2)C=C1 UJAWGGOCYUPCPS-UHFFFAOYSA-N 0.000 description 1

- OUBMGJOQLXMSNT-UHFFFAOYSA-N CC(C)NC1=CC=C(NC2=CC=CC=C2)C=C1 Chemical compound CC(C)NC1=CC=C(NC2=CC=CC=C2)C=C1 OUBMGJOQLXMSNT-UHFFFAOYSA-N 0.000 description 1

- GVJHHUAWPYXKBD-UHFFFAOYSA-N CC1=C(C)C2=C(CCC(C)(CCCC(C)CCCC(C)CCCC(C)C)O2)C(C)=C1O Chemical compound CC1=C(C)C2=C(CCC(C)(CCCC(C)CCCC(C)CCCC(C)C)O2)C(C)=C1O GVJHHUAWPYXKBD-UHFFFAOYSA-N 0.000 description 1

- HXIQYSLFEXIOAV-UHFFFAOYSA-N CC1=C(SC2=C(C)C=C(O)C(C(C)(C)C)=C2)C=C(C(C)(C)C)C(O)=C1 Chemical compound CC1=C(SC2=C(C)C=C(O)C(C(C)(C)C)=C2)C=C(C(C)(C)C)C(O)=C1 HXIQYSLFEXIOAV-UHFFFAOYSA-N 0.000 description 1

- NLZUEZXRPGMBCV-UHFFFAOYSA-N CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 NLZUEZXRPGMBCV-UHFFFAOYSA-N 0.000 description 1

- UMKDJTJHNLXALI-UHFFFAOYSA-N CC1=CC(C(C)(C)C)=C(O)C(C2CC3CC2C2C(C4=CC(C)=CC(C(C)(C)C)=C4O)CCC32)=C1 Chemical compound CC1=CC(C(C)(C)C)=C(O)C(C2CC3CC2C2C(C4=CC(C)=CC(C(C)(C)C)=C4O)CCC32)=C1 UMKDJTJHNLXALI-UHFFFAOYSA-N 0.000 description 1

- KGRVJHAUYBGFFP-UHFFFAOYSA-N CC1=CC(CC2=CC(C)=CC(C(C)(C)C)=C2O)=C(O)C(C(C)(C)C)=C1 Chemical compound CC1=CC(CC2=CC(C)=CC(C(C)(C)C)=C2O)=C(O)C(C(C)(C)C)=C1 KGRVJHAUYBGFFP-UHFFFAOYSA-N 0.000 description 1

- QGJUTAZDTUOKHX-UHFFFAOYSA-N CC1=CC(CCC(=O)OCC(C)(C)C2OCCCO2)=CC(C(C)(C)C)=C1O Chemical compound CC1=CC(CCC(=O)OCC(C)(C)C2OCCCO2)=CC(C(C)(C)C)=C1O QGJUTAZDTUOKHX-UHFFFAOYSA-N 0.000 description 1

- PRWJPWSKLXYEPD-UHFFFAOYSA-N CC1=CC(O)=C(C(C)(C)C)C=C1C(CC(C)C1=C(C)C=C(O)C(C(C)(C)C)=C1)C1=C(C)C=C(O)C(C(C)(C)C)=C1 Chemical compound CC1=CC(O)=C(C(C)(C)C)C=C1C(CC(C)C1=C(C)C=C(O)C(C(C)(C)C)=C1)C1=C(C)C=C(O)C(C(C)(C)C)=C1 PRWJPWSKLXYEPD-UHFFFAOYSA-N 0.000 description 1

- MQWCQFCZUNBTCM-UHFFFAOYSA-N CC1=CC(SC2=CC(C)=CC(C(C)(C)C)=C2O)=C(O)C(C(C)(C)C)=C1 Chemical compound CC1=CC(SC2=CC(C)=CC(C(C)(C)C)=C2O)=C(O)C(C(C)(C)C)=C1 MQWCQFCZUNBTCM-UHFFFAOYSA-N 0.000 description 1

- SJWYZHHYVYDWAA-UHFFFAOYSA-N CC1=CC=C(P(OC2=C(C(C)(C)C)C=C(C(C)(C)C)C=C2)OC2=C(C(C)(C)C)C=C(C(C)(C)C)C=C2)C=C1 Chemical compound CC1=CC=C(P(OC2=C(C(C)(C)C)C=C(C(C)(C)C)C=C2)OC2=C(C(C)(C)C)C=C(C(C)(C)C)C=C2)C=C1 SJWYZHHYVYDWAA-UHFFFAOYSA-N 0.000 description 1

- OEUBLIJAIONETH-UHFFFAOYSA-N CC1C(C)(C)NC2=CC=CC=C2C1(C)C Chemical compound CC1C(C)(C)NC2=CC=CC=C2C1(C)C OEUBLIJAIONETH-UHFFFAOYSA-N 0.000 description 1

- MYMKXVFDVQUQLG-UHFFFAOYSA-N CC1C2=CC(C(C)(C)C)=CC(C(C)(C)C)=C2OP(F)OC2=C1C=C(C(C)(C)C)C=C2C(C)(C)C Chemical compound CC1C2=CC(C(C)(C)C)=CC(C(C)(C)C)=C2OP(F)OC2=C1C=C(C(C)(C)C)C=C2C(C)(C)C MYMKXVFDVQUQLG-UHFFFAOYSA-N 0.000 description 1

- GGGUYFOGPQJIPT-UHFFFAOYSA-N CCC(=O)OC1CC(C)(C)NC(C)(C)C1 Chemical compound CCC(=O)OC1CC(C)(C)NC(C)(C)C1 GGGUYFOGPQJIPT-UHFFFAOYSA-N 0.000 description 1

- DDABTHPFNLQHDZ-UHFFFAOYSA-N CCC(O)CN1C(=O)C(C2CC(C)(C)N(C)C(C)(C)C2)OC12CCCCCCCCCCC2 Chemical compound CCC(O)CN1C(=O)C(C2CC(C)(C)N(C)C(C)(C)C2)OC12CCCCCCCCCCC2 DDABTHPFNLQHDZ-UHFFFAOYSA-N 0.000 description 1

- PFANXOISJYKQRP-UHFFFAOYSA-N CCCC(C1=CC(C(C)(C)C)=C(O)C=C1C)C1=CC(C(C)(C)C)=C(O)C=C1C Chemical compound CCCC(C1=CC(C(C)(C)C)=C(O)C=C1C)C1=CC(C(C)(C)C)=C(O)C=C1C PFANXOISJYKQRP-UHFFFAOYSA-N 0.000 description 1

- NCOTZCXAAPHBMO-UHFFFAOYSA-N CCCCC(CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1)C(=O)OC1CC(C)(C)N(C)C(C)(C)C1 Chemical compound CCCCC(CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1)C(=O)OC1CC(C)(C)N(C)C(C)(C)C1 NCOTZCXAAPHBMO-UHFFFAOYSA-N 0.000 description 1

- NZQVVZSSXKEVOW-UHFFFAOYSA-N CCCCCCCCCC1=CC=C(OP)C=C1 Chemical compound CCCCCCCCCC1=CC=C(OP)C=C1 NZQVVZSSXKEVOW-UHFFFAOYSA-N 0.000 description 1

- SAEZGDDJKSBNPT-UHFFFAOYSA-N CCCCCCCCCCCCC1CC(=O)N(C2CC(C)(C)N(C)C(C)(C)C2)C1=O Chemical compound CCCCCCCCCCCCC1CC(=O)N(C2CC(C)(C)N(C)C(C)(C)C2)C1=O SAEZGDDJKSBNPT-UHFFFAOYSA-N 0.000 description 1

- FGYJSJUSODGXAR-UHFFFAOYSA-N CCCCCCCCOP1OC2=C(C=C(C(C)(C)C)C=C2C(C)(C)C)CC2=CC(C(C)(C)C)=CC(C(C)(C)C)=C2O1 Chemical compound CCCCCCCCOP1OC2=C(C=C(C(C)(C)C)C=C2C(C)(C)C)CC2=CC(C(C)(C)C)=CC(C(C)(C)C)=C2O1 FGYJSJUSODGXAR-UHFFFAOYSA-N 0.000 description 1

- GAODDBNJCKQQDY-UHFFFAOYSA-N CCCCCCCCSCC1=CC(C)=C(O)C(CSCCCCCCCC)=C1 Chemical compound CCCCCCCCSCC1=CC(C)=C(O)C(CSCCCCCCCC)=C1 GAODDBNJCKQQDY-UHFFFAOYSA-N 0.000 description 1

- MFRLBYZDRASZCI-UHFFFAOYSA-N CCCCCCOC1=CC=C(C2=NC(C3=C(C)C=C(C)C=C3)=NC(C3=C(C)C=C(C)C=C3)=N2)C(O)=C1 Chemical compound CCCCCCOC1=CC=C(C2=NC(C3=C(C)C=C(C)C=C3)=NC(C3=C(C)C=C(C)C=C3)=N2)C(O)=C1 MFRLBYZDRASZCI-UHFFFAOYSA-N 0.000 description 1

- LEVFXWNQQSSNAC-UHFFFAOYSA-N CCCCCCOC1=CC=C(C2=NC(C3=CC=CC=C3)=NC(C3=CC=CC=C3)=N2)C(O)=C1 Chemical compound CCCCCCOC1=CC=C(C2=NC(C3=CC=CC=C3)=NC(C3=CC=CC=C3)=N2)C(O)=C1 LEVFXWNQQSSNAC-UHFFFAOYSA-N 0.000 description 1

- SPAHJEALWTYFOH-UHFFFAOYSA-N CCCCNC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CCCCNC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 SPAHJEALWTYFOH-UHFFFAOYSA-N 0.000 description 1

- DFMYXZSEXKBYDI-UHFFFAOYSA-N CCCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CCCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 DFMYXZSEXKBYDI-UHFFFAOYSA-N 0.000 description 1

- MKIXMFNEKHGPSP-UHFFFAOYSA-N CCOC(=O)CC(C)(C1=CC=CC(C(C)(C)C)=C1)C1=CC(C(C)(C)C)=CC=C1 Chemical compound CCOC(=O)CC(C)(C1=CC=CC(C(C)(C)C)=C1)C1=CC(C(C)(C)C)=CC=C1 MKIXMFNEKHGPSP-UHFFFAOYSA-N 0.000 description 1

- ZCWSUZJGZZFSHM-UHFFFAOYSA-N CCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 ZCWSUZJGZZFSHM-UHFFFAOYSA-N 0.000 description 1

- ZBNMOUGFCKAGGQ-UHFFFAOYSA-N CCOC1=CC=C(C(C)(C)C)C=C1NC(=O)C(=O)NC1=C(CC)C=CC=C1 Chemical compound CCOC1=CC=C(C(C)(C)C)C=C1NC(=O)C(=O)NC1=C(CC)C=CC=C1 ZBNMOUGFCKAGGQ-UHFFFAOYSA-N 0.000 description 1

- YIMHRDBSVCPJOV-UHFFFAOYSA-N CCOC1=CC=CC=C1NC(=O)C(=O)NC1=C(CC)C=CC=C1 Chemical compound CCOC1=CC=CC=C1NC(=O)C(=O)NC1=C(CC)C=CC=C1 YIMHRDBSVCPJOV-UHFFFAOYSA-N 0.000 description 1

- PMNUMBDGKXUREB-UHFFFAOYSA-N CCOCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CCOCCOC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 PMNUMBDGKXUREB-UHFFFAOYSA-N 0.000 description 1

- OMSFKVDRZKEVOO-UHFFFAOYSA-N CCOO(CC)[PH+]([O-])CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CCOO(CC)[PH+]([O-])CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 OMSFKVDRZKEVOO-UHFFFAOYSA-N 0.000 description 1

- WBSRIXCTCFFHEF-UHFFFAOYSA-M CCO[P+]([O-])([O-])CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[Ca+2] Chemical compound CCO[P+]([O-])([O-])CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1.[Ca+2] WBSRIXCTCFFHEF-UHFFFAOYSA-M 0.000 description 1

- RSOILICUEWXSLA-UHFFFAOYSA-N CN1C(C)(C)CC(OC(=O)CCCCCCCCC(=O)OC2CC(C)(C)N(C)C(C)(C)C2)CC1(C)C Chemical compound CN1C(C)(C)CC(OC(=O)CCCCCCCCC(=O)OC2CC(C)(C)N(C)C(C)(C)C2)CC1(C)C RSOILICUEWXSLA-UHFFFAOYSA-N 0.000 description 1

- KACKESNWCSECLK-UHFFFAOYSA-N CNC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 Chemical compound CNC(=O)CCC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 KACKESNWCSECLK-UHFFFAOYSA-N 0.000 description 1

- JMFYZMAVUHNCPW-UHFFFAOYSA-N COC(=O)C(=CC1=CC=C(OC)C=C1)C(=O)OC Chemical compound COC(=O)C(=CC1=CC=C(OC)C=C1)C(=O)OC JMFYZMAVUHNCPW-UHFFFAOYSA-N 0.000 description 1

- CTJXKCPBMVLOQI-UHFFFAOYSA-N COC1CC(C)(C)N(CCOC(=O)CCC(C)=O)C(C)(C)C1 Chemical compound COC1CC(C)(C)N(CCOC(=O)CCC(C)=O)C(C)(C)C1 CTJXKCPBMVLOQI-UHFFFAOYSA-N 0.000 description 1

- WQQAPJITHNMMNQ-UHFFFAOYSA-N COP1OCCCO1 Chemical compound COP1OCCCO1 WQQAPJITHNMMNQ-UHFFFAOYSA-N 0.000 description 1

- QMMFVYPAHWMCMS-UHFFFAOYSA-N CSC Chemical compound CSC QMMFVYPAHWMCMS-UHFFFAOYSA-N 0.000 description 1

- HVKIPMYCYSBVNZ-UHFFFAOYSA-N [HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[H]N1C(C)(C)CC(N2C(=O)CC(C#CC#CC#CC#CC#CC#C)C2=O)CC1(C)C Chemical compound [HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[HH].[H]N1C(C)(C)CC(N2C(=O)CC(C#CC#CC#CC#CC#CC#C)C2=O)CC1(C)C HVKIPMYCYSBVNZ-UHFFFAOYSA-N 0.000 description 1

- AHLWLUHCTSFOOA-UHFFFAOYSA-N [HH].[HH].[HH].[H]N1C(C)(C)CN(CCN(C2=NC(N(CCN3CC(C)(C)N([H])C(C)(C)C3=O)C3CCCCC3)=NC(N(CCN3CC(C)(C)N(C)C(C)(C)C3=O)C3CCCCC3)=N2)C2CCCCC2)C(=O)C1(C)C Chemical compound [HH].[HH].[HH].[H]N1C(C)(C)CN(CCN(C2=NC(N(CCN3CC(C)(C)N([H])C(C)(C)C3=O)C3CCCCC3)=NC(N(CCN3CC(C)(C)N(C)C(C)(C)C3=O)C3CCCCC3)=N2)C2CCCCC2)C(=O)C1(C)C AHLWLUHCTSFOOA-UHFFFAOYSA-N 0.000 description 1

- MSGFTHUDDIBEMG-UHFFFAOYSA-N [H]N(C(=O)OCC(C)O)N([H])C(=O)OCC(C)O Chemical compound [H]N(C(=O)OCC(C)O)N([H])C(=O)OCC(C)O MSGFTHUDDIBEMG-UHFFFAOYSA-N 0.000 description 1

- ZKVZXCHPGHPFFL-UHFFFAOYSA-N [H]N1C(C)(C)CC(N(C)CCCCCCN(C2=NC(C)=NC(N3CCOCC3)=N2)C2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C Chemical compound [H]N1C(C)(C)CC(N(C)CCCCCCN(C2=NC(C)=NC(N3CCOCC3)=N2)C2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C ZKVZXCHPGHPFFL-UHFFFAOYSA-N 0.000 description 1

- TZPIRNSFKLBHSS-UHFFFAOYSA-N [H]N1C(C)(C)CC(N(C)CCCCCCN(C2=NC(C)=NC(NC(C)(C)CC(C)(C)C)=N2)C2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C Chemical compound [H]N1C(C)(C)CC(N(C)CCCCCCN(C2=NC(C)=NC(NC(C)(C)CC(C)(C)C)=N2)C2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C TZPIRNSFKLBHSS-UHFFFAOYSA-N 0.000 description 1

- XITRBUPOXXBIJN-UHFFFAOYSA-N [H]N1C(C)(C)CC(OC(=O)CCCCCCCCC(=O)OC2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C Chemical compound [H]N1C(C)(C)CC(OC(=O)CCCCCCCCC(=O)OC2CC(C)(C)N([H])C(C)(C)C2)CC1(C)C XITRBUPOXXBIJN-UHFFFAOYSA-N 0.000 description 1

- OZZSZUAKZMPLIK-UHFFFAOYSA-N [H]N1C(C)(C)CC(OCCC[Si](C)(C)OC)CC1(C)C Chemical compound [H]N1C(C)(C)CC(OCCC[Si](C)(C)OC)CC1(C)C OZZSZUAKZMPLIK-UHFFFAOYSA-N 0.000 description 1

- IVVLFHBYPHTMJU-UHFFFAOYSA-N [H]N1C(C)(C)CC2(CC1(C)C)OC1(CCCCCCCCCCC1)NC2=O Chemical compound [H]N1C(C)(C)CC2(CC1(C)C)OC1(CCCCCCCCCCC1)NC2=O IVVLFHBYPHTMJU-UHFFFAOYSA-N 0.000 description 1

- QOEPHLNBBYWJOY-UHFFFAOYSA-N [H]N1C(C)(C)CC2(CC1(C)C)OC1COC3(CC(C)(C)N([H])C(C)(C)C3)OC1C(C(O)CO)O2 Chemical compound [H]N1C(C)(C)CC2(CC1(C)C)OC1COC3(CC(C)(C)N([H])C(C)(C)C3)OC1C(C(O)CO)O2 QOEPHLNBBYWJOY-UHFFFAOYSA-N 0.000 description 1

- GUCMKIKYKIHUTM-UHFFFAOYSA-N [H]N1C(C)(C)CN(CCN2CC(C)(C)N([H])C(C)(C)C2=O)C(=O)C1(C)C Chemical compound [H]N1C(C)(C)CN(CCN2CC(C)(C)N([H])C(C)(C)C2=O)C(=O)C1(C)C GUCMKIKYKIHUTM-UHFFFAOYSA-N 0.000 description 1

- PJIFVFAHRPWQPS-UHFFFAOYSA-N [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(CC)=C1 Chemical compound [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(CC)=C1 PJIFVFAHRPWQPS-UHFFFAOYSA-N 0.000 description 1

- CUWRRXIHOSRXGN-UHFFFAOYSA-N [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OC)=C1C Chemical compound [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OC)=C1C CUWRRXIHOSRXGN-UHFFFAOYSA-N 0.000 description 1

- QUAMTGJKVDWJEQ-UHFFFAOYSA-N [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OCCCCCCCC)=C1 Chemical compound [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OCCCCCCCC)=C1 QUAMTGJKVDWJEQ-UHFFFAOYSA-N 0.000 description 1

- ARVUDIQYNJVQIW-UHFFFAOYSA-N [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OCCCCCCCCCCCC)=C1 Chemical compound [H]OC1=C(C(=O)C2=CC=CC=C2)C=CC(OCCCCCCCCCCCC)=C1 ARVUDIQYNJVQIW-UHFFFAOYSA-N 0.000 description 1

- UWSMKYBKUPAEJQ-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC(Cl)=CC3=N2)C=C(C(C)(C)C)C=C1C(C)(C)C Chemical compound [H]OC1=C(N2N=C3C=CC(Cl)=CC3=N2)C=C(C(C)(C)C)C=C1C(C)(C)C UWSMKYBKUPAEJQ-UHFFFAOYSA-N 0.000 description 1

- OCWYEMOEOGEQAN-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC(Cl)=CC3=N2)C=C(C)C=C1C(C)(C)C Chemical compound [H]OC1=C(N2N=C3C=CC(Cl)=CC3=N2)C=C(C)C=C1C(C)(C)C OCWYEMOEOGEQAN-UHFFFAOYSA-N 0.000 description 1

- RTNVDKBRTXEWQE-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)C)C=C1C(C)CC Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)C)C=C1C(C)CC RTNVDKBRTXEWQE-UHFFFAOYSA-N 0.000 description 1

- OLFNXLXEGXRUOI-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)C2=CC=CC=C2)C=C1C(C)(C)C1=CC=CC=C1 Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)C2=CC=CC=C2)C=C1C(C)(C)C1=CC=CC=C1 OLFNXLXEGXRUOI-UHFFFAOYSA-N 0.000 description 1

- IYAZLDLPUNDVAG-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)CC(C)(C)C)C=C1 Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)CC(C)(C)C)C=C1 IYAZLDLPUNDVAG-UHFFFAOYSA-N 0.000 description 1

- ZEVZJMWPXPVOTJ-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)CC(C)(C)C)C=C1C Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)CC(C)(C)C)C=C1C ZEVZJMWPXPVOTJ-UHFFFAOYSA-N 0.000 description 1

- ZMWRRFHBXARRRT-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)CC)C=C1C(C)(C)CC Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C(C)(C)CC)C=C1C(C)(C)CC ZMWRRFHBXARRRT-UHFFFAOYSA-N 0.000 description 1

- MCPKSFINULVDNX-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C)C=C1 Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C)C=C1 MCPKSFINULVDNX-UHFFFAOYSA-N 0.000 description 1

- VQMHSKWEJGIXGA-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C)C=C1CCCCCCCCCCCC Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(C)C=C1CCCCCCCCCCCC VQMHSKWEJGIXGA-UHFFFAOYSA-N 0.000 description 1

- DQNYFEGHFOQRNK-UHFFFAOYSA-N [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(CCC(=O)OCCCC)C=C1C(C)(C)C Chemical compound [H]OC1=C(N2N=C3C=CC=CC3=N2)C=C(CCC(=O)OCCCC)C=C1C(C)(C)C DQNYFEGHFOQRNK-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D175/00—Coating compositions based on polyureas or polyurethanes; Coating compositions based on derivatives of such polymers

- C09D175/04—Polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/16—Nitrogen-containing compounds

- C08K5/22—Compounds containing nitrogen bound to another nitrogen atom

- C08K5/24—Derivatives of hydrazine

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/08—Processes

- C08G18/10—Prepolymer processes involving reaction of isocyanates or isothiocyanates with compounds having active hydrogen in a first reaction step

- C08G18/12—Prepolymer processes involving reaction of isocyanates or isothiocyanates with compounds having active hydrogen in a first reaction step using two or more compounds having active hydrogen in the first polymerisation step

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/2805—Compounds having only one group containing active hydrogen

- C08G18/2815—Monohydroxy compounds

- C08G18/283—Compounds containing ether groups, e.g. oxyalkylated monohydroxy compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/30—Low-molecular-weight compounds

- C08G18/38—Low-molecular-weight compounds having heteroatoms other than oxygen

- C08G18/3819—Low-molecular-weight compounds having heteroatoms other than oxygen having nitrogen

- C08G18/3823—Low-molecular-weight compounds having heteroatoms other than oxygen having nitrogen containing -N-C=O groups

- C08G18/3834—Low-molecular-weight compounds having heteroatoms other than oxygen having nitrogen containing -N-C=O groups containing hydrazide or semi-carbazide groups

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/4009—Two or more macromolecular compounds not provided for in one single group of groups C08G18/42 - C08G18/64

- C08G18/4018—Mixtures of compounds of group C08G18/42 with compounds of group C08G18/48

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L75/00—Compositions of polyureas or polyurethanes; Compositions of derivatives of such polymers

- C08L75/04—Polyurethanes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

- Y10T428/2933—Coated or with bond, impregnation or core

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2982—Particulate matter [e.g., sphere, flake, etc.]

- Y10T428/2991—Coated

- Y10T428/2993—Silicic or refractory material containing [e.g., tungsten oxide, glass, cement, etc.]

- Y10T428/2996—Glass particles or spheres

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31551—Of polyamidoester [polyurethane, polyisocyanate, polycarbamate, etc.]

- Y10T428/31598—Next to silicon-containing [silicone, cement, etc.] layer

- Y10T428/31601—Quartz or glass

Definitions

- the present invention relates to aqueous polyurethane-polyurea dispersions which are stabilized with respect to thermal yellowing, and to their preparation and use.

- aqueous binders in particular polyurethane-polyurea (PU) dispersions, are increasingly being used.

- PU polyurethane-polyurea

- PU dispersions are used as aqueous binders. Due to the comparatively high temperatures in the coating and drying processes and in the compounding of the sized glass fibers into a plastics matrix, thermal yellowing of the coatings produced often occurs and is undesired.

- the prior art discloses numerous stabilizers and additives which can reduce thermal yellowing of binders.

- the use of these compounds in aqueous systems, such as PU dispersions, is often possible only to a limited extent.

- the systems disclosed in the prior art do not adequately meet the needs for protecting an aqueous PU dispersion or the coating resulting therefrom from thermal yellowing.

- U.S. Pat. No. 5,216,078 discloses a stabilizer which significantly reduces the thermal yellowing of blocked isocyanates, in particular isocyanates blocked with butanone oxime. This compound is a hydrazine adduct.

- EP-A 0 829 500 describes a combination of compounds as a stabilizer for blocked polyisocyanates, one of the compounds having at least one 2,2,6,6-tetramethylpiperidinyl radical, the so-called HALS (hindered amine light stabilizer) radical, and the other having a hydrazide structure.

- HALS hindered amine light stabilizer

- This object may be achieved with the aqueous PU dispersions according to the invention, which are protected from thermal yellowing by certain combinations of hydrazides and sterically hindered amines.

- the present invention relates to a binder composition containing

- the present invention also relates to a process for the preparation of these binder compositions.

- the polyurethane dispersions are manufactured in the presence of components a) and b). It is possible for components a) and b), depending on the grade used, to be incorporated into the polymer framework as structural units.

- binder compositions comprising

- c) optionally a stabilizing compound other than a) and b), are also the subject matter of the invention in question.

- the present invention relates to coating, adhesive and sizing compositions containing the binder compositions according to the invention.

- the present invention also relates to glass fibers sized with sizing compositions containing the binder compositions according to the invention.

- the binder composition contains 78.0 to 99.8% by weight, preferably 84.0 to 99.6% by weight and more preferably 90.0 to 99.0% by weight, of component A); and 0.2 to 22.0% by weight, preferably 0.4 to 16.0% by weight and more preferably 1.0 to 10.0% by weight, of component B), wherein the sum of the components is 100% by weight, based on the solids contents of components A) and B).

- the binder compositions according to the invention contain 0.1 to 11.0% by weight, preferably 0.2 to 8.0% by weight and more preferably 0.5 to 4.0% by weight, of amines containing a stuctural unit corresponding to formula (I); 0.1 to 11.0% by fweight, preferably 0.2 to 8.0% by weight and more preferably 0.5 to 4.0% by weight, of hydrazides containing a structural unit corresponding to formula (II); and 0 to 5.0% by weight of stabilizers c), which differ from a) and b).

- Suitable PU dispersions for use as component A) include those that are known in the prior art.

- PU dispersions (A) may be composed of the components

- A3) optionally mono- or polyalcohols and mono- or polyamines other than component A2),

- a potential ionic group is a group which is capable of forming an ionic group.

- PU dispersions (A) contain 7 to 45% by weight, preferably 10 to 30% by weight and more preferably 8 to 27% by weight of A1); 50 to 91% by weight, preferably 65 to 90% by weight and more preferably 65 to 85% by weight of A2); 0 to 15% by weight, preferably 0 to 10% by weight and more preferably 0 to 8% by weight of A5); 0 to 12% by weight, preferably 3 to 9% by weight and more preferably 3 to 8% by weight of ionic or potentially ionic compounds A4); and optionally 0 to 30% by weight, preferably 0 to 10% by weight and more preferably 0 to 8% by weight of compounds A3), wherein the sum of the components is 100% by weight and the sum of components A4) and A5) is not 0.

- Suitable diisocyanates (A1) include those having a molecular weight of 140 to 400 and having aliphatically, cycloaliphatically, araliphatically and/or aromatically bound isocyanate groups. Examples include 1,4-diisocyanatobutane, 1,6-diisocyanatohexane (HDI), 2-methyl-1,5-diisocyanatopentane, 1,5-diisocyanato-2,2-dimethylpentane, 2,2,4- and 2,4,4-trimethyl-1,6-diisocyanatohexane, 1,10-diisocyanatodecane, 1,3- and 1,4-diisocyanatocyclohexane, 1,3- and 1,4-bis-(isocyanatomethyl)-cyclohexane, 1-isocyanato-3,3,5-trimethyl-5-isocyanatomethylcyclohexane (isophorone diisocyanate

- Preferred polyisocyanates are those having exclusively aliphatically and/or cycloaliphatically bound isocyanate groups, more preferably HDI, IPDI and/or 4,4′-diisocyanatodicyclohexylmethane.

- lacquer polyisocyanates prepared from the preceding monomeric aliphatic, cycloaliphatic, araliphatic and/or aromatic diisocyanates and containing uretdione, isocyanurate, urethane, allophanate, biuret, iminooxadiazinedione and/or oxadiazinetrione groups, which are described, for example, in J. Prakt. Chem. 336 (1994), pages 185-200.

- Suitable polymeric polyols (A2) include the known polyols having a number average molecular weight of 400 to 6000 and an OH functionality of 1.8 to 4. Examples include polyacrylates, polyesters, polylactones, polyethers, polycarbonates, polyester carbonates, polyacetals, polyolefins and polysiloxanes. Polyols having a number average molecular weight of 600 to 2 500 and an OH functionality of 2 to 3 are preferred.

- Suitable polycarbonates having hydroxyl groups are obtained by reacting carbonic acid derivatives, e.g. diphenyl carbonate, dimethyl carbonate or phosgene, with diols.

- Suitable diols include ethylene glycol, 1,2- and 1,3-propanediol, 1,3- and 1,4-butanediol, 1,6-hexanediol, 1,8-octanediol, neopentylglycol, 1,4-bishydroxymethylcyclohexane, 2-methyl-1,3-propanediol, 2,2,4-trimethyl-1,3-pentanediol, dipropylene glycol, polypropylene glycols, dibutylene glycol, polybutylene glycols, bisphenol A, tetrabromobisphenol A and lactone-modified diols.

- the diol component preferably contains 40 to 100% by weight of hexanediol, preferably 1,6-hexanediol, and/or hexanediol derivatives, preferably those which have ether or ester groups in addition to terminal OH groups.

- examples include the product obtained by reacting 1 mole of hexanediol with at least 1 mole, preferably 1 to 2 moles, of caprolactone according to DE-A 17 70 245 or by etherifying hexanediol with itself to give di- or trihexylene glycol.

- the preparation of such derivatives is disclosed, for example, in DE-A 15 70 540.

- the polyether-polycarbonate diols described in DE-A 37 17 060 can also be used.

- the polycarbonate polyols should be substantially linear. However, they may be slightly branched by incorporation of polyfunctional components, in particular low molecular weight polyols. Examples include glycerol, trimethylolpropane, 1,2,6-hexanetriol, 1,2,4-butanetriol, trimethylolpropane, pentaerythritol, quinitol, mannitol and sorbitol, methylglycoside and 1,3,4,6-dianhydrohexitols.

- polyfunctional components in particular low molecular weight polyols. Examples include glycerol, trimethylolpropane, 1,2,6-hexanetriol, 1,2,4-butanetriol, trimethylolpropane, pentaerythritol, quinitol, mannitol and sorbitol, methylglycoside and 1,3,4,6-dianhydrohexitols.

- Suitable polyether polyols include the known polytetramethylene glycol polyethers and can be prepared, for example, via polymerization of tetrahydrofuran by cationic ring cleavage.

- Other suitable polyether polyols are those prepared by the alkoxylation of initiator molecules with styrene oxide, propylene oxide, butylene oxides or epichlorohydrins, in particular propylene oxide.

- Suitable polyester polyols include the reaction products of polyhydric, preferably dihydric and optionally additionally trihydric, alcohols with polybasic, preferably dibasic, carboxylic acids.

- polyhydric preferably dihydric and optionally additionally trihydric

- alcohols with polybasic, preferably dibasic, carboxylic acids.

- free polycarboxylic acids it is also possible to use the corresponding polycarboxylic anhydrides or corresponding polycarboxylic esters of lower alcohols or their mixtures for the preparation of the polyester.

- the polycarboxylic acids may be aliphatic, cycloaliphatic, aromatic and/or heterocyclic and are optionally substituted, for example by halogen atoms, and/or unsaturated.

- Monofunctional alcohols and monoamines which are suitable for for terminating the polyurethane prepolymer may be used as component (A3).

- Preferred monoalcohols include aliphatic monoalcohols having 1 to 18 C atoms, such as ethanol, n-butanol, ethylene glycol monobutyl ether, 2-ethylhexanol, 1-octanol, 1-dodecanol and 1-hexadecanol.

- Preferred monoamines are aliphatic monoamines, such as diethylamine, dibutylamine, ethanolamine, N-methylethanolamine or N,N-diethanolamine.

- polyols, aminopolyols or polyamines which are known and have a number average molecular weight of less than 400 are also suitable as component (A3).

- Examples of preferred components (A3) are:

- alkanediols such as ethanediol, 1,2- and 1,3-propanediol, 1,4- and 2,3-butanediol, 1,5-pentanediol, 1,3-dimethyl-propanediol, 1,6-hexanediol, neopentylglycol, cyclohexanedimethanol and 2-methyl-1,3-propanediol,

- alkanediols such as ethanediol, 1,2- and 1,3-propanediol, 1,4- and 2,3-butanediol, 1,5-pentanediol, 1,3-dimethyl-propanediol, 1,6-hexanediol, neopentylglycol, cyclohexanedimethanol and 2-methyl-1,3-propanediol,

- etherdiols such as diethylene diglycol, triethylene glycol or hydroquinone dihydroxyethyl ether

- R is an alkylene or arylene radical having 1 to 10 C atoms, preferably 2 to 6 C atoms,

- x is 2 to 6

- y is 3 to 5

- polyamines such as ethylenediamine, 1,2- and 1,3-diaminopropane, 1,4-diaminobutane, 1,6-diaminohexane, isophoronediamine, isomer mixture of 2,2,4- and 2,4,4-trimethylhexa-methylenediamine, 2-methyl-pentamethylenediamine, diethylene-triamine, 1,3- and 1,4-xylylenediamine, ⁇ , ⁇ , ⁇ ′, ⁇ ′,-tetramethyl-1,3- and -1,4-xylylenediamine and 4,4-diaminodicyclohexylmethane.

- polyamines such as ethylenediamine, 1,2- and 1,3-diaminopropane, 1,4-diaminobutane, 1,6-diaminohexane, isophoronediamine, isomer mixture of 2,2,4- and 2,4,4-trimethylhexa-methylenediamine, 2-

- Suitable diamines in the context of the invention are also hydrazine, hydrazine hydrate and substituted hydrazines, such as N-methylhydrazine, N,N′-dimethylhydrazine and their homologs and acid dihydrazides, adipic acid, ⁇ -methyladipic acid, sebacic acid, hydracrylic acid and terephthalic acid, semicarbazidoalkylene hydrazides such as ⁇ -semicarbazidopropionic acid hydrazide (e.g.

- Suitable ionic or potential ionic compounds (A4) include mono- and dihydroxycarboxylic acids, mono- and diaminocarboxylic acids, mono- and dihydroxysulphonic acids, mono- and diaminosulphonic acids, mono- and dihydroxyphosphonic acids and mono- and diaminophosphonic acids and their salts.

- Examples include dimethylolpropionic acid, hydroxypivalic acid, N-(2-aminoethyl)- ⁇ -alanine, 2-(2-amino-ethylamino)-ethanesulphonic acid, ethylenediamine-propanesulphonic, ethylenediamine-butanesulphonic acid, 1,2- or 1,3-propylenediamine- ⁇ -ethylsulphonic acid, lysine or 3,5-diaminobenzoic acid.

- the hydrophilic agent according to Example 1 of EP-A 0 916 647 and its alkali metal and/or ammonium salts are also suitable.

- the adduct of sodium bisulphite with but-2-ene-1,4-diol, polyethersulphonate, the propoxylated adduct of 2-butenediol and NaHSO 3 e.g. in DE-A 24 46 440, pages 5-9, U.S. Pat. No. 4,108,814) and building blocks, such as N-methyldiethanolamine, which can be converted into cationic groups, can also be used as hydrophilic components.

- Preferred ionic or potential ionic compounds (A4) are those which have carboxyl, carboxylate, sulphonate groups and/or ammonium groups.

- Particularly preferred ionic compounds (A4) are those which contain carboxylate and/or sulphonate groups as ionic or potential ionic groups, such as the salts of N-(2-aminoethyl)- ⁇ -alanine or 2-(2-aminoethylamino)-ethanesulphonic acid, the hydrophilic agent according to Example 1 of EP-A 0 916 647 and dimethylolpropionic acid.

- PU dispersions (A) contain a combination of nonionic and ionic hydrophilic agents. Combinations of nonionic and anionic hydrophilizing agents are particularly preferred.

- the hydroxy components among components (A2), (A3) and (A4) may contain double bonds which may originate, for example, from long-chain aliphatic carboxylic acids or fatty alcohols. Functionalization with olefinic double bonds is possible, for example, by the incorporation of allylic groups or acrylic acid or methacrylic acid and their respective esters.

- Polyurethane dispersions (A) may contain nonionic hydrophilic compounds (A5), such as polyoxyalkylene ethers having at least one hydroxyl or amino group. These polyethers contain a proportion of 30% by weight to 100% by weight of building blocks which are derived from ethylene oxide. Also suitable are linear polyethers having a functionality of 1 to 3 and compounds corresponding to formula (V)

- R 1 and R 2 independently of one another, each represent a divalent aliphatic, cycloaliphatic or aromatic radical having 1 to 18 carbon atoms, which may be interrupted by oxygen and/or nitrogen atoms, and

- R 3 represents a non-hydroxyl-terminated polyester or polyether, preferably a polyether and more preferably an alkoxy-terminated polyethylene oxide radical.

- aqueous polyurethane dispersions (A) is carried out in known manner.

- the polyisocyanate component, polymeric polyol and low molecular weight chain extender are reacted to give a polyurethane.

- a solvent, which can be separated off, may optionally be used.

- Suitable solvents include ethyl acetate, butyl acetate, 1-methoxyprop-2-yl acetate, 3-methoxy-n-butyl acetate, acetone, 2-butanone, 4-methyl-2-pentanone, cyclohexanone, toluene, xylene, chlorobenzene, mineral spirits; mixtures which contain substituted aromatics, which are commercially available, for example, under the names Solvent Naphtha, Solvesso® (Exxon Chemicals, Houston, USA), Cypar® (Shell Chemicals, Eschborn, DE), Cyclo Sol® (Shell Chemicals, Eschborn, DE), Tolu Sol® (Shell Chemicals, Eschborn, DE), Shellsol® (Shell Chemicals, Eschborn, DE); carbonic acid esters such as dimethyl carbonate, diethyl carbonate, 1,2-ethylene carbonate and 1,2-propylene carbonate; lactones such as ⁇ -propiolactone, ⁇ -butano

- groups capable of neutralization are then optionally converted into the salt form and transferred to the aqueous phase.

- the dispersion may be very finely divided so that it has the appearance of a solution or very coarse. Either are sufficiently stable. However, mean particle sizes of less than 300 nm are preferred since these improve the emulsification of a polyisocyanate and hence the quality of the coating.

- the solids content may be varied within limits from 10 to 70% by weight.

- the binder compositions according to the invention preferably contain PU dispersions (A), which have been prepared by the known acetone process.

- Excess isocyanate groups can be reacted by reaction with polyfunctional isocyanate-reactive compounds (A3).

- Water, polyamines (A3) preferably di- and triamines), hydrazine and the sodium salt of 2-(2-amino-ethylamino)-ethanesulphonic acid are preferably used for this purpose.

- Termination with a monoamine, such as diethylamine, dibutylamine, ethanolamine, N-methylethanolamine and N,N-diethanolamine is also possible.

- Optionally used solvents can then be removed by distillation.

- binder compositions according to the invention with polyacrylates.

- an emulsion polymerization of olefinically unsaturated monomers for example esters of (meth)acrylic acid and alcohols having 1 to 18 carbon atoms, styrene, vinyl esters and/or butadiene, is carried out in the presence of polyurethane dispersion (A), as described, for example, in DE-A 19 53 348, EP-A 0 167 188, EP-A 0 189 945 and EP-A 0 308 115.

- the monomers may also contain functional groups, such as hydroxyl, epoxy, methylol or acetoacetoxy groups.

- the emulsion polymerization can be carried out before or after the modification with component (B).

- compositions according to the invention contain a stabilizer mixture B) which contains a) an amine having a structural unit corresponding to formula (I)

- Suitable compounds a) are those which have a 2,2,6,6-tetramethylpiperidinyl radical (HALS ring).

- HALS ring 2,2,6,6-tetramethylpiperidinyl radical

- the piperidinyl nitrogen of the HALS ring is not substituted and has no hydrazide structures at all.

- Preferred compounds a) are the compounds shown in Table 1. TABLE 1 Compounds a) CAS Reg. No. Structure 24860-22-8 79720-19-7 64338-16-5 52829-07-9 99473-08-2 71029-16-8 71878-19-8 90751-07-8 154636-38-1 100631-44-5 115810-23-6 164648-93-5 96204-36-3

- the stabilizer B) of the compositions according to the invention also contains a compound b) corresponding to formula (II)

- Suitable compounds b) include acid hydrazides and acid dihydrazides, such as acetic acid hydrazide, adipic acid hydrazide and adipic acid dihydrazide; and hydrazine adducts of hydrazine and cyclic carbonates, as described, for example, in EP-A 654 490 (page 3, line 48 to page 4, line 3). Adipic acid dihydrazide and the adduct of 2 moles of propylene carbonate and 1 mole of hydrazine corresponding to formula (VII)

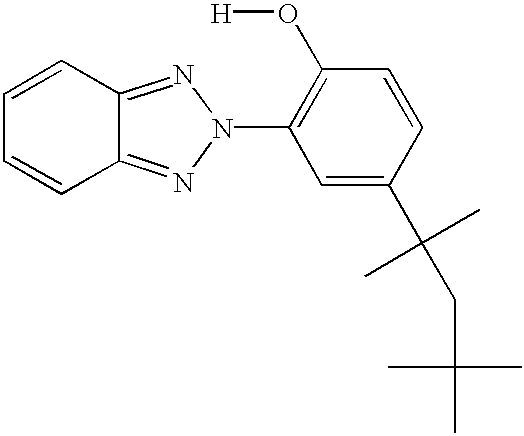

- Suitable compounds c) include antioxidants such as 2,6-di-tert-butyl-4-methylphenol; UV absorbers of the 2-hydroxyphenyl-benzotriazole type; light stabilizers of the HALS type wherein the nitrogen atom is substituted, such as Tinuvin® 292 (Ciba Spezialitäten GmbH, Lampertheim, DE); and other commercially available stabilizers, as described, for example, in “Lichtstoffstoffsch für Lacke” [Light stabilizers for finishes] (A. Valet, Vincentz Verlag, Hanover, 1996, and “Stabilization of Polymeric Materials” (H. Zweifel, Springer Verlag, Berlin, 1997, Appendix 3, pages 181-213). Preferred compounds c) are shown in Table 2.

- the binder compositions according to the invention are obtained by reacting component A1) with components A2), A3), A4), A5), a), b) and c) in any desired sequence, optionally with the aid of an organic solvent.

- Suitable methods known from the prior art, for the preparation of PU dispersions include the emulsifier shear force process, the acetone process, the prepolymer mixing process, the melt emulsification process, the ketimine process, the solid spontaneous dispersing process and derivatives thereof.

- Methodsen der organischen Chemie [Methods of organic chemistry] (Houben-Weyl, supplementary and subsequent volumes for the 4th edition, Volume E20, H. Bartl and J. Falbe, Stuttgart, New York, Thieme 1987, pages 1617-1682).

- A1) is first reacted with components A2), A5), a) and b), optionally in the presence of a catalyst.

- the resulting prepolymer is then dissolved in a solvent, optionally in combination with components b) and/or c), and components A3) and A4) are then added.

- the resulting hydrophilic prepolymer is dissolved in a solvent and converted into an aqueous dispersion or solution in a further step by adding water.

- additional components A3) and A4) can be removed by distillation after the dispersion is formed.

- the binder compositions according to the invention have a solids content of 10 to 70% by weight, preferably 20 to 60% by weight and more preferably 25 to 60% by weight.

- the proportion of organic solvent, based on the total composition is preferably less than 15% by weight, more preferably less than 5% by weight.

- the binder compositions according to the invention are used either alone or in combination with other aqueous binders for the preparation of coating compositions.

- these other aqueous binders include polyester polymers, polyacrylate polymers, polybutadiene polymers, polyvinyl acetate polymers, polyepoxide polymers and other polyurethane polymers. They may also be used in combination with radiation-curable binders as described, for example, in EP-A-0 753 531.

- Coatings prepared from the compositions according to the invention can be applied to any desired substrates, for example metal, wood, glass, glass fibers, carbon fibers, stone, ceramic minerals, concrete, rigid and flexible plastics, woven and nonwoven textiles, leather, paper, hard fibers, straw and bitumen.

- substrates for example metal, wood, glass, glass fibers, carbon fibers, stone, ceramic minerals, concrete, rigid and flexible plastics, woven and nonwoven textiles, leather, paper, hard fibers, straw and bitumen.

- substrates can optionally be provided with customary primer coats prior to coating.

- Preferred substrates are glass fibers, carbon fibers, metals, textiles and leather.

- a particularly preferred substrate is glass fibers.

- binder compositions according to the invention can be used alone or in combination with the additives known from coating technology.

- additives known from coating technology.

- examples include nonionic and/or anionic thickeners, fillers, pigments, waxes, handle compositions, dyes, solvents, leveling agents and crosslinking agents.

- crosslinking agents prior to application.

- Hydrophilic polyisocyanate crosslinking agents are preferably used.

- the coating compositions can be applied by known methods, such as brushing, pouring, knife coating, spraying, rolling and immersion.

- the coating can be dried at room temperature or elevated temperatures of up to 200° C.

- the binder compositions according to the invention are storable and shippable and can be processed at any desired later time. Depending on the chosen chemical composition of the polyurethane, coatings having different properties are obtained. Thus, soft tacky coats and thermoplastic and elastomeric products having a wide range of hardnesses up to glass-hard thermosetting plastics can be obtained. Thus, the binder compositions according to the invention can also be used as adhesives, but their use in glass fiber sizes is preferred.

- binder compositions according to the invention can be used in the sizes alone or preferably with other binders, such as polyacrylate dispersions, polyurethane-polyacrylate hybrid dispersions, polyvinyl ether or polyvinyl ester dispersions, polystyrene or polyacrylonitrile dispersions. They can also be used with crosslinking agents, such as blocked polyisocyanates and amino crosslinking resins, such as melamine resins.

- binders such as polyacrylate dispersions, polyurethane-polyacrylate hybrid dispersions, polyvinyl ether or polyvinyl ester dispersions, polystyrene or polyacrylonitrile dispersions.

- crosslinking agents such as blocked polyisocyanates and amino crosslinking resins, such as melamine resins.

- the binder compositions according to the invention are used as binder components and may contain other components, such as emulsifiers, other film-forming resins, adhesion promoters, lubricants and additives, e.g., wetting agents or antistatic agents.

- emulsifiers such as emulsifiers, other film-forming resins, adhesion promoters, lubricants and additives, e.g., wetting agents or antistatic agents.

- adhesion promoters, lubricants and additives, the process for preparing the sizes, and the process for sizing glass fibers and the subsequent processing of the glass fibers are known and described, for example, in K. L. Loewenstein, “The Manufacturing Technology of Continuous Glass Fibers”, Elsevier Scientific Publishing Corp., Amsterdam, London, New York, 1983.

- both the known glass types used for glass filament manufacture such as E, A, C and S glass, and the other known products from glass fiber manufacturers are suitable for the sized glass fibers.

- the E glass fibers because of freedom from alkali, high tensile strength and high modulus of elasticity, are the most important for reinforcing plastics.

- thermoplastic and duromeric polymers can be used as matrix polymers.

- Diaminosulphonate NH 2 —CH 2 CH 2 —NH—CH 2 CH 2 —SO 3 Na (45% in water)

- the binder compositions described below were applied to test metal sheets which have been coated with a commercial, white base coat from Spies & Hecker, in a wet film thickness of 120 ⁇ m.

- the test metal sheets were dried for 30 minutes at room temperature and then baked for 30 minutes at 170° C. in a drying oven. Thereafter, the color measurement was carried out by the CIELAB method. The greater the determined positive b* value, the greater was the resulting yellow discoloration of the coating prepared from the binder composition.

- Baybond® PU 401 anionic-nonionic PU dispersion having a solids content of 40% and a mean particle size of 100-300 nm, Bayer AG, Leverkusen, DE

- the resulting prepolymer was dissolved in a solution of 16.0 g of Irganox® 245 (Ciba Spezialitäten GmbH, Lampertheim, DE), 16.0 g of Tinuvin® 770 DF (Ciba Spezialitäten GmbH, Lampertheim, DE) and 1671.1 g of acetone at 50° C.

- a solution of 9.0 g of hydrazine hydrate, 19.0 g of isophorone diamine and 121.6 g of water was then metered in within 10 min.

- stirring was continued for 15 min and a dispersion was prepared by adding 2971.9 g of water within 20 min. This was followed by the removal of the solvent by distillation under vacuum.

- a storage stable dispersion having a solids content of 40.4% was obtained.

- a solution of 7.8 g of adipic acid dihydrazide, 9.0 g of hydrazine hydrate, 21.4 g of isophoronediamine and 136.6 g of water was then metered in within 10 min. After the addition of 189.9 g of diaminosulphonate, stirring was continued for 15 min and a dispersion was prepared by adding 2942.7 g of water within 20 min. This was followed by the removal of the solvent by distillation under vacuum. A storagestable dispersion having a solids content of 40.8% was obtained.

- Example 1 Baybond ® PU 401

- Example 4 (Comparison Example 2 Example 3 (according example, prior (Comparison (Comparison to the art) example) example) invention) Solids 40% 40.5 40.4 40.8 content [1%] Mean particle 100-300 nm 161.0 165.5 162.7 size [nm] Compound of — — — X the formula VII Tinuvin 770 — — X X DF Adipic acid — X — X dihydrazide CIE/LAB b* 1.3 0.5 0.9 0.0 values

- Example 4 exhibits substantially less yellowing compared with PU dispersions of the prior art (Example 1) and conventionally stabilized PU dispersions (Examples 2 and 3).

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Materials Engineering (AREA)

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Polyurethanes Or Polyureas (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Paints Or Removers (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

- Paper (AREA)

Abstract

Description

- The present invention relates to aqueous polyurethane-polyurea dispersions which are stabilized with respect to thermal yellowing, and to their preparation and use.

- In the coating of substrates, aqueous binders, in particular polyurethane-polyurea (PU) dispersions, are increasingly being used. In some applications high temperatures, which lead to undesired yellowing of the coating, are required for drying the coatings.

- In the area of sizing of glass fibers, PU dispersions are used as aqueous binders. Due to the comparatively high temperatures in the coating and drying processes and in the compounding of the sized glass fibers into a plastics matrix, thermal yellowing of the coatings produced often occurs and is undesired.

- The prior art discloses numerous stabilizers and additives which can reduce thermal yellowing of binders. The use of these compounds in aqueous systems, such as PU dispersions, is often possible only to a limited extent. The systems disclosed in the prior art do not adequately meet the needs for protecting an aqueous PU dispersion or the coating resulting therefrom from thermal yellowing.

- U.S. Pat. No. 5,216,078 discloses a stabilizer which significantly reduces the thermal yellowing of blocked isocyanates, in particular isocyanates blocked with butanone oxime. This compound is a hydrazine adduct.

- EP-A 0 829 500 describes a combination of compounds as a stabilizer for blocked polyisocyanates, one of the compounds having at least one 2,2,6,6-tetramethylpiperidinyl radical, the so-called HALS (hindered amine light stabilizer) radical, and the other having a hydrazide structure.

- However, the disadvantage of the abovementioned systems is that they are suitable only for solvent-containing finishes, coatings and sizing systems and not for aqueous systems.

- The preparation of aqueous PU dispersions is known in principle. The various possibilities for preparing such dispersions are summarized, for example, by D. Dietrich in a review article (D. Dietrich, Prog. Org. Coatings 9, 281 (1981)). However, the problem of thermal yellowing has not been solved at present in a satisfactory manner in the prior art.

- Therefore, it is an object of the present invention to provide PU dispersions which are stable to thermal yellowing and are suitable as one-component or two-component binders in finishes, sizes and coatings.

- This object may be achieved with the aqueous PU dispersions according to the invention, which are protected from thermal yellowing by certain combinations of hydrazides and sterically hindered amines.

- The present invention relates to a binder composition containing

- A) at least one aqueous polyurethane-polyurea dispersion and

- B) at least one stabilizer containing

-

- which has no hydrazide groups,

- b) at least one compound having a structural unit corresponding to formula (II)

- —CO—NH—NH— (II)

- and

- c) optionally a stabilizing compound other than a) and b).

- The present invention also relates to a process for the preparation of these binder compositions.

- The polyurethane dispersions are manufactured in the presence of components a) and b). It is possible for components a) and b), depending on the grade used, to be incorporated into the polymer framework as structural units.

- For this reason binder compositions comprising

- A) at least one aqueous polyurethane dispersion, containing structural units of at least one stabilizing agent or mixture of stabilizing agents B) based on

-

- which has no hydrazide groups,

- b) at least one compound with the general formula (II),

- —CO—NH—NH— (II)

- and

- c) optionally a stabilizing compound other than a) and b), are also the subject matter of the invention in question.

- Further, the present invention relates to coating, adhesive and sizing compositions containing the binder compositions according to the invention.

- Finally, the present invention also relates to glass fibers sized with sizing compositions containing the binder compositions according to the invention.

- The binder composition contains 78.0 to 99.8% by weight, preferably 84.0 to 99.6% by weight and more preferably 90.0 to 99.0% by weight, of component A); and 0.2 to 22.0% by weight, preferably 0.4 to 16.0% by weight and more preferably 1.0 to 10.0% by weight, of component B), wherein the sum of the components is 100% by weight, based on the solids contents of components A) and B).

- Based on the total solids content, the binder compositions according to the invention contain 0.1 to 11.0% by weight, preferably 0.2 to 8.0% by weight and more preferably 0.5 to 4.0% by weight, of amines containing a stuctural unit corresponding to formula (I); 0.1 to 11.0% by fweight, preferably 0.2 to 8.0% by weight and more preferably 0.5 to 4.0% by weight, of hydrazides containing a structural unit corresponding to formula (II); and 0 to 5.0% by weight of stabilizers c), which differ from a) and b).

- Suitable PU dispersions for use as component A) include those that are known in the prior art. PU dispersions (A) may be composed of the components

- A1) polyisocyanates,

- A2) polymeric polyols having number average molecular weights of 400 to 6 000 and

- A3) optionally mono- or polyalcohols and mono- or polyamines other than component A2),

- and at least one compound selected from

- A4) compounds which have at least one ionic or potential ionic group and

- A5) nonionic hydrophilic compounds.

- In the context of the invention, a potential ionic group is a group which is capable of forming an ionic group.

- Preferably, PU dispersions (A) contain 7 to 45% by weight, preferably 10 to 30% by weight and more preferably 8 to 27% by weight of A1); 50 to 91% by weight, preferably 65 to 90% by weight and more preferably 65 to 85% by weight of A2); 0 to 15% by weight, preferably 0 to 10% by weight and more preferably 0 to 8% by weight of A5); 0 to 12% by weight, preferably 3 to 9% by weight and more preferably 3 to 8% by weight of ionic or potentially ionic compounds A4); and optionally 0 to 30% by weight, preferably 0 to 10% by weight and more preferably 0 to 8% by weight of compounds A3), wherein the sum of the components is 100% by weight and the sum of components A4) and A5) is not 0.

- Suitable diisocyanates (A1) include those having a molecular weight of 140 to 400 and having aliphatically, cycloaliphatically, araliphatically and/or aromatically bound isocyanate groups. Examples include 1,4-diisocyanatobutane, 1,6-diisocyanatohexane (HDI), 2-methyl-1,5-diisocyanatopentane, 1,5-diisocyanato-2,2-dimethylpentane, 2,2,4- and 2,4,4-trimethyl-1,6-diisocyanatohexane, 1,10-diisocyanatodecane, 1,3- and 1,4-diisocyanatocyclohexane, 1,3- and 1,4-bis-(isocyanatomethyl)-cyclohexane, 1-isocyanato-3,3,5-trimethyl-5-isocyanatomethylcyclohexane (isophorone diisocyanate or IPDI), 4,4′-diisocyanatodicyclohexylmethane, 1-isocyanato-1-methyl-4(3)-isocyanatomethylcyclohexane, bis-(isocyanatomethyl)-norbornane, 1,3- and 1,4-bis-(2-isocyanato-prop-2-yl)-benzene (TMXDI), 2,4- and 2,6-diisocyanatotoluene (TDI), 2,4′- and 4,4′-diisocyanatodiphenylmethane, 1,5-diisocyanatonaphthalene and mixtures thereof.

- Preferred polyisocyanates are those having exclusively aliphatically and/or cycloaliphatically bound isocyanate groups, more preferably HDI, IPDI and/or 4,4′-diisocyanatodicyclohexylmethane.

- Also suitable are lacquer polyisocyanates prepared from the preceding monomeric aliphatic, cycloaliphatic, araliphatic and/or aromatic diisocyanates and containing uretdione, isocyanurate, urethane, allophanate, biuret, iminooxadiazinedione and/or oxadiazinetrione groups, which are described, for example, in J. Prakt. Chem. 336 (1994), pages 185-200.

- Suitable polymeric polyols (A2) include the known polyols having a number average molecular weight of 400 to 6000 and an OH functionality of 1.8 to 4. Examples include polyacrylates, polyesters, polylactones, polyethers, polycarbonates, polyester carbonates, polyacetals, polyolefins and polysiloxanes. Polyols having a number average molecular weight of 600 to 2 500 and an OH functionality of 2 to 3 are preferred.

- Suitable polycarbonates having hydroxyl groups are obtained by reacting carbonic acid derivatives, e.g. diphenyl carbonate, dimethyl carbonate or phosgene, with diols. Suitable diols include ethylene glycol, 1,2- and 1,3-propanediol, 1,3- and 1,4-butanediol, 1,6-hexanediol, 1,8-octanediol, neopentylglycol, 1,4-bishydroxymethylcyclohexane, 2-methyl-1,3-propanediol, 2,2,4-trimethyl-1,3-pentanediol, dipropylene glycol, polypropylene glycols, dibutylene glycol, polybutylene glycols, bisphenol A, tetrabromobisphenol A and lactone-modified diols.

- The diol component preferably contains 40 to 100% by weight of hexanediol, preferably 1,6-hexanediol, and/or hexanediol derivatives, preferably those which have ether or ester groups in addition to terminal OH groups. Examples include the product obtained by reacting 1 mole of hexanediol with at least 1 mole, preferably 1 to 2 moles, of caprolactone according to DE-A 17 70 245 or by etherifying hexanediol with itself to give di- or trihexylene glycol. The preparation of such derivatives is disclosed, for example, in DE-A 15 70 540. The polyether-polycarbonate diols described in DE-A 37 17 060 can also be used.

- The polycarbonate polyols should be substantially linear. However, they may be slightly branched by incorporation of polyfunctional components, in particular low molecular weight polyols. Examples include glycerol, trimethylolpropane, 1,2,6-hexanetriol, 1,2,4-butanetriol, trimethylolpropane, pentaerythritol, quinitol, mannitol and sorbitol, methylglycoside and 1,3,4,6-dianhydrohexitols.

- Suitable polyether polyols include the known polytetramethylene glycol polyethers and can be prepared, for example, via polymerization of tetrahydrofuran by cationic ring cleavage. Other suitable polyether polyols are those prepared by the alkoxylation of initiator molecules with styrene oxide, propylene oxide, butylene oxides or epichlorohydrins, in particular propylene oxide.

- Suitable polyester polyols include the reaction products of polyhydric, preferably dihydric and optionally additionally trihydric, alcohols with polybasic, preferably dibasic, carboxylic acids. Instead of the free polycarboxylic acids, it is also possible to use the corresponding polycarboxylic anhydrides or corresponding polycarboxylic esters of lower alcohols or their mixtures for the preparation of the polyester. The polycarboxylic acids may be aliphatic, cycloaliphatic, aromatic and/or heterocyclic and are optionally substituted, for example by halogen atoms, and/or unsaturated.

- Monofunctional alcohols and monoamines, which are suitable for for terminating the polyurethane prepolymer may be used as component (A3). Preferred monoalcohols include aliphatic monoalcohols having 1 to 18 C atoms, such as ethanol, n-butanol, ethylene glycol monobutyl ether, 2-ethylhexanol, 1-octanol, 1-dodecanol and 1-hexadecanol. Preferred monoamines are aliphatic monoamines, such as diethylamine, dibutylamine, ethanolamine, N-methylethanolamine or N,N-diethanolamine.

- Polyols, aminopolyols or polyamines which are known and have a number average molecular weight of less than 400 are also suitable as component (A3).

- Examples of preferred components (A3) are:

- a) alkanediols, such as ethanediol, 1,2- and 1,3-propanediol, 1,4- and 2,3-butanediol, 1,5-pentanediol, 1,3-dimethyl-propanediol, 1,6-hexanediol, neopentylglycol, cyclohexanedimethanol and 2-methyl-1,3-propanediol,

- b) etherdiols, such as diethylene diglycol, triethylene glycol or hydroquinone dihydroxyethyl ether,

- c) esterdiols corresponding to formulas (III) and (IV)

- HO—(CH2)x—CO—O—(CH2)y—OH (III)

- HO—(CH2)x—O—CO—R—CO—O(CH2)x—OH (IV)

- wherein

- R is an alkylene or arylene radical having 1 to 10 C atoms, preferably 2 to 6 C atoms,

- x is 2 to 6 and

- y is 3 to 5,

- such as α-hydroxybutyl ε-hydroxycaproate, ω-hydroxyhexyl γ-hydroxybutyrate, β-hydroxyethyl adipate and bis(β-hydroxyethyl) terephthalate, and

- d) polyamines, such as ethylenediamine, 1,2- and 1,3-diaminopropane, 1,4-diaminobutane, 1,6-diaminohexane, isophoronediamine, isomer mixture of 2,2,4- and 2,4,4-trimethylhexa-methylenediamine, 2-methyl-pentamethylenediamine, diethylene-triamine, 1,3- and 1,4-xylylenediamine, α,α,α′,α′,-tetramethyl-1,3- and -1,4-xylylenediamine and 4,4-diaminodicyclohexylmethane. Suitable diamines in the context of the invention are also hydrazine, hydrazine hydrate and substituted hydrazines, such as N-methylhydrazine, N,N′-dimethylhydrazine and their homologs and acid dihydrazides, adipic acid, β-methyladipic acid, sebacic acid, hydracrylic acid and terephthalic acid, semicarbazidoalkylene hydrazides such as β-semicarbazidopropionic acid hydrazide (e.g. DE-A 17 70 591), semicarbazidoalkylene-carbazine esters such as 2-semicar-bazidoethylcarbazine ester (e.g. DE-A 19 18 504) and aminosemicarbazide compounds such as β-aminoethyl semicarbazido-carbonate (e.g. DE-A 19 02 931).

- Suitable ionic or potential ionic compounds (A4) include mono- and dihydroxycarboxylic acids, mono- and diaminocarboxylic acids, mono- and dihydroxysulphonic acids, mono- and diaminosulphonic acids, mono- and dihydroxyphosphonic acids and mono- and diaminophosphonic acids and their salts. Examples include dimethylolpropionic acid, hydroxypivalic acid, N-(2-aminoethyl)-β-alanine, 2-(2-amino-ethylamino)-ethanesulphonic acid, ethylenediamine-propanesulphonic, ethylenediamine-butanesulphonic acid, 1,2- or 1,3-propylenediamine-β-ethylsulphonic acid, lysine or 3,5-diaminobenzoic acid. The hydrophilic agent according to Example 1 of EP-A 0 916 647 and its alkali metal and/or ammonium salts are also suitable. The adduct of sodium bisulphite with but-2-ene-1,4-diol, polyethersulphonate, the propoxylated adduct of 2-butenediol and NaHSO 3 (e.g. in DE-A 24 46 440, pages 5-9, U.S. Pat. No. 4,108,814) and building blocks, such as N-methyldiethanolamine, which can be converted into cationic groups, can also be used as hydrophilic components.

- Preferred ionic or potential ionic compounds (A4) are those which have carboxyl, carboxylate, sulphonate groups and/or ammonium groups. Particularly preferred ionic compounds (A4) are those which contain carboxylate and/or sulphonate groups as ionic or potential ionic groups, such as the salts of N-(2-aminoethyl)-β-alanine or 2-(2-aminoethylamino)-ethanesulphonic acid, the hydrophilic agent according to Example 1 of EP-A 0 916 647 and dimethylolpropionic acid.

- Preferably, PU dispersions (A) contain a combination of nonionic and ionic hydrophilic agents. Combinations of nonionic and anionic hydrophilizing agents are particularly preferred.

- The hydroxy components among components (A2), (A3) and (A4) may contain double bonds which may originate, for example, from long-chain aliphatic carboxylic acids or fatty alcohols. Functionalization with olefinic double bonds is possible, for example, by the incorporation of allylic groups or acrylic acid or methacrylic acid and their respective esters.

- Polyurethane dispersions (A) may contain nonionic hydrophilic compounds (A5), such as polyoxyalkylene ethers having at least one hydroxyl or amino group. These polyethers contain a proportion of 30% by weight to 100% by weight of building blocks which are derived from ethylene oxide. Also suitable are linear polyethers having a functionality of 1 to 3 and compounds corresponding to formula (V)

- wherein

- R 1 and R2 independently of one another, each represent a divalent aliphatic, cycloaliphatic or aromatic radical having 1 to 18 carbon atoms, which may be interrupted by oxygen and/or nitrogen atoms, and

- R 3 represents a non-hydroxyl-terminated polyester or polyether, preferably a polyether and more preferably an alkoxy-terminated polyethylene oxide radical.

- The preparation of aqueous polyurethane dispersions (A) is carried out in known manner. The polyisocyanate component, polymeric polyol and low molecular weight chain extender are reacted to give a polyurethane. A solvent, which can be separated off, may optionally be used. Suitable solvents are known and include ethyl acetate, butyl acetate, 1-methoxyprop-2-yl acetate, 3-methoxy-n-butyl acetate, acetone, 2-butanone, 4-methyl-2-pentanone, cyclohexanone, toluene, xylene, chlorobenzene, mineral spirits; mixtures which contain substituted aromatics, which are commercially available, for example, under the names Solvent Naphtha, Solvesso® (Exxon Chemicals, Houston, USA), Cypar® (Shell Chemicals, Eschborn, DE), Cyclo Sol® (Shell Chemicals, Eschborn, DE), Tolu Sol® (Shell Chemicals, Eschborn, DE), Shellsol® (Shell Chemicals, Eschborn, DE); carbonic acid esters such as dimethyl carbonate, diethyl carbonate, 1,2-ethylene carbonate and 1,2-propylene carbonate; lactones such as β-propiolactone, γ-butyrolactone, ε-caprolactone and ε-methylcaprolactone; propylene glycol diacetate, diethylene glycol dimethyl ether, dipropylene glycol dimethyl ether, diethylene glycol ethyl and butyl ether acetate, N-methylpyrrolidone, N-methylcaproiactam and mixtures thereof. Preferred solvents are acetone, 2-butanone and N-methylpyrrolidone. Acetone is particularly preferred.

- In a further step, groups capable of neutralization (potential ionic groups) are then optionally converted into the salt form and transferred to the aqueous phase. Depending on the degree of neutralization and content of ionic groups, the dispersion may be very finely divided so that it has the appearance of a solution or very coarse. Either are sufficiently stable. However, mean particle sizes of less than 300 nm are preferred since these improve the emulsification of a polyisocyanate and hence the quality of the coating. The solids content may be varied within limits from 10 to 70% by weight.

- The binder compositions according to the invention preferably contain PU dispersions (A), which have been prepared by the known acetone process.

- Excess isocyanate groups can be reacted by reaction with polyfunctional isocyanate-reactive compounds (A3). Water, polyamines (A3) (preferably di- and triamines), hydrazine and the sodium salt of 2-(2-amino-ethylamino)-ethanesulphonic acid are preferably used for this purpose. Termination with a monoamine, such as diethylamine, dibutylamine, ethanolamine, N-methylethanolamine and N,N-diethanolamine is also possible.

- Optionally used solvents can then be removed by distillation.

- It is also possible to modify the binder compositions according to the invention with polyacrylates. For this purpose, an emulsion polymerization of olefinically unsaturated monomers, for example esters of (meth)acrylic acid and alcohols having 1 to 18 carbon atoms, styrene, vinyl esters and/or butadiene, is carried out in the presence of polyurethane dispersion (A), as described, for example, in DE-A 19 53 348, EP-A 0 167 188, EP-A 0 189 945 and EP-A 0 308 115.

- In addition to one or more olefinic double bonds, the monomers may also contain functional groups, such as hydroxyl, epoxy, methylol or acetoacetoxy groups. The emulsion polymerization can be carried out before or after the modification with component (B).

-

- Suitable compounds a) are those which have a 2,2,6,6-tetramethylpiperidinyl radical (HALS ring). The piperidinyl nitrogen of the HALS ring is not substituted and has no hydrazide structures at all. Preferred compounds a) are the compounds shown in Table 1.

TABLE 1 Compounds a) CAS Reg. No. Structure 24860-22-8 79720-19-7 64338-16-5 52829-07-9 99473-08-2 71029-16-8 71878-19-8 90751-07-8 154636-38-1 100631-44-5 115810-23-6 164648-93-5 96204-36-3 -

- The stabilizer B) of the compositions according to the invention also contains a compound b) corresponding to formula (II)

- —CO—NH—NH— (II).

- Suitable compounds b) include acid hydrazides and acid dihydrazides, such as acetic acid hydrazide, adipic acid hydrazide and adipic acid dihydrazide; and hydrazine adducts of hydrazine and cyclic carbonates, as described, for example, in EP-A 654 490 (page 3, line 48 to page 4, line 3). Adipic acid dihydrazide and the adduct of 2 moles of propylene carbonate and 1 mole of hydrazine corresponding to formula (VII)

- are preferably used. The adduct of 2 moles of propylene carbonate and 1 mole of hydrazine is particularly preferred.

- Suitable compounds c) include antioxidants such as 2,6-di-tert-butyl-4-methylphenol; UV absorbers of the 2-hydroxyphenyl-benzotriazole type; light stabilizers of the HALS type wherein the nitrogen atom is substituted, such as Tinuvin® 292 (Ciba Spezialitäten GmbH, Lampertheim, DE); and other commercially available stabilizers, as described, for example, in “Lichtschutzmittel für Lacke” [Light stabilizers for finishes] (A. Valet, Vincentz Verlag, Hanover, 1996, and “Stabilization of Polymeric Materials” (H. Zweifel, Springer Verlag, Berlin, 1997, Appendix 3, pages 181-213). Preferred compounds c) are shown in Table 2.

TABLE 2 Compounds c) CAS Reg. No. Structure 10191-41-0 128-37-0 2082-79-3 12643-61-0 119-47-1 35074-77-2 23128-74-7 976-56-7 65140-91-2 36443-68-2 85-60-9 90498-90-1 1709-70-2 1843-03-4 G34137-09-2 27676-62-6 40601-76-1 6683-19-8 32509-66-3 31851-03-3 96-69-5 90-66-4 110553-27-0 41484-35-9 991-84-4 103-99-1 63843-89-0 4221-80-1 67845-93-6 61167-58-6 128961-68-2 135-88-6 26780-96-1 101-72-4 90-30-2 68411-46-1 10081-67-1 32687-78-8 70331-94-1 6629-10-3 26523-78-4 31570-04-4 26741-53-7 80693-00-1 140221-14-3 38613-77-3 118337-09-0 3806-34-6 80410-33-9 693-36-7 123-28-4 16545-54-3 2500-88-1 131-57-7 1843-05-6 2985-59-3 43221-33-6 57472-50-1 2440-22-4 3147-75-9 3896-11-5 3846-71-7 23328-53-2 25973-55-1 36437-37-3 3864-99-1 70321-86-7 103597-45-1 84268-08-6 147315-50-2 2725-22-6 23949-66-8 35001-52-6 7443-25-6 106917-30-0 41556-26-7 65447-77-0 78276-66-1 130277-45-1 - The binder compositions according to the invention are obtained by reacting component A1) with components A2), A3), A4), A5), a), b) and c) in any desired sequence, optionally with the aid of an organic solvent. Suitable methods, known from the prior art, for the preparation of PU dispersions include the emulsifier shear force process, the acetone process, the prepolymer mixing process, the melt emulsification process, the ketimine process, the solid spontaneous dispersing process and derivatives thereof. A summary of these methods appears in “Methoden der organischen Chemie” [Methods of organic chemistry] (Houben-Weyl, supplementary and subsequent volumes for the 4th edition, Volume E20, H. Bartl and J. Falbe, Stuttgart, New York, Thieme 1987, pages 1617-1682).