US20030192899A1 - Paint cap closure with exterior pull ring - Google Patents

Paint cap closure with exterior pull ring Download PDFInfo

- Publication number

- US20030192899A1 US20030192899A1 US10/413,300 US41330003A US2003192899A1 US 20030192899 A1 US20030192899 A1 US 20030192899A1 US 41330003 A US41330003 A US 41330003A US 2003192899 A1 US2003192899 A1 US 2003192899A1

- Authority

- US

- United States

- Prior art keywords

- closure

- pull ring

- wall

- opening

- beaded rim

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D43/00—Lids or covers for rigid or semi-rigid containers

- B65D43/02—Removable lids or covers

- B65D43/0202—Removable lids or covers without integral tamper element

- B65D43/0204—Removable lids or covers without integral tamper element secured by snapping over beads or projections

- B65D43/0212—Removable lids or covers without integral tamper element secured by snapping over beads or projections only on the outside, or a part turned to the outside, of the mouth

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00018—Overall construction of the lid

- B65D2543/00064—Shape of the outer periphery

- B65D2543/00074—Shape of the outer periphery curved

- B65D2543/00092—Shape of the outer periphery curved circular

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00018—Overall construction of the lid

- B65D2543/00259—Materials used

- B65D2543/00296—Plastic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00481—Contact between the container and the lid on the inside or the outside of the container

- B65D2543/0049—Contact between the container and the lid on the inside or the outside of the container on the inside, or a part turned to the inside of the mouth of the container

- B65D2543/00509—Cup

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00481—Contact between the container and the lid on the inside or the outside of the container

- B65D2543/00537—Contact between the container and the lid on the inside or the outside of the container on the outside, or a part turned to the outside of the mouth of the container

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00481—Contact between the container and the lid on the inside or the outside of the container

- B65D2543/00555—Contact between the container and the lid on the inside or the outside of the container on both the inside and the outside

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00592—Snapping means

- B65D2543/00601—Snapping means on the container

- B65D2543/00611—Profiles

- B65D2543/00629—Massive bead

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00592—Snapping means

- B65D2543/00601—Snapping means on the container

- B65D2543/00675—Periphery concerned

- B65D2543/00685—Totality

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00592—Snapping means

- B65D2543/00712—Snapping means on the lid

- B65D2543/00722—Profiles

- B65D2543/0074—Massive bead

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00444—Contact between the container and the lid

- B65D2543/00592—Snapping means

- B65D2543/00712—Snapping means on the lid

- B65D2543/00787—Periphery concerned

- B65D2543/00796—Totality

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2543/00—Lids or covers essentially for box-like containers

- B65D2543/00009—Details of lids or covers for rigid or semi-rigid containers

- B65D2543/00824—Means for facilitating removing of the closure

- B65D2543/00833—Integral tabs, tongues, handles or similar

- B65D2543/00842—Integral tabs, tongues, handles or similar outside of the lid

Definitions

- This invention relates in general to plug and cap shaped plastic closures for liquid containers for removable disposition onto apertures with upstanding beaded rims, and in particular to an exterior pull ring with associated lever for releasing the closure skirt from underlying the beaded rim for easy removal of the closure by hand.

- the invention also relates to the use of a tamper evident tab located inside the pull ring.

- a tamper evident tab located inside the pull ring.

- the closure is designed for easy reinstallation by manual press fit.

- plug shaped plastic closures are commonly used to contain and dispense paint and other liquids from plastic and metal pails. These industrial shipping containers are generally provided with circular apertures in the cover for press fit installation of the plug shaped closures. These plug shaped closures are commonly provided with an integral pull ring for easy manual installation and removal. For example closures may have to be removed to add color tinting to paint. The closures are then replaced to seal the container for mixing the tint with the paint. Mixing is commonly done by shaker agitation. The closure must be capable of achieving an air tight seal to protect the paint from drying. The closure must also be capable of withstanding the forces applied by paint mixing and by container handling and shipping.

- Plug shaped plastic closures are commonly used because their simple construction makes them inexpensive, and press fit installation makes these closures easy to install.

- Plastic plug shaped closures have worked well on metal paint pails. This is due to the dimensional accuracy of making openings in metal covers.

- the metal covers also present a relatively sharp metal edge which grips and seals well with the softer plastic plug closure.

- Plug shaped plastic closures are less satisfactory when installed on plastic pails covers. Openings in plastic covers typically have dimensional variances due to uneven plastic shrinkage and due to plastic flash or defects around the edge of the cover opening. Plastic cover openings may further vary due to shrinkage from post molding flame treatment. The interference fit between the plastic cover opening and the outside diameter of the plug shaped closure is difficult to control, and is a source of air or liquid leaks.

- Prior art plug shaped closures for packaging paint are common.

- the closures typically are manufactured of flexible plastic or similar material.

- a generally circular flat bottom piece connects to a generally cylindrical wall.

- the cylindrical wall is slightly conical, with the diameter adjacent the flat bottom being small diameter than the container opening to aid initial insertion.

- the wall tapers to a larger diameter towards the top and is terminated by a generally outward looking annular top flange.

- the wall is sized to be a compression fit when fully installed inside the container opening.

- Prior art devices can include a small annular projection or lip on the wall outside surface which acts as a resistance to the insertion and removal of the plug shaped closure.

- the top flange has a larger diameter than the container opening, and stops the closure from passing through the container opening.

- An annular pull ring is typically mounted inside the closure and is attached to the flat bottom or side wall. By pulling on the ring, the closure annular lip is released from beneath the container annular opening, and the closure may be removed. There are generally no tamper evident features.

- One common complaint is that the annular lip may release suddenly as the paint plug is being removed under tension. Paint can be splattered on bystanders.

- a closure which can be slowly lifted off a container beaded rim would be an improvement.

- the ability of the plug shaped closure to seal the container relies on a tight interference fit between the closure and the container opening.

- the closures are a plug fit within a planar container opening.

- the sealing surface is limited to the width of the planar container opening.

- the width of the seal is typically the thickness of the metal.

- Metal walled containers are typically 0.01 to 0.02 inches thick.

- the ability of the closure to create a seal is aided by the tendency of the narrow metal edge to slightly penetrate the softer plastic closure wall.

- the width of the seal is typically greater relative to the metal edge referred to above to add stiffness.

- the seal width is typically 0.02 to 0.05 inches for plastic walled containers.

- U.S. Pat. No. 5,799,813 relates to a plug closure with an integral pull ring.

- This patent describes a removable plug for use in combination with a planar container cover having an aperture formed therein.

- the plug body is of shallow cylindrical configuration and has a top flange which is partially sub-divided into inner and outer ring portions by a combination of weak frangible links and strong non-frangible links.

- a tab integral with the outer ring portion overlies a ledge ring on the closure body to facilitate initialization of the removal process.

- Location of the pull ring around the maximum diameter of the top flange maximizes leverage and provides a large ring capable of accommodating several fingers of one's hand.

- This design follows the prior art design of a plug fit closure in a planer opening. The closure performance is limited by the ability to achieve an effective seal with a minimum of surface contact between the closure and container opening.

- Canadian Patent 2,191,149 describes a container opening molded with both a threaded neck finish and a planer opening for the insertion of a removable plug.

- a standard plug fit closure is first installed and is held in position by installing an overlying threaded cap.

- the combination of plug fit closure and threaded cap solve performance problems such as the plug closure coming out during transportation or agitation on the paint vibratory mixer.

- This invention relates in general to plug and cap shaped plastic closures for industrial shipping containers for removable disposition in apertures with upstanding beaded rims, and in particular to an exterior pull ring and lever for easy removal of the closure.

- the invention relates to the attachment and removal from a container beaded rim of a closure with a mating recess.

- the closure recess is formed by an inner wall and outer skirt. Closures which both plug fit inside and wrap around a beaded rim opening have greater contact surface than closures which simply plug into a planar opening. Greater contact area between the closure and the container beaded rim improves the sealing of the container, and protection of the container contents.

- the closure outer skirt When installed on the container cover, the closure outer skirt partially underlies the cover beaded rim to hold the closure in position.

- a finger pull ring is provided for easy removal of the closure without tools.

- the pull ring is positioned outside of the main body of the closure and is connected to the closure body lever and gusset. Lifting on the exterior pull ring transfers part of the upward directed force through the lever and gusset to the outer skirt, releasing the skirt from underlying the beaded rim, thereby allowing the closure to be more easily removed.

- the pull ring has a novel tamper evident feature. This is an optional feature.

- the insertion of a finger through the pull ring is blocked by a central tab within the pull ring.

- the central tab is held in position inside the pull ring by one or more frangible webs.

- the closure may be removed by first breaking the frangible webs which hold the tamper evident tab within the pull ring, allowing finger access to the pull ring.

- the closure can now be pulled off the container beaded rim. While the closure is typically replaced, the broken webs are evidence of prior container opening.

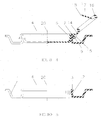

- FIG. 1 is a side & cross-sectional view of a press fit closure before installation on a container cover.

- FIG. 2 is a side & cross sectional view of a press fit closure after installation on a container cover.

- FIG. 3 is a top view of the closure.

- FIG. 4 is a side & cross-sectional view of the closure with the pull ring tamper evident tab opened.

- FIG. 5 is sectional view of a typical container cover opening.

- FIG. 1 is a side and cross-sectional view of a press fit closure (or closure) 4 .

- the closure 4 is generally made of flexible plastic or the like.

- the closure has an external pull ring 16 for the removal of the closure 4 from container cover 1 .

- the pull ring 16 is exterior or external to the closure body.

- Closure 4 is comprised of a circular closure bottom 5 attached to inner wall 6 .

- the inner wall 6 is generally cylindrical in shape and leads to top wall 7 and outer skirt 8 .

- Outer skirt 8 is cylindrical in shape, and lies radically outside of inner wall 6 .

- Inner wall 6 , top wall 7 and outer skirt 8 together form an annular recess 10 which is sized to attach to container cover 1 .

- Connecting member or lever 14 connects top wall 7 to cylindrical pull ring 16 .

- Gusset 15 underlies lever 14 and connects lever 14 to outer skirt 8 and outer flange 9 .

- Tamper evident tab 17 lies within the perimeter of pull ring 16 .

- Tab 17 is attached to pull ring 16 and is initially held in position by one or more frangible webs 18 .

- FIG. 2 is a side & cross-sectional view of press fit closure 4 after installation on a container cover 1 .

- the container 1 presents a cover opening 2 having a generally upstanding cylindrical wall with an outwardly bulbous beaded rim 3 adapted to be received or captured by the annular recess 10 in a manner to be more fully described herein.

- Cylindrical inner wall 6 braces against cover opening 2 and body top wall 7 and outer skirt 8 overlie beaded rim 3 .

- the body outer flange 9 expands in diameter as the beaded rim 3 passes along annular recess 10 .

- the closure 4 is pressed over the beaded rim 3 until rim 3 reaches mating annular recess 10 .

- the body outer flange 9 relaxes to a smaller diameter and underlies beaded rim 3 .

- the interference fit resists removal of closure 4 from container cover 1 .

- FIG. 3 is a top view of the closure 4 .

- Lever 14 is shown connecting the top wall 7 with pull ring 16 .

- FIG. 4 is a side & cross-sectional view of the closure 4 with the pull ring tamper evident tab 17 shown in the open position.

- Pull ring 16 is shown partially lifted to initiate closure 4 removal from beaded rim 3 .

- Lever 14 flexes under the lifting force applied to pull ring 16 .

- Part of the removal force is transferred from lever 14 through gusset 15 to outer flange 9 .

- the removal force partially lifts outer flange 9 from underlying beaded rim 3 .

- This novel design improves the removal of the closure 4 from container 1 , in a gentle even fashion.

- the closure 4 described herein slowly permits the removal of the closure 4 from the cover 1 in a manner which minimizes the sudden release of the plug from the cover and minimizes the chance of splattering a bystander.

- FIG. 5 is sectional view of a typical container cover opening 1 with cover opening 2 and beaded rim 3 .

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

Abstract

A closure for a container cover opening, said opening defined by an upstanding cylindrical wall with a beaded rim, said closure comprising a circular closure bottom, inner wall, top wall, outer skirt and outer flange presenting an annular recess for engaging said cylindrical wall and said beaded rim; a pull ring; said pull ring connected to the exterior of said top wall; said closure to be removed by inserting a finger through said pull ring and lifting said closure off said beaded rim.

Description

- Applicant claims priority from U.S. app. No. 60/372,117 filed Apr. 15, 2002.

- This invention relates in general to plug and cap shaped plastic closures for liquid containers for removable disposition onto apertures with upstanding beaded rims, and in particular to an exterior pull ring with associated lever for releasing the closure skirt from underlying the beaded rim for easy removal of the closure by hand.

- The invention also relates to the use of a tamper evident tab located inside the pull ring. To access the pull ring and remove the closure, the tamper resistant tab webs must first be broken. The closure is designed for easy reinstallation by manual press fit.

- One piece plug shaped plastic closures are commonly used to contain and dispense paint and other liquids from plastic and metal pails. These industrial shipping containers are generally provided with circular apertures in the cover for press fit installation of the plug shaped closures. These plug shaped closures are commonly provided with an integral pull ring for easy manual installation and removal. For example closures may have to be removed to add color tinting to paint. The closures are then replaced to seal the container for mixing the tint with the paint. Mixing is commonly done by shaker agitation. The closure must be capable of achieving an air tight seal to protect the paint from drying. The closure must also be capable of withstanding the forces applied by paint mixing and by container handling and shipping.

- Plug shaped plastic closures are commonly used because their simple construction makes them inexpensive, and press fit installation makes these closures easy to install. Plastic plug shaped closures have worked well on metal paint pails. This is due to the dimensional accuracy of making openings in metal covers. The metal covers also present a relatively sharp metal edge which grips and seals well with the softer plastic plug closure.

- Plug shaped plastic closures are less satisfactory when installed on plastic pails covers. Openings in plastic covers typically have dimensional variances due to uneven plastic shrinkage and due to plastic flash or defects around the edge of the cover opening. Plastic cover openings may further vary due to shrinkage from post molding flame treatment. The interference fit between the plastic cover opening and the outside diameter of the plug shaped closure is difficult to control, and is a source of air or liquid leaks.

- Air entry may cause undesirable drying of the paint in the pail. Tint plugs may unexpectedly come out during shipping, handling and mixing. This leads to expensive product loss and clean up.

- Prior art plug shaped closures for packaging paint are common. The closures typically are manufactured of flexible plastic or similar material. A generally circular flat bottom piece connects to a generally cylindrical wall. The cylindrical wall is slightly conical, with the diameter adjacent the flat bottom being small diameter than the container opening to aid initial insertion. The wall tapers to a larger diameter towards the top and is terminated by a generally outward looking annular top flange. The wall is sized to be a compression fit when fully installed inside the container opening.

- Prior art devices can include a small annular projection or lip on the wall outside surface which acts as a resistance to the insertion and removal of the plug shaped closure. The top flange has a larger diameter than the container opening, and stops the closure from passing through the container opening. An annular pull ring is typically mounted inside the closure and is attached to the flat bottom or side wall. By pulling on the ring, the closure annular lip is released from beneath the container annular opening, and the closure may be removed. There are generally no tamper evident features. One common complaint is that the annular lip may release suddenly as the paint plug is being removed under tension. Paint can be splattered on bystanders. A closure which can be slowly lifted off a container beaded rim would be an improvement.

- The ability of the plug shaped closure to seal the container relies on a tight interference fit between the closure and the container opening. The closures are a plug fit within a planar container opening. The sealing surface is limited to the width of the planar container opening. For metal containers, the width of the seal is typically the thickness of the metal. Metal walled containers are typically 0.01 to 0.02 inches thick. The ability of the closure to create a seal is aided by the tendency of the narrow metal edge to slightly penetrate the softer plastic closure wall.

- For plastic containers, the width of the seal is typically greater relative to the metal edge referred to above to add stiffness. The seal width is typically 0.02 to 0.05 inches for plastic walled containers. The ability of the closure to create an effective seal in a plastic container is hampered by the common presence of flash and other imperfections around the plastic opening. The plastic container does not effectively penetrate the softer plastic closure wall.

- U.S. Pat. No. 5,799,813 relates to a plug closure with an integral pull ring. This patent describes a removable plug for use in combination with a planar container cover having an aperture formed therein. The plug body is of shallow cylindrical configuration and has a top flange which is partially sub-divided into inner and outer ring portions by a combination of weak frangible links and strong non-frangible links. A tab integral with the outer ring portion overlies a ledge ring on the closure body to facilitate initialization of the removal process. Location of the pull ring around the maximum diameter of the top flange maximizes leverage and provides a large ring capable of accommodating several fingers of one's hand. This design follows the prior art design of a plug fit closure in a planer opening. The closure performance is limited by the ability to achieve an effective seal with a minimum of surface contact between the closure and container opening.

- Canadian Patent 2,191,149 describes a container opening molded with both a threaded neck finish and a planer opening for the insertion of a removable plug. A standard plug fit closure is first installed and is held in position by installing an overlying threaded cap. The combination of plug fit closure and threaded cap solve performance problems such as the plug closure coming out during transportation or agitation on the paint vibratory mixer.

- This prior art closure combination requires the use of both a cap and tint plug, which makes it a more costly packaging solution.

- A single piece closure as described, that meets all performance requirements at a low cost, would be an improvement on prior art.

- This invention relates in general to plug and cap shaped plastic closures for industrial shipping containers for removable disposition in apertures with upstanding beaded rims, and in particular to an exterior pull ring and lever for easy removal of the closure. The invention relates to the attachment and removal from a container beaded rim of a closure with a mating recess. The closure recess is formed by an inner wall and outer skirt. Closures which both plug fit inside and wrap around a beaded rim opening have greater contact surface than closures which simply plug into a planar opening. Greater contact area between the closure and the container beaded rim improves the sealing of the container, and protection of the container contents.

- When installed on the container cover, the closure outer skirt partially underlies the cover beaded rim to hold the closure in position. A finger pull ring is provided for easy removal of the closure without tools. The pull ring is positioned outside of the main body of the closure and is connected to the closure body lever and gusset. Lifting on the exterior pull ring transfers part of the upward directed force through the lever and gusset to the outer skirt, releasing the skirt from underlying the beaded rim, thereby allowing the closure to be more easily removed.

- The pull ring has a novel tamper evident feature. This is an optional feature. The insertion of a finger through the pull ring is blocked by a central tab within the pull ring. The central tab is held in position inside the pull ring by one or more frangible webs. The closure may be removed by first breaking the frangible webs which hold the tamper evident tab within the pull ring, allowing finger access to the pull ring. The closure can now be pulled off the container beaded rim. While the closure is typically replaced, the broken webs are evidence of prior container opening.

- FIG. 1 is a side & cross-sectional view of a press fit closure before installation on a container cover.

- FIG. 2 is a side & cross sectional view of a press fit closure after installation on a container cover.

- FIG. 3 is a top view of the closure.

- FIG. 4 is a side & cross-sectional view of the closure with the pull ring tamper evident tab opened.

- FIG. 5 is sectional view of a typical container cover opening.

- Like parts shall be given like numbers throughout the figures

- FIG. 1 is a side and cross-sectional view of a press fit closure (or closure) 4. The

closure 4 is generally made of flexible plastic or the like. The closure has anexternal pull ring 16 for the removal of theclosure 4 fromcontainer cover 1. Thepull ring 16 is exterior or external to the closure body. -

Closure 4 is comprised of a circular closure bottom 5 attached toinner wall 6. Theinner wall 6 is generally cylindrical in shape and leads totop wall 7 andouter skirt 8.Outer skirt 8 is cylindrical in shape, and lies radically outside ofinner wall 6.Inner wall 6,top wall 7 andouter skirt 8 together form anannular recess 10 which is sized to attach tocontainer cover 1. Connecting member orlever 14 connectstop wall 7 tocylindrical pull ring 16.Gusset 15 underlieslever 14 and connectslever 14 toouter skirt 8 andouter flange 9. Tamperevident tab 17 lies within the perimeter ofpull ring 16.Tab 17 is attached to pullring 16 and is initially held in position by one or morefrangible webs 18. - FIG. 2 is a side & cross-sectional view of press

fit closure 4 after installation on acontainer cover 1. Thecontainer 1 presents acover opening 2 having a generally upstanding cylindrical wall with an outwardly bulbousbeaded rim 3 adapted to be received or captured by theannular recess 10 in a manner to be more fully described herein. Cylindricalinner wall 6 braces againstcover opening 2 and bodytop wall 7 andouter skirt 8 overlie beadedrim 3. During installation ofclosure 4 installation, the bodyouter flange 9 expands in diameter as thebeaded rim 3 passes alongannular recess 10. Theclosure 4 is pressed over thebeaded rim 3 untilrim 3 reaches matingannular recess 10. After installation, the bodyouter flange 9 relaxes to a smaller diameter and underlies beadedrim 3. The interference fit resists removal ofclosure 4 fromcontainer cover 1. - FIG. 3 is a top view of the

closure 4.Lever 14 is shown connecting thetop wall 7 withpull ring 16. - FIG. 4 is a side & cross-sectional view of the

closure 4 with the pull ring tamperevident tab 17 shown in the open position. Pullring 16 is shown partially lifted to initiateclosure 4 removal frombeaded rim 3.Lever 14 flexes under the lifting force applied to pullring 16. Part of the removal force is transferred fromlever 14 throughgusset 15 toouter flange 9. The removal force partially liftsouter flange 9 from underlying beadedrim 3. This novel design improves the removal of theclosure 4 fromcontainer 1, in a gentle even fashion. In other words theclosure 4 described herein slowly permits the removal of theclosure 4 from thecover 1 in a manner which minimizes the sudden release of the plug from the cover and minimizes the chance of splattering a bystander. - FIG. 5 is sectional view of a typical container cover opening 1 with

cover opening 2 and beadedrim 3. - Although the invention described herein can be used with plastic container covers, it can also be used with metallic container covers.

- Various embodiments of the invention have now been described in detail. Since changes in and/or additions to the above-described best mode may be made without departing from the nature, spirit or scope of the invention, the invention is not to be limited to said details.

Claims (20)

1. A closure for a container cover opening, said opening defined by an upstanding cylindrical wall with a beaded rim, said closure comprising:

(a) a circular closure bottom, inner wall, top wall, outer skirt and outer flange presenting an annular recess for engaging said cylindrical wall and said beaded rim;

(b) a pull ring;

(c) said pull ring connected to the exterior of said top wall;

(d) said closure to be removed by inserting a finger through said pull ring and lifting said closure off said beaded rim.

2. A closure as claimed in claim 1 wherein said pull ring includes a tamper evident tab, said tamper evident tab comprising;

(a) a flat portion partially connected to the inner circumference of said pull ring;

(b) one or more thin frangible webs connecting said flat portion to said inner circumference;

(c) said frangible webs being broken and said flat portion being displaced to allow a finger to pass through the closure pull ring;

(d) said broken webs evidencing prior removal of the closure.

3. A press fit closure for a container cover opening, said opening presenting an upstanding cylindrical wall with a beaded rim, said closure being adapted to mount on said opening, said closure comprising;

(a) a circular closure bottom attached to an inner wall which is cylindrical in shape and leads to a top wall, an outer skirt and an outer flange;

(b) said outer skirt being cylindrical in shape and located beyond the inner wall;

(c) said inner wall, said top wall and said outer skirt defining an annular recess adapted to receive said beaded rim when said closure is pressed over said beaded rim;

(d) said outer flange partially underlying said beaded rim when the closure is installed;

(e) a pull ring connected to the exterior of said closure;

(f) a connecting means including a lever and a gusset for connecting said pull ring to said closure;

(g) said pull ring adapted to allow a finger to apply upward removal force to said closure;

(h) said lever and gusset partially rotate under said upward force to transmit an outward force on said outer flange, releasing said outer flange from underlying said beaded rim, and permitting easy removal of the closure off said container opening.

4. A closure as claimed in claim 1 comprising flexible plastic.

5. A closure as claimed in claim 4 wherein said pull ring is connected to said top wall by a connecting member.

6. A closure as claimed in claim 5 wherein said connecting member includes a gusset.

7. A closure as claimed in claim 6 wherein said gusset extends from said connecting member to said outer skirt.

8. A closure as claimed in claim 7 wherein said closure is adapted to cover a plastic container opening.

9. A closure for a container cover opening having a beaded rim comprising:

(a) a generally circular closure body adapted for insertion into said opening;

(b) said closure body presents an annular recess for capturing said beaded rim;

(c) a pull ring disposed beyond and connected to said annular recess for permitting removal of said closure from said rim by lifting said ring.

10. A closure as claimed in claim 9 wherein said pull ring permits partial removal of said annual recess from said beaded rim.

11. A closure as claimed in claim 10 wherein said closure body, annular recess and opening are co-axially disposed when said closure closes said opening.

12. A closure as claimed in claim 11 wherein said pull ring is disposed outside said annular recess.

13. A closure as claimed in claim 12 wherein said annular recess requires an annular inner wall, annular top wall and annular skirt.

14. A claim as claimed in claim 13 wherein said circular closure body presents said annual inner wall upstanding from said closure body.

15. A closure as claimed in claim 14 wherein said annular inner wall presents an annular top wall disposed axially outwardly from said inner wall, and said top wall presents an annular outer skirt disposed downwardly from said top wall.

16. A closure as claimed in claim 15 when said pull ring includes a taper evident tab.

17. A closure as claimed in claim 9 wherein said closure body and pull ring have spaced apart centres.

18. A closure as claimed in claim 13 wherein said inner wall, top wall and skirt contact said beaded rim when said closure closes said opening.

19. A closure as claimed in claim 18 wherein said pull ring is connected to said top wall.

20. A closure as claimed in claim 19 further including a gusset extending from said skirt to said pull ring.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/413,300 US20030192899A1 (en) | 2002-04-15 | 2003-04-15 | Paint cap closure with exterior pull ring |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US37211702P | 2002-04-15 | 2002-04-15 | |

| US10/413,300 US20030192899A1 (en) | 2002-04-15 | 2003-04-15 | Paint cap closure with exterior pull ring |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20030192899A1 true US20030192899A1 (en) | 2003-10-16 |

Family

ID=28794452

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/413,300 Abandoned US20030192899A1 (en) | 2002-04-15 | 2003-04-15 | Paint cap closure with exterior pull ring |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US20030192899A1 (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070108084A1 (en) * | 2005-11-17 | 2007-05-17 | Randall Susan M | Paint storage and touch-up container |

| CN104257295A (en) * | 2005-09-05 | 2015-01-07 | 布瑞威利私人有限公司 | Blender Jug And Lid |

| USD763079S1 (en) * | 2015-06-02 | 2016-08-09 | Apc Products Limited | Closure vent with body skirt and hinged cap |

| US20190009951A1 (en) * | 2017-07-05 | 2019-01-10 | Chase Corporation | Pull Ring Seal System for Containers |

| USD988070S1 (en) * | 2022-05-05 | 2023-06-06 | Xiamen Yangchangsheng Silicone Rubber Products Co., Ltd. | Water bottle cap |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3379237A (en) * | 1965-10-24 | 1968-04-23 | Worthington Henry Miller | Frame construction for screens |

| US4171062A (en) * | 1978-02-16 | 1979-10-16 | Buckeye Molding Company | Container having closure fastening means |

| US4212409A (en) * | 1978-04-10 | 1980-07-15 | Ab Akerlund & Rausing | Container closure members |

| US5125528A (en) * | 1989-12-18 | 1992-06-30 | Polystar Packaging, Inc. | Container closure, and method for producing same |

| US5511680A (en) * | 1993-09-03 | 1996-04-30 | The Procter And Gamble Company | Tear-away canister lid |

| US5806710A (en) * | 1995-11-14 | 1998-09-15 | Shiffer; David A. | Container and closure lid |

| USD411106S (en) * | 1998-01-23 | 1999-06-15 | Ball Corporation | Combined closure and container attachment |

| USD448969S1 (en) * | 2000-06-26 | 2001-10-09 | Holiday Housewares, Inc. | Lid for a container |

| US6644490B2 (en) * | 2001-05-17 | 2003-11-11 | Solo Cup Company | Lid |

-

2003

- 2003-04-15 US US10/413,300 patent/US20030192899A1/en not_active Abandoned

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3379237A (en) * | 1965-10-24 | 1968-04-23 | Worthington Henry Miller | Frame construction for screens |

| US4171062A (en) * | 1978-02-16 | 1979-10-16 | Buckeye Molding Company | Container having closure fastening means |

| US4212409A (en) * | 1978-04-10 | 1980-07-15 | Ab Akerlund & Rausing | Container closure members |

| US5125528A (en) * | 1989-12-18 | 1992-06-30 | Polystar Packaging, Inc. | Container closure, and method for producing same |

| US5511680A (en) * | 1993-09-03 | 1996-04-30 | The Procter And Gamble Company | Tear-away canister lid |

| US5806710A (en) * | 1995-11-14 | 1998-09-15 | Shiffer; David A. | Container and closure lid |

| USD411106S (en) * | 1998-01-23 | 1999-06-15 | Ball Corporation | Combined closure and container attachment |

| USD448969S1 (en) * | 2000-06-26 | 2001-10-09 | Holiday Housewares, Inc. | Lid for a container |

| US6644490B2 (en) * | 2001-05-17 | 2003-11-11 | Solo Cup Company | Lid |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104257295A (en) * | 2005-09-05 | 2015-01-07 | 布瑞威利私人有限公司 | Blender Jug And Lid |

| US20070108084A1 (en) * | 2005-11-17 | 2007-05-17 | Randall Susan M | Paint storage and touch-up container |

| USD763079S1 (en) * | 2015-06-02 | 2016-08-09 | Apc Products Limited | Closure vent with body skirt and hinged cap |

| US20190009951A1 (en) * | 2017-07-05 | 2019-01-10 | Chase Corporation | Pull Ring Seal System for Containers |

| US10479562B2 (en) * | 2017-07-05 | 2019-11-19 | Chase Corporation | Pull ring seal system for containers |

| USD988070S1 (en) * | 2022-05-05 | 2023-06-06 | Xiamen Yangchangsheng Silicone Rubber Products Co., Ltd. | Water bottle cap |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5799813A (en) | Plug closure with integral pull ring | |

| CN1639020B (en) | jar plastic lid | |

| US4407423A (en) | Detachable resealable closure | |

| CA2661297C (en) | Container closure with internal threading system | |

| EP0088185B1 (en) | Nondetachable resealable closure | |

| CA1161795A (en) | Pilferproof closure | |

| AU737104B2 (en) | Dispensing closure for package containing a consumable beverage | |

| US4562937A (en) | Internally-seating container closure | |

| US7690525B2 (en) | Screw cap | |

| US7584866B2 (en) | All plastic paint container | |

| CA2325196A1 (en) | A resealing overcap for a cylindrical container | |

| CA2249953A1 (en) | Tamper-evident container closure | |

| PL1971531T3 (en) | Plug device for a container and container provided with one such device | |

| US7028858B2 (en) | Quick-twist pop-off closure | |

| HK1049139A1 (en) | Container closure system | |

| US7607551B2 (en) | Tint plug for paint container | |

| US20030192899A1 (en) | Paint cap closure with exterior pull ring | |

| KR20090087887A (en) | Closed structure of cans | |

| US5810190A (en) | Plastic bung seal | |

| US6923333B2 (en) | Tamper resistant plastic industrial container with pail, cover and pour spout closure | |

| JP3686982B2 (en) | Container opening and closing device | |

| MXPA01008269A (en) | Container lid with stopper. | |

| CN1878701A (en) | Reclosable beverage can | |

| JPH02242754A (en) | Composite container lid | |

| CA1190896A (en) | Detachable resealable closure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment |

Owner name: APC PRODUCTS LIMITED, ONTARIO Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:STURK, RON;REEL/FRAME:013975/0787 Effective date: 20020412 |

|

| STCB | Information on status: application discontinuation |

Free format text: ABANDONED -- FAILURE TO RESPOND TO AN OFFICE ACTION |