US20030192845A1 - Extendable rack - Google Patents

Extendable rack Download PDFInfo

- Publication number

- US20030192845A1 US20030192845A1 US10/122,653 US12265302A US2003192845A1 US 20030192845 A1 US20030192845 A1 US 20030192845A1 US 12265302 A US12265302 A US 12265302A US 2003192845 A1 US2003192845 A1 US 2003192845A1

- Authority

- US

- United States

- Prior art keywords

- longitudinal

- horizontal body

- retaining

- elongated horizontal

- cantilever support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 210000003414 extremity Anatomy 0.000 claims description 6

- 210000001364 upper extremity Anatomy 0.000 claims description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47F—SPECIAL FURNITURE, FITTINGS, OR ACCESSORIES FOR SHOPS, STOREHOUSES, BARS, RESTAURANTS OR THE LIKE; PAYING COUNTERS

- A47F5/00—Show stands, hangers, or shelves characterised by their constructional features

- A47F5/08—Show stands, hangers, or shelves characterised by their constructional features secured to the wall, ceiling, or the like; Wall-bracket display devices

- A47F5/0807—Display panels, grids or rods used for suspending merchandise or cards supporting articles; Movable brackets therefor

- A47F5/0846—Display panels or rails with elongated channels; Sliders, brackets, shelves, or the like, slidably attached therein

Definitions

- the present invention relates in general to storage racks for hanging a plurality of cantilever supports and, more particularly, to an extendable rack.

- the section bar comprises a front portion suitable for receiving various kinds of cantilever supports and a rear portion suitable for being assembled on the fastener.

- the latter is mounted and fastened to a carrier bracket.

- This suspending system is considered to have several disadvantages. First, the suspending system is cumbersome due to the overall width of the fastener and the carrier bracket. Second, Nava et al. suspending system requires special molds for manufacturing the fastener and the carrier bracket. Third, the smoothness in use of Nava et al. system is reduced due to the sliding friction surfaces.

- the apparel support device comprises an elongated base member having a longitudinal channel defined by opposed side walls and elongated parallel opposed grooves formed in the side walls.

- a plurality of hanger members is used. Each hanger member has a shank portion and an integral crank end portion connected to a link at spaced apart intervals on the link.

- the device comprises as well an elongated channel shaped hanger support having a web portion and spaced apart parallel flanges connected to the web portion and supported at their distal end in the grooves. Crank supports are provided on the parallel side flanges for supporting and retaining the hanger members.

- Dillingham device has shortcomings. It is complicated and uses numerous components.

- a first objective of the present invention is to provide an extendable rack which is reliable, simple and allows to reduce the material and labor costs. Such savings may be passed to the users, which constitute an undeniable advantage.

- a second objective of this invention is to provide a well-engineered extendable rack characterized by compactness and including a well-tested, mass produced slide.

- the present invention provides an extendable rack adapted for retaining one or more cantilever support(s) and also adapted for attaching to a panel via a slide.

- the extendable rack comprises an elongated body including, at one side, means for retaining one or more cantilever support(s); and, at another side, a longitudinal passage adapted for locating almost entirely the slide, the latter being firmly secured with one part to the longitudinal channel and with another part to the panel.

- the means for retaining one or more cantilever support(s) includes an elongated horizontal body provided with a longitudinal channel, C-shaped in cross section, with a perimeter defined by a standing segment extending, at the top, into a downwardly curved segment and, at the bottom, into an upwardly curved segment, so that opposing niches are formed.

- Each opposing niche is adapted to capture at least a flange of at least one of several cantilever supports.

- the means for retaining one or more cantilever support(s) includes an elongated horizontal body provided with a central longitudinal wall, extending, close to the top, outwardly and upwardly and forming a longitudinal top recess. Close to the bottom, the central longitudinal wall extends outwardly and downwardly forming a longitudinal bottom recess.

- the longitudinal top and bottom recesses are adapted to capture at least one flange of at least one of several cantilever supports.

- the means for retaining one or more cantilever support(s) is provided with a central longitudinal wall extending from midway of its height, outwardly, then upwardly and downwardly, thus forming longitudinal top and bottom recesses adapted to capture at least one flange of at least one of several cantilever supports.

- the elongated horizontal body having Longitudinal cavities, is provided, at a front extremity, with a finger-pull having upper and lower projections for press fitting into the longitudinal cavities.

- a cap attached to a back extremity of the elongated horizontal body also comprises upper and lower projections for press fitting into the longitudinal cavities.

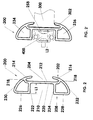

- FIG. 1 illustrates in an exploded, perspective view the extendable rack, according to the present invention

- FIG. 2 illustrates a transversal cross section of the elongated horizontal body according to a first embodiment

- FIG. 2′ illustrates the cross section of FIG. 2 together with a cantilever support and a slide, the former and the latter shown in phantom lines;

- FIG. 3 illustrates transversal cross section of the elongated horizontal body according to a second embodiment

- FIG. 4 illustrates transversal cross section of the elongated horizontal body according to a third embodiment.

- An extendable rack 100 as shown in FIG. 1, comprises essentially an elongated horizontal body 200 .

- extendable rack 100 has its elongated horizontal body 200 provided, in a first side 202 , with a longitudinal channel 204 .

- the latter is adapted for retaining one or more cantilever supports 300 .

- Elongated horizontal body 200 is provided in a second side 208 , usually opposed to first side 202 , with a longitudinal passage 210 .

- elongated horizontal body 200 is suitable for being glidingly assembled on slide 400 .

- elongated horizontal body 200 has longitudinal channel 204 , C-shaped in cross section, with a perimeter defined by a standing segment 212 extending, at the top, into a downwardly curved segment 214 and, at the bottom, into an upwardly curved segment 216 .

- Opposing niches 218 are formed. Each opposing niche 218 is adapted to capture a flange 302 of cantilever support 300 .

- Longitudinal channel 204 extends along elongated horizontal body 200 .

- Elongated horizontal body 200 has longitudinal passage 210 , U-shaped in cross section, and a length also commensurate with elongated horizontal body 200 .

- Longitudinal passage 210 has one upright segment 220 extending at the top and at the bottom into horizontal segments 222 and 224 . Joints formed between upright segment 220 and horizontal segments 222 and 224 are rounded.

- a first horizontal dimension L 1 of longitudinal passage 210 is lesser than a second horizontal dimension L 2 of a mounted slide 400 .

- slide 400 extends laterally beyond horizontal passage 210 .

- a movement of elongated horizontal body 200 , with respect to a part of slide 400 , which is firmly secured to a fixed panel, is therefore possible.

- Each horizontal segment 222 and 224 continues, at each outside extremity, with vertical segments 226 and 228 , respectively opposed, which further continues with a curved segment 230 and 232 , to finally merge with downwardly and upwardly projecting segments 214 and 216 .

- longitudinal cavities 234 and 236 having lengths commensurate with the lengths of longitudinal channel 204 and longitudinal passage 210 are formed.

- a finger-pull 240 is attached to a front extremity 238 of elongated horizontal body 200 , while a cap 242 is attached to a back extremity 244 of the same.

- Finger-pull 240 and cap 242 comprise upper and lower projections 246 and 248 press fitted into longitudinal cavities 234 and 236 .

- Front and back extremities 238 and 244 are closed by finger-pull 240 and by cap 242 .

- Finger-pull 240 is used to drive elongated horizontal body 200 outwardly and inwardly.

- a wall 254 formed between standing segment 212 and upright segment 220 , contains, at each extremity, holes 256 located midway between the horizontal segments 222 and 224 .

- Fasteners 258 disposed in holes 256 are used to attach slide 400 to elongated horizontal body 200 .

- an elongated horizontal body 260 has a central longitudinal wall 262 .

- Central longitudinal wall 262 close to its top, extends outwardly and upwardly and forms a longitudinal top recess 264 .

- central longitudinal wall 262 close to its bottom, extends outwardly and downwardly forming a longitudinal bottom recess 266 .

- the purpose of longitudinal top and bottom recesses 264 and 266 is to retain opposite flanges 304 .

- elongated horizontal body 260 The remaining features of elongated horizontal body 260 are essentially similar with those described in elongated horizontal body 200 .

- an elongated horizontal body 268 has a central longitudinal wall 270 .

- the latter extends, from midway of its height, outwardly, then upwardly and downwardly forming longitudinal top and bottom recesses 272 and 274 , respectively.

- the purpose of longitudinal top and bottom recesses 272 and 274 is to retain opposite flanges 306 .

- elongated horizontal body 268 The remaining features of elongated horizontal body 268 are essentially similar with those described in elongated horizontal body 200 .

- Elongated horizontal bodies 200 , 260 and 268 are advantageously formed by an extrusion process. Aluminum, plastic and wood composite are usually used.

- slider 400 is of a conventional and known design, mass-produced in different sizes, a further explanation of the same appears to be unnecessary.

- precision ball bearing drawer slides are sold under the trademark AccurideTM by Accuride, Santa Fe Springs, Calif.

- Cantilever supports 300 are designed in various shapes to accommodate different items, such as neckties, belts, trays etc.

Landscapes

- Holders For Apparel And Elements Relating To Apparel (AREA)

- Assembled Shelves (AREA)

Abstract

The present invention provides an extendable rack adapted for retaining one or more cantilever support(s) and also adapted for attaching to a panel via a slide. The extendable rack comprises an elongated body including, at one side, a longitudinal channel for retaining one or more cantilever support(s); and, at another side, a longitudinal passage adapted for locating almost entirely the slide and for attaching permanently one side of it. Another side of the slide is firmly secured to the panel. In one embodiment, the longitudinal channel is C-shaped in cross section. Opposing niches are formed. Each opposing niche is adapted to capture at least a flange of at least one of several cantilever supports. In another embodiment, instead of the longitudinal channel, the elongated horizontal body comprises a central longitudinal wall extending, close to its top, outwardly and upwardly and forming a longitudinal top recess. Close to its bottom, the central longitudinal wall extends outwardly and downwardly forming a longitudinal bottom recess. The longitudinal top and bottom recesses are functionally equivalent to the niches. In another embodiment, the elongated horizontal body is provided with a central longitudinal wall extending, from midway of its height, outwardly, then upwardly and downwardly. Thus, longitudinal top and bottom recesses equivalent to the above recesses are formed.

Description

- 1. Field of the Invention

- The present invention relates in general to storage racks for hanging a plurality of cantilever supports and, more particularly, to an extendable rack.

- 2. Description of the Prior Art

- Racks particularly designed to fit inside wardrobes and/or wardrobe cabinets, or for wall mounting are well known. The consumer satisfaction depends upon several factors including reliability, easy access and minimal space required. Attempts have been made in the past to develop an improved rack. For example, U.S. Pat. No. 6,152,312, dated Nov. 28, 2000 and granted to Nava et al. for a “SUSPENDING SYSTEM FOR VARIOUS TYPES OF HANGING SUPPORTS, IN PARTICULAR DESIGNED TO FIT WARDROBES” describes a System structurally formed by three components, i.e., a section bar, a fastener and a bracket. The section bar comprises a front portion suitable for receiving various kinds of cantilever supports and a rear portion suitable for being assembled on the fastener. The latter is mounted and fastened to a carrier bracket. This suspending system is considered to have several disadvantages. First, the suspending system is cumbersome due to the overall width of the fastener and the carrier bracket. Second, Nava et al. suspending system requires special molds for manufacturing the fastener and the carrier bracket. Third, the smoothness in use of Nava et al. system is reduced due to the sliding friction surfaces. U.S. Pat. No. 4,569,450, dated Feb. 11, 1986 and granted to Dillingham for a “NECKTIE STORAGE WITH FOLDING HANGER MEMBERS” describes an apparel support device particularly adapted for hanging a plurality of neckties. The apparel support device comprises an elongated base member having a longitudinal channel defined by opposed side walls and elongated parallel opposed grooves formed in the side walls. A plurality of hanger members is used. Each hanger member has a shank portion and an integral crank end portion connected to a link at spaced apart intervals on the link. The device comprises as well an elongated channel shaped hanger support having a web portion and spaced apart parallel flanges connected to the web portion and supported at their distal end in the grooves. Crank supports are provided on the parallel side flanges for supporting and retaining the hanger members. Dillingham device has shortcomings. It is complicated and uses numerous components.

- In view of the above considerations based on the identified prior art, there is a need to address rack design concerns and, consequently, to develop a rack that eliminates or, at least, alleviates the foregoing disadvantages and shortcomings.

- Thus, a first objective of the present invention is to provide an extendable rack which is reliable, simple and allows to reduce the material and labor costs. Such savings may be passed to the users, which constitute an undeniable advantage.

- A second objective of this invention is to provide a well-engineered extendable rack characterized by compactness and including a well-tested, mass produced slide.

- Broadly stating, the present invention provides an extendable rack adapted for retaining one or more cantilever support(s) and also adapted for attaching to a panel via a slide. The extendable rack comprises an elongated body including, at one side, means for retaining one or more cantilever support(s); and, at another side, a longitudinal passage adapted for locating almost entirely the slide, the latter being firmly secured with one part to the longitudinal channel and with another part to the panel. In accordance with one aspect of the present invention, the means for retaining one or more cantilever support(s) includes an elongated horizontal body provided with a longitudinal channel, C-shaped in cross section, with a perimeter defined by a standing segment extending, at the top, into a downwardly curved segment and, at the bottom, into an upwardly curved segment, so that opposing niches are formed. Each opposing niche is adapted to capture at least a flange of at least one of several cantilever supports.

- In accordance with another aspect of the present invention, the means for retaining one or more cantilever support(s) includes an elongated horizontal body provided with a central longitudinal wall, extending, close to the top, outwardly and upwardly and forming a longitudinal top recess. Close to the bottom, the central longitudinal wall extends outwardly and downwardly forming a longitudinal bottom recess. The longitudinal top and bottom recesses are adapted to capture at least one flange of at least one of several cantilever supports.

- In accordance with still another aspect of the present invention, the means for retaining one or more cantilever support(s) is provided with a central longitudinal wall extending from midway of its height, outwardly, then upwardly and downwardly, thus forming longitudinal top and bottom recesses adapted to capture at least one flange of at least one of several cantilever supports.

- In a last aspect of the present invention, the elongated horizontal body, having Longitudinal cavities, is provided, at a front extremity, with a finger-pull having upper and lower projections for press fitting into the longitudinal cavities. A cap attached to a back extremity of the elongated horizontal body also comprises upper and lower projections for press fitting into the longitudinal cavities.

- Although the characteristic features of this invention will be particularly pointed out in the claims, the invention itself and the manner in which it may be made and used, may be better understood by referring to the following description taken in connection with the accompanying drawings forming part hereof, wherein like reference numerals refer to like parts throughout the several views in which:

- FIG. 1 illustrates in an exploded, perspective view the extendable rack, according to the present invention;

- FIG. 2 illustrates a transversal cross section of the elongated horizontal body according to a first embodiment;

- FIG. 2′ illustrates the cross section of FIG. 2 together with a cantilever support and a slide, the former and the latter shown in phantom lines;

- FIG. 3 illustrates transversal cross section of the elongated horizontal body according to a second embodiment; and

- FIG. 4 illustrates transversal cross section of the elongated horizontal body according to a third embodiment.

- An

extendable rack 100, as shown in FIG. 1, comprises essentially an elongatedhorizontal body 200. - It is to be agreed, that terms such as “horizontal”, “top”, “bottom”, “outwardly”, “upwardly” and “downwardly” are conventionally used in the present description with reference to the normal position in which

extendable rack 100 would be used. In general, (see FIGS. 2 and 2′)extendable rack 100 has its elongatedhorizontal body 200 provided, in afirst side 202, with alongitudinal channel 204. The latter is adapted for retaining one or more cantilever supports 300. Elongatedhorizontal body 200 is provided in asecond side 208, usually opposed tofirst side 202, with alongitudinal passage 210. - The latter is adapted for locating almost entirely a

slide 400, which is firmly secured with one part tolongitudinal passage 210 and with another part to a panel (not shown). Thus, elongatedhorizontal body 200 is suitable for being glidingly assembled onslide 400. - Referring now in detail to FIGS. 2 and 2′, in a first embodiment, elongated

horizontal body 200 haslongitudinal channel 204, C-shaped in cross section, with a perimeter defined by a standingsegment 212 extending, at the top, into a downwardlycurved segment 214 and, at the bottom, into an upwardlycurved segment 216.Opposing niches 218 are formed. Eachopposing niche 218 is adapted to capture aflange 302 ofcantilever support 300. -

Longitudinal channel 204 extends along elongatedhorizontal body 200. - Elongated

horizontal body 200 haslongitudinal passage 210, U-shaped in cross section, and a length also commensurate with elongatedhorizontal body 200.Longitudinal passage 210 has oneupright segment 220 extending at the top and at the bottom intohorizontal segments upright segment 220 andhorizontal segments longitudinal passage 210 is lesser than a second horizontal dimension L2 of amounted slide 400. Thus, slide 400 extends laterally beyondhorizontal passage 210. A movement of elongatedhorizontal body 200, with respect to a part ofslide 400, which is firmly secured to a fixed panel, is therefore possible. - Each

horizontal segment vertical segments curved segment segments - As a result,

longitudinal cavities longitudinal channel 204 andlongitudinal passage 210 are formed. - Conveniently, a finger-

pull 240 is attached to afront extremity 238 of elongatedhorizontal body 200, while acap 242 is attached to aback extremity 244 of the same. Finger-pull 240 andcap 242 comprise upper andlower projections longitudinal cavities extremities pull 240 and bycap 242. Finger-pull 240 is used to drive elongatedhorizontal body 200 outwardly and inwardly. - A

wall 254, formed between standingsegment 212 andupright segment 220, contains, at each extremity, holes 256 located midway between thehorizontal segments Fasteners 258 disposed inholes 256 are used to attachslide 400 to elongatedhorizontal body 200. - In a second embodiment, (see FIG. 3), an elongated

horizontal body 260 has a centrallongitudinal wall 262. Centrallongitudinal wall 262, close to its top, extends outwardly and upwardly and forms a longitudinaltop recess 264. At the bottom, centrallongitudinal wall 262, close to its bottom, extends outwardly and downwardly forming alongitudinal bottom recess 266. The purpose of longitudinal top andbottom recesses opposite flanges 304. - The remaining features of elongated

horizontal body 260 are essentially similar with those described in elongatedhorizontal body 200. - In a third embodiment, (see FIG. 4), an elongated

horizontal body 268 has a centrallongitudinal wall 270. The latter extends, from midway of its height, outwardly, then upwardly and downwardly forming longitudinal top andbottom recesses bottom recesses opposite flanges 306. - The remaining features of elongated

horizontal body 268 are essentially similar with those described in elongatedhorizontal body 200. - Elongated

horizontal bodies - Since

slider 400 is of a conventional and known design, mass-produced in different sizes, a further explanation of the same appears to be unnecessary. For example, precision ball bearing drawer slides are sold under the trademark Accuride™ by Accuride, Santa Fe Springs, Calif. - Cantilever supports 300 are designed in various shapes to accommodate different items, such as neckties, belts, trays etc.

- As required, detailed embodiments of the present invention are disclosed herein; however, it is to be understood that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various forms. Therefore, specific structural and functional details disclosed therein are not to be interpreted as limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the present invention in virtually any appropriately detailed structure.

Claims (5)

1. Expandable rack, adapted for retaining one or more cantilever support(s) and also adapted for attaching to a panel via a slide, comprising, in combination

an elongated body including at one side

means for retaining said one or more cantilever support(s); and

at another side

a longitudinal passage adapted for locating almost entirely said slide, which is firmly secured with one part to said longitudinal passage and with another part to said panel.

2. Expandable rack, as defined in claim 1 , wherein said means for retaining one or more cantilever support(s) includes

said elongated horizontal body provided with a longitudinal channel, C-shaped in cross section, with a perimeter defined by a standing segment extending, at the top, into a downwardly curved segment and, at the bottom, into an upwardly curved segment, so that opposing niches are formed, each opposing niche being adapted to capture at least a flange of at least one of said cantilever supports.

3. Expandable rack, as defined in claim 1 , wherein said means for retaining one or more cantilever support(s) includes

said elongated horizontal body provided with a central longitudinal wall extending, close to its top, outwardly and upwardly and forming a longitudinal top recess and, at the bottom,

said central longitudinal wall extends, close to its bottom, outwardly and downwardly forming a longitudinal bottom recess,

said longitudinal top and bottom recesses being adapted to capture at least one flange.

4. Expandable rack, as defined in claim 1 , wherein said means for retaining or more cantilever support(s) includes

an elongated horizontal body provided with a central longitudinal wall extending from midway of its height, outwardly, then

upwardly and downwardly, thus forming longitudinal top and bottom recesses adapted to capture at least one flange of at least one of said cantilever supports.

5. Expandable rack, as defined in claim 1 , wherein said means for retaining or more cantilever support(s) includes

an elongated horizontal body provided with longitudinal cavities;

a finger-pull having upper and lower projections for press fitting into said longitudinal cavities, at a front extremity of said elongated horizontal body; and

a cap attached to a back extremity of said elongated horizontal body, said cap also comprises said upper and lower projections for press fitting into said longitudinal cavities.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/122,653 US6698603B2 (en) | 2002-04-15 | 2002-04-15 | Extendable rack |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/122,653 US6698603B2 (en) | 2002-04-15 | 2002-04-15 | Extendable rack |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20030192845A1 true US20030192845A1 (en) | 2003-10-16 |

| US6698603B2 US6698603B2 (en) | 2004-03-02 |

Family

ID=28790590

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/122,653 Expired - Lifetime US6698603B2 (en) | 2002-04-15 | 2002-04-15 | Extendable rack |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US6698603B2 (en) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060011568A1 (en) * | 1999-11-09 | 2006-01-19 | Remmers Lee E | Track-mounted shelving systems and components |

| US7137515B1 (en) * | 2005-07-20 | 2006-11-21 | Stephen Lawson | Extendable storage rack |

| US7261213B2 (en) | 2004-09-13 | 2007-08-28 | Bilco Products Acquisition, Llc | Closet partition system |

| USD604978S1 (en) * | 2008-03-14 | 2009-12-01 | Illinois Tool Works Inc. | Wall mountable rail system |

| USD604979S1 (en) * | 2008-03-14 | 2009-12-01 | Illinois Tool Works Inc. | Rail system arm |

| US20100133213A1 (en) * | 2005-07-20 | 2010-06-03 | Jui-Chien Kao | Suspension display rack |

| CN105299431A (en) * | 2015-10-23 | 2016-02-03 | 重庆华万伦电器有限公司 | Double-sided hanging aluminum alloy extrusion board for exhibition |

| US20170141547A1 (en) * | 2012-07-25 | 2017-05-18 | Friedrich Lütze GmbH | Mounting system for arranging electric devices, for example, especially in switchgear cabinets |

| US9763515B2 (en) * | 2016-02-18 | 2017-09-19 | Brian J. Fratilla | Wall mounted modular wine rack storage apparatus |

| US20180266754A1 (en) * | 2017-03-16 | 2018-09-20 | Sub-Zero, Inc. | Door for a freezer drawer |

| US10408528B2 (en) | 2017-03-16 | 2019-09-10 | Sub-Zero, Inc. | Single door covering a freezer compartment and a refrigerator compartment |

| US10799041B1 (en) * | 2019-03-26 | 2020-10-13 | Tag Hardware Systems Ltd. | Wall mounted organizer rack |

| US10993565B2 (en) * | 2017-10-23 | 2021-05-04 | Fifi Lynn Larney | Stemless wine glasses rack |

| US20220000265A1 (en) * | 2018-11-16 | 2022-01-06 | Parallax Group International, Llc | Wall and ceiling track system for mounting devices |

Families Citing this family (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7341231B2 (en) * | 2003-09-29 | 2008-03-11 | Lund Boat Company | Accessory mounting system for a boat |

| US20050247653A1 (en) * | 2004-05-06 | 2005-11-10 | Dr. Brooks Innovations, L.L.C. | System for holding implements |

| US20070114195A1 (en) * | 2005-11-23 | 2007-05-24 | Inventions Dimitri Enr. | Rack for stem glasses |

| DE602006015597D1 (en) * | 2006-01-13 | 2010-09-02 | Whirlpool Co | cooling unit |

| US7913862B2 (en) * | 2006-05-04 | 2011-03-29 | Hallmark Cards, Incorporated | Display tray with movable dividers |

| US20080035589A1 (en) * | 2006-08-08 | 2008-02-14 | Db Studios, Inc, | Dispensing slidable tray systems and methods |

| US7775379B2 (en) * | 2006-10-03 | 2010-08-17 | American Greetings Corporation | Retail display for greeting cards |

| US20090145866A1 (en) * | 2007-12-10 | 2009-06-11 | Michael Harmik Panosian | Wall organizing system |

| USD580745S1 (en) | 2008-03-14 | 2008-11-18 | Illinois Tool Works Inc. | Hook |

| US8066130B2 (en) * | 2008-03-14 | 2011-11-29 | Illinois Tool Works Inc. | Storage system |

| USD589728S1 (en) | 2008-03-14 | 2009-04-07 | Illinois Tool Works Inc. | Receptacle |

| USD619881S1 (en) | 2008-03-14 | 2010-07-20 | Illinois Tool Works Inc. | Hook |

| USD580744S1 (en) | 2008-03-14 | 2008-11-18 | Illinois Tool Works Inc. | Hook |

| USD589278S1 (en) | 2008-03-14 | 2009-03-31 | Illinois Tool Works Inc. | Holder |

| USD632114S1 (en) * | 2009-08-05 | 2011-02-08 | Harry Anthony Roenick | Rail |

| DE102009043767A1 (en) * | 2009-09-30 | 2011-03-31 | GM Global Technology Operations, Inc., Detroit | Fastening system for fastening objects to a backrest of a motor vehicle seat |

| USD627179S1 (en) * | 2009-10-13 | 2010-11-16 | Morgan Olson Corporation | Rail for a shelving system |

| US8491044B2 (en) | 2010-03-03 | 2013-07-23 | Morgan Olson Corporation | Infinitely adjustable, modular shelving for vehicles |

| US20110254420A1 (en) * | 2010-04-16 | 2011-10-20 | Kevin Esparza | Adjustable Cabinet Drawer Pullout System |

| WO2011140074A1 (en) | 2010-05-03 | 2011-11-10 | Illinois Tool Works Inc. | Storage system |

| CN102448259A (en) * | 2010-10-08 | 2012-05-09 | 鸿富锦精密工业(深圳)有限公司 | cabinet |

| US9427619B2 (en) | 2013-09-20 | 2016-08-30 | James Wesley Franks | Physical therapy system with interchangeable heads |

| US10300833B2 (en) | 2014-01-29 | 2019-05-28 | Dowco, Inc. | Resilient cover clip |

| US9629457B2 (en) | 2014-06-20 | 2017-04-25 | Kohler Co. | Bathing area accessories |

| US9295326B2 (en) * | 2014-08-25 | 2016-03-29 | Jeff Sassman | Guitar storage and display rack |

| USD773695S1 (en) | 2014-09-29 | 2016-12-06 | Dowco, Inc. | Rail |

| USD773691S1 (en) | 2014-09-29 | 2016-12-06 | Dowco, Inc. | Keder |

| US9545716B2 (en) * | 2015-03-18 | 2017-01-17 | Chih-Chien Hsieh | End piece of a tool suspension rack |

| CA3034109C (en) * | 2016-08-09 | 2021-06-15 | Peter SCHMID-KOEMMERLING | Device for mounting a preferably planar object to a building structure |

| TWI698309B (en) * | 2019-06-27 | 2020-07-11 | 謝志堅 | Tool rack |

| US10858071B1 (en) | 2019-10-09 | 2020-12-08 | Dowco, Inc. | Universal cover |

| USD899091S1 (en) | 2019-10-24 | 2020-10-20 | Grip Holdings Llc | Elongated alternate rail body of a tool holding device |

| US11253086B1 (en) * | 2020-08-11 | 2022-02-22 | Chin-Chen Huang | Hanging structure for painting tool |

| EP4275847B1 (en) | 2022-05-13 | 2024-08-28 | Techtronic Cordless GP | Rail storage system with end caps |

| USD1076661S1 (en) | 2022-05-13 | 2025-05-27 | Techtronic Cordless Gp | Rail end cap set |

| US20250136018A1 (en) * | 2023-10-30 | 2025-05-01 | GM Global Technology Operations LLC | Mounting rail for vehicle accessories |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4869378A (en) * | 1988-08-29 | 1989-09-26 | Hospital Systems, Inc. | Mounting rail for hospital appliances and bracket |

| US5429252A (en) * | 1993-11-02 | 1995-07-04 | Liu; Hung-Yang | Versatile rail for supporting objects in kitchen |

| US5412912A (en) * | 1994-03-15 | 1995-05-09 | Bo-Man, Inc. | Modular slatwall assembly |

| ATE227535T1 (en) * | 1996-05-21 | 2002-11-15 | Terragni Ezio | HANGING SYSTEM FOR VARIOUS HANGING EQUIPMENT, ESPECIALLY FOR WARDROBE |

| US5794795A (en) * | 1996-06-17 | 1998-08-18 | Stemmons; William L. | Framework system for electrical/electronic controls |

| US5740927A (en) | 1997-01-09 | 1998-04-21 | Zag Ltd. | Tool rack |

| CA2200422C (en) | 1997-03-19 | 2002-05-07 | Jan B. Leurdijk | Storage track system |

| US5904412A (en) * | 1997-04-23 | 1999-05-18 | Accuride International, Inc. | Drawer slide mounting bracket with gussetted mounting tab |

| CA2223852C (en) | 1997-12-05 | 2004-01-20 | George Albert Neil | Track and hook arrangement for storing a variety of articles |

| CA2245809A1 (en) | 1998-08-27 | 2000-02-27 | Vic De Zen | Support and attachment wall mount assembly |

| US6227387B1 (en) | 1999-08-17 | 2001-05-08 | Robert J. Rose | Apparatus for supporting utensils |

| JP2001088668A (en) * | 1999-09-21 | 2001-04-03 | Aisin Seiki Co Ltd | Brake control device |

-

2002

- 2002-04-15 US US10/122,653 patent/US6698603B2/en not_active Expired - Lifetime

Cited By (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060011568A1 (en) * | 1999-11-09 | 2006-01-19 | Remmers Lee E | Track-mounted shelving systems and components |

| US7261213B2 (en) | 2004-09-13 | 2007-08-28 | Bilco Products Acquisition, Llc | Closet partition system |

| US7137515B1 (en) * | 2005-07-20 | 2006-11-21 | Stephen Lawson | Extendable storage rack |

| US20100133213A1 (en) * | 2005-07-20 | 2010-06-03 | Jui-Chien Kao | Suspension display rack |

| US7980400B2 (en) * | 2005-07-20 | 2011-07-19 | Jui-Chien Kao | Suspension display rack |

| USD604978S1 (en) * | 2008-03-14 | 2009-12-01 | Illinois Tool Works Inc. | Wall mountable rail system |

| USD604979S1 (en) * | 2008-03-14 | 2009-12-01 | Illinois Tool Works Inc. | Rail system arm |

| US20170141547A1 (en) * | 2012-07-25 | 2017-05-18 | Friedrich Lütze GmbH | Mounting system for arranging electric devices, for example, especially in switchgear cabinets |

| US9948072B2 (en) * | 2012-07-25 | 2018-04-17 | Friedrich Luetze Gmbh | Mounting system for arranging electric devices, for example, especially in switchgear cabinets |

| CN105299431A (en) * | 2015-10-23 | 2016-02-03 | 重庆华万伦电器有限公司 | Double-sided hanging aluminum alloy extrusion board for exhibition |

| US9763515B2 (en) * | 2016-02-18 | 2017-09-19 | Brian J. Fratilla | Wall mounted modular wine rack storage apparatus |

| US20180266754A1 (en) * | 2017-03-16 | 2018-09-20 | Sub-Zero, Inc. | Door for a freezer drawer |

| US10234194B2 (en) * | 2017-03-16 | 2019-03-19 | Sub-Zero, Inc. | Door manufacturing method for a freezer drawer |

| US10408528B2 (en) | 2017-03-16 | 2019-09-10 | Sub-Zero, Inc. | Single door covering a freezer compartment and a refrigerator compartment |

| US10993565B2 (en) * | 2017-10-23 | 2021-05-04 | Fifi Lynn Larney | Stemless wine glasses rack |

| US20220000265A1 (en) * | 2018-11-16 | 2022-01-06 | Parallax Group International, Llc | Wall and ceiling track system for mounting devices |

| US12232616B2 (en) * | 2018-11-16 | 2025-02-25 | The Parallax Group International, Llc | Wall and ceiling track system for mounting devices |

| US20250261755A1 (en) * | 2018-11-16 | 2025-08-21 | The Parallax Group International, Llc | Wall and ceiling track system for mounting devices |

| US10799041B1 (en) * | 2019-03-26 | 2020-10-13 | Tag Hardware Systems Ltd. | Wall mounted organizer rack |

Also Published As

| Publication number | Publication date |

|---|---|

| US6698603B2 (en) | 2004-03-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6698603B2 (en) | Extendable rack | |

| US6871749B2 (en) | Extendable/retractable valet rack | |

| US5855279A (en) | Hanging shoe rack | |

| US20080210827A1 (en) | Display hanger for curtain rod | |

| US7243884B2 (en) | Tilt-out laundry bag assembly | |

| US6230907B1 (en) | Shelving system | |

| US6152312A (en) | Suspending system for various types of hanging supports, in particular designed to fit wardrobes | |

| US6679392B1 (en) | Sliding hanger assembly | |

| US6464086B1 (en) | Hanging modular storage unit | |

| US3233852A (en) | Supporting shelf assembly | |

| US20140284291A1 (en) | Adjustable storage system for clothing | |

| US7137515B1 (en) | Extendable storage rack | |

| US6168031B1 (en) | Hanging file support apparatus | |

| US20050230577A1 (en) | Hanger for use on metal rack | |

| US3225940A (en) | Closet shelf and hanger | |

| SK285709B6 (en) | Storage assembly with expandable double hanging closet | |

| US20170332782A1 (en) | Contractible storage apparatus | |

| US5934524A (en) | Multiple purpose garment and accessory rack | |

| US3358847A (en) | Garment rack | |

| US5725110A (en) | Space organizing system | |

| US5191984A (en) | Display or storage rack for neckties and the like | |

| KR102362961B1 (en) | System furniture accessory hanger | |

| US7281634B2 (en) | Side slider for storing or organizing objects | |

| CA2374145C (en) | Extendable rack | |

| US5551580A (en) | Slidable storage wall-mount |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STCF | Information on status: patent grant |

Free format text: PATENTED CASE |

|

| AS | Assignment |

Owner name: LAWSON, STEPHEN, CANADA Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:ISFELD, CHRISTOPHER;REEL/FRAME:019725/0677 Effective date: 20070726 |

|

| REMI | Maintenance fee reminder mailed | ||

| FPAY | Fee payment |

Year of fee payment: 4 |

|

| SULP | Surcharge for late payment | ||

| FPAY | Fee payment |

Year of fee payment: 8 |

|

| FPAY | Fee payment |

Year of fee payment: 12 |