US1859918A - Arc guide for metallic vapor rectifiers - Google Patents

Arc guide for metallic vapor rectifiers Download PDFInfo

- Publication number

- US1859918A US1859918A US324181A US32418128A US1859918A US 1859918 A US1859918 A US 1859918A US 324181 A US324181 A US 324181A US 32418128 A US32418128 A US 32418128A US 1859918 A US1859918 A US 1859918A

- Authority

- US

- United States

- Prior art keywords

- guides

- cells

- cathode

- arc guide

- container

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 9

- 238000005192 partition Methods 0.000 description 7

- 230000005494 condensation Effects 0.000 description 5

- 238000009833 condensation Methods 0.000 description 5

- 210000005244 lower chamber Anatomy 0.000 description 5

- 238000010276 construction Methods 0.000 description 4

- 239000010406 cathode material Substances 0.000 description 3

- 229910052753 mercury Inorganic materials 0.000 description 3

- 229940041669 mercury Drugs 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 241000906446 Theraps Species 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010891 electric arc Methods 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J13/00—Discharge tubes with liquid-pool cathodes, e.g. metal-vapour rectifying tubes

- H01J13/02—Details

- H01J13/48—Circuit arrangements not adapted to a particular application of the tube and not otherwise provided for

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H6/00—Buildings for parking cars, rolling-stock, aircraft, vessels or like vehicles, e.g. garages

- E04H6/08—Garages for many vehicles

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J13/00—Discharge tubes with liquid-pool cathodes, e.g. metal-vapour rectifying tubes

- H01J13/50—Tubes having a single main anode

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2893/00—Discharge tubes and lamps

- H01J2893/0072—Disassembly or repair of discharge tubes

- H01J2893/0088—Tubes with at least a solid principal cathode and solid anodes

Definitions

- This invention relates-to improvements in metallic vapor electric current'rectifier apparatus; I i

- Metallic vapor rectifiers of the character described are usually provided with a mercury condensing chamber or dome 'WlllCl'lfllIl metal container rectifiers for large outputs, extends into the Containers.

- a mercury condensing chamber or dome 'WlllCl'lfllIl metal container rectifiers for large outputs extends into the Containers.

- the sleeves above mentioned' have been omitted and replaced] by radially outwardly extending walls which divided the annular anode space between the container wall and the condensation dome into substantially sector shaped cells.

- the undesirable features of the prior con-' 7 struction may be avoided by enclosing the sector shaped anode cellsorspaces by a partition separating such spaces or cells from that portion of the containerincluding the cathode; A passageway'for mercury vapor between the cathode space and the anode cells is formed by water cooled are guides 324,181, and in Germ any DeceinIier IlB, 1927. i v

- Aifurther obj ect'of theinvention is to pro; vide an electric current rectifier construction in which eachiof the anodes is separately en closed, a V Another object of the invention'is to pro: v1de anelectric current rectifier construction inwhicha restricted passage between the cathode chamber thereof and theseparate anode chambers prevents entrance'of 'an -excessive amount 'of Inercuryvapor'andserves 1 t as an arc guide.”

- the double-walled sleeves or. are guides 13 are set into the openings through partition 11 in a mercury-tight relation so that mercury vapor must pass through the arc guides to enter theanode cells.

- the cells are accordingly under a lower Va por pressure than was the case in construetions proposed heretofore, thus providing for operation of the apparatus with a greater degree of safety.

- the condensation of mer cury vapor onlthe are guides 13 may be increased by increasing the surface of the walls of the guidesin any well-known manner, such as providing the same with ribs or fins.

- the invention'claimed is: I c

- a container In an electric current rectifier of the metalliciva'por type, a container,'a hollow wall V horizontalwall connecting with said dependingwall, a plurality of radial wlalls connectmg with said depending and said horizontal walls to form a plurality ofvapor expansion tion afiixed to said wall and to the said containcr to efi'ect division of the said container into upper and lower chambers, a vaporizable cathode supported within the said lower a chamber, a plurality of radially extending Walls aflixed.

- tallic vapor type, arcontainer a condensing chamber having a wall depending vertically into the said container from the top wall thereof, a horizontally extending partition affixed to said wall and to the said container to effect the division of the said container into upper and lower chambers, avaporizable cathode supported within the said lower chamber, a plurality of anodes supported within the said upper chamber, a plurality of spaced double-walled arc guides affixed to the said partition and constituting restricted passages for the flow of cathode material from the said lower chamber into the saidupper chamber, meansqfor effecting the flow of cooling medium'between the said walls of said are guides to cause condensation of vaporized cathode material flowing fromthe said lowerchamber into the said passages, and a plural-V ity of radially extending partitionsaffixed to said walls and said horizontally extending partition to form cells about the said anodes and to permit expansion of cathode material flolvlving through the said guides into thesaid ce

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Apparatus Associated With Microorganisms And Enzymes (AREA)

Description

y 1932- A. GAU DENZI ARC GUIDE FOR METALLIC VAPOR RECTIFIERS Filed Dec. 6, 1928 Inventor Arthur Gaudenzi By (D Attorney Patented May 24, 1932 y ms ARTHUR GAUDENZIQOF BADEN SWITZERLANDVASSIGNOR TO nKrIENGEsELLscnArr BROWN BOVERI ,& GIE., OF BADE'N' SWITZEBLAND A JOINT-STOCK GOMZPANYTOIF' i v SWITZERLAND And GUIDE non METALLIC VAPOR Ree n -Inn's Application filed December 6,1928, Serial No.

This invention relates-to improvements in metallic vapor electric current'rectifier apparatus; I i

,In apparatus of the character referred to, ithas been proposed heretofore to enclose the anodes within sleeves in order to reduce the possibility of back-firingwhich may occur when a particular anode is not in operation. I Such sleeves have in some constructionsbeen made of insulating material, which wasunsatisfactory because of the low mechanical strength of the material and because radiation ofheat' fromthe anodes was prevented thereby. Iron Tsleeveshave'also been proposed, but'were found to be unsatisfactory because of the danger of -short-cir-' cuiting between the sleeves and the anodes, induced by the occlusion of gases-from the sleeve and the collection of positive ions thereabout when the particular anode is out of operation. i y

Metallic vapor rectifiers of the character described are usually provided with a mercury condensing chamber or dome 'WlllCl'lfllIl metal container rectifiers for large outputs, extends into the Containers. In rectifiers with a condensation dome extendingintothe rectifyingchamber, the sleeves above mentioned'have been omitted and replaced] by radially outwardly extending walls which divided the annular anode space between the container wall and the condensation dome into substantially sector shaped cells. These constructions are undesirable because an excessive amount of mercury vapor may collect withinthe sleeves or within the anode cells, thereby rending the condensation of mercury much more likely in the space closely adja cent the anode and causing back-firing therein and because no provision is made for are guides which are desirable to maintain the arc in the desired direction. 1

The undesirable features of the prior con-' 7 struction may be avoided by enclosing the sector shaped anode cellsorspaces by a partition separating such spaces or cells from that portion of the containerincluding the cathode; A passageway'for mercury vapor between the cathode space and the anode cells is formed by water cooled are guides 324,181, and in Germ any DeceinIier IlB, 1927. i v

in such partitions which guides :prevehtentrance of an excessive amount of mercury vapor-into the anode; cellsandmaintain the 7 electric arc'in the propertdirectioml' 1 I, v

It'is, therefore, among the objects-of the 65 present invention to provide airect'ifier con tainer construction in which the anodes of an electric current" rectifierare shutofi from the. cathode thereof. I

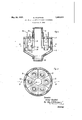

Aifurther obj ect'of theinvention is to pro; vide an electric current rectifier construction in which eachiof the anodes is separately en closed, a V Another object of the invention'is to pro: v1de anelectric current rectifier construction inwhicha restricted passage between the cathode chamber thereof and theseparate anode chambers prevents entrance'of 'an -excessive amount 'of Inercuryvapor'andserves 1 t as an arc guide." i f 'Other objects and advantages will appear to thoseskillediin the art upon consideration of theufollowing description and the draw ingsaccompanyingari forming a part of this" ..v specification, and wherein" a 7 Figure 1" is: a vertical cross sectional-1 view 7 of apparatus embodying the present improvecondensation dome 6, also Water -jacketed" for cooling, extends upwardly afid F down== wardly from therap late: ,7 of-the rectifier, container eat approximately the central thereof; The downwardly erltend" iw'all the condensation-dome 'and the e error T11 of the-rectifier chambea form an ann' space within which the usual anodes 8- re arrangedi e mpM IityerQ Q-MS 9 extend radiaH one;

wardly from the downwardly extendin wall: 7 offthecondensation domeandare"joinedi to the" sidewallsei tlre rectifier-container all 7 vided with are guides 13, which are formed as a double-walled hollow sleeve, and are connected to an inlet conduit 14 and an outlet conduit 16' connected to a suitable source 7 of co'olingmedium.

The double-walled sleeves or. are guides 13 are set into the openings through partition 11 in a mercury-tight relation so that mercury vapor must pass through the arc guides to enter theanode cells. A portion of the mercury vapor arising from the cathode v12 'is condensed before its entrance into the anode cells by the water-cooled are guides 13, so that onlyrelatively small portions of the mercury vapor actually enter these cells.

I The cells are accordingly under a lower Va por pressure than was the case in construetions proposed heretofore, thus providing for operation of the apparatus with a greater degree of safety. The condensation of mer cury vapor onlthe are guides 13 may be increased by increasing the surface of the walls of the guidesin any well-known manner, such as providing the same with ribs or fins.

; Although but one embodiment of the invention hasbeen shown and described, it will be understood that various changes may be made, such as in the size, shape and arrange-' 'ments of the parts withoutdeparting from the spirit ofthe inventionor the'scope of the I depending from the top of said container,"a

The invention'claimed is: I c

In an electric current rectifier of the metalliciva'por type, a container,'a hollow wall V horizontalwall connecting with said dependingwall,a plurality of radial wlalls connectmg with said depending and said horizontal walls to form a plurality ofvapor expansion tion afiixed to said wall and to the said containcr to efi'ect division of the said container into upper and lower chambers, a vaporizable cathode supported within the said lower a chamber, a plurality of radially extending Walls aflixed. to the said 'walls to divide the said upper chamber into a plurality of cells, an anode supported within each of the said cells, a plurality of double walled are guides" aiiixed to the said'partition to constitute re'-' 3. In an electric current rectifier of the.me--

tallic vapor type, arcontainer, a condensing chamber having a wall depending vertically into the said container from the top wall thereof, a horizontally extending partition affixed to said wall and to the said container to effect the division of the said container into upper and lower chambers, avaporizable cathode supported within the said lower chamber, a plurality of anodes supported within the said upper chamber, a plurality of spaced double-walled arc guides affixed to the said partition and constituting restricted passages for the flow of cathode material from the said lower chamber into the saidupper chamber, meansqfor effecting the flow of cooling medium'between the said walls of said are guides to cause condensation of vaporized cathode material flowing fromthe said lowerchamber into the said passages, and a plural-V ity of radially extending partitionsaffixed to said walls and said horizontally extending partition to form cells about the said anodes and to permit expansion of cathode material flolvlving through the said guides into thesaid ce 3. a In testimony whereof I have hereunto subscribed my name this 15th day of November ArD. 1928. v a

' .A TH R-G UD N L.

cells, apluralityof anodes within said con-. 7

said cells, a vaporizable metallic cathode bee low said horizontal wall, and double-walled are guides connecting each anode cell with the space occupied by said cathode, said are guides being adapted to be cooled by aimedium flowing therethrough, for condensing vgporpa'ssing from the cathode to the'an- Q68.- fl T 1 2. In an electric current rectifier of. the

" f metallievap'or type, a container, a' 'condens V 1 ing chamber having :a wall depending vertia callyinto the "said:'container'from the-top wall thereof, a horizontally-extending parti

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE1859918X | 1927-12-19 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1859918A true US1859918A (en) | 1932-05-24 |

Family

ID=7746435

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US324181A Expired - Lifetime US1859918A (en) | 1927-12-19 | 1928-12-06 | Arc guide for metallic vapor rectifiers |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1859918A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2793312A (en) * | 1952-12-24 | 1957-05-21 | Rca Corp | Electron gun structure |

-

1928

- 1928-12-06 US US324181A patent/US1859918A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2793312A (en) * | 1952-12-24 | 1957-05-21 | Rca Corp | Electron gun structure |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1859918A (en) | Arc guide for metallic vapor rectifiers | |

| US2089542A (en) | Electric vacuum-discharge apparatus | |

| US2172221A (en) | Vapor-electric device | |

| US2156048A (en) | Electric discharge device | |

| US1811521A (en) | Electric current rectifier | |

| US1847646A (en) | Electric power rectifier cathode construction | |

| US2595634A (en) | Pressurized alkali-metal tube | |

| US1894806A (en) | Arc discharge device | |

| US1871745A (en) | Mercury-arc rectifier | |

| US1919263A (en) | Rectifier | |

| US2011638A (en) | Electrolytic cell | |

| US1802185A (en) | Mercury-arc rectifier | |

| US2290913A (en) | Electric discharge tube | |

| US3246194A (en) | Steel-capsuled mercury-vapour discharge vessel | |

| US1942317A (en) | Metal vapor rectifier for heavy currents | |

| SU50399A1 (en) | Arc straightener | |

| US1871434A (en) | Electric current rectifier | |

| US1729463A (en) | Rectifier tank | |

| US2210682A (en) | Mercury arc rectifier | |

| US2196401A (en) | Baffle for ignitrons | |

| US2431152A (en) | Mercury vapor tube | |

| GB821649A (en) | Improvements in or relating to single-anode mercury-pool cathode rectifiers | |

| US2479853A (en) | Current converter | |

| GB555126A (en) | Improvements in or relating to vapour electric converters | |

| GB510993A (en) | Improvements in and relating to the coating of articles by means of thermally vaporised material |