US1857039A - Garnett or batting machine - Google Patents

Garnett or batting machine Download PDFInfo

- Publication number

- US1857039A US1857039A US438468A US43846830A US1857039A US 1857039 A US1857039 A US 1857039A US 438468 A US438468 A US 438468A US 43846830 A US43846830 A US 43846830A US 1857039 A US1857039 A US 1857039A

- Authority

- US

- United States

- Prior art keywords

- rolls

- pins

- roll

- machine

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004140 cleaning Methods 0.000 description 14

- 239000004744 fabric Substances 0.000 description 6

- 238000009950 felting Methods 0.000 description 4

- 230000006378 damage Effects 0.000 description 3

- 208000027418 Wounds and injury Diseases 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 208000014674 injury Diseases 0.000 description 2

- TVEXGJYMHHTVKP-UHFFFAOYSA-N 6-oxabicyclo[3.2.1]oct-3-en-7-one Chemical group C1C2C(=O)OC1C=CC2 TVEXGJYMHHTVKP-UHFFFAOYSA-N 0.000 description 1

- 238000009960 carding Methods 0.000 description 1

- 239000002223 garnet Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01G—PRELIMINARY TREATMENT OF FIBRES, e.g. FOR SPINNING

- D01G15/00—Carding machines or accessories; Card clothing; Burr-crushing or removing arrangements associated with carding or other preliminary-treatment machines

- D01G15/76—Stripping or cleaning carding surfaces; Maintaining cleanliness of carding area

- D01G15/80—Arrangements for stripping cylinders or rollers

Definitions

- This invention relates broadly totirarnett or batting machines, and more partlcularly to apparatus for cleaning the doffer rolls of such machines.

- a particular object of the invention is to provide cleaning apparatus of the kind described which will obviate the necessity of cleaning the doffer rolls manually without the attendant risks of injury to the operator.

- One form of the invention is embodied in a batting-machine. or Garnett machine provided with two dofi'er rolls, the cloth covering of which comprises the usual bent wires or pins. Associated with each dofi'er roll 1s an adjustably mounted brush or cleaning roll having numerous bristles or wires projecting therefrom and adapted to clean the bent wires or pins'of the dofl'er rolls. The cleaning rolls are driven in the same direction asthe dofi'errolls so that the contacting parts of their surfaces travel in opposite'directions.

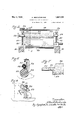

- Figure 1 isa somewhat diagrammatic elevation of .a Garnett or felting machine embodying the invention.

- Fig. 2 is a somewhat diagrammatic longitudinal vertical section taken through the im- Fig. 4 is an enlarged section taken on line Fig. 5 is a section taken on line 55 of Fig. 4.

- ' ig. 6 is afragmentary elevation of the-side of the -machine opposite to that shown in Fig. 1, and

- Fig. 7 is a fragmentary elevation of one of the cleaning brushes, the bristles or wires being partly broken away to illustrate certain details of construction.

- the reference character 10 designates the frame of a .Garnett o'r felting machine adapt? ed to form batting from linters, .or the equiv.-

- the usual hopper 11' is positioned, into which hopper the linters, or the equivalent, are fed.

- the hopper contains the usual spike apron (not shown) and the linters are delivered from the hopper a feed apron 12.

- the feed apron l2 delivers the feltingmaterial to feed rolls 14 rotatably mounted in the frame 10, the feed rolls being arranged to co-operate with a lickerin roll15, alsojournaled in the frame 10.

- the usual cylinders '17 and 18 and-the usual doffer rolls 20 and 21, together with the usual fancy and fancy stripper rolls are also jou'rnaled in the frame 10. From the doffer roll 20, the felting material passes to the runway apron24. p

- the runway apron 24 is driven by a roll 25 mounted on a shaft26' which is journaled source of power.

- Apinion 27 fixed to the shaft 2.6 meshes with a gear 28 "mounted .on a shaft 29 which carries thedoffer roll 20 (seeFig. 1).

- a sprocket 31 mounted on the shaft 29 meshes with a sprocket chain 32 which meshes with a sprocket 33 secured to a shaft v34 which carries the middle doffer roll 21.

- the direction in which the 'dofiier rolls rotate is indicated by arrows in Fig. 2.

- the posts 47 I and 48 are rotatably journaled in bracket tated in either direction toraise-orlower the 7 brush or roll 43 at will.

- each shaft 44 is provided with a sprocket-wheel 59 which is operatively connected by a sprocket chain 60vto a sprocket-wheel 61 mounted upon the associatedfancy-stripper roll shaft 38 or 39;

- Each cleaning roll is rotated in the same direction as its associated Take-upmechanism comprising an idler- Troll, or sheave, 63 is provided for each sprocket chain to takeup play in the sprocket chain when the associated roll 43 is raised orlowered.

- the doffer rolls are covered with the usual cloth from which bent wires or pins project, the pins being identified by the reference character 65.

- the cleaning rolls 43 preferably comprise rubberized fabric, or rubber wrapped around the shafts 44 and provided with numerous bristles or wires 66 which enter the spaces between the bent pins during the'cleaning operation and remove linte-rs therefrom.

- the rubberized cloth, or rubber, wrapped around the shafts 44 is preferablyin the form of strips 67 which have their ends rigidly secured tothe shafts 44 and which are wrapped spirally around the shafts (see Fig. 7).

- the cleaning rolls may be brought into contact therewith at predetermined intervals, if itis so desired.

- the linters are; advanced. through the apparatus, and through the action of the cylinders 17 and 18, the dofier rolls 20 and 21 and the accompanying worker rolls, fancy-rolls andfancy-stripperrolls are matted into felting or batting. Linters will tendito adhere to the pins 65 and are brushed therefrom by the cleaning rolls 43.

- Another advantage of the invention is that the dofi'er rolls may be cleaned continuously, or at such intervals that the linters do not have an opportunity to mat between the pins 65 and, therefore, it is unnecessary to later scrape the pins with such force as to damage or de stroythem.

- the invention is particularly advantageous as it obviates the necessity of having the opr erator clean the doffer rolls with a brush, or

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Preliminary Treatment Of Fibers (AREA)

Description

y 1932- A. BRECKENRIDGE 57,039

GARNETT OR BATTING MACHINE Filed March 24, 1950 2 Sheets-Sheet 2 A A u AAAAA Patented May 3, 1932 UNITED STATES PATENT F E ALBERT BRECKENRIDGE, or crrxcaco, ILLINOIS, Assrenoaro summon Ann BEDDING co, A conronnrronor ILLINOIS GARNET! BATTING MACHINE Application filed March 24,1930. sci-m nt. 438,468.

This invention relates broadly totirarnett or batting machines, and more partlcularly to apparatus for cleaning the doffer rolls of such machines.

A particular object of the invention is to provide cleaning apparatus of the kind described which will obviate the necessity of cleaning the doffer rolls manually without the attendant risks of injury to the operator.

Another particular object ofthe invention '44 of Fig. 1.

is to provide cleaning apparatus of the kind described which will lengthen the life of the cloth or covering ofthe dofi'er rolls. 7 One form of the invention is embodied in a batting-machine. or Garnett machine provided with two dofi'er rolls, the cloth covering of which comprises the usual bent wires or pins. Associated with each dofi'er roll 1s an adjustably mounted brush or cleaning roll having numerous bristles or wires projecting therefrom and adapted to clean the bent wires or pins'of the dofl'er rolls. The cleaning rolls are driven in the same direction asthe dofi'errolls so that the contacting parts of their surfaces travel in opposite'directions.

Many other objects and advantages will appear as this description progresses,-reference being had to the accompanying drawings, wherein: I

Figure 1 isa somewhat diagrammatic elevation of .a Garnett or felting machine embodying the invention.

Fig. 2 is a somewhat diagrammatic longitudinal vertical section taken through the im- Fig. 4 is an enlarged section taken on line Fig. 5 is a section taken on line 55 of Fig. 4.

' ig. 6 is afragmentary elevation of the-side of the -machine opposite to that shown in Fig. 1, and

Fig. 7 is a fragmentary elevation of one of the cleaning brushes, the bristles or wires being partly broken away to illustrate certain details of construction.

Referringto the drawings wherein a pres fcrred form of the invention is illustrated, the reference character 10 designates the frame of a .Garnett o'r felting machine adapt? ed to form batting from linters, .or the equiv.-

alen-t. At the front endv of the machine the usual hopper 11'is positioned, into which hopper the linters, or the equivalent, are fed. In this instance, the hopper contains the usual spike apron (not shown) and the linters are delivered from the hopper a feed apron 12. V

The feed apron l2 delivers the feltingmaterial to feed rolls 14 rotatably mounted in the frame 10, the feed rolls being arranged to co-operate with a lickerin roll15, alsojournaled in the frame 10. i

The usual cylinders '17 and 18 and-the usual doffer rolls 20 and 21, together with the usual fancy and fancy stripper rolls are also jou'rnaled in the frame 10. From the doffer roll 20, the felting material passes to the runway apron24. p

The runway apron 24 is driven by a roll 25 mounted on a shaft26' which is journaled source of power. Apinion 27 fixed to the shaft 2.6 meshes with a gear 28 "mounted .on a shaft 29 which carries thedoffer roll 20 (seeFig. 1). i A sprocket 31 mounted on the shaft 29 meshes with a sprocket chain 32 which meshes with a sprocket 33 secured to a shaft v34 which carries the middle doffer roll 21. The direction in which the 'dofiier rolls rotate is indicated by arrows in Fig. 2.

The above mentioned fancy-stripper rolls are designated by the reference characters 36 and 37 and are mounted on shafts 38 and 39, respectively, the shafts 38 and 39 being driven from the shafts 29 and 34, respective-- -screw-threaded posts47 and 48 are rotated the brush or roll 43 is raised or lowered, de-

in the frame 10 and driven from any suitable pending upon the direction in which the posts 47 and 48 are rotated. The posts 47 I and 48 are rotatably journaled in bracket tated in either direction toraise-orlower the 7 brush or roll 43 at will.

As best shown in Figs. 3, 4 and 6, each shaft 44 is provided with a sprocket-wheel 59 which is operatively connected by a sprocket chain 60vto a sprocket-wheel 61 mounted upon the associatedfancy-stripper roll shaft 38 or 39; Each cleaning roll is rotated in the same direction as its associated Take-upmechanism comprising an idler- Troll, or sheave, 63 is provided for each sprocket chain to takeup play in the sprocket chain when the associated roll 43 is raised orlowered.

As indicated diagrammatically in Figs. 4 and 5, the doffer rolls are covered with the usual cloth from which bent wires or pins project, the pins being identified by the reference character 65. The cleaning rolls 43 preferably comprise rubberized fabric, or rubber wrapped around the shafts 44 and provided with numerous bristles or wires 66 which enter the spaces between the bent pins during the'cleaning operation and remove linte-rs therefrom.

In the preferred form of the invention, the rubberized cloth, or rubber, wrapped around the shafts 44 is preferablyin the form of strips 67 which have their ends rigidly secured tothe shafts 44 and which are wrapped spirally around the shafts (see Fig. 7).

- The operation of the above described apparatus is substantially as follows: Assuming that the machine is in operation, it is obvious that the rolls 43 may be adjusted to 7 clean the doffer rolls 20 and 21 continuously,

or the cleaning rolls may be brought into contact therewith at predetermined intervals, if itis so desired.

The linters are; advanced. through the apparatus, and through the action of the cylinders 17 and 18, the dofier rolls 20 and 21 and the accompanying worker rolls, fancy-rolls andfancy-stripperrolls are matted into felting or batting. Linters will tendito adhere to the pins 65 and are brushed therefrom by the cleaning rolls 43.

the equivalent, while the machine is in operation. This has been the usual practice heretofore and has often resulted in injury to the operator. Another advantage of the invention is that the dofi'er rolls may be cleaned continuously, or at such intervals that the linters do not have an opportunity to mat between the pins 65 and, therefore, it is unnecessary to later scrape the pins with such force as to damage or de stroythem.

Still another importantadvantage of the apparatus described above is that depth through whichthe wires 66 enter between the bent pins .65 can be accurately adjusted so that the wires 66will enter deep enough to remove the lint adhering to .th'epins .65f but will not injure the cloth to which the pins 65 are secured. v V

Cleaning the doffer rolls as described above results in better carding and insures that the felt produced willgbe of a good quality.

WhileI have shown and described certain embodiments of my. invention, it is to be understood that it is capable of many modifications. Changes, therefore, in the construction and arrangement may be made without departing from the spirit and scope of the invention as disclosed in the appended claims, in which it is my intention to claim all novelty inherentin my invention as broadly as possible, in view of the prior art.

7 What I regard asne and desire to secure by Letters Patent, is:

1. Ina machine of the character set forth, the combination with a roll covered with cardcljoth, of meansfor cleaning said roll comprising rotatably journaled pins, bearing blocks screw-threaded on said pins, a shaft journaled i1 1 said bearing blocks, a brush on said shaft, means vfor driving said shaft, means operatively connecting said pins whereby they are constrained to rotate in unison, and manually operable means for rotating said pins to bringsaid brush into and out of effective engagement with said roll. 1

2. In a machine of the character set forth, the combination with a roll covered with cardcloth, of means for clamping said roll com prising rotatably journaled pins, bearing blocks screw-threaded on. said pins, a'shaft journaled in said bearing blocks, a brush on said shaft, means for driving said shaft, sprockets on said pins, an endless sprocket chain meshing with said sprockets, and a handwheel on one of said pins whereby said pins may be rotated to bring said brush into anlri. out of effective engagement with-said ro In testimony whereof, I hereunto afliX my signature this 10th day of March, 1930.

ALBERT BRECKENRIDGE;

The invention is particularly advantageous as it obviates the necessity of having the opr erator clean the doffer rolls with a brush, or

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US438468A US1857039A (en) | 1930-03-24 | 1930-03-24 | Garnett or batting machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US438468A US1857039A (en) | 1930-03-24 | 1930-03-24 | Garnett or batting machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1857039A true US1857039A (en) | 1932-05-03 |

Family

ID=23740771

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US438468A Expired - Lifetime US1857039A (en) | 1930-03-24 | 1930-03-24 | Garnett or batting machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1857039A (en) |

-

1930

- 1930-03-24 US US438468A patent/US1857039A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3081499A (en) | Fiber integrating apparatus | |

| US1834309A (en) | Machine for making insulating bats | |

| US1857039A (en) | Garnett or batting machine | |

| US3253432A (en) | Rug cleaning machine | |

| DE1410604A1 (en) | Carding machine | |

| US1425920A (en) | Disintegrating machine | |

| US1913016A (en) | Card cleaning apparatus | |

| CN213896090U (en) | Cleaning device of carding machine | |

| US2682086A (en) | Device for stripping garnetting machines | |

| US1648050A (en) | Attachment for carding machines | |

| DE2164108C3 (en) | Device for removing the cover plaster on cards | |

| US2233753A (en) | Scutching machine | |

| USRE16449E (en) | von osten | |

| US1821673A (en) | Method and apparatus for treating fiber-bearing plants | |

| US1447449A (en) | Machine for treating flax straw | |

| US2481002A (en) | Process for improving the carding effect of carding cylinders | |

| DE436049C (en) | Pre-card for carding machines and similar machines | |

| US2910735A (en) | Carding apparatus and method | |

| US1732860A (en) | Card-cleaning device | |

| US966565A (en) | Doffer or knocking-off apparatus for the doffer-rollers of carding-machines. | |

| US1962945A (en) | Method of and means for dealing with flat strippings of cotton and other fibers in revolving flat carding engines | |

| US2676362A (en) | Machine for combing fibrous materials | |

| US1967567A (en) | Cotton huller and cleaner | |

| US1270216A (en) | Cleaning device. | |

| US1023473A (en) | Flax-felt machine. |