US1856728A - Transit mixer actuating means - Google Patents

Transit mixer actuating means Download PDFInfo

- Publication number

- US1856728A US1856728A US449302A US44930230A US1856728A US 1856728 A US1856728 A US 1856728A US 449302 A US449302 A US 449302A US 44930230 A US44930230 A US 44930230A US 1856728 A US1856728 A US 1856728A

- Authority

- US

- United States

- Prior art keywords

- barrel

- truck

- frame

- transit mixer

- supporting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000003756 stirring Methods 0.000 description 20

- 241000282472 Canis lupus familiaris Species 0.000 description 11

- 230000010355 oscillation Effects 0.000 description 8

- 239000000463 material Substances 0.000 description 6

- 239000004568 cement Substances 0.000 description 4

- 241000196324 Embryophyta Species 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000000153 supplemental effect Effects 0.000 description 2

- 241000219793 Trifolium Species 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28C—PREPARING CLAY; PRODUCING MIXTURES CONTAINING CLAY OR CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28C5/00—Apparatus or methods for producing mixtures of cement with other substances, e.g. slurries, mortars, porous or fibrous compositions

- B28C5/42—Apparatus specially adapted for being mounted on vehicles with provision for mixing during transport

- B28C5/4272—Apparatus specially adapted for being mounted on vehicles with provision for mixing during transport with rotating drum rotating about a horizontal or inclined axis, e.g. comprising tilting or raising means for the drum

- B28C5/4275—Apparatus specially adapted for being mounted on vehicles with provision for mixing during transport with rotating drum rotating about a horizontal or inclined axis, e.g. comprising tilting or raising means for the drum with a drum rotating about a horizontal axis, e.g. perpendicular to the longitudinal axis of the vehicle

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/15—Intermittent grip type mechanical movement

- Y10T74/1526—Oscillation or reciprocation to intermittent unidirectional motion

- Y10T74/1529—Slide actuator

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/15—Intermittent grip type mechanical movement

- Y10T74/1558—Grip units and features

- Y10T74/1584—Gripper mountings, slide

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/18—Mechanical movements

- Y10T74/1856—Reciprocating or oscillating to intermittent unidirectional motion

Definitions

- This invention relates to transit mixers and has for one of its objects to utilize the various undulations or the roughness of the roadway over which the vehicle may be operated to rotate the agitating barrel in which the cementitious material is transported.

- the use of central mixing plants is becoming more desirable, especially on small jobs, since it is not necessary for the contractor to have his capital tied up in expensive concrete mixing machinery, nor is it necessary to have the usual sand and gravel deposits which are required by this machinery.

- central mixing plants are provided with one or more stationary concrete mixers and usually have a fleet of so-called transit mixers which consist of a type of power operated tumbler or mixing barrel mounted on a motor truck.

- the batch of cement is poured into the barrel from the mixer and is transported to the place where it is to be used. During this transportation the barrel is slowly rotated to prevent the tendency of the cement to set, and to resist the tendency of the heavier aggregates to settle to the bottom.

- a separate drive from the engine of the motor truck is utilized to provide the power for rotating the barrel to produce the above referred to stirring action or agitation of the material therein, while in other instances a separate motor unit is provided for causing the said rotation of the'barrel.

- Another object is to resiliently mount the stirrlng barrel with respect to the supporting wheels or traction members of the barrel transporting truck, and to provide a connection between the axles for the Wheels and the barrel to produce a stirring action of the contents of the barrel incident to vertical movement of the barrel or the supporting traction members.

- a still further object is to so mount the bar-. rel with respect to the supporting truck that the relatively vertical movement in both directions thereof is converted into rotary movement to rotate the barrel.

- Another object is to mount thebarrel on a truck for rotation in a horizontal plane and provide the truck with traction members whlch are resiliently mounted on the truck frame to move in a substantially vertical plane and provide a positive driving connection between the barrel and the traction members so that vertical movement of the latter lncident to the unevenness of the surface over which they operate causes rotation of the former.

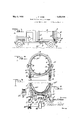

- Fig. 1 is a side elevation of my improved transit mixer

- Fig. 2 is a section on line 2-2 of Fig. 1;

- Fig. 3 is a fragmentary detail of one of the spring pressed dogs for rotating the stirring barrel;

- Fig. 4 is a side elevation of a modified form of my. invention, showing in dotted lines the supporting frame and agitating barrel in dumping position;

- Fig. 5 is a vertical cross sectional view on line 55 of Fig. 4:; and 1 Fig. 6 is a fragmentary verticalcross sectional view through a transit mixer truck having a further modification ofmy invention applied thereto.

- FIG. 1 indicates a motor truck having pivoted thereto at 2 a concrete agitating barrel supporting frame 3, as seen in Fig. 1.

- a stirring or agitating barrel 4 is rotatably carried in spaced annular bearings or guide members 5 and 6.

- Stirring ribs 4a are longitudinally disposed in spaced relation around the interior of the barrel 4.

- the forward bearing member 5 is pivotally secured to the frame 3 at 7 to permit oscillation or swinging in a vertical plane of the barrel 4 supported thereby.

- the rear hearing member 6 is yieldably supported by the compression springs 9 on the vertically dis,- posed standards 8 and is limited in its upward movement by the adjustable stop nuts er bolts 10 carried by the standards. 7

- brackets or arms 11 and 12 Positioned adjacent the rear bearing 6 at each side of the barrel 4 are a pair of brackets or arms 11 and 12 which have spring pressed dogs 13 and 14 pivoted thereto. These dogs are positioned to engage the teeth of an annular rack or gear 15 fixed to the barrel 4 to cause rotation of the barrel incident to relative vertical movement between the barrel 4 and the standards 11 and 12 due to the unevenness of the roadbed over which the truck may be operating.

- the dog 14 becomes operative to engage the rack 1 5 and rdtates the barrel in the direction of the arraw, asseen in Fig. 2 while, when the barrel and frame move away from each other, the dog 13 then becomes operative to continue the said rotation of the barrel.

- Fig. 6 discloses a further modification in which the barrel 4 is rotatably mounted in guides 5" which are rigidly carried by the supporting frame 3'.

- the oscillation of the rear axle '22 with respect to the main and transit mixer frames 1" and 3 is utilized to positively rotate the barrel 4" which is, as before mentioned, mounted in the guides 5 to permit only rota'tive movement of the barrel in con tradistinction to the combined rotati'v'e and oscillative movement as contemplated in the other'forms of my invention.

- T he barrel 4" is disclosed in this View as having a clover leaf type of interior agitating shell, as indicated at 40, and the barrel is provided eX- teriorly with the ratchet ring member 15" which is engaged by the ratchet dogs or levers 16 and 17.

- These levers are pivotally secured to bell cranks 18 and 19 which are in turn pivotally supported at 18 and 19 upon bracket members 20 and 21 fixed to the main frame 1 of the motor truck.

- the ends of the bell crank levers 18 and 19 are slotted at 18a and 19a to receive the actuating link 23 which is pivotally secured at 21 to the rear axle or housing 22.

- any type of suitable power operated means may be utilized, such as the conventional hydraulic hoist indicated generally at 25 in Figs. 1 and 4:;

- a transit mixer a supporting truck, a stirring barrel, guide member's forsupporting said barrel on, said truck,- eertain of said guide members beingyield'ably carried by the truck to permit relative movement between the barrel and truck, and cooperating means on said truck and barrel for rotating the barrel upon vertical movement of the truck with respect to the barrel due to the unevenness of a roadbed over which the truck may be operated.

- a supporting truck a stirring barrel, Eguide members forsupport; ing said barrel on'said gagln certain of said guide members being .yieldabl'y carried by the truck to permit relative movement between the barrel and truck, and cooperative means on said truck and barrel for rotating the barrel incident to said relative movement.

- a supporting truck adapted to travel over a roadway, a stirring barrel movably supported by said truck for receiving a quantity of plastic material, means for stirring the plastic material within the barrel, and cooperating means between the supporting truck and barrel to cause actuation of the stirring means upon relative movement between the said supporting truck and barrel due to unevenness of the roadway over which the transit mixer is operated.

- a supporting truck adapted to travel over a roadway, a stirring barrel movably carried on said truck, resilient means for yieldably supporting said barrel on said truck, and cooperating means on said truck and barrel for causing movement of said barrel to produce a stirring movement of a plastic material when placed within the barrel upon relative movement between the barrel and supporting means due to unevenness of the roadway over which the truck may be operated.

- a transit mixer of the class described a supporting truck adapted to travel over a roadway, a transit mixer frame pivotally and yieldably carried by said truck, a transit mixer stirring barrel rotatably carried on said frame cooperating means on said barrel and truck for rotating the barrel upon relative oscillation between the frame and truck due to unevenness of the roadway over which the truck may be operating, and means for tilting the pivoted frame to eifect a discharge of a plastic material placed within the barrel.

- a motor truck a transit mixer stirring barrel supporting frame pivotally and yieldably carried on said truck, a stirring barrel rotatably carried on said mixing frame, an annular rack surrounding said barrel, and actuating means carried by said frame for engagement with said rack incident to relative oscillation between said barrel and frame due to vertical movement of the truck incident to unevenness of the roadway over which the truck is operating.

- a supporting truck adapted to travel over a roadway, a transit mixer frame pivotally and yieldably carried by said truck, a transit mixer stirring barrel rotatably carried on said frame, and cooperating means on said barrel and truck for rotating the barrel upon relative oscillation between the barrel and truck due to unevenness of the roadway over which the truck may be operating.

- a supporting truck adapted to travel over a traction surface, an inertia member yieldably supported by said truck, a rotatable barrel supported in said inertia member, and 00-- operating means on said barrel and truck for rotating said barrel upon relative movement between said truck and inertia member due to unevenness of the traction surface upon which the truck travels.

- a transit mixer a supporting truck, a transit mixer frame having one end thereof pivoted to said truck and having the other end yieldably supported thereby, a rotatable mixing barrel carried by said frame and sub stantially coextensive therewith, and cooperating means on said supporting truck and barrel for rotating said barrel upon relative movement between the yieldably supported end of said frame and truck.

- a transit mixer a supporting truck, a transit mixer frame having one end thereof pivoted to said truck and having the other end yieldably supported thereby, a rotatable mixing barrel carried by said frame and substantially coextensive therewith, cooperating means on said supporting truck and barrel for rotating said barrel upon relative movement between the yieldably supported end of said frame and truck, and means for tilting said mixing barrel carrying frame.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Structural Engineering (AREA)

- Preparation Of Clay, And Manufacture Of Mixtures Containing Clay Or Cement (AREA)

Description

Tial.

May 3, 1932 J RQBB 1 1,856,728

TRANSIT MIXER ACTUATING MEANS Filed May 2, 1930 2 Sheets-Sheet l Ma 3, 1932. J. F. ROBB 1,856,728

TRANSIT MIXER ACTUATING MEANS Joiuoljzabb Patented May 3, 1932 UNITED STATES JOHN F. ROBB, F CLEVELAND HEIGHTS, OHIO TRANSIT MIXER ACTUA'IIN'G MEANS Application filed May 2, 1930. Serial No. 449,302.

This invention relates to transit mixers and has for one of its objects to utilize the various undulations or the roughness of the roadway over which the vehicle may be operated to rotate the agitating barrel in which the cementitious material is transported. In concrete construction work, the use of central mixing plants is becoming more desirable, especially on small jobs, since it is not necessary for the contractor to have his capital tied up in expensive concrete mixing machinery, nor is it necessary to have the usual sand and gravel deposits which are required by this machinery.

These central mixing plants are provided with one or more stationary concrete mixers and usually have a fleet of so-called transit mixers which consist of a type of power operated tumbler or mixing barrel mounted on a motor truck. The batch of cement is poured into the barrel from the mixer and is transported to the place where it is to be used. During this transportation the barrel is slowly rotated to prevent the tendency of the cement to set, and to resist the tendency of the heavier aggregates to settle to the bottom.

In some instances a separate drive from the engine of the motor truck is utilized to provide the power for rotating the barrel to produce the above referred to stirring action or agitation of the material therein, while in other instances a separate motor unit is provided for causing the said rotation of the'barrel.

From the above it should be observed that considerable power is utilized in performing this stirring action which, of course, must be paid for and included in the cost of the cement; also the increase in size and cost of the engine of the truck, or the supplemental engine, as the case may be, requires a further expense.

In my improved type of transit mixer, I propose to dispense with all supplemental power plants, utilizing the vertical osci1lation of the truck body or the tumbler barrel,'as the case may be, incident to the unevenness of the roadbed over which the truck is operating, to produce the necessary power for rotating the cement stirring or agitating barrel.

Another object is to resiliently mount the stirrlng barrel with respect to the supporting wheels or traction members of the barrel transporting truck, and to provide a connection between the axles for the Wheels and the barrel to produce a stirring action of the contents of the barrel incident to vertical movement of the barrel or the supporting traction members.

' A still further object is to so mount the bar-. rel with respect to the supporting truck that the relatively vertical movement in both directions thereof is converted into rotary movement to rotate the barrel.

Another object is to mount thebarrel on a truck for rotation in a horizontal plane and provide the truck with traction members whlch are resiliently mounted on the truck frame to move in a substantially vertical plane and provide a positive driving connection between the barrel and the traction members so that vertical movement of the latter lncident to the unevenness of the surface over which they operate causes rotation of the former.

Other and further objects and advantages of the invention will be hereinafter'set forth and the novel features thereof defined by the appended claims.

In the drawings:

Fig. 1 is a side elevation of my improved transit mixer;

Fig. 2 is a section on line 2-2 of Fig. 1; Fig. 3 is a fragmentary detail of one of the spring pressed dogs for rotating the stirring barrel;

Fig. 4 is a side elevation of a modified form of my. invention, showing in dotted lines the supporting frame and agitating barrel in dumping position;

Fig. 5 is a vertical cross sectional view on line 55 of Fig. 4:; and 1 Fig. 6 is a fragmentary verticalcross sectional view through a transit mixer truck having a further modification ofmy invention applied thereto.

Like reference characters refer to like parts in the several figures of the drawings,

in which 1 indicates a motor truck having pivoted thereto at 2 a concrete agitating barrel supporting frame 3, as seen in Fig. 1. A stirring or agitating barrel 4 is rotatably carried in spaced annular bearings or guide members 5 and 6. Stirring ribs 4a are longitudinally disposed in spaced relation around the interior of the barrel 4.

The forward bearing member 5 is pivotally secured to the frame 3 at 7 to permit oscillation or swinging in a vertical plane of the barrel 4 supported thereby. The rear hearing member 6 is yieldably supported by the compression springs 9 on the vertically dis,- posed standards 8 and is limited in its upward movement by the adjustable stop nuts er bolts 10 carried by the standards. 7

Positioned adjacent the rear bearing 6 at each side of the barrel 4 are a pair of brackets or arms 11 and 12 which have spring pressed dogs 13 and 14 pivoted thereto. These dogs are positioned to engage the teeth of an annular rack or gear 15 fixed to the barrel 4 to cause rotation of the barrel incident to relative vertical movement between the barrel 4 and the standards 11 and 12 due to the unevenness of the roadbed over which the truck may be operating.

During the downward movement of the barre-l 4, or the upward movement of the frame 3, as the "case may be, the dog 14 becomes operative to engage the rack 1 5 and rdtates the barrel in the direction of the arraw, asseen in Fig. 2 while, when the barrel and frame move away from each other, the dog 13 then becomes operative to continue the said rotation of the barrel.

In 4 and 5,- the agitat ng barrel 4 is supported on the bearings 5 and 6, which are in turn pivoted at 7 to permit oscillation of the barrel around a longitudinal axis disposed adjacent to one side of the supporting frame 3. Spring suspension means similar to that disclosed in my preferred form at 9. are provided for the barrel as indicated at 9' in Figs. 4 and 5. In this form of my invention, only one set of brac zets 11' having a spring pressed pawl or dog 13' is used. These dogs engage the rack 15 to cause rotation of the barrel 4 incident 'to the swinging movement of the same around the pivots 7.

Fig. 6 discloses a further modification in which the barrel 4 is rotatably mounted in guides 5" which are rigidly carried by the supporting frame 3'. In this form of the invention the oscillation of the rear axle '22 with respect to the main and transit mixer frames 1" and 3 is utilized to positively rotate the barrel 4" which is, as before mentioned, mounted in the guides 5 to permit only rota'tive movement of the barrel in con tradistinction to the combined rotati'v'e and oscillative movement as contemplated in the other'forms of my invention. T he barrel 4" is disclosed in this View as having a clover leaf type of interior agitating shell, as indicated at 40, and the barrel is provided eX- teriorly with the ratchet ring member 15" which is engaged by the ratchet dogs or levers 16 and 17. These levers are pivotally secured to bell cranks 18 and 19 which are in turn pivotally supported at 18 and 19 upon bracket members 20 and 21 fixed to the main frame 1 of the motor truck. The ends of the bell crank levers 18 and 19 are slotted at 18a and 19a to receive the actuating link 23 which is pivotally secured at 21 to the rear axle or housing 22. Springs 24 are interposed between the long arms of the bell cranks 18 and 19 and the dogs 16 and 17 to maintain the dogs in engaging relationwith respect to the ratchet rack 15". The usual truck springs 2261 between the; rear axle 22 and themain frame 1 provide the yieldabl'e means for permitting oscillation between these parts, and byreferring to Fig. 6 it will be noted that upon vertical oscillation of the rear aX-l'e due to unevenness of the roadbed over which the tru'ek may be operating, the link member 23 willgcauseactuation of the bell cranks 18 and 19 which will in turn cause the dog members 16 and 17 to engage and actuate the rack 15', causing rotation of the tumbler or stirring barrel 4 In order to tilt the stirring barrel, any type of suitable power operated means may be utilized, such as the conventional hydraulic hoist indicated generally at 25 in Figs. 1 and 4:;

When the pivoted mixer frame 3 has been tilted to the position shown in dotted lines in Fig. 4, the contents of the barrel 4" are permitted to be discharged out of the conical shaped opening or discharge end of the mixing barrel.

While the specific details of construction have been herein shown and described, the invention is not confined thereto as changes and alterations may be made withoutdeparting from the spirit thereof as defined by the appended claims.

'H'aving thus described my invention, What I claim as new and desire to secure by Letters Patent is:

1. In a transit mixer, a supporting truck, a stirring barrel, guide member's forsupporting said barrel on, said truck,- eertain of said guide members beingyield'ably carried by the truck to permit relative movement between the barrel and truck, and cooperating means on said truck and barrel for rotating the barrel upon vertical movement of the truck with respect to the barrel due to the unevenness of a roadbed over which the truck may be operated.

2. In a transit mixer, a supporting truck, a stirring barrel, Eguide members forsupport; ing said barrel on'said trucln certain of said guide members being .yieldabl'y carried by the truck to permit relative movement between the barrel and truck, and cooperative means on said truck and barrel for rotating the barrel incident to said relative movement.

3. In a transit mixer, a supporting truck adapted to travel over a roadway, a stirring barrel movably supported by said truck for receiving a quantity of plastic material, means for stirring the plastic material within the barrel, and cooperating means between the supporting truck and barrel to cause actuation of the stirring means upon relative movement between the said supporting truck and barrel due to unevenness of the roadway over which the transit mixer is operated.

4. In a transit mixer of the class described, a supporting truck adapted to travel over a roadway, a stirring barrel movably carried on said truck, resilient means for yieldably supporting said barrel on said truck, and cooperating means on said truck and barrel for causing movement of said barrel to produce a stirring movement of a plastic material when placed within the barrel upon relative movement between the barrel and supporting means due to unevenness of the roadway over which the truck may be operated.

5. In a transit mixer of the class described, a supporting truck adapted to travel over a roadway, a transit mixer frame pivotally and yieldably carried by said truck, a transit mixer stirring barrel rotatably carried on said frame cooperating means on said barrel and truck for rotating the barrel upon relative oscillation between the frame and truck due to unevenness of the roadway over which the truck may be operating, and means for tilting the pivoted frame to eifect a discharge of a plastic material placed within the barrel.

6. In a concrete transit mixer of the class described, a motor truck, a transit mixer stirring barrel supporting frame pivotally and yieldably carried on said truck, a stirring barrel rotatably carried on said mixing frame, an annular rack surrounding said barrel, and actuating means carried by said frame for engagement with said rack incident to relative oscillation between said barrel and frame due to vertical movement of the truck incident to unevenness of the roadway over which the truck is operating.

7. In a transit mixer of the class described, a supporting truck adapted to travel over a roadway, a transit mixer frame pivotally and yieldably carried by said truck, a transit mixer stirring barrel rotatably carried on said frame, and cooperating means on said barrel and truck for rotating the barrel upon relative oscillation between the barrel and truck due to unevenness of the roadway over which the truck may be operating.

8. In a device of the character described, a supporting truck adapted to travel over a traction surface, an inertia member yieldably supported by said truck, a rotatable barrel supported in said inertia member, and 00-- operating means on said barrel and truck for rotating said barrel upon relative movement between said truck and inertia member due to unevenness of the traction surface upon which the truck travels.

9. In a transit mixer, a supporting truck, a transit mixer frame having one end thereof pivoted to said truck and having the other end yieldably supported thereby, a rotatable mixing barrel carried by said frame and sub stantially coextensive therewith, and cooperating means on said supporting truck and barrel for rotating said barrel upon relative movement between the yieldably supported end of said frame and truck.

10. In a transit mixer, a supporting truck, a transit mixer frame having one end thereof pivoted to said truck and having the other end yieldably supported thereby, a rotatable mixing barrel carried by said frame and substantially coextensive therewith, cooperating means on said supporting truck and barrel for rotating said barrel upon relative movement between the yieldably supported end of said frame and truck, and means for tilting said mixing barrel carrying frame.

In testimony whereof I affix my signature.

JOHN F. ROBB.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US449302A US1856728A (en) | 1930-05-02 | 1930-05-02 | Transit mixer actuating means |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US449302A US1856728A (en) | 1930-05-02 | 1930-05-02 | Transit mixer actuating means |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1856728A true US1856728A (en) | 1932-05-03 |

Family

ID=23783658

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US449302A Expired - Lifetime US1856728A (en) | 1930-05-02 | 1930-05-02 | Transit mixer actuating means |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1856728A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2664276A (en) * | 1951-02-16 | 1953-12-29 | Wagner Iron Works | Concrete mixer with lifting and tilting mechanism |

| US6595846B1 (en) * | 1998-06-05 | 2003-07-22 | Metalquimia, S.A. | Machine for the treatment of meat pieces |

| US20040240310A1 (en) * | 2003-05-30 | 2004-12-02 | Lang Damian L. | Slurry mixing apparatus |

| US20140346191A1 (en) * | 2011-11-28 | 2014-11-27 | Fillon Technologies | Device for storing, selecting, and distributing a plurality of products each of which is packaged in a container provided with an ejection opening |

-

1930

- 1930-05-02 US US449302A patent/US1856728A/en not_active Expired - Lifetime

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2664276A (en) * | 1951-02-16 | 1953-12-29 | Wagner Iron Works | Concrete mixer with lifting and tilting mechanism |

| US6595846B1 (en) * | 1998-06-05 | 2003-07-22 | Metalquimia, S.A. | Machine for the treatment of meat pieces |

| US20040240310A1 (en) * | 2003-05-30 | 2004-12-02 | Lang Damian L. | Slurry mixing apparatus |

| US7165877B2 (en) * | 2003-05-30 | 2007-01-23 | Lang Damian L | Slurry mixing apparatus |

| US20140346191A1 (en) * | 2011-11-28 | 2014-11-27 | Fillon Technologies | Device for storing, selecting, and distributing a plurality of products each of which is packaged in a container provided with an ejection opening |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE202020102896U1 (en) | Reloading-free, immediately pouring rail bed concrete casting tank wagon | |

| US1856728A (en) | Transit mixer actuating means | |

| US3131913A (en) | Tiltable transit mixer | |

| US2500293A (en) | Vibratory dump truck | |

| US2447071A (en) | Concrete mixer | |

| US2102432A (en) | Combination truck and conveyer | |

| US1928380A (en) | Concrete mixer | |

| CN113373782A (en) | A highway crack processing apparatus for highway engineering | |

| CN107030891A (en) | It is a kind of with forklift function from feeding concrete mixer | |

| US3326537A (en) | Transit concrete mixer | |

| US2096911A (en) | Propulsion means for rollers | |

| US1506762A (en) | Truck | |

| US1368886A (en) | Truck | |

| CN210389670U (en) | Concrete mixing equipment for vehicle | |

| US2013360A (en) | Transit concrete mixer | |

| US1885350A (en) | Apparatus for transporting and conditioning ready-mixed concrete | |

| US1641913A (en) | Plastic-concrete-delivery vehicle | |

| US1636926A (en) | Drive for transit concrete mixers | |

| US1889558A (en) | Mixer | |

| CN205086743U (en) | From loading and unloading desilting car | |

| US1926622A (en) | Apparatus for transporting concrete | |

| US2006473A (en) | Road spreader | |

| US1763249A (en) | Transit concrete mixer | |

| US1657762A (en) | Apparatus for handling, mixing, and pouring concrete | |

| CN207846153U (en) | A kind of bituminous concrete one paver |