US1855024A - Plumbing fitting - Google Patents

Plumbing fitting Download PDFInfo

- Publication number

- US1855024A US1855024A US320113A US32011328A US1855024A US 1855024 A US1855024 A US 1855024A US 320113 A US320113 A US 320113A US 32011328 A US32011328 A US 32011328A US 1855024 A US1855024 A US 1855024A

- Authority

- US

- United States

- Prior art keywords

- fitting

- opening

- closet

- bowl

- openings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009428 plumbing Methods 0.000 title description 9

- 239000002699 waste material Substances 0.000 description 16

- 210000002445 nipple Anatomy 0.000 description 7

- 239000002689 soil Substances 0.000 description 7

- 238000005192 partition Methods 0.000 description 5

- 238000009434 installation Methods 0.000 description 3

- 238000010276 construction Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 241000408495 Iton Species 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 239000011505 plaster Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D11/00—Other component parts of water-closets, e.g. noise-reducing means in the flushing system, flushing pipes mounted in the bowl, seals for the bowl outlet, devices preventing overflow of the bowl contents; devices forming a water seal in the bowl after flushing, devices eliminating obstructions in the bowl outlet or preventing backflow of water and excrements from the waterpipe

- E03D11/13—Parts or details of bowls; Special adaptations of pipe joints or couplings for use with bowls, e.g. provisions in bowl construction preventing backflow of waste-water from the bowl in the flushing pipe or cistern, provisions for a secondary flushing, for noise-reducing

- E03D11/14—Means for connecting the bowl to the wall, e.g. to a wall outlet

Definitions

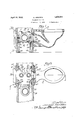

- My invention relates in general to plumb- Fig. 2 is a plan View oft-he fitting of my ing fittings. It relates more particularly to invention and showing its manner of use; 7 a fitting for connecting a closet bowl to a Fig. 3 is afront View of the fitting, half soil or waste pipe and the combination of in section, the section line being along the such fitting with the bowl. line 3-3 of Fig. 4; r I

- Fig. 4 is a plan view of the fitting, partly pipes have been'carried in the floor but for broken away,- and v a number of reasons known to the trade F ig.5is afragmentar sectional view taken this is not satisfactory; and attempts are along the line 55 of ig. 4 looking in the made now Wherever possible to carry all of directions of the arrows. v

- a fitdrawings t e fitting A is adapted to connect ting adapted-to connect the two closet bowls to bowls B and G which are of a wall hung back'to'backto a soil or waste pipe without type and are connected against a standard Y the other.

- the fitting A has one opening 10 for con-

- Another object isthe provision of such a necti'onby means of a nipple 11 and T12 to fitting which at the same time may be placed the usual soil or waste pipe 13.

- the other inastandardtoilet room partition. openings 14 and 16 are disposed opposite fitting particularly adapted for use with a openinglO and are adapted to be connected Wallhung type of bowl. to the bowls B and C respectively.

- this baffle 19 extends beyond the edge of the openings so that no matter how water is discharged through the opening it will be impossible for it to cross to the other bowl but it will strike the bafile 19 and be deflected 21 must be at least as large'as the opening- 16. I obtain this result by forming the sweep and in this way I am able to obtain more than the area of the opening 16 at the sweep opening. With the area of the opening 16 slightly more than 12 square inches (4 inches diameter) the sweep opening 21 may be formed so as to obtain almost 17 square inches of area.

- any other usual adjusting means may be provided, for any usual way of connecting the bowl may be utilized.

- the present invention is not meant to be entirely self suflicient but where necessary depending upon the installation may be hooked up with any ofthe present standard plumbing appliances. In installing my fitting the usual methods of roughing in etc. are used, the plaster. being finished to the'fitting as is the custom.

- the fitting of my invention can be em ployed on either a vertical or horizontal waste pipe and is of very great advantage in either case.

- a horizontal line there is considerable advantage.

- these fittings can beplaced' in and the elevation thereof very easily controlledoradjusted forby choosing nipples ll'of suitable length to bring these fittings to the elevation required.

- these nipples 11 can be controlled in length to adjust the position of the fitting with respect to a vertical, line.

- a three way fitting of substantially standard T dimensions for connecting closet bowls back to back having a closet connection with the usual circular opening, a soil or waste pipe connection with the usual circular opening,and a baflle between the closet bowl connections extending toward the waste pipe opening, the baffle forming a'relatively narrow sweep opening on each side thereof, each sweep opening being formed higher resulting in an oblong opening having at least the area of the closet bowl openings.

- a plumbing fitting for mounting closet bowls back to back comprising a T with the outward general appearance and dimensions of a standard T fitting, oppositely disposed openings adapted for connection to the closet bowls and a right angularly placed opening communicating with the oppositely disposed openings and adapted by suitable means to be connected to a waste pipe and a baflie between the two closet openings to prevent discharge across from one to the other, the opening at the baffle being oval shaped to have at least the area of the closet openings to avoid any possibility of back pressure into the closets and maintaining the outward size of a standard T fitting so that a minimum amount of wall space is needed to make connections.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Sanitary Device For Flush Toilet (AREA)

Description

April 19, 1932. 5 s Q I 1,855,024

PLUMBING FITTING Filed Nov. 17, 1928 2 Sheets-Sheet 2 23 J0-/ /g Q. 27 l1 EJGWW Patented Apr. 19, 1932 a 4- UNITED-STATES PATENT OFFICE" f Application filed November 17, 1928. Serial No. 320,113.

My invention relates in general to plumb- Fig. 2 is a plan View oft-he fitting of my ing fittings. It relates more particularly to invention and showing its manner of use; 7 a fitting for connecting a closet bowl to a Fig. 3 is afront View of the fitting, half soil or waste pipe and the combination of in section, the section line being along the such fitting with the bowl. line 3-3 of Fig. 4; r I

In old style plumbing installations the Fig. 4 is a plan view of the fitting, partly pipes have been'carried in the floor but for broken away,- and v a number of reasons known to the trade F ig.5is afragmentar sectional view taken this is not satisfactory; and attempts are along the line 55 of ig. 4 looking in the made now Wherever possible to carry all of directions of the arrows. v

the pipes in the partitions. In this connec- In carrying out my invention I provide'a ti'on wall hung type of closet bowls have fitting with a three way connection, one runbeen brought into use and with some degree ning to each closet bowl and thethird runof success.- It hasbeen suggested to mount ning connection to the usual soil orwaste the bowlsback to back but this has not been 'pipe. A baffle is provided to prevent dis- 65 I anypossibility of one howl discharging into toilet room partition D.

40 Another object istheprovision of such a from each other and atright angles to the i detailed description taken with the accomto the openings 14 and 16.

entirely satisfactory for a number of reacharge straight across the fitting from one sons principally because when the bowls were bowl to another, but the fitting is proporconnected directly discharge would take place tioned so that the areaof the sweep opening from one bowl into another and of course is the same or greater than the area of the in- 20 this was entirely unsatisfactory. Another take opening so that it is impossibleto get disadvantage was the fact that a large any'back pressure and whatever city ordiamount of space was required in the partinance may exist regulating the size ofthe tion or pipe space so that the floor space acopening can be readily complied with. The tually lost became a serious item. No fitting ends ofthe fitting project through" the toilet 25 or method of connecting a fitting which room wall and means is provided for hangwould solve these difliculties has ever been ing the bowl with its horn in direct contact employed in the plumbing trade as far as With the projecting end of the fitting. This I am aware. I is my preferred form but the inventionmay Accordingly the principal object of the be modfied in many ways Without depart- 30 present invention is the provision'of a new ing from the spirit and scope thereof. so plumbing fitting of the type described. Referring now more particularly to the Another object is the provision of a fitdrawings t e fitting A is adapted to connect ting adapted-to connect the two closet bowls to bowls B and G which are of a wall hung back'to'backto a soil or waste pipe without type and are connected against a standard Y the other. The fitting A has one opening 10 for con- Another object isthe provision of such a necti'onby means of a nipple 11 and T12 to fitting which at the same time may be placed the usual soil or waste pipe 13. The other inastandardtoilet room partition. openings 14 and 16 are disposed opposite fitting particularly adapted for use with a openinglO and are adapted to be connected Wallhung type of bowl. to the bowls B and C respectively. Smaller Other objects and features of the invention openings 17 and 18' are provided for vent will be apparent from a consideration of the purposes at suitable positions with. respect panying drawings wherein V It is obvious that the usual type of three Fig, 1 is a vertical fragmentary sectional way connection cannot be employed as the view showing a closet bowl mounted directfitting A or the discharge would takeplace ly ontothe fitting, the section irregular and from the bowl B to the bowLC andvice versa.

50 takenalongztheline1i-1 of'Fig'. 2; ToovercomethisI place a baffle 19 between I the two openings and, as Fig. 4 illustrates,

' opening higher as can be done at this point this baffle 19 extends beyond the edge of the openings so that no matter how water is discharged through the opening it will be impossible for it to cross to the other bowl but it will strike the bafile 19 and be deflected 21 must be at least as large'as the opening- 16. I obtain this result by forming the sweep and in this way I am able to obtain more than the area of the opening 16 at the sweep opening. With the area of the opening 16 slightly more than 12 square inches (4 inches diameter) the sweep opening 21 may be formed so as to obtain almost 17 square inches of area. This is done by making the distance from the tip of the baflie to the opposite wall of the fitting three inches, and the height of the opening, that is the distance represented by the broken line a-a in Fig. 5 is 5 inches. This height is obtained by taking advantage of the natural shape of the, fitting at this point, and modifying dimensions slightly.

' One of the most necessary things in the design of this fitting is that the discharge have a clean sweep around the bend so that there will be no obstruction to an even flow, -or

nothing on which any waste matter might'become lodged and so interrupt the discharge movement. To secure this result I provide no'shoulders or the like. at the discharge openings,-that is the openings to which the bowls connect; but the running line connected to the nipple 11 is provided with a continuous flange 22 from a shoulder against which the nipple 11 projects. ,This flange is arranged to besubstantially the same width as the thickness of the nipple.

For securing the bowl to the fitting lugs .2323 are cast on to the fitting'and hinges -24-24are secured thereto by cap screws 2626. The unconnected legs of the hinges are provided with slots through which bolts "2727 ext nd for drawin the horn 28 of the bowl against the end of the fitting. The

Any other usual adjusting means may be provided, for any usual way of connecting the bowl may be utilized. The present invention is not meant to be entirely self suflicient but where necessary depending upon the installation may be hooked up with any ofthe present standard plumbing appliances. In installing my fitting the usual methods of roughing in etc. are used, the plaster. being finished to the'fitting as is the custom.

have not attempted to show any particular type of wall construction, as the fitting may be mounted in any standard toilet room partition. Most of these partitions even when employing the floor type bowls are approximately-10 inches in thickness, but I am able to mount my fitting ma 9 inch wall and do away with'lost floorspace entirely.

The fitting of my invention can be em ployed on either a vertical or horizontal waste pipe and is of very great advantage in either case. In mounting iton a horizontal line, there is considerable advantage. in certaintypes of construction particularly where cement-is used because the horizontal waste pipe or running line as itis-called can be roughed in. atthe floor level with the proper pitch and embedded in cement before the closet bowl fittings are installed. Subsequently, these fittings can beplaced' in and the elevation thereof very easily controlledoradjusted forby choosing nipples ll'of suitable length to bring these fittings to the elevation required. Similarly, these nipples 11 can be controlled in length to adjust the position of the fitting with respect to a vertical, line.

While my provision of the baflie 19 is apparently of extreme simplicity, I, found avery great deal of designing andstudy over. a period of years required before Iobta'in'ed fully satisfactory results. It is to be noted'that with the particular manner of supporting the enable those skilled in the art to practice it,

I do not restrict myself to the use of any particular form of fitting except within the scope of the appended claims. 7

What I claim as new and desire to protect by' Letters Patent of the United States is:

1. A plumbing fitting of substantially.

standard T dimensions for mountingjtwo closet bowls backto back comprising .a connection for a soil .or waste pipe oppositely disposed connections for the bowls-communicating with the waste pipe connection, and a bafiie disposed between the closet bowl connections forming sweep openings on both sidesthereof, leading to'the waste pipe connection, each sweep opening having an area at least as large as the opening in the closet bowl connection.

2. A three way fitting of substantially standard T dimensions for connecting closet bowls back to back having a closet connection with the usual circular opening, a soil or waste pipe connection with the usual circular opening,and a baflle between the closet bowl connections extending toward the waste pipe opening, the baffle forming a'relatively narrow sweep opening on each side thereof, each sweep opening being formed higher resulting in an oblong opening having at least the area of the closet bowl openings.

3. A plumbing fitting for mounting closet bowls back to back, said fitting comprising a T with the outward general appearance and dimensions of a standard T fitting, oppositely disposed openings adapted for connection to the closet bowls and a right angularly placed opening communicating with the oppositely disposed openings and adapted by suitable means to be connected to a waste pipe and a baflie between the two closet openings to prevent discharge across from one to the other, the opening at the baffle being oval shaped to have at least the area of the closet openings to avoid any possibility of back pressure into the closets and maintaining the outward size of a standard T fitting so that a minimum amount of wall space is needed to make connections. 7

4c. In a plumbing installation, a fitting for connection to a soil or waste pipe of and having the dimensions and appearance substantially of a standard T, oppositely faced connections for closet bowls, a waste pipe connection communicating with the closet connections, and a baflle between the closet connections for preventing discharge from one bowl to the other and formed to produce sweep openings having at least the cross sectional area of the closet openings, and a pipe nipple for interconnecting the waste opening of the fitting with the waste pipe.

- In witness whereof, I hereunto subscribe my name this 27th day of October, 1928.

SAMUEL KERSTEN.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US320113A US1855024A (en) | 1928-11-17 | 1928-11-17 | Plumbing fitting |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US320113A US1855024A (en) | 1928-11-17 | 1928-11-17 | Plumbing fitting |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1855024A true US1855024A (en) | 1932-04-19 |

Family

ID=23244944

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US320113A Expired - Lifetime US1855024A (en) | 1928-11-17 | 1928-11-17 | Plumbing fitting |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1855024A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2875453A (en) * | 1955-03-18 | 1959-03-03 | J A Zurn Mfg Co | Siphon leg and water closet combination |

| US2878483A (en) * | 1956-07-10 | 1959-03-24 | J A Zurn Mfg Co | Combination wall mounted water closet and flush tank with siphon leg |

| US3110907A (en) * | 1961-12-11 | 1963-11-19 | Rohr Corp | Unitized bathroom structure |

| US3398409A (en) * | 1966-12-02 | 1968-08-27 | Simpli Ci Ty Products Corp | Fixture for back-to-back mounting of water closets |

| US20060277673A1 (en) * | 2005-06-10 | 2006-12-14 | Onofrio Brescia | Support for wall mounted toilets |

| US20100101673A1 (en) * | 2008-10-24 | 2010-04-29 | Walter Cornwall | Aerator fitting having curved baffle |

-

1928

- 1928-11-17 US US320113A patent/US1855024A/en not_active Expired - Lifetime

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2875453A (en) * | 1955-03-18 | 1959-03-03 | J A Zurn Mfg Co | Siphon leg and water closet combination |

| US2878483A (en) * | 1956-07-10 | 1959-03-24 | J A Zurn Mfg Co | Combination wall mounted water closet and flush tank with siphon leg |

| US3110907A (en) * | 1961-12-11 | 1963-11-19 | Rohr Corp | Unitized bathroom structure |

| US3398409A (en) * | 1966-12-02 | 1968-08-27 | Simpli Ci Ty Products Corp | Fixture for back-to-back mounting of water closets |

| US20060277673A1 (en) * | 2005-06-10 | 2006-12-14 | Onofrio Brescia | Support for wall mounted toilets |

| US7945972B2 (en) * | 2005-06-10 | 2011-05-24 | Onofrio Brescia | Support for wall mounted toilets |

| US20110185486A1 (en) * | 2005-06-10 | 2011-08-04 | Rush University Medical Center | Support for Wall Mounted Toilets |

| US8122524B2 (en) | 2005-06-10 | 2012-02-28 | Rush University Medical Center | Support for wall mounted toilets |

| US20100101673A1 (en) * | 2008-10-24 | 2010-04-29 | Walter Cornwall | Aerator fitting having curved baffle |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1855024A (en) | Plumbing fitting | |

| US1606396A (en) | Backwater valve | |

| US2078879A (en) | Fittings for plumbing systems | |

| US406977A (en) | Soil or sewer pipe flushing device | |

| US1063637A (en) | Sewer-valve. | |

| US2878483A (en) | Combination wall mounted water closet and flush tank with siphon leg | |

| US2344649A (en) | Water closet | |

| US1740553A (en) | Plumbing fixture | |

| US748936A (en) | Combined floor-drain and backwater-trap | |

| JP7249480B2 (en) | drain trap | |

| JP2014105719A (en) | Self-sealing type valve member and joint member | |

| US1497171A (en) | Wall closet | |

| US2065104A (en) | Lavatories | |

| US2945240A (en) | Wall hung water closet | |

| US1718450A (en) | Pipe fitting | |

| US1524306A (en) | Flushing device | |

| US2875453A (en) | Siphon leg and water closet combination | |

| US1213343A (en) | Water-closet structure. | |

| JP2018044294A (en) | adapter | |

| US235134A (en) | John demakest | |

| US1172836A (en) | Waste-pipe connection. | |

| US742866A (en) | Water-closet. | |

| US2266035A (en) | Plumbing | |

| US2280952A (en) | Pipe fitting | |

| US1771945A (en) | Lavatory and toilet seat |