US1854739A - Ruling machine - Google Patents

Ruling machine Download PDFInfo

- Publication number

- US1854739A US1854739A US50657A US5065725A US1854739A US 1854739 A US1854739 A US 1854739A US 50657 A US50657 A US 50657A US 5065725 A US5065725 A US 5065725A US 1854739 A US1854739 A US 1854739A

- Authority

- US

- United States

- Prior art keywords

- ruling

- block

- shaft

- impression cylinder

- rollers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011435 rock Substances 0.000 description 16

- 208000032837 Ring chromosome 16 syndrome Diseases 0.000 description 9

- 241000282472 Canis lupus familiaris Species 0.000 description 3

- 238000000034 method Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41G—APPARATUS FOR BRONZE PRINTING, LINE PRINTING, OR FOR BORDERING OR EDGING SHEETS OR LIKE ARTICLES; AUXILIARY FOR PERFORATING IN CONJUNCTION WITH PRINTING

- B41G3/00—Apparatus for printing lines

Definitions

- My f invention f relates to ruling 'L machinesA of the rotary type.

- rollersA are adapted tobefa'djustedo'n theirrespective levers so as to wary the radial distance' off the: centres" from the rulingblock shaft'about Which-'the levers rock. It

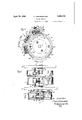

- Fig. ⁇ l is an end elevation

- Fig'. 2 is' a plan view, showingthose parts of a ruling" machine having three ruling blocks whichV are important for the understanding of'my invention

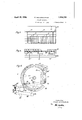

- Figs. 6 to 10 illustrate details of the niachine on a larger scale.

- Fig. 6 is a plan view showing the parts below and at the right of the ruling-block shaft, while Fig. 7 is an elevation of a lever for a beginning roller having a straight guiding slot for the block on which the beginning roller is' carried,

- Fig. 8 is a similar view of a lever for an end roller

- Fig. 9 is an elevation of means for adjusting the ruling block radially with regard to its shaft and Fig. 10 is a similar View of a lever similar to that shown in Fig. 7 but having a curved slot.

- 1 is the impression cylinder to which sheets 27 are fed by a feeding appliance to be described below with reference to Fig. 5, and 2, 2 are frame members in which the shaft 3 of the impression cylinder 1 is mounted to rotate.

- the number of sheets which can be printed on an impression cylinder at the same time obviously is a function of their lengths and of the diameter of the cylinder.

- the impression cylinder is able to receive three sheets at a time and therefore three ruling blocks indicated generally by I, Il and HI in Fig. 1, have been provided.

- I, Il and HI in Fig. 1 As all the ruling blocks are identical, only one of them, to wit, No. III, will be described.

- 6 is the ruling-block shaft referred to in the 1ntroduction which is mounted to rotate in the frame members 2, as best seen in Fig. 6.

- 7 and 13 are the levers on which the beginning rollers 8 and the end rollers 20, respectively, are mounted. These levers are free to rock about the ruling-block shaft 6.

- brackets 11 and 14 which are keyed on the shaft 6 and provided with adjustable checks in the shape of screws 12 and 14.

- the screw 14 engages a forkshaped extension 13 at the inner side of the lever 13 and its bracket 14 is connected with theframe 2 by a spring 142.

- 6 and 62, Fig. 2 are arms which are keyed to the rulingblock shaft 6

- 63 Fig. 6

- blocks which are fitted to slide in the slotted ends of the arms 6 and 62, as illustrated for the arm 62 in Fig.

- 61 is the hand ⁇ wheel of a screw spindle by which the block 6.3 is displaced in the arm 62, 5 is a shaft which is rotatably supported at either end in the block 63 of the corresponding arm 6 or 62, and 4 are the ruling rollers which aresecured on the shaft 5. It will be understood that the spring 142 tends to hold the rollers4 engaged with the sheet or sheets Von the impression cylinder 1.

- the beginning roller 8 is mounted to rotate on a slide 21 in a slot 10 of its lever 7,

- A9 being a threaded spindle with a knurled handle 9, 10 being a graduation extending along one edge of the slot 10, and a mark is made on the slide 21 for indicating its position in the slot 10.

- the pin 20 about which the'end roller 2O rotates is supported in an eye of its lever 13 by means of an eccentric bearing (Fig. 8) and a knurled handle 202 is secured on the end of the pin, as will appear from Fig. 6.

- Fig. 10 An example of such modification is illustrated in Fig. 10 where the slot 100 for the block 210 in the lever is curved on an arc of a circle about the axis of the impression cylinder 1.

- the nut 211 ofthe spindle 90 is spherical and the block 210 is recessed so as to make room for the required rocking motion of the spindle 90.

- the end of the spindle 90 is guided in a slot 71 at the free end of the lever 70 and curved checks 92 and 93 are formed on the spindle 90 to abut against the slotted end of the lever 70 from both sides.

- the ruling blocks are controlled by tripping cams 19, 19 and 192 which cooperate with the beginning rollers 8, by tripping cams 23, 23 and 232 which cooperate with the end rollers 20, and by cams 22, 22 and 222 which bridge the gap between two beginning and end cams.

- the cams are adjustably held in a cam support 18 which is keyed on the shaft 3 of the impression cylinder 1.

- 'lwo grooved rings 16 and 16 are secured at the front and rear ends of the cam support 18, the cams 19, 19 and 192 being inserted in the groove of the ring 16, and the cams 22, 22 and 222, and 23, 23 and 232 being inserted in the groove of the ring 16.

- Each cam is provided with a sector-shaped base which is adapted to be inserted in the groove of the corresponding ring, as shown in Fig. 6 at the lower lefthand corner, where the groove of the ring 16 is partly broken open.

- a bracket of L-section is inserted in the groove of the ring 16, and enters a recess in the base of the cam with the web which is parallel to the axis of the ring, while the other web abuts on one of the faces of the groove.

- a wedge 232 is inserted between the base of the cam and an inclined face on the inside of the adjacent web of the bracket.

- a screw 233 is inserted in a threaded hole of the wedge 232 so that the base of the cam is clamped firmly between the wedge and the wall of the groove.

- the active portion of each cam is a curved rib projecting from its base.

- the .cam support 18 is provided with graduations for adjusting the grooved rings 2.65 the spindles 9;for the beginning rollerl 8 and 16, .16.

- Fig. 4 shows the graduationfor the ring16, and also diagrammatically the cams 19, 19 and192.

- the positions of the.cams withrespectto the graduation are indicated by marks on the ring ⁇ 16 which indicate degrees. Similar means, ⁇ not shown, are provided ⁇ for indicating the positions ofthe cams 23,23 and 232 on the ring 16.

- the feeding apparatus ⁇ is shown diagrammatically in Fig. 5.

- l27 is a sheet vwhich is supplied to the impression cylinder 1 yby two endless-conveyers28 and29.

- the conveyer belt 28 is/supportedon rollers 30, 31 and 32.

- the conveyer belt29 ⁇ is partly supportedvon thefimpressioncylinder 1, and partly on a roller 33 which holds it engaged with-the belt 28 between the rollers 30 and 32.

- 26 is a check-forcontrolling-the feeding ofthe sheets 27.

- the check is secured to the end of an arm" 34 which is fulcrumed at 35 and is reciprocated by a link 25.

- the link is equipped with a pulleback spring 36 tending tohold it against afixed check 37 on the frame of the machine.

- the other end of the link 25 is pivoted to a cam 24 which in turn is pivoted to a suspension link 24.

- vDogs 17, 17 and 172 arezarranged at the rear face of the cam support 18 the dog 17 2appearing in ⁇ Fig. 6.

- the number of dogs' is equal to the number of ruling blocks, in the present instance three.

- Fig. 1 The direction in which the sheets are fed into the machine and the length of-the ruled spaces are indicated ⁇ in Fig. 1. Assumethat threesheetsare to be ruled during one rotation of. theimpression cylinder 1. Each sheet is fed to the impression cylinder as determined by the operation ofthe check 26 in Figr. Each ruling blockthen performs on each sheet a predetermined ruling operation, forjinstance, the first-block I drawsthelines tz ⁇ as shown in Fig. 3, the second'block II draws the lines. b, and the third block 'III draws the lines c. Assume-further that the beginning of the ruled space on each sheet'is at aA ⁇ distance fl from thetop ⁇ of-the sheet and that this distance is equal to onefinch.

- cams 19, 19 and 192 are now secured in the grooved ring 16 so that their ends are oppositethe marks 0 at vthe centre, 120:0 at the left and 1200 at the right, Fig. 4, the cams being thus equally distributed over the circumference of the ring 16.

- the cams 23,231and 232 are adjusted similarly ontheir grooved ring 16. ,A

- the ruling block lhasdrawn the lines a on a sheet andhas been lifted ofi' that sheet by the cam 232 and-the end, roller 20 ⁇ and is 'retained upon further rot-ation of the impression cylinder by :the cam 222 acting as a bridge, and the cam192 until the cam 192 has moved past the roller 8 of the ruling block I, whereupon the blockv starts ruling the next sheet.

- the ruling block I-I draws thelines b on the sheet on which the block I has drawn the lines wand the. operation of the block IIwill be'arrested 'when the cam 23 reaches its-end roller 20,;raising-the rulingrollers 4 from thesheetr and maintaining the block II in-inactive position until its beginning roller 8 hasbeenreleased bythe cam 192 rwhen its rulingrollers begin onra new sheet.

- the distances from. the top ⁇ of the sheet at which the various ruling'o-perationsstart is a function of relative position of the ruling blocks I, II and III and the adjustment of the tripping cams, and it will alsobe understood that when the cams and thebeginning and end rollers have been adjusted Vonce and for all-an operation which is performed readily, eXactly and to the elimination of all cut-and-t-ry methods by the-.means described-.the machine can be startediand will rule correctly the first as well as the last sheetof its pile and .waste is entirely eliminated.

- a ruling machine of the rotary type comprising a frame, a rotaryimpressioncylinder mounted in said frame,;meansforfeed ing sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected with said shaft, means for yieldably holding said ruling rollerson said block in Contact With the sheets on said impression cylinder, and tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to co-operate respectively yWith said beginning and end rollers.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation with respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, an adjustable beginning and an end roller operatively connected With said shaft, means for adjusting said beginning roller on said ruling block, means for yieldably holding said ruling rollers on said block in contact with the sheets on said irnpression cylinder, and tripping cams connected to said impression cylinder so as to partake in its rotationand adapted to co-operate respectively with said beginning and end rollers.V

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets tol said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an adjustable end roller operatively connected With said shaft, means for adjusting said end roller on said ruling block, means for yieldably holding said ruling rollers on said block in contact with the sheets on said impression cylinder, and tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to cooperate respectively With said beginning and end rollers.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheet-s to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft including tvvo levers mounted on and free to rock about said shaft, a beginning roller on one of said levers, an end roller on the other lever, and ruling rollers supported by said shaft, means for restricting the rocking motion of saidV levers Wi th respect to said ruling-block shaft, Whereby upon continued rocking motion of anyone of said levers said shaft is rotated, and tripping cams connected to said impression cylinder so as to partake in its rotation, one of said cams being adapted to -cooperate With said beginning roller, and the other cam being adapted to cooperate with said end roller.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft including two levers mounted on and free to rock about said shaft, an adjustable beginning roller on one of said levers, means for adjusting said beginning roller on its lever, an end roller on the other lever, and ruling rollers supported by said shaft, means for restricting the rocking motion of said levers With respect to said rulingblock shaft, whereby upon continued rocking motion of anyone of said levers said shaft is rotated, ⁇ and tripping cams connected to said impression cylinder so as to partake in its rotation, one of said cams being adapted t0 cooperate with said beginning roller, and the other cam being adapted to cooperate With said end roller.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block vshaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft including tWo levers mounted on and fre-e to rock about said shaft, a beginning roller on one of said levers, an adjustable end roller on the other lever, means for adjusting said end roller on its lever, and ruling rollers supported by said shaft, means for restricting the rocking motion of said levers With respect to said ruling-block shaft, whereby upon continued rocking motion of anyone of said levers said shaft is rotated, and tripping cams connected to said impression cylinder so as to partake in its rotation, one of said cams being adapted to cooperate with said beginning roller, and the other cam being adapted to cooperate With said end roller.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted'to rock in said frame and extending inparallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning andan end roller operatively connected With said shaft, means for yieldably'holding said ruling rollers onfsaidl block in contact with the sheets ion on said impression cylinder, a support connected to said impression cylinder, a ring adjustably mounted on said support, and tripping cams on said ring adapted to cooperate respectively with said beginning and end rollers.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected with said shaft,

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and eX- tending in parallel relation with respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected With said shaft, means for yieldably holding said ruling rollers on said block in contact With the sheets on said impression cylinder, divided tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to cooperate respectively With said beginning and end rollers, and means for holding the parts of said divided cams in adjusted position with respect to each other, said cams also including a part adapted to bridge an interstice between two parts of said divided cam.

- a ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets tosaid cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected With said shaft, means for yieldably holding said ruling rollers on said block in contact with the sheets on said impression cylinder, a support connected to said impression cylinder, a plurality of rings adjustably mounted on said support, and a cam part on each ring, said parts on said rings being adapted to make up complete cams upon relative adjustment of said rings.

Landscapes

- Making Paper Articles (AREA)

Description

April 19, 1932. F. HINTERDRFER `1,854,739

v RULING MACHINE Filed Aug. 1'7, 1925 4 Sheets-Sheet l April 19, 1932 F. HINTERDRFER 1,854,739

v RULING MACHINE Filed Aug. 17, 1925 4 Sheets-Sheet 2 April 19, 1932.

F. HINTERDR-'ER RULING MACHINE Filed Aug. 17I 1925 4 Sheets-Sheet 3 April 19, 1932.

F. HNTERDRFER RULING MACHINE Filed Aug. 17, 1925 \4 Sheets-Sheet 4 all mmm lw i Patented Apr. 19, 1932 PATENT OFFICE riunzfnun'rnnnonran, onnnniarns, HUNGARY; .Lisseiiiorv To' G. n REINHARDT, i LINIER-MASCHINENLUND BUCH'DRUCKMETALL-UTENsILIEN-FABRIK, 0F LEIPZIG;

RULING MAC'I'N'E Application med August 17,* isa-,-s'eriifno. 50,657, and in Germany 'August 26, 1924.

My f invention f relates to ruling 'L machinesA of the rotary type.

It is 4an object of1 my invention ito rprovide improved tripping :meansfforxa lmachine-of the kind described.-

In machines of this type a Ashaft extendingi in parallel to the axis about'.vvhichthe impression cylinder rotates, is' usually mounted torock inthe frame `ofthe machine. This ,10,=` shaftwillbel referred toas the ruling-block shaft. It supportsa block-or anynumber of blocks whichwill be referred to as the rulingfblocks7- Each ruling-block includes a set of ruling..ro'llers andother-elem'ents, as:

sheet and is therefore termed the beginning roller. The other rollerldetermnes the end ofl the rulin-gl at orlnearuthe bottomy of'f a'` y sheetrand is therefore termed the"end roller. 25 The rollersA are adapted tobefa'djustedo'n theirrespective levers so as to wary the radial distance' off the: centres" from the rulingblock shaft'about Which-'the levers rock. It

will be understood that, two levers, -Withthe' :50 beginning. andthe end rollers, and a set of ruling rollers' between the two levers, make upV the unit which has been'den'ed above vas the Lfruling blockl. Tripping-cams are op# erativelycon'nected to the impression cylinder l so las to partake in-rotation'fandioperatethe rollers of the ruling blocks 1 when' they are engage'dby the cams;-

In machines ofthis kindasheretoforedesigned asingle 'lever" is secured Von"V one end ofAv the 'ruling-blockishaft and the beginning and end rollers are supported onV this v single leverto rotate about' a.com'fmo-r'i!pivot.v Separate cams are provided for` controlling the beginning'andl Vend rollers.

adjustable l in grooves off a support Vand partake in' the rotation ofthe impression"cylin-y der. This lold system hasfthe' drawback that every cani must be adjusted separately which noton'ly is slow and laborious, but; also uncertainAA as the proper positions-"offthe'f cams The cams va're'- must'be found by cut-and-try methods andmust be tested on sheets which are wasted untilthe operator has succeeded in properly adj ustingthe cams. Conditionsobviously become-particularly difficult if several sheets are ruled at'the same time on a single impression cylinder, for each sheet requires separate'adjustment of thesetof cams 'bywhioh its ruling.' blocks are controlled Forv instance, it is desi-redto rule three sheets on4v a single impression cylinder, and each sheetl ha'srthree headings so that each sheet requires three sets of lines of various lengths, not less than -nine cams require adjustment for the headings alone and, unless all lines extend-tov the same vdistance fromthe bottom of the sheets, a corresponding number of cams must be Aadjusted for the .ends ofthe lines.

These drawbacks of the old system and they waste-of labour, timeand material entailed areavoided in my machine'in'which only two cams pershe`etrequire adjustment, one Cain for 'thebeginningg and the other forthe end adjustment, and for each additional sheet one4 more set of cams and rollers must'be adjusted. Obviously the adjusting operation is much facilitated and accelerated by these means.

In'the drawings afIiXed to this specification and forming part thereof a machine embodying myv invention is illustrated diagrammatically by way of example.

In the drawings Fig.` l is an end elevation,

Fig'. 2 is' a plan view, showingthose parts of a ruling" machine having three ruling blocks whichV are important for the understanding of'my invention,

Fig. Billustrates aruled'sheet, j

Fig. Llisa developed illustration ofthe graduationfor adjusting the tripping cams, Fig. 5is a"diagrammati`c elevation lof the feedingapparatus,` Y

Figs. 6 to 10 illustrate details of the niachine on a larger scale.

Fig. 6 is a plan view showing the parts below and at the right of the ruling-block shaft, while Fig. 7 is an elevation of a lever for a beginning roller having a straight guiding slot for the block on which the beginning roller is' carried,

Fig. 8 is a similar view of a lever for an end roller,

Fig. 9 is an elevation of means for adjusting the ruling block radially with regard to its shaft and Fig. 10 is a similar View of a lever similar to that shown in Fig. 7 but having a curved slot.

Referring now to the drawings, 1 is the impression cylinder to which sheets 27 are fed by a feeding appliance to be described below with reference to Fig. 5, and 2, 2 are frame members in which the shaft 3 of the impression cylinder 1 is mounted to rotate.

The number of sheets which can be printed on an impression cylinder at the same time, obviously is a function of their lengths and of the diameter of the cylinder. In the present instance, it has been assumed that the impression cylinder is able to receive three sheets at a time and therefore three ruling blocks indicated generally by I, Il and HI in Fig. 1, have been provided. As all the ruling blocks are identical, only one of them, to wit, No. III, will be described. 6 is the ruling-block shaft referred to in the 1ntroduction which is mounted to rotate in the frame members 2, as best seen in Fig. 6. 7 and 13 are the levers on which the beginning rollers 8 and the end rollers 20, respectively, are mounted. These levers are free to rock about the ruling-block shaft 6. Their rocking motion is limited by brackets 11 and 14 which are keyed on the shaft 6 and provided with adjustable checks in the shape of screws 12 and 14. The screw 14 engages a forkshaped extension 13 at the inner side of the lever 13 and its bracket 14 is connected with theframe 2 by a spring 142. 6 and 62, Fig. 2, are arms which are keyed to the rulingblock shaft 6, 63 (Fig. 6) are blocks which are fitted to slide in the slotted ends of the arms 6 and 62, as illustrated for the arm 62 in Fig. 6, 61 is the hand` wheel of a screw spindle by which the block 6.3 is displaced in the arm 62, 5 is a shaft which is rotatably supported at either end in the block 63 of the corresponding arm 6 or 62, and 4 are the ruling rollers which aresecured on the shaft 5. It will be understood that the spring 142 tends to hold the rollers4 engaged with the sheet or sheets Von the impression cylinder 1. The arms 6 and A62, with the blocks k6,3, the screw spindles and the hand wheels 61, the

'1 shaft 5 and the ruling rollers 4, make up one of the units which have been termed ruling blocks.

The beginning roller 8 is mounted to rotate on a slide 21 in a slot 10 of its lever 7,

A9 being a threaded spindle with a knurled handle 9, 10 being a graduation extending along one edge of the slot 10, and a mark is made on the slide 21 for indicating its position in the slot 10. The pin 20 about which the'end roller 2O rotates is supported in an eye of its lever 13 by means of an eccentric bearing (Fig. 8) and a knurled handle 202 is secured on the end of the pin, as will appear from Fig. 6.

It will be understood that the means for adjusting the rollers 8 and 2O in their respective levers may be modified in various ways. An example of such modification is illustrated in Fig. 10 where the slot 100 for the block 210 in the lever is curved on an arc of a circle about the axis of the impression cylinder 1. The nut 211 ofthe spindle 90 is spherical and the block 210 is recessed so as to make room for the required rocking motion of the spindle 90. The end of the spindle 90 is guided in a slot 71 at the free end of the lever 70 and curved checks 92 and 93 are formed on the spindle 90 to abut against the slotted end of the lever 70 from both sides.

The ruling blocks are controlled by tripping cams 19, 19 and 192 which cooperate with the beginning rollers 8, by tripping cams 23, 23 and 232 which cooperate with the end rollers 20, and by cams 22, 22 and 222 which bridge the gap between two beginning and end cams.

The cams are adjustably held in a cam support 18 which is keyed on the shaft 3 of the impression cylinder 1. 'lwo grooved rings 16 and 16 are secured at the front and rear ends of the cam support 18, the cams 19, 19 and 192 being inserted in the groove of the ring 16, and the cams 22, 22 and 222, and 23, 23 and 232 being inserted in the groove of the ring 16. Each cam is provided with a sector-shaped base which is adapted to be inserted in the groove of the corresponding ring, as shown in Fig. 6 at the lower lefthand corner, where the groove of the ring 16 is partly broken open. As will appear from this figure a bracket of L-section is inserted in the groove of the ring 16, and enters a recess in the base of the cam with the web which is parallel to the axis of the ring, while the other web abuts on one of the faces of the groove. A wedge 232 is inserted between the base of the cam and an inclined face on the inside of the adjacent web of the bracket. A screw 233 is inserted in a threaded hole of the wedge 232 so that the base of the cam is clamped firmly between the wedge and the wall of the groove. The active portion of each cam is a curved rib projecting from its base. The .cam support 18 is provided with graduations for adjusting the grooved rings 2.65 the spindles 9;for the beginning rollerl 8 and 16, .16. Fig. 4shows the graduationfor the ring16, and also diagrammatically the cams 19, 19 and192. The positions of the.cams withrespectto the graduation are indicated by marks on the ring`16 which indicate degrees. Similar means, `not shown, are provided `for indicating the positions ofthe cams 23,23 and 232 on the ring 16.

The feeding apparatus `is shown diagrammatically in Fig. 5. l27 is a sheet vwhich is supplied to the impression cylinder 1 yby two endless-conveyers28 and29. The conveyer belt 28 is/ supportedon rollers 30, 31 and 32. The conveyer belt29` is partly supportedvon thefimpressioncylinder 1, and partly on a roller 33 which holds it engaged with-the belt 28 between the rollers 30 and 32. 26 is a check-forcontrolling-the feeding ofthe sheets 27. The check is secured to the end of an arm" 34 which is fulcrumed at 35 and is reciprocated by a link 25. The link is equipped with a pulleback spring 36 tending tohold it against afixed check 37 on the frame of the machine. The other end of the link 25 is pivoted to a cam 24 which in turn is pivoted to a suspension link 24. vDogs 17, 17 and 172 arezarranged at the rear face of the cam support 18 the dog 17 2appearing in` Fig. 6. The number of dogs'is equal to the number of ruling blocks, in the present instance three. The

dogs engage thecam 24 at regular intervals, operating the link 25 and retracting the check 26. `It will be understood that the check 26 retains the sheets 27 while the belts 28l and 29.1nove on. Vhen the-check is retracted, the belts deliver the sheet to the impression cylinder.

The operation of my improved machine is as follows:

The direction in which the sheets are fed into the machine and the length of-the ruled spaces are indicated` in Fig. 1. Assumethat threesheetsare to be ruled during one rotation of. theimpression cylinder 1. Each sheet is fed to the impression cylinder as determined by the operation ofthe check 26 in Figr. Each ruling blockthen performs on each sheet a predetermined ruling operation, forjinstance, the first-block I drawsthelines tz `as shown in Fig. 3, the second'block II draws the lines. b, and the third block 'III draws the lines c. Assume-further that the beginning of the ruled space on each sheet'is at aA` distance fl from thetop `of-the sheet and that this distance is equal to onefinch. The cams 19, 19 and 192 are now secured in the grooved ring 16 so that their ends are oppositethe marks 0 at vthe centre, 120:0 at the left and 1200 at the right, Fig. 4, the cams being thus equally distributed over the circumference of the ring 16. The cams 23,231and 232 are adjusted similarly ontheir grooved ring 16. ,A

f Further `adjustment is effectedby means of by gmeallS 'of theshaft'20 forthe endrollers 20.

.Igngthe position of parts illustrated in Fig.

1 the ruling block lhasdrawn the lines a on a sheet andhas been lifted ofi' that sheet by the cam 232 and-the end, roller 20` and is 'retained upon further rot-ation of the impression cylinder by :the cam 222 acting as a bridge, and the cam192 until the cam 192 has moved past the roller 8 of the ruling block I, whereupon the blockv starts ruling the next sheet. Y

,The ruling block I-I draws thelines b on the sheet on which the block I has drawn the lines wand the. operation of the block IIwill be'arrested 'when the cam 23 reaches its-end roller 20,;raising-the rulingrollers 4 from thesheetr and maintaining the block II in-inactive position until its beginning roller 8 hasbeenreleased bythe cam 192 rwhen its rulingrollers begin onra new sheet.

`When the beginning rollerS of a given shaft'6ghasbeen released by one of the cams 19, 19 and 192, the spring 142 rotates the shaft 6 and moves the ruling VVrollers 4 into contact withthe sheet on the impression cylinderg1. At-the end ofthe ruling operation the end roller 20is engaged -by one of the cams2323 and232, the shaft 6 is rotated against theaction of the spring 142, and the ruling,;rollers `4'ar e raised from the sheet. Independent rollers and independent means for regulating the position of the rollers'in their respective levers 7 and 13, are provided for determining exactly the beginning and the endofga'line without such rollers and regulatingmeansinterfering with each other.

' The sheet on ,whichthe blockII has drawn the lines b now `passes on to the block III which willstart drawing the linesA c-as soon asthe cam 19 will have released its beginning roller 18.

It will be understood that the distances from. the top` of the sheet at which the various ruling'o-perationsstart, is a function of relative position of the ruling blocks I, II and III and the adjustment of the tripping cams, and it will alsobe understood that when the cams and thebeginning and end rollers have been adjusted Vonce and for all-an operation which is performed readily, eXactly and to the elimination of all cut-and-t-ry methods by the-.means described-.the machine can be startediand will rule correctly the first as well as the last sheetof its pile and .waste is entirely eliminated.

I wish `it to be understood that I donot desire to be limited tothe exact details of construction shown and described, for obvious modifications `will occur to a person skilled in the art.

'I claim: Y

1. A ruling machine of the rotary type comprising a frame, a rotaryimpressioncylinder mounted in said frame,;meansforfeed ing sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected with said shaft, means for yieldably holding said ruling rollerson said block in Contact With the sheets on said impression cylinder, and tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to co-operate respectively yWith said beginning and end rollers.

2. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation with respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, an adjustable beginning and an end roller operatively connected With said shaft, means for adjusting said beginning roller on said ruling block, means for yieldably holding said ruling rollers on said block in contact with the sheets on said irnpression cylinder, and tripping cams connected to said impression cylinder so as to partake in its rotationand adapted to co-operate respectively with said beginning and end rollers.V

3. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets tol said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an adjustable end roller operatively connected With said shaft, means for adjusting said end roller on said ruling block, means for yieldably holding said ruling rollers on said block in contact with the sheets on said impression cylinder, and tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to cooperate respectively With said beginning and end rollers.

t. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheet-s to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft including tvvo levers mounted on and free to rock about said shaft, a beginning roller on one of said levers, an end roller on the other lever, and ruling rollers supported by said shaft, means for restricting the rocking motion of saidV levers Wi th respect to said ruling-block shaft, Whereby upon continued rocking motion of anyone of said levers said shaft is rotated, and tripping cams connected to said impression cylinder so as to partake in its rotation, one of said cams being adapted to -cooperate With said beginning roller, and the other cam being adapted to cooperate with said end roller.

5. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft including two levers mounted on and free to rock about said shaft, an adjustable beginning roller on one of said levers, means for adjusting said beginning roller on its lever, an end roller on the other lever, and ruling rollers supported by said shaft, means for restricting the rocking motion of said levers With respect to said rulingblock shaft, whereby upon continued rocking motion of anyone of said levers said shaft is rotated,`and tripping cams connected to said impression cylinder so as to partake in its rotation, one of said cams being adapted t0 cooperate with said beginning roller, and the other cam being adapted to cooperate With said end roller.

6. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block vshaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft including tWo levers mounted on and fre-e to rock about said shaft, a beginning roller on one of said levers, an adjustable end roller on the other lever, means for adjusting said end roller on its lever, and ruling rollers supported by said shaft, means for restricting the rocking motion of said levers With respect to said ruling-block shaft, whereby upon continued rocking motion of anyone of said levers said shaft is rotated, and tripping cams connected to said impression cylinder so as to partake in its rotation, one of said cams being adapted to cooperate with said beginning roller, and the other cam being adapted to cooperate With said end roller.

7. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted'to rock in said frame and extending inparallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning andan end roller operatively connected With said shaft, means for yieldably'holding said ruling rollers onfsaidl block in contact with the sheets ion on said impression cylinder, a support connected to said impression cylinder, a ring adjustably mounted on said support, and tripping cams on said ring adapted to cooperate respectively with said beginning and end rollers.

8. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected with said shaft,

means for yieldably holding said ruling rollers on said block in Contact with the sheets on said impression cylinder, divided tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to cooperate respectively With said beginning and end rollers, and means for holding the parts of said divided cams in adjusted position With respect to each other. i

9. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets to said cylinder, a ruling-block shaft mounted to rock in said frame and eX- tending in parallel relation with respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected With said shaft, means for yieldably holding said ruling rollers on said block in contact With the sheets on said impression cylinder, divided tripping cams connected to said impression cylinder so as to partake in its rotation and adapted to cooperate respectively With said beginning and end rollers, and means for holding the parts of said divided cams in adjusted position with respect to each other, said cams also including a part adapted to bridge an interstice between two parts of said divided cam.

10. A ruling machine of the rotary type comprising a frame, a rotary impression cylinder mounted in said frame, means for feeding sheets tosaid cylinder, a ruling-block shaft mounted to rock in said frame and extending in parallel relation With respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected With said shaft, means for yieldably holding said ruling rollers on said block in contact with the sheets on said impression cylinder, a support connected to said impression cylinder, a plurality of rings adjustably mounted on said support, and a cam part on each ring, said parts on said rings being adapted to make up complete cams upon relative adjustment of said rings.

shaft mounted to rock in said frame and extending in parallel relation with respect to the axis of said impression cylinder, a ruling block on said shaft, said ruling block including ruling rollers, a beginning and an end roller operatively connected With said shaft, means for yieldably holding said ruling rollers on said block in contact with the sheets on said impression cylinder, a support connected to said impression cylinder, a graduated disc on said support, marked rings mounted to rotate on said support and adapted to be fixed with respect to said disc, and a cam part on each ring, said parts being adapted to make up complete cams upon relative adjustment of said rings.

In testimony whereof I aix my signature.

FRANZ HINTERDRFER.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE1854739X | 1924-08-26 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1854739A true US1854739A (en) | 1932-04-19 |

Family

ID=7746153

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US50657A Expired - Lifetime US1854739A (en) | 1924-08-26 | 1925-08-17 | Ruling machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1854739A (en) |

-

1925

- 1925-08-17 US US50657A patent/US1854739A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2577099A (en) | Method of and means for registering impressions in multiunit sheet printing machines | |

| GB1380054A (en) | Devices for sensing irregularities in moving webs of material | |

| GB2093438A (en) | Impression cylinders for sheet-fed rotogravure presses | |

| US2539965A (en) | Printing plate mounting and proofing press | |

| US3864879A (en) | Cam grinding | |

| US2364942A (en) | Duplicating machine | |

| US3026796A (en) | Doctor blade assembly | |

| US3696743A (en) | Apparatus for regulating a color dosing device in relation to a color doctor roller | |

| US2525931A (en) | Plate mounting means for rotary printing machines | |

| US1854739A (en) | Ruling machine | |

| US1814367A (en) | Long bar grinder | |

| US3618516A (en) | Support for offset cylinders of printing machines | |

| US3163110A (en) | Interrupter for rotary printing machines | |

| US3150588A (en) | Cylinder mounting, adjusting and interrupting means for offset printing and like machines | |

| GB1291915A (en) | MACHINES FOR IMPRINTING HOLLOW CYLINDRICAL ARTICLES e.g. CUPS | |

| US3610149A (en) | Arrangement for adjustment of the position of an ink spreader roll | |

| US5732628A (en) | Sheet-conveying drum for printing machines | |

| US923242A (en) | Apparatus for printing transfer-designs on paper in two or more colors or mediums. | |

| DE3865456D1 (en) | PRINT WORK. | |

| US1780348A (en) | Sheet-registering mechanism for printing machines | |

| US2804015A (en) | Printing gap adjusting device for printing machines | |

| US2294980A (en) | Sheet registering mechanism for printing machines | |

| US2788741A (en) | Printing press accessory | |

| US1296008A (en) | Gripper-pad adjustment. | |

| US3815496A (en) | Apparatus for adjusting the relative positions of the cylinders in offset printing machines |