US1853680A - Grain door nailing strip - Google Patents

Grain door nailing strip Download PDFInfo

- Publication number

- US1853680A US1853680A US332354A US33235429A US1853680A US 1853680 A US1853680 A US 1853680A US 332354 A US332354 A US 332354A US 33235429 A US33235429 A US 33235429A US 1853680 A US1853680 A US 1853680A

- Authority

- US

- United States

- Prior art keywords

- nailing

- strip

- nailing strip

- grain door

- wooden

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002184 metal Substances 0.000 description 15

- 230000006378 damage Effects 0.000 description 4

- 208000027418 Wounds and injury Diseases 0.000 description 2

- 208000014674 injury Diseases 0.000 description 2

- 241000287181 Sturnus vulgaris Species 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61D—BODY DETAILS OR KINDS OF RAILWAY VEHICLES

- B61D19/00—Door arrangements specially adapted for rail vehicles

- B61D19/001—Door arrangements specially adapted for rail vehicles for wagons or vans

- B61D19/002—Door arrangements specially adapted for rail vehicles for wagons or vans specially adapted for grain cars

Definitions

- This invention relates to a grain door nailing strip.

- the invention comprises the novel struc ture and combinations of parts hereinafter described and more particularly pointed out and defined in the appended claims.

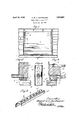

- Figure l is an interior elevational View of a house car embodyingpnailing strips involving this invention.

- Figure 2 is an enlarged sectional view taken upon the line II-II ofFgure 1.

- Figure 3 is a View similar to Figure 2 illustrating a slightly modified form of the invention.

- Figure 4L is a fragmentary plan view of a metal sheathing for enclosing the nailing strip.

- Figure 5 is a fragmentary perspective view of the metal sheath for enclosing the nailing stri Aps an eXemplification of this invention

- a grain door nailing stripv embodying a wooden portion ll having a flat side which is adapted to lfit against the inner side of the door post 5 and extends in a vertical direction.

- rIhis wooden strip Vl is -metal bound upon three sides by metal sheet-h2 which isin the form of a channel for encompassing the threesides of the wooden strip.

- metal sheet-h2 which isin the form of a channel for encompassing the threesides of the wooden strip.

- rEhe outwardly directed portion of' the metal binding 'or in' other words the web thereof is ⁇ provided ⁇ with a series of apertures 8 thro-ugh which the boards 6 that constitute thegrain door are adapted to beA nailed.

- the Vmetal sheath is provided with inset or countersunk seclretsl for receiving the heads of the bolts T that attach the nailing strips to the posts.

- eachnailing stripl has a depression for recei'ving'the countersunlr socket tof the sheath in order that the head of the bolt 7 may be flush with.l the outer rsurface of the metal sheath.”

- F iguresv l and 2 illustrate a house car ofthe single sheathed type.

- F igure 3 there is i illustrated a part vofa house car known as the double sheathed type.

- the wood-en portion of the grain door nailing strip is indicated by the reference numeral la and it will be noted that this wooden portion is cut away as indicated at lb for receiving the inner sheathing 8 of the car.

- the metal sheath 2a is provided with unequal flanges.

- the shorter fiange 2b is adapted toV abut the sheathing 8.

- the modified form of nailing strip is however similar to the first form in that the whole exposedV area of the wooden lportion is completely yencased in a metal sheath.

- the metal sheath not only protects the wooden strip against injury and damage in use but also prevents the same from splitting or spreading'. Further it is easier to pry the boards 'loose from the nailing strip due to the metal sheath without causing any undue damageto the nailing strip. It will be ob# vious that the metal sheath of the nailing strip prolongs the life of the nailing strips and results in economy of operation and costs in the maintenance of the car.

- a grain door nailing strip comprising a Wooden portion having a channel shaped m metal member attached thereto, said member having a substantially ⁇ continuons surface provided with a plurality of spaced holes for receiving the securing nails and having sunken recesses for receiving portions of the l5 attaching means.

- a grain door nailing strip consisting of aHWooden portion, a channel shaped metal member-partially enclosing said portion and affording aY substantially continuous surface o provided with a series'of spaced holes, said surface having countersunk holes andmeans extending through said countersunk holes for securing said member to said Wooden portion.

- a grain door nailing structure comprising a Wooden portion, a metallic member having a continuous surface partly embracing said Wooden portion, said surface being provided With a plurality of spaced holes for receiving vsecuring nails and countersunk holes, aand means extending through said countersiink ⁇ holesA for securing lsaid .member to ysaid Wooden: portion.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Securing Of Glass Panes Or The Like (AREA)

Description

APill 12, 1932- A. w. l-lARTBAuER- GRAIN DOOR lNAILING STRIP Filed Jan. 14, 1929 Patented Apr. 12, 1932 entre stares AUGUST W. L. HARTBAUERQF CHICAGO, rLLnve'i's GRAIN noon MAILING s'rnrrv Application filed January 14, 192e.` serial No. 332,354.

This invention relates to a grain door nailing strip.

In the past, it has been customary to nail or fasten a pair of wooden strips to the inner A sides of the door posts. Upon these strips,

suitable boards were nailed to board up' the doorway when it. was desiredto earry'grain in the car. After the car is unloaded, or during unloading process these boards or planks are hammered loose fro-m the strips. Of course, when the car is to be used again, for hauling grain these boards or planks may be nailed upon the strips again. The severe and rough usage to which these nailing strips are put7 soon cause injury and damage to the same. Moreover, in applying the boards to the strips the same are apt to spread and split more or less. y

It is an obj ect of this invention to obviate the objections heretofore existing in the use of wooden nailing strips. rlhis is done by binding the nailing strip in a metal sheath and perforating the metal sheath to .receive the nails and fastening means for the strip.

The invention comprises the novel struc ture and combinations of parts hereinafter described and more particularly pointed out and defined in the appended claims.

In the accompanying drawings which illustrate a preferred embodiment of this in'- vention and in which similar reference numerals refer to similar features in the different views:

Figure l is an interior elevational View of a house car embodyingpnailing strips involving this invention.

Figure 2 is an enlarged sectional view taken upon the line II-II ofFgure 1.

Figure 3 is a View similar to Figure 2 illustrating a slightly modified form of the invention.

Figure 4L is a fragmentary plan view of a metal sheathing for enclosing the nailing strip. Y

Figure 5 is a fragmentary perspective view of the metal sheath for enclosing the nailing stri Aps an eXemplification of this invention,

there is shown in the drawings a grain door nailing stripv embodying a wooden portion ll having a flat side which is adapted to lfit against the inner side of the door post 5 and extends in a vertical direction. rIhis wooden strip Vl is -metal bound upon three sides by metal sheet-h2 which isin the form of a channel for encompassing the threesides of the wooden strip. rEhe outwardly directed portion of' the metal binding 'or in' other words the web thereof is` provided `with a series of apertures 8 thro-ugh which the boards 6 that constitute thegrain door are adapted to beA nailed. At suitable points the Vmetal sheath is provided with inset or countersunk seclretsl for receiving the heads of the bolts T that attach the nailing strips to the posts.

In referring to Figure 2, it will be noted that thewooden portion l of eachnailing stripl has a depression for recei'ving'the countersunlr socket tof the sheath in order that the head of the bolt 7 may be flush with.l the outer rsurface of the metal sheath."

F iguresv l and 2 illustrate a house car ofthe single sheathed type. In F igure 3 there is i illustrated a part vofa house car known as the double sheathed type. In this case the wood-en portion of the grain door nailing strip is indicated by the reference numeral la and it will be noted that this wooden portion is cut away as indicated at lb for receiving the inner sheathing 8 of the car. In this modified form of grain door nailing strip, the metal sheath 2a is provided with unequal flanges. The shorter fiange 2b is adapted toV abut the sheathing 8. The modified form of nailing strip is however similar to the first form in that the whole exposedV area of the wooden lportion is completely yencased in a metal sheath.

The metal sheath not only protects the wooden strip against injury and damage in use but also prevents the same from splitting or spreading'. Further it is easier to pry the boards 'loose from the nailing strip due to the metal sheath without causing any undue damageto the nailing strip. It will be ob# vious that the metal sheath of the nailing strip prolongs the life of the nailing strips and results in economy of operation and costs in the maintenance of the car.

I am aware that numerous details of conteI struction may be varied and many changes may be made through a Wide range Without departing from the principles of this invention, and I therefore do not purpose limiting the patent granted hereon otherwise than necessitated by the prior art.

I claim as my invention:

l. A grain door nailing strip comprising a Wooden portion having a channel shaped m metal member attached thereto, said member having a substantially `continuons surface provided with a plurality of spaced holes for receiving the securing nails and having sunken recesses for receiving portions of the l5 attaching means.

2. A grain door nailing strip consisting of aHWooden portion, a channel shaped metal member-partially enclosing said portion and affording aY substantially continuous surface o provided with a series'of spaced holes, said surface having countersunk holes andmeans extending through said countersunk holes for securing said member to said Wooden portion.

3. A grain door nailing structure comprising a Wooden portion, a metallic member having a continuous surface partly embracing said Wooden portion, said surface being provided With a plurality of spaced holes for receiving vsecuring nails and countersunk holes, aand means extending through said countersiink` holesA for securing lsaid .member to ysaid Wooden: portion.

In' testimony whereof I have hereunto subscribedwmy-na'meat Ghicago, Cook County,

Illinois. v

AUGUST W. L. Y HARTBAUER.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US332354A US1853680A (en) | 1929-01-14 | 1929-01-14 | Grain door nailing strip |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US332354A US1853680A (en) | 1929-01-14 | 1929-01-14 | Grain door nailing strip |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853680A true US1853680A (en) | 1932-04-12 |

Family

ID=23297862

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US332354A Expired - Lifetime US1853680A (en) | 1929-01-14 | 1929-01-14 | Grain door nailing strip |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853680A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4043274A (en) * | 1975-08-27 | 1977-08-23 | Pullman Incorporated | Railway car nailable door post |

| US4180000A (en) * | 1975-08-22 | 1979-12-25 | Pullman Incorporated | Freight car door post |

-

1929

- 1929-01-14 US US332354A patent/US1853680A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4180000A (en) * | 1975-08-22 | 1979-12-25 | Pullman Incorporated | Freight car door post |

| US4043274A (en) * | 1975-08-27 | 1977-08-23 | Pullman Incorporated | Railway car nailable door post |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4154172A (en) | Deck means for a railroad car | |

| US3102613A (en) | Nailable metal flooring | |

| US1853680A (en) | Grain door nailing strip | |

| US3996861A (en) | Nailable metal post and strap anchor structure | |

| US1790348A (en) | Staple | |

| US2733670A (en) | Strap anchor for freight cars | |

| US3149664A (en) | Expendable grain car door | |

| US2731660A (en) | Anchor edge | |

| US1348142A (en) | Draw-board fastener | |

| US1762664A (en) | Plastering gauge for door or window openings | |

| US1708613A (en) | Vehicle shipping device | |

| US1694673A (en) | Plaster casing | |

| US4043274A (en) | Railway car nailable door post | |

| US2060164A (en) | Floor protection for railway cars | |

| US2300018A (en) | Ladder structure | |

| US1785174A (en) | Doorframe | |

| US1454240A (en) | Grain-door fastener | |

| US1596244A (en) | Collapsible carrier | |

| US2576798A (en) | Car side construction and load bracing apparatus | |

| US4180000A (en) | Freight car door post | |

| US212694A (en) | Improvement in devices for loading and unloading lumber | |

| US2827861A (en) | Lading strap anchor for freight cars | |

| US1836846A (en) | Plaster trim form for openings in walls | |

| US1587331A (en) | Mixing receptacle | |

| US1424218A (en) | Shipping coop |