US1853594A - Drop side container car - Google Patents

Drop side container car Download PDFInfo

- Publication number

- US1853594A US1853594A US503299A US50329930A US1853594A US 1853594 A US1853594 A US 1853594A US 503299 A US503299 A US 503299A US 50329930 A US50329930 A US 50329930A US 1853594 A US1853594 A US 1853594A

- Authority

- US

- United States

- Prior art keywords

- car

- compartments

- partitions

- door

- uprights

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005192 partition Methods 0.000 description 34

- 238000009740 moulding (composite fabrication) Methods 0.000 description 19

- 238000010276 construction Methods 0.000 description 9

- 244000186140 Asperula odorata Species 0.000 description 4

- 235000008526 Galium odoratum Nutrition 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 241001225883 Prosopis kuntzei Species 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 241001474033 Acar Species 0.000 description 1

- VRDIULHPQTYCLN-UHFFFAOYSA-N Prothionamide Chemical compound CCCC1=CC(C(N)=S)=CC=N1 VRDIULHPQTYCLN-UHFFFAOYSA-N 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 210000005069 ears Anatomy 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61D—BODY DETAILS OR KINDS OF RAILWAY VEHICLES

- B61D3/00—Wagons or vans

- B61D3/16—Wagons or vans adapted for carrying special loads

- B61D3/20—Wagons or vans adapted for carrying special loads for forwarding containers

Definitions

- This invention relates to improvements in container cars of the type broadly disclosed in Reissue Patent No. 16,073, of May 19, 1925, and. more particularly to improvements in drop side container cars of the type shown, for example, in my prior application Serial No. ess rem,v filed April .12, 1929, Pat. No. 1,7 88,075; Jan. 6, 1931, and my prior application Serial No. 359,392, filed April30, 1929, Pat. No.

- the main object of the'present invention is to provide a drop side container car in which i the construction of the combined compartment forming partitions anddoor jambs is simplified'and rendered less heavy and cumbersome and more open than in the drop side container cars hereinbefore in use, without sacrifice of strength and durability, and with theadvantage ofreducing the cost of construction and the amount of dead weight carried by thecar, andof producing acar which may be readily and conveniently cleaned and repaired and kept in thorough working condition at materially, less cost.

- a further object of the invention is to pro,-

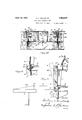

- Fig. 3 is a perspective view of the container car, looking toward ,the carfrom a point adjacent one end 'thereo'f, and showing clearly the constructionof the compartment forming partitions and door jambs and the opentype of cars produced'thereby, some of. the drop doors being shown in closed position and othersin open position.

- F ig. 5' is a similar sectional view,-taken on a line at one side of the partition.

- Fig.- 6 is'a section on line 6+6 of Fig. 5;

- Figs. 7 and 8 are sections on lines 7--7 and 79 8'8 of Fig, 4 looking, respe'ctively, toward .the cross rail of the partition and toward the floor of the'car.

- FIG. 9 is a view similar toFig. 5 showing in dotted linesthe door in released'position and in dot and dash lines the door in let down position and employed in conjunction with a'runway. 7 v

- Fig. 10 is' a view on an enlarged scale of aportion of the car looking toward aclos'ed 7 door.

- Fig. 11' isa-vertical section v on the line transversely disposed partitions 3 into spaces or compartments 4to receive the containers 5.

- the containers 5 may be of the well'known' forms and constructions in general use, those shown in the present instance being of that type provided with depending feet 6 to rest upon the floor or platform 2. Suitable means may "be provided in each compartment for engaging and holding the container 7 from shifting therein.

- the floor or platform is provided at the corners of each compartment with recesses or sockets 7 to receive the lower ends'of the feet 6, or-retaining members thereon, whereby the containers are held from shiftng movements.

- Each partition 3 comprises a cross bar or rail 8, preferably of metal and of T-shape in cross-section, said bar being horizontally disposed with its flat face uppermost and provided'with a depending central flange 9.

- the longitudinally extending parts 13 of the angle metal plates are arranged to form door jambs at the sides of the respective compartments 4, and the lower ends of said parts 13 are riveted, bolted or otherwise rigidly fastened to the side frame 11.

- the parts 11, 11' 12 and 13 form posts or standards at the sides of the car, and jambs or abutments against which the door 4 may close, and said parts cooperate with the cross bars 8 to provide arched partitions across the car and subdividing the same into the compartments 4.

- the cross bars or rails 8 have secured thereto abutment or wear strips 15 of wood or'other '40 suitable material, designed, without material addition of weight, to 'form renewable abutment surfaces increasing the width andstrength of the partition bars an'd'forming abutments against which the containers may '45 bear and which will sustain any rubbing wear and relieve themetal bars themselves therefrom,"said strips also providing comparatively soft wear surfaces to avoid marring or injuring the containers.

- These strips fit beneath the body portions of the bars and bear fagainstthe flanges 9 thereof and are secured to the flanges .

- partitions comprising the cross bars or rails 8, legs 11, angle metal plates 12,- fillers 12', and wear strips 15 as set forth, providesvvery light but strong and-durable, partitions for sub dividing the car into containing receiving compartments f which are in communication with each other beneaththe cross bars, thus doing away with the useof' solid or substantially solid bulk I heads of the character heretoforein use.

- a moreopen type of car is pro- W **d, that is,

- cross bars or rails 8 in some cases, may be left entirely in the clear between the posts to which it is attached, but it is preferable to provide suitable intermediate bracing means, such as in verted U-shaped braces 16 comprisingmembers riveted at their upper ends to the flange 9 and attheir lower ends to suitable portions of the car underframe.

- the car is provided with end walls 17, preferably of stationary or rigid type, and formed of metal plates provided at their upper edges with end cross bars or rails 18, which may include wear strips similar to the wear strips 15.

- the side walls of the car are of sectional type, each comprising a plurality of independently movable sections or doors 19 equal in number to the compartments 4 and adapted when in normal position to close the normally open sides of said compartments.

- Each door is provided adjacent its lower corner portions with trunnions 20, fitted to rotate and to have vertical sliding movements in elongated trunnion bearings 21 secured tothe outwardly extending flanges or webs 13 of the postsl2.

- the posts are provided with bolts or latch members 22 adapted for engagement with elongated bearing and keeper slots 23 in keeper plates 24, also secured to said flanges13 of the posts 12.

- the slots 23 open at their upper ends through the forward edges of the keeper plates,

- each door through the sliding engagement ofits trunnions 20-with the trunnion bearings-21 may be swung inwardly and slid, downwardly to a closed position in which bolts 22 will restat the bottom of the keeper slots 23 and holdtfhe door :in'such po' sition, as shown in full lines-in.

- Fig. 9 or the door may he slid upwardly to released posi tion, a shown in dotted lines in Fig. 9,'a1nd then downwardly to let-down or open position, as shown in dot and dash lines in Fig. 9

- the door When the door is disposed in open position, it is adapted to function asa sgangplank between the car and a station platform, as shown in Fig. 9, allowing a hand truck or other transfer device carrying aEcontainer to be moved to and from the station platform for loading the containers into'the car compartments 4 or removing the same therefrom.

- the bolts 22 and keepers 24 are provided for lockingithe doors in! closed position against outward movement aseach door is moved inwardly and downwardly-to such .

- Reintorcements 27 are provided on each door for sustaining the door against bulging and against distorting pressures when employed as a gangpla-nk,

- a stop 28 is provided on the side frame 11 for cooperation with each door to furtheras- 'sist in sustaining it against bulging pressures.

- This stop when the "door is 1n closed position, engages a recess in a flange'at the lower end of the door, and on the door is'an abutment strip 29 which reinforces the recessed part of the flange.

- Handholds 30 may also be provided on the door to further enable it to be readily and conveniently manipulated in its opening and closing movements.

- each door areformed openings 31 with 1 which hooks 32 on a runway board 33 may be engaged to hold the runway board securely against the upper edge of thedoor when the latter is in position to form a gangway, as

- fastening means for this purpose comprises a pivoted gravity or spring-operated locking member 34 for engagement with a locking projection at the upper end of each keeper plate 24, said locking member 34 being pivoted at its inner end to a bar 8, as at 35, and provided at its outer free endwith a beveled surface and a hook to engage the locking projection, whereby when the dooris closed latch each bar 8 for coaction with each locking member 34 is a holdingdog 36, pivoted at its inner end, as at 37, and having an outer end 38 forming a stop shoulder for engagement with the pivoted end of themember 34 when said member 34 is inlocking position, thus" preventing said member 34 from swinging upwardly to released position.

- Both the looking or latch member 34 and the dog 36 are of suflicient weight to lie in their engag:

- my invention provides acontainer car which enables the objects of the invention to be carried out in a simple, reliable :and; efi'ective manner, and which will be of requisite strength and durability,while-cheaper in construction, than prior ears of this type having solid bulk heads, and that the construction is also such 'as to. adapt the car to be cleaned and repaired in a'readier and easier manner, and sothat the .cost of repairing and maintaining the .samein serviceable condition will be reduced.

- Other advantages of the invention willibe readily understood bythose versed intheart without .a further and extended description.

- a containercar provided with container receiving compartments "formed by :transverse partitions of open-work character and establishing communication between therespective compartments, each comprising uprights at the sides of the .car and a'crossbar ;connecting said "uprights, thezuprights of adacent partitions forming doorways for the interveningcompartment at opposite sides of thezcar.

- a container car havingiendrwalls, and a longitudinal seriesof compartments vfor-riled by transverse partitions of jopenwork construction and-establishing communication bectween tthe COITIDa-EtHIEIItQfHDd closures 'for'the sidesof the compartments forming :drop side walls'o t'the car. member 34 will automatically move into en- I gagement with the. projection. Arranged on .3.

- a seontai-ner car having a longitudinal series of compartments formed by' arched transversely extending partitions, said 'compartments being open: at the sides of the car and havingjam'bs formed by the partitions, anddoors for said compartments adapted to close against saidjanibs and providing drop sides for the compartments adapted'to'serve as gan planks.

- I 1 I r 7 4 A 'on'tamer car having a longitudinal" series ot-compartments formed by :a rched openwork partitions, the compartments beingopen at the sides of the car and the ends of the. Y partition forming jambs at opposite sides of the openings, and side walls forthe 'car. com-- prising independent sections forming doors for the compartments adapted to close against a said jambs.

- a container car having end Walls, compartment forming partitions between the end walls, each partitioncomprising uprights at the sides of the carand a cross-bar connecting said uprights, said uprights 'serving'as door jambs and doors at the sides of the car for closing the compartments and'adapted to close against-said jambs andfo'rming' the drop-side walls of the car.

- a containerfcar having compartment forming partitions, and renewable wear by partitions, each partition comprising upstrips carried by said partitions.

- a contamer car having a plurality of container receivlng compartments formed rightssat'thesides of the'car and a crosspiece connecting said uprights, and renewable strips secured to the sides of the cross piecey 8.

- a container car having-a longitudinal series of compartments formed by transverse partitions, each including uprights and a cross-bar, said cross-bar being T-shaped in cross-section, and removable wear strips underlyingthehorizontal' webs of the bar and secured to the flange thereof.

- 'A containerv car having a floor and a longitudinal series ofcompartments formed thelsides of the car, and a of arched openwork partitions, each embodying 'flanged members forming uprights at flanged crossbar connecting said uprights, the flanges of r the upright forming members'providing'door 'jambs at the sidesof the car, and doors adapted to close against said j ambsb i 11*;

- a container, car having alongitudinal series of compartments formed by transverse pa-rtitionsj each comprising jamb forming uprights at the sides of the car an'da crosspiece connecting said uprights, elongatedr bearings on the uprights, open recessed keep .7 ers on the uprights, doors having trunnions and locking projections respectively engag- 1 ,12.

- a container car having a longitudinal series of compartments formed; by transverse part tions, each comprising Jamb forming 1 4 5 uprights atthe sides of the car and a cross 7 ,ing the bearings and keepers, and means adapted to interlock with the doors to hold the same from sliding movement.

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Wing Frames And Configurations (AREA)

Description

April 12, 1932. G. c. WOODRUFF 1,853,594

DROP SIDE CONTAINER CAR Filed Dec. 18, 1950 4 Sheet-Sheet 1 April 12, .1932. e. c. WOODRUFF DROP SIDE CONTAINER CAR Filed Dec. 18, 1930 4 Sheets-Sheet 2 April 12, 1932. G. c. WOODRUFF DROP SIDE CONTAINER CAR 18, 1950 4 Sheets-Sheet 3 Filed Dec.

gwoe'nlor 0M April 12, 1932. G. c. WOODRUFF DROP SIDE CONTAINER CAR] Filed Dec. 18, 1950 4 Sheets-Sheet 4 Patented Apr. 12, 1932 UNITED STATES PATENT- OFFICE. 'a

GI-R-AHAMv C. W OODRUFF, F BRONXVILLE, NEW. YORK,.,ASSIGNOR TO C. L. COR- IPOBATION, A CORPORATION OF DELAWARE l nnor srnn CONTAINER one Application filed December 18, 1930. SerialN o) 503,299.

This invention relates to improvements in container cars of the type broadly disclosed in Reissue Patent No. 16,073, of May 19, 1925, and. more particularly to improvements in drop side container cars of the type shown, for example, in my prior application Serial No. ess rem,v filed April .12, 1929, Pat. No. 1,7 88,075; Jan. 6, 1931, and my prior application Serial No. 359,392, filed April30, 1929, Pat. No. 1,807 ,268, May2 5, 1931, inwhich the container holding spaces or compartments ofa gondola car are formed by transverse bulk heads or partitions, closed at the sides of the car by drop doors designed tobe let down to serve as gang planks for the transfer of the containers to and from the car and forming the drop sides of the car. This "drop side type of car is of advantage'in allowing the containers to be loaded on or 7 removed from the car without the use ofan overhead crane with which many stations are not equipped. V

The main object of the'present invention is to provide a drop side container car in which i the construction of the combined compartment forming partitions anddoor jambs is simplified'and rendered less heavy and cumbersome and more open than in the drop side container cars hereinbefore in use, without sacrifice of strength and durability, and with theadvantage ofreducing the cost of construction and the amount of dead weight carried by thecar, andof producing acar which may be readily and conveniently cleaned and repaired and kept in thorough working condition at materially, less cost.

A further object of the invention is to pro,-

vide a construction whichpermits ready renewal ofabutment parts of the compartment forming partitions when damaged or worn,

and which provides a more reliable and ellicient type of locking means for preventing casual release of thelocking devices holding the drop doors in closed position.

The invention consists of the V of parts, hereinafter fully described and claimed, reference'being had to the accompanying drawings, in which:

features of construction,.comblnatlon and arrangement tainer ca'r embodying my invention, with containers mounted therein, and'showing some of the drop doors in letdown POSltlOIl.

F 1g. 2 1s a similar vlew with containers-'removed and all the drop sides let down.

Fig. 3is a perspective view of the container car, looking toward ,the carfrom a point adjacent one end 'thereo'f, and showing clearly the constructionof the compartment forming partitions and door jambs and the opentype of cars produced'thereby, some of. the drop doors being shown in closed position and othersin open position.

Fig; L is a vertical transverse section through'the car-and taken-on a line through one ofthe'partitions.

F ig. 5'is a similar sectional view,-taken on a line at one side of the partition.

Fig.- 6 is'a section on line 6+6 of Fig. 5;

1 Figs. 7 and 8 are sections on lines 7--7 and 79 8'8 of Fig, 4 looking, respe'ctively, toward .the cross rail of the partition and toward the floor of the'car.

I Fig. 9 is a view similar toFig. 5 showing in dotted linesthe door in released'position and in dot and dash lines the door in let down position and employed in conjunction with a'runway. 7 v

Fig. 10 :is' a view on an enlarged scale of aportion of the car looking toward aclos'ed 7 door.

' Fig. 11' isa-vertical section v on the line transversely disposed partitions 3 into spaces or compartments 4to receive the containers 5.

The containers 5 may be of the well'known' forms and constructions in general use, those shown in the present instance being of that type provided with depending feet 6 to rest upon the floor or platform 2. Suitable means may "be provided in each compartment for engaging and holding the container 7 from shifting therein. In the present instance, the floor or platform is provided at the corners of each compartment with recesses or sockets 7 to receive the lower ends'of the feet 6, or-retaining members thereon, whereby the containers are held from shiftng movements.

Each partition 3 comprises a cross bar or rail 8, preferably of metal and of T-shape in cross-section, said bar being horizontally disposed with its flat face uppermost and provided'with a depending central flange 9. The

ends of the flange 9 of the bar or rail 8 are secured by bolts or rivets 10 to legs,

, stanchions'or upright bracket'plates 11 at the plates, the lower ends of the said parts 12 of which plates are riveted or otherwise firmly fastened to a. filler. plate 12', whereby such "lower ends ofthe parts 12 are stayed and held in properly spaced relation. The longitudinally extending parts 13 of the angle metal plates are arranged to form door jambs at the sides of the respective compartments 4, and the lower ends of said parts 13 are riveted, bolted or otherwise rigidly fastened to the side frame 11. The parts 11, 11' 12 and 13 form posts or standards at the sides of the car, and jambs or abutments against which the door 4 may close, and said parts cooperate with the cross bars 8 to provide arched partitions across the car and subdividing the same into the compartments 4. The cross bars or rails 8 have secured thereto abutment or wear strips 15 of wood or'other '40 suitable material, designed, without material addition of weight, to 'form renewable abutment surfaces increasing the width andstrength of the partition bars an'd'forming abutments against which the containers may '45 bear and which will sustain any rubbing wear and relieve themetal bars themselves therefrom,"said strips also providing comparatively soft wear surfaces to avoid marring or injuring the containers. These strips. fit beneath the body portions of the bars and bear fagainstthe flanges 9 thereof and are secured to the flanges .by

proved fastenings.

. The construction of the partitions comprising the cross bars or rails 8, legs 11, angle metal plates 12,- fillers 12', and wear strips 15 as set forth, providesvvery light but strong and-durable, partitions for sub dividing the car into containing receiving compartments f which are in communication with each other beneaththe cross bars, thus doing away with the useof' solid or substantially solid bulk I heads of the character heretoforein use. By this means a moreopen type of car is pro- W duced, that is,

bolts, rivets or other ap I a car which is open from end to end beneath the partition bars or rails 8, whereby the use and transportation of a large amount of dead weight, such as exists in solid bulk heads, is avoided, without materially reducing the strength and rigidity of the car and the partitions between the container receiving compartments. This open type of car is not only cheaper to construct, but cheaper to clean and repair in order to maintain it in first class'working condition, as access may be more readily and conveniently obtained to all parts thereof. The cross bars or rails 8, in some cases, may be left entirely in the clear between the posts to which it is attached, but it is preferable to provide suitable intermediate bracing means, such as in verted U-shaped braces 16 comprisingmembers riveted at their upper ends to the flange 9 and attheir lower ends to suitable portions of the car underframe. v

' The car is provided with end walls 17, preferably of stationary or rigid type, and formed of metal plates provided at their upper edges with end cross bars or rails 18, which may include wear strips similar to the wear strips 15. The side walls of the car, however, are of sectional type, each comprising a plurality of independently movable sections or doors 19 equal in number to the compartments 4 and adapted when in normal position to close the normally open sides of said compartments. Each door is provided adjacent its lower corner portions with trunnions 20, fitted to rotate and to have vertical sliding movements in elongated trunnion bearings 21 secured tothe outwardly extending flanges or webs 13 of the postsl2. Near their upper corners the posts are provided with bolts or latch members 22 adapted for engagement with elongated bearing and keeper slots 23 in keeper plates 24, also secured to said flanges13 of the posts 12. The slots 23 open at their upper ends through the forward edges of the keeper plates,

whereby each door through the sliding engagement ofits trunnions 20-with the trunnion bearings-21 may be swung inwardly and slid, downwardly to a closed position in which bolts 22 will restat the bottom of the keeper slots 23 and holdtfhe door :in'such po' sition, as shown in full lines-in. Fig. 9, or the door may he slid upwardly to released posi tion, a shown in dotted lines in Fig. 9,'a1nd then downwardly to let-down or open position, as shown in dot and dash lines in Fig. 9 When the door is disposed in open position, it is adapted to function asa sgangplank between the car and a station platform, as shown in Fig. 9, allowing a hand truck or other transfer device carrying aEcontainer to be moved to and from the station platform for loading the containers into'the car compartments 4 or removing the same therefrom.

The bolts 22 and keepers 24 are provided for lockingithe doors in! closed position against outward movement aseach door is moved inwardly and downwardly-to such .In addition, there may be protion against any possibility of casual upward displacement. It will be observed, however,

that as each door when closed is locked auto-i matically against opening movement by means which, under all ordinary conditions,

will hold it securely'against opening move-" ment while the car is en route, or at a station, .even though the manually operable latches' are not latched, there is little or no danger of a door swinging outwardly-when the car is in transit and sideswiping another car on an adjacent track. Reintorcements 27 are provided on each door for sustaining the door against bulging and against distorting pressures when employed as a gangpla-nk,

and a stop 28 is provided on the side frame 11 for cooperation with each door to furtheras- 'sist in sustaining it against bulging pressures. This stop, when the "door is 1n closed position, engages a recess in a flange'at the lower end of the door, and on the door is'an abutment strip 29 which reinforces the recessed part of the flange. Handholds 30 may also be provided on the door to further enable it to be readily and conveniently manipulated in its opening and closing movements.

In each door areformed openings 31 with 1 which hooks 32 on a runway board 33 may be engaged to hold the runway board securely against the upper edge of thedoor when the latter is in position to form a gangway, as

shown in Fig. 9.

It is desirable in practice to provide fastening means of automatic type to engage the closed doors and hold the same positively from upward movement, so that, even in the event of failureto engage the latches 25 with their keepers 26, the doors will beheld against any possibility of upwardmovement. The

fastening means for this purpose comprises a pivoted gravity or spring-operated locking member 34 for engagement with a locking projection at the upper end of each keeper plate 24, said locking member 34 being pivoted at its inner end to a bar 8, as at 35, and provided at its outer free endwith a beveled surface and a hook to engage the locking projection, whereby when the dooris closed latch each bar 8 for coaction with each locking member 34 is a holdingdog 36, pivoted at its inner end, as at 37, and having an outer end 38 forming a stop shoulder for engagement with the pivoted end of themember 34 when said member 34 is inlocking position, thus" preventing said member 34 from swinging upwardly to released position. Both the looking or latch member 34 and the dog 36 are of suflicient weight to lie in their engag:

.ing: positions. by gravity against .any movements of the-car liable'to shift themto an inoperative position under movements of the car in travel, so that a reliable safety automatic rlock will .be provided. The locking members 34 or their equivalent are designed to be used at all times whether or not the locking elements 22and 23am used. It will be'evident, of course, that the-secured doors, =therefore,-can not "be opened untilthe safety -dogsi36 are shifted to retracted position.

From the oregoin'g,it 'willbe seen that my invention provides acontainer car which enables the objects of the invention to be carried out in a simple, reliable :and; efi'ective manner, and which will be of requisite strength and durability,while-cheaper in construction, than prior ears of this type having solid bulk heads, and that the construction is also such 'as to. adapt the car to be cleaned and repaired in a'readier and easier manner, and sothat the .cost of repairing and maintaining the .samein serviceable condition will be reduced. Other advantages of the invention willibe readily understood bythose versed intheart without .a further and extended description. e v I While the constructiondisclosed is preferred, it is to be understood that changes in the form, fconstruction,arrangement and proportions of parts may be made within the scope of' the "appended claims, without departing from .the spirit .or sacrificingany of the'advantages of this invention 1 Having thus fully described my invention,

I claim: 1

1. A containercar provided with container receiving compartments "formed by :transverse partitions of open-work character and establishing communication between therespective compartments, each comprising uprights at the sides of the .car and a'crossbar ;connecting said "uprights, thezuprights of adacent partitions forming doorways for the interveningcompartment at opposite sides of thezcar. I.

5. A container car having end Walls, compartment forming partitions between the end walls, each partitioncomprising uprights at the sides of the carand a cross-bar connecting said uprights, said uprights 'serving'as door jambs and doors at the sides of the car for closing the compartments and'adapted to close against-said jambs andfo'rming' the drop-side walls of the car.

' 6, A containerfcar having compartment forming partitions, and renewable wear by partitions, each partition comprising upstrips carried by said partitions.

7. A contamer car having a plurality of container receivlng compartments formed rightssat'thesides of the'car and a crosspiece connecting said uprights, and renewable strips secured to the sides of the cross piecey 8. A container car having-a longitudinal series of compartments formed by transverse partitions, each including uprights and a cross-bar, said cross-bar being T-shaped in cross-section, and removable wear strips underlyingthehorizontal' webs of the bar and secured to the flange thereof.

piec connecting said uprights, elongated bearings on the uprights, open recessed keepers on the uprights, doorshaving trunnions and locking projections respectively engaging the bea'ringsrand keepers, pivoted locklng members on the partitions adapted to. engage the doors to hold the same from uprights, said uprights and cross-piece eing T-shapedincross-section, wear strips secured to the cross pieces of thebars, and independ 'ent'doors adapted to rest in closed position against the uprights and partitions and to close the sides of the compartments and 1 adapted to drop down to open position to afford access to the sides of the compartments. 14, A'containercar having end Walls and arched partitions forming communicating compartments between the end walls, the portions of the partitions at the sides of the car providing door jambs, and drop doors adapted to close against said jambs.

In testimony whereof I affix my signature.

' GRAHAM C. WOODRUFF.

9.v A container carfhaving a longitudinal I series of compartments formed by transverse partitions, each comprising door jamb 'form ing uprights at the'sides ofthe car and a cross railconnecting said uprights, wear strips secured to the cross rail, and wall forming drop doors at the oppositesi'des of the car-adapted to rest against said j ambs to close said compartments. I

. 10. 'A containerv car having a floor and a longitudinal series ofcompartments formed thelsides of the car, and a of arched openwork partitions, each embodying 'flanged members forming uprights at flanged crossbar connecting said uprights, the flanges of r the upright forming members'providing'door 'jambs at the sidesof the car, and doors adapted to close against said j ambsb i 11*; A container, car having alongitudinal series of compartments formed by transverse pa-rtitionsj each comprising jamb forming uprights at the sides of the car an'da crosspiece connecting said uprights, elongatedr bearings on the uprights, open recessed keep .7 ers on the uprights, doors having trunnions and locking projections respectively engag- 1 ,12. A container car having a longitudinal series of compartments formed; by transverse part tions, each comprising Jamb forming 1 4 5 uprights atthe sides of the car and a cross 7 ,ing the bearings and keepers, and means adapted to interlock with the doors to hold the same from sliding movement. V

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US503299A US1853594A (en) | 1930-12-18 | 1930-12-18 | Drop side container car |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US503299A US1853594A (en) | 1930-12-18 | 1930-12-18 | Drop side container car |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853594A true US1853594A (en) | 1932-04-12 |

Family

ID=24001513

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US503299A Expired - Lifetime US1853594A (en) | 1930-12-18 | 1930-12-18 | Drop side container car |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853594A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2919661A (en) * | 1956-02-13 | 1960-01-05 | Acf Ind Inc | Container cars |

| US3180281A (en) * | 1962-04-23 | 1965-04-27 | Pullman Inc | Container support and locking arrangement |

| US3693554A (en) * | 1970-05-11 | 1972-09-26 | Acf Ind Inc | Flat car having a plurality of fixed intermediate bulkheads |

| RU226785U1 (en) * | 2024-03-20 | 2024-06-21 | Акционерное Общество "Научно-Производственная Корпорация "Уралвагонзавод" Имени Ф.Э.Дзержинского | SIDE WEDGE OF A UNIVERSAL PLATFORM CAR |

-

1930

- 1930-12-18 US US503299A patent/US1853594A/en not_active Expired - Lifetime

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2919661A (en) * | 1956-02-13 | 1960-01-05 | Acf Ind Inc | Container cars |

| US3180281A (en) * | 1962-04-23 | 1965-04-27 | Pullman Inc | Container support and locking arrangement |

| US3693554A (en) * | 1970-05-11 | 1972-09-26 | Acf Ind Inc | Flat car having a plurality of fixed intermediate bulkheads |

| RU226785U1 (en) * | 2024-03-20 | 2024-06-21 | Акционерное Общество "Научно-Производственная Корпорация "Уралвагонзавод" Имени Ф.Э.Дзержинского | SIDE WEDGE OF A UNIVERSAL PLATFORM CAR |

| RU227417U1 (en) * | 2024-03-20 | 2024-07-19 | Акционерное общество "Научно-производственная корпорация "Уралвагонзавод" имени Ф.Э.Дзержинского" | SIDE WEDGE OF A UNIVERSAL PLATFORM CAR |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2996020A (en) | Railway car | |

| US3168055A (en) | Movable bulkhead for railroad cars | |

| US2200277A (en) | Container | |

| US2030773A (en) | Box car | |

| US1400140A (en) | Car construction | |

| US2226042A (en) | Floor rack | |

| US1853594A (en) | Drop side container car | |

| US2291472A (en) | Floor rack for refrigerator cars | |

| US2994285A (en) | Doorway construction | |

| US2077649A (en) | Stowing facility for commodities in railway and other vehicles, and in storage warehouses | |

| US1627135A (en) | Moving van | |

| US2650737A (en) | Knockdown shipping container | |

| US3351024A (en) | Automobile bridge plate | |

| US1486046A (en) | Compartment freight car | |

| USRE20860E (en) | Box cab | |

| US2390873A (en) | Freight car | |

| US3283729A (en) | Lading separating bulkheads for railway boxcars | |

| US2070347A (en) | Container for container cars or automobile trucks | |

| US3165076A (en) | Door post locking means for open side railway cars or the like | |

| US3220359A (en) | Freight transportation systems | |

| US1399079A (en) | Refrigerator-car | |

| USRE20811E (en) | Boxcar | |

| US2083178A (en) | Means for use in loading and unloading container cars | |

| US1788075A (en) | Drop-side car | |

| USRE19831E (en) | Drop side container car |