US1853479A - Method of forming wheels - Google Patents

Method of forming wheels Download PDFInfo

- Publication number

- US1853479A US1853479A US432719A US43271930A US1853479A US 1853479 A US1853479 A US 1853479A US 432719 A US432719 A US 432719A US 43271930 A US43271930 A US 43271930A US 1853479 A US1853479 A US 1853479A

- Authority

- US

- United States

- Prior art keywords

- felloe

- pads

- protuberances

- forming

- sockets

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title description 6

- 239000002184 metal Substances 0.000 description 6

- 229910052751 metal Inorganic materials 0.000 description 6

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 238000001816 cooling Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 230000001502 supplementing effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21K—MAKING FORGED OR PRESSED METAL PRODUCTS, e.g. HORSE-SHOES, RIVETS, BOLTS OR WHEELS

- B21K25/00—Uniting components to form integral members, e.g. turbine wheels and shafts, caulks with inserts, with or without shaping of the components

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49481—Wheel making

- Y10T29/49492—Land wheel

- Y10T29/49513—Compression, e.g., nontension, spoke type wheel making

- Y10T29/49517—Joining spokes to rim

Definitions

- one of the problems is to so secure the felloe to the spokes as to assure rigidity and certainty of the connection so that it will remain looked as to driving strains and as to all types of road shocks.

- the present invention is designed to form such a wheel with a comparatively light felloe and one that may be readily fabricated. It is a division of application filed by me, April 18, 1929, Serial Number 356,108. Features and details of the invention will appear from the specification and claims.

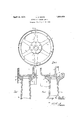

- FIG. 1 shows a side elevation of the finished wheel.

- Fig 3 a similar view with the felloe and wheel end in the process of assembly.

- spokes 1 marks a wheel center with spokes 1a. This is ordinarily of cast metal.

- the spokes are provided with felloe pads 2 at their outer ends, these pads having felloe seats 3 and 4.

- An inwardly faced shoulder 5 is arranged just outside of the seat 4 and a locking socket 6 is arranged in the inner edge of the pad 2 along the seat 3.

- a channel-shaped felloe 7 surrounds the wheel center and has protuberances 8 formed in the metal that extend into the sockets 6. The outer edge of the felloe engages the shoulder 5 supplementing the protuberances in looking the felloe in place. It will be noted that the protuberances not only extend internally but laterally into the sockets.

- the wheel center is cast in the ordinary manner and the seats formed on the felloe pads.

- the felloe is formed with an initial diameter slightly less than that of the pads with the protuberances arranged therein. It is expanded so that it may be introduced over the shoulder 5 into place on the seats with the protuberances in place in the sockets.

- the felloe Upon the cooling of the felloe it securely seats itself on the pads and locks the wheel in place with the protuber- PATENT; orms ances locking the wheel as. to driving strains 7 and the sockets and shoulder holding the felloe in place.

- the rim may be assembled by moving it to its position axially with the protuberances off-set circumferentially from the shoulders 5 and the felloe may then be rotated to bring the protuberances into register with the sockets.

- the protuberances may extend inquiring an expansion sufficient to carry the protuberances outside of the shoulders 55. This permits, therefore, of deeper sockets and larger protuberances than would be the case if it was necessary to move these in an axial direction over the shoulders.

- the method of formingwheels which consists in forming a wheel center with spokes having felloe pads with locking sockets therein, forming a felloe of less initial diameter than the wheel center as defined by the seating surfaces of the pads and with" protuberances in the metal thereof, expandthe pads with the protuberances in register spokes having felloe pads, said pads having inwardly faced shoulders and locking sockets therein, forming a felloe of initially less diameter than the wheel center as defined by the seating surfaces of the pads and with pro-.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Electromechanical Clocks (AREA)

- Air Bags (AREA)

Description

April 12, 1932. L, E WAITE 1,853,479

METHQD OF FORMING WHEELS Original Filed April 18, 1929 ATTORNEYS.

Patented Apr. .12, 1932 srrss LORENZO E. WAITE, F ERIE, PENNSYLVANIA, ASSIGNOR TO ERIE" 1VIALLEABLE IRON COMPANY, OF ERIE, PENNSYLVANIA, A CORPORATION OF PENNSYLVANIA{ METHOD OF FORMING WHEELS Original application filed. April 18, 1929, Serial No. 356,108. Divided and this application filed March 3, 1930. Serial No. 432,719.

In forming metal wheels one of the problems is to so secure the felloe to the spokes as to assure rigidity and certainty of the connection so that it will remain looked as to driving strains and as to all types of road shocks. The present invention is designed to form such a wheel with a comparatively light felloe and one that may be readily fabricated. It is a division of application filed by me, April 18, 1929, Serial Number 356,108. Features and details of the invention will appear from the specification and claims.

A preferred embodiment of the wheel illustrating the method by which it is made i shown in the accompanying drawings as follows Fig. 1 shows a side elevation of the finished wheel. V s

Fig. 2 an enlarged section on the line 22 in Fig. 1. i

Fig 3 a similar view with the felloe and wheel end in the process of assembly.

1 marks a wheel center with spokes 1a. This is ordinarily of cast metal. The spokes are provided with felloe pads 2 at their outer ends, these pads having felloe seats 3 and 4. An inwardly faced shoulder 5 is arranged just outside of the seat 4 and a locking socket 6 is arranged in the inner edge of the pad 2 along the seat 3.

A channel-shaped felloe 7 surrounds the wheel center and has protuberances 8 formed in the metal that extend into the sockets 6. The outer edge of the felloe engages the shoulder 5 supplementing the protuberances in looking the felloe in place. It will be noted that the protuberances not only extend internally but laterally into the sockets.

In forming the wheel, the wheel center is cast in the ordinary manner and the seats formed on the felloe pads. The felloe is formed with an initial diameter slightly less than that of the pads with the protuberances arranged therein. It is expanded so that it may be introduced over the shoulder 5 into place on the seats with the protuberances in place in the sockets. Upon the cooling of the felloe it securely seats itself on the pads and locks the wheel in place with the protuber- PATENT; orms ances locking the wheel as. to driving strains 7 and the sockets and shoulder holding the felloe in place. It will be noted that the rim may be assembled by moving it to its position axially with the protuberances off-set circumferentially from the shoulders 5 and the felloe may then be rotated to bring the protuberances into register with the sockets. In this way the protuberances may extend inquiring an expansion sufficient to carry the protuberances outside of the shoulders 55. This permits, therefore, of deeper sockets and larger protuberances than would be the case if it was necessary to move these in an axial direction over the shoulders.

What I claim as new is:

1. The method of formingwheels which consists in forming a wheel center with spokes having felloe pads with locking sockets therein, forming a felloe of less initial diameter than the wheel center as defined by the seating surfaces of the pads and with" protuberances in the metal thereof, expandthe pads with the protuberances in register spokes having felloe pads, said pads having inwardly faced shoulders and locking sockets therein, forming a felloe of initially less diameter than the wheel center as defined by the seating surfaces of the pads and with pro-.

tuberances in the metal thereof, expanding the felloe by heat, placing the same on the pads with the protuberances in register with the sockets, and permitting the felloe to shrink into seating position.

3.IThe method of forming wheels which consists in forming a wheel center with spokes having felloe pads, said pads having inwardly faced shoulders and locking sockets therein, forming a felloe of initially less diameter than the wheel center as defined by the seating surfaces of the pads and with protuberances in the metal thereof, expanding the felloe by heat, placing the same on the,

ice

wardly beyond the seats 3 and 4 without re- 1 7 ing the felloe by heat, placing the same on] pads by an axial movement of the felloe relatively t0 the pads and a rotative movement of the felloe to brin the protuberances into register with the soc ets, and permitting the felloe to shrink into seating position.

In testimony whereof I have hereunto set my hand. V LORENZO EPWAITE.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US432719A US1853479A (en) | 1929-04-18 | 1930-03-03 | Method of forming wheels |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US356108A US1837302A (en) | 1929-04-18 | 1929-04-18 | Wheel |

| US432719A US1853479A (en) | 1929-04-18 | 1930-03-03 | Method of forming wheels |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853479A true US1853479A (en) | 1932-04-12 |

Family

ID=26999128

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US432719A Expired - Lifetime US1853479A (en) | 1929-04-18 | 1930-03-03 | Method of forming wheels |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853479A (en) |

-

1930

- 1930-03-03 US US432719A patent/US1853479A/en not_active Expired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1993430A (en) | Wheel | |

| US2231427A (en) | Composite cast gear and method of making same | |

| US1853479A (en) | Method of forming wheels | |

| US1837302A (en) | Wheel | |

| US1961095A (en) | Rim | |

| US1175315A (en) | Wheel for vehicles. | |

| US2291217A (en) | Wheel and rim for vehicles | |

| US1076605A (en) | Pulley. | |

| US2440858A (en) | Combination cast and stamped wheel | |

| US2486569A (en) | Wheel | |

| US1982057A (en) | Adapter ring | |

| US1684552A (en) | Sectional wheel | |

| US1736985A (en) | Brake | |

| US2038211A (en) | Wheel | |

| US1339439A (en) | Wheel | |

| US1855023A (en) | Appearance ring and method of constructing and fitting the same | |

| US1540414A (en) | Wheel for automobiles or other vehicles | |

| US1928882A (en) | Airplane wheel | |

| US1504090A (en) | Hub and spoke connection | |

| US1395362A (en) | Vehicle-wheel | |

| US1268526A (en) | Demountable rim for wheels. | |

| US2013805A (en) | Mechanical free-floating brake drum | |

| US1610024A (en) | Sectional wheel | |

| US1208222A (en) | Demountable-rim construction. | |

| USD82497S (en) | Design fob |