US1853093A - Fuse - Google Patents

Fuse Download PDFInfo

- Publication number

- US1853093A US1853093A US266615A US26661528A US1853093A US 1853093 A US1853093 A US 1853093A US 266615 A US266615 A US 266615A US 26661528 A US26661528 A US 26661528A US 1853093 A US1853093 A US 1853093A

- Authority

- US

- United States

- Prior art keywords

- tube

- fuse

- contact

- contacts

- insulating material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011810 insulating material Substances 0.000 description 17

- 230000003014 reinforcing effect Effects 0.000 description 14

- 230000004888 barrier function Effects 0.000 description 10

- 239000002184 metal Substances 0.000 description 8

- 239000007789 gas Substances 0.000 description 3

- 239000011324 bead Substances 0.000 description 2

- 239000004568 cement Substances 0.000 description 2

- 238000009825 accumulation Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229910052573 porcelain Inorganic materials 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H85/00—Protective devices in which the current flows through a part of fusible material and this current is interrupted by displacement of the fusible material when this current becomes excessive

- H01H85/02—Details

- H01H85/38—Means for extinguishing or suppressing arc

- H01H85/42—Means for extinguishing or suppressing arc using an arc-extinguishing gas

Definitions

- This invention relates to certain new and useful improvements in fuses and refers more particularly to thetype commonly known as expulsion fuses.

- Another object of this invention resides in the provision of a fuse of the character described in which the major portion of the tube is enclosed in a meta-l sheeting or housgAnd another object of this invention resides in the provision of a fuse of the character described in which the metal of one of its contacts is elongated to enclose the major portion of its length and in which a barrier of insulating material is provided between the other contact and thek extend portion and the first contact.

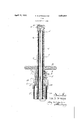

- the single figure is a transverse section taken through a fuse embodying my invention.

- 5 designates a tube of insulating material preferably of fibre or the like, on one end of which is positioned a contact member 6 having an elongated tubular portion 7 enclosing the tube 5 for the major portion of its length.

- the outer portion of the contact 6 is provided with a centrally aperatured and externally threaded projection 8 which is adapted to receive a cap member 9 threaded thereon, between the inner wall of which and the end of the contact 6 the adjacent end of a fuse element 10 is adapted to be impinged; the end of the fuse element being preferably bent to T shape as illustrated.

- That portion of the tube 5 extending be* yond the extension 7 of the contact 6 has mounted thereon a tubular insulating member 11 preferably formed of porcelain or the like and provided with a flange or disc 12 at its upper portion.

- the member 11 is secured on the lower portion of the tube 5 by cement or other means 13 which is retained in place by annular grooves 14 formed in the tube outer wall and by inwardly extending annular beads 15 extending from the inner wall of the member 11.

- a second contact lmember 16 having a longitudinal bore 17 is positioned overthe tubular extension of the member 11, being secured thereon in a like manner, annular grooves 18 formed in the bore 17 cooperating with annular beads 19 extended from the outer wall of the member 11 to retain the cement in position.

- the contact 16 has an annular flange 20 which is'exteriorly threaded to receive a collar member 21, and that portion of the contact 16 below the flange 20 is taperingly reduced, as at 22.

- the collar member 21 has an inwardly extended flange 23, the inner peripheral wall of which is correspondingly tapered to receiver therebetween the free end of the fuse element l0.

- the element is brought downwardly through the tube 5 and it is then directed upwardly along the outside of the tube, as at 24, to be impinged between the tapered faces of the flanges 22 and 28 to electrically connect the element with the contact 16.

- a second tube of insulating material 25 may be extended from the collar member 2l to enclose the lower portion of the tube 5 and the upwardly directed portion 24 of the fuse element.

- fuse elements of this type are provided with a portion 26 of reduced cross sectional area which is lplaced at the upper portion of the tube, so that when an overload in the circuit with which the fuse is connected occurs, the rupture of the element takes place at the reduced section and inasmuch as the entire upper portion of the tube is enclosed in metal, its mechanical strength is sufficient to withstand the extreme eXpansion of gases which takes place upon the volatilization of the element.

- the annular flange or disc l2 of insulating material provides sufficient creepage distance between the end of the extension 7 and the contact 16 thus preventing shorting between the contacts, as will be readily obvious.

- a fuse of the character described having a tube of insulating material, a contact member mounted at one end of the tube, a tubular metal reinforcing member extending from the contactmember and enclosing a portion of the tube, a second contact member, a fuse element electrically connecting the contact members, and an insulating barrier between the second contact member and the tubular reinforcing member.

- a tube of insulating material al member enclosing a portion of the tube to increase its mechanical strength, a contact mounted on the tube adjacent said member, an insulating bushing mount-ed on that portion of the tube not enclosed by said member, a second contact member mounted on the insulating bushing, and a fuse element electrically connecting the contacts.

- a tube of insulating material In a fuse of the character described, a tube of insulating material. a reinforcing member enclosing a portion of the tube, a. contact mounted on the tube adjacent the reinforcing member, a bushing of insulating material positioned over the tube beyond the reinforcing member, a second contact member carried by the bushing, a fuse element electrically connecting the contacts, and a flange formed on the insulating bushing to increase the creepage distance between the contacts.

- a tube of insulating material a contact positioned at one end thereof, an extension formed on the contact and enclosing the tube to reinforce the same, said extension projecting throughout the major portion of the length of the tube, a bushing of insulating material enclosing the tube beyond the extension, a second contact mounted on the insulating bushing, a fuse element electrically connecting the cont-acts, and a iange formed on the bushing to increase the creepage distance between the extension and the secondmentioned contact.

- a tube of insulating material a contact mounted on the tube adjacent one end, a bushing of insulating material receiving thetube other end portion, a second contact member carried by the bushing at a distance fromthe adjacent end of the tube, a fuse element electrically connecting ⁇ the contacts, and an insulating barrier carried by the bushing and positioned between the contacts.

- a fuse structure of the character described including a tube of insulating material, Contact members mounted on the tube adjacent its opposite ends and a fuse element electrically connecting the contact members, a metal casing on the tube adj acentone contact member to increase the mechanical strength thereof, and an insulating barrier carried by the fuse structure and disposed between said metal casing and the other contact member to increase the creepa-ge distance therebetween.

- a fuse structure of the character described including a tube of insulating material, Contact members mounted on the tube adjacentits opposite ends and a. fuse element electrically bridging the Contact members, means positioned on the tube to increase its mechanical strength, and an insulating barrier independent of the means for increasing the mechanical strength of the tube and carried by the fuse structure between one of the contacts and the means for increasing the mechanical strength of the tube to increase the creepage distance therebetween.

- a fuse of the character described including a tube of insulating material, contacts adjacent the opposite ends of the tube, and a fuse element electrically connecting the contacts, said fuse element having a portion of reduced cross section adjacent one end of the tube to locate the point of initial rupture at said end portion of the tube, a reinforcing member' mounted on and enclosing said end portion of the tube and extending toward the other end of the tube for part of the tubes length, and an insulating barrier mounted on the tube beyond the end of the reinforcing member to increase the creepage distancebetween the contacts.

- a fuse of the character' described including a tubeV of insulating material, contacts on the tube, one at one end portion thereof and the other intermediate the ends of the tube, a fuse element elecrically connecting the contacts, and having a portion of reduced cross section adjacent the first mentioned Contact to locate the point of initial rupture of the fuse at the end portion of the tube at which said contact is mounted, a reinforcing member enclosing the portion of the tube in which initial rupture takes place, an insulating barrier on the tube between the reinforcing member and the second mentioned contact, and an insulating bushing carried by the insulating barrier and spacing the second mentioned contact from the tube.

- a fuse including a tube of insulating material, a contact mounted at one end portion of the tube, a second contact adjacent to but spaced from the other end portion of the tube and a fuse element electrically connecting the contacts and having means for positively locating the initial rupture of the fuse adjacent the first mentioned end portion of the tube, a metal reinforcing member surrounding said end portion of the tube, an insulating bushing surrounding the opposite end portion of the tube and mounting the second mentioned contact, and an insulatingr barrier between the reinforcing member and the bushing to increase the creepage distance between the second mentioned contact and the reinforcing member.

- a fuse of the character described including a tube, a contact on one end portion of the tube, a second contact adjacent the other end portion of the tube, and a fuse element electrically connecting the contacts, said fuse element having means for positively locating the initial rupture of the fuse adjacent the first mentioned end portion of the tube, a metal reinforcing member carried by and surrounding the tube for a part of the distance from the first contact toward the opposite end portion of the tube to increase the mechanical strength of the tube at its portion within which initial rupture takes place, and an insulating barrier between the met-al reinforcing member and the second mentioned contact.

- An expulsion fuse comprising an insulating tube, spaced contacts, one of which is adjacent one end of the tube, a fuse element substantially within the tube and electrically bridging the contacts, said fuse element having a portion of reduced cross-section to positively locate the initial rupture of the fuse near said end of the tube, and a metal sheath extending from said contact adjacent said end of the tube and snugly engaging the tube to reinforce the same at its portion at which the initial rupture takes place, said sleeve terminating short of the other contact.

Landscapes

- Fuses (AREA)

Description

April 12, 1932. A; G. sTElNMAYER FUSE Filed April 2, 1928 /o 7 J N M 33%@10407/77/6,

Patented Apr. 12, 1932 UNITED STATES PATENT OFFCE ALWIN Gr. STEINMAYER, OF MILWAUKEE, WISCONSIN, ASSIGNOR, BY MESNE ASSIGN- MENTS, TO LINE MATERIAL COMPANY, OF SOUTH MILWAUKEE, TJVISCONS, A COR- roRATioN or DELAWARE FUSE Application led April 2,

This invention relates to certain new and useful improvements in fuses and refers more particularly to thetype commonly known as expulsion fuses.

In my copending application, Serial No. 173,557 filed March 7, 1927, which has matured into Patent No. 1,779,196, granted October 21, 1930, I have illustrated a fuse of this type and while the same functions satisfactorily, it is desirable to increase the capacity thereof, which heretofore has been limited by the ability of the fuse tube to withstand the expansion of the gases. Increasing the inside diameter of the tube to relieve the accumulation of gas pressure is one method of increasing the capacity, but while this expedient eliminates the possibility of failure due to expansion, it reduces the speed of volatilization of the fuse element, which is especially undesirable when relatively high voltages are used. Therefore, it is an object of this invention to provide means for mechanically increasing the strength of a fuse tube to increase the capacity of the fuse without increasing the inside diameter of the tube:

Another object of this invention resides in the provision of a fuse of the character described in which the major portion of the tube is enclosed in a meta-l sheeting or housgAnd another object of this invention resides in the provision of a fuse of the character described in which the metal of one of its contacts is elongated to enclose the major portion of its length and in which a barrier of insulating material is provided between the other contact and thek extend portion and the first contact.

With the above and other objects in view which will appear as the description proceeds, my invention resides in the novel construction, combination and arrangement of parts substantially as hereinafter described and more particularly defined by the appended claims, it being understood that such changes in the precise embodiment of the herein disclosed invention may be made as come within the scope of the claims.

l In the accompanying drawing I have illustrated one complete example of the physical 1928. Serial N0. 266,615.

embodiment of my invention constructed according to the best mode I have so far devised for the practical application of the principles thereof, and in which:

The single figure is a transverse section taken through a fuse embodying my invention.

Referring now more particularly to the accompanying drawing, 5 designates a tube of insulating material preferably of fibre or the like, on one end of which is positioned a contact member 6 having an elongated tubular portion 7 enclosing the tube 5 for the major portion of its length. The outer portion of the contact 6 is provided with a centrally aperatured and externally threaded projection 8 which is adapted to receive a cap member 9 threaded thereon, between the inner wall of which and the end of the contact 6 the adjacent end of a fuse element 10 is adapted to be impinged; the end of the fuse element being preferably bent to T shape as illustrated.

That portion of the tube 5 extending be* yond the extension 7 of the contact 6 has mounted thereon a tubular insulating member 11 preferably formed of porcelain or the like and provided with a flange or disc 12 at its upper portion. The member 11 is secured on the lower portion of the tube 5 by cement or other means 13 which is retained in place by annular grooves 14 formed in the tube outer wall and by inwardly extending annular beads 15 extending from the inner wall of the member 11. A second contact lmember 16 having a longitudinal bore 17 is positioned overthe tubular extension of the member 11, being secured thereon in a like manner, annular grooves 18 formed in the bore 17 cooperating with annular beads 19 extended from the outer wall of the member 11 to retain the cement in position. The contact 16 has an annular flange 20 which is'exteriorly threaded to receive a collar member 21, and that portion of the contact 16 below the flange 20 is taperingly reduced, as at 22. The collar member 21 has an inwardly extended flange 23, the inner peripheral wall of which is correspondingly tapered to receiver therebetween the free end of the fuse element l0.

The element is brought downwardly through the tube 5 and it is then directed upwardly along the outside of the tube, as at 24, to be impinged between the tapered faces of the flanges 22 and 28 to electrically connect the element with the contact 16. If desired, a second tube of insulating material 25 may be extended from the collar member 2l to enclose the lower portion of the tube 5 and the upwardly directed portion 24 of the fuse element.

As is customary, fuse elements of this type are provided with a portion 26 of reduced cross sectional area which is lplaced at the upper portion of the tube, so that when an overload in the circuit with which the fuse is connected occurs, the rupture of the element takes place at the reduced section and inasmuch as the entire upper portion of the tube is enclosed in metal, its mechanical strength is sufficient to withstand the extreme eXpansion of gases which takes place upon the volatilization of the element. The annular flange or disc l2 of insulating material provides sufficient creepage distance between the end of the extension 7 and the contact 16 thus preventing shorting between the contacts, as will be readily obvious.

What I claim as my invention is:

1. In a fuse of the character described having a tube of insulating material, a contact member mounted at one end of the tube, a tubular metal reinforcing member extending from the contactmember and enclosing a portion of the tube, a second contact member, a fuse element electrically connecting the contact members, and an insulating barrier between the second contact member and the tubular reinforcing member.

2. In a fuse of the character described, a tube of insulating material, al member enclosing a portion of the tube to increase its mechanical strength, a contact mounted on the tube adjacent said member, an insulating bushing mount-ed on that portion of the tube not enclosed by said member, a second contact member mounted on the insulating bushing, and a fuse element electrically connecting the contacts.

3. In a fuse of the character described, a tube of insulating material. a reinforcing member enclosing a portion of the tube, a. contact mounted on the tube adjacent the reinforcing member, a bushing of insulating material positioned over the tube beyond the reinforcing member, a second contact member carried by the bushing, a fuse element electrically connecting the contacts, and a flange formed on the insulating bushing to increase the creepage distance between the contacts.

4. In a fuse of the character' described, a tube of insulating material, a contact positioned at one end thereof, an extension formed on the contact and enclosing the tube to reinforce the same, said extension projecting throughout the major portion of the length of the tube, a bushing of insulating material enclosing the tube beyond the extension, a second contact mounted on the insulating bushing, a fuse element electrically connecting the cont-acts, and a iange formed on the bushing to increase the creepage distance between the extension and the secondmentioned contact.

5. In a fuse of the character described, a tube of insulating material, a contact mounted on the tube adjacent one end, a bushing of insulating material receiving thetube other end portion, a second contact member carried by the bushing at a distance fromthe adjacent end of the tube, a fuse element electrically connecting` the contacts, and an insulating barrier carried by the bushing and positioned between the contacts.

6. In a fuse structure of the character described, including a tube of insulating material, Contact members mounted on the tube adjacent its opposite ends and a fuse element electrically connecting the contact members, a metal casing on the tube adj acentone contact member to increase the mechanical strength thereof, and an insulating barrier carried by the fuse structure and disposed between said metal casing and the other contact member to increase the creepa-ge distance therebetween.

7. In a fuse structure of the character described, including a tube of insulating material, Contact members mounted on the tube adjacentits opposite ends and a. fuse element electrically bridging the Contact members, means positioned on the tube to increase its mechanical strength, and an insulating barrier independent of the means for increasing the mechanical strength of the tube and carried by the fuse structure between one of the contacts and the means for increasing the mechanical strength of the tube to increase the creepage distance therebetween.

S. In a fuse of the character described including a tube of insulating material, contacts adjacent the opposite ends of the tube, and a fuse element electrically connecting the contacts, said fuse element having a portion of reduced cross section adjacent one end of the tube to locate the point of initial rupture at said end portion of the tube, a reinforcing member' mounted on and enclosing said end portion of the tube and extending toward the other end of the tube for part of the tubes length, and an insulating barrier mounted on the tube beyond the end of the reinforcing member to increase the creepage distancebetween the contacts.

9. In a fuse of the character' described including a tubeV of insulating material, contacts on the tube, one at one end portion thereof and the other intermediate the ends of the tube, a fuse element elecrically connecting the contacts, and having a portion of reduced cross section adjacent the first mentioned Contact to locate the point of initial rupture of the fuse at the end portion of the tube at which said contact is mounted, a reinforcing member enclosing the portion of the tube in which initial rupture takes place, an insulating barrier on the tube between the reinforcing member and the second mentioned contact, and an insulating bushing carried by the insulating barrier and spacing the second mentioned contact from the tube.

10. In a fuse including a tube of insulating material, a contact mounted at one end portion of the tube, a second contact adjacent to but spaced from the other end portion of the tube and a fuse element electrically connecting the contacts and having means for positively locating the initial rupture of the fuse adjacent the first mentioned end portion of the tube, a metal reinforcing member surrounding said end portion of the tube, an insulating bushing surrounding the opposite end portion of the tube and mounting the second mentioned contact, and an insulatingr barrier between the reinforcing member and the bushing to increase the creepage distance between the second mentioned contact and the reinforcing member.

11. In a fuse of the character described including a tube, a contact on one end portion of the tube, a second contact adjacent the other end portion of the tube, and a fuse element electrically connecting the contacts, said fuse element having means for positively locating the initial rupture of the fuse adjacent the first mentioned end portion of the tube, a metal reinforcing member carried by and surrounding the tube for a part of the distance from the first contact toward the opposite end portion of the tube to increase the mechanical strength of the tube at its portion within which initial rupture takes place, and an insulating barrier between the met-al reinforcing member and the second mentioned contact.

l2. An expulsion fuse comprising an insulating tube, spaced contacts, one of which is adjacent one end of the tube, a fuse element substantially within the tube and electrically bridging the contacts, said fuse element having a portion of reduced cross-section to positively locate the initial rupture of the fuse near said end of the tube, and a metal sheath extending from said contact adjacent said end of the tube and snugly engaging the tube to reinforce the same at its portion at which the initial rupture takes place, said sleeve terminating short of the other contact.

In testimony whereof I have hereunto affixed my signature.

ALVVIN Gr. STEINMAYER.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US266615A US1853093A (en) | 1928-04-02 | 1928-04-02 | Fuse |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US266615A US1853093A (en) | 1928-04-02 | 1928-04-02 | Fuse |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853093A true US1853093A (en) | 1932-04-12 |

Family

ID=23015300

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US266615A Expired - Lifetime US1853093A (en) | 1928-04-02 | 1928-04-02 | Fuse |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853093A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2702842A (en) * | 1953-07-24 | 1955-02-22 | Mcgraw Electric Co | Cutout construction |

| US4808964A (en) * | 1987-12-24 | 1989-02-28 | Westinghouse Electric Corp. | Erosion resistant high current draw-out fuseholder |

-

1928

- 1928-04-02 US US266615A patent/US1853093A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2702842A (en) * | 1953-07-24 | 1955-02-22 | Mcgraw Electric Co | Cutout construction |

| US4808964A (en) * | 1987-12-24 | 1989-02-28 | Westinghouse Electric Corp. | Erosion resistant high current draw-out fuseholder |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5892427A (en) | Current limiting high voltage fuse | |

| US3134874A (en) | Current limiting fuse | |

| US2157907A (en) | Fuse | |

| US2306153A (en) | Electric circuit interrupting device | |

| US2343224A (en) | Electric circuit-interrupting device | |

| US1853093A (en) | Fuse | |

| US3925745A (en) | High voltage fuse with localized gas evolving suppressors | |

| US4166266A (en) | Electric fuse having composite support for fusible element | |

| US2439674A (en) | Current limiting fuse | |

| US3213242A (en) | Current limiting fuse | |

| US2567768A (en) | Circuit interrupter | |

| US3742415A (en) | Current limiting fuse | |

| US2543245A (en) | Fuse construction | |

| US2183728A (en) | Fuse | |

| US2337504A (en) | Current limiting fuse | |

| US2417268A (en) | Indicating means for thermal circuit interrupters | |

| US3259719A (en) | Current limiting indicating fuse having shearing forces on the strain element | |

| US3251968A (en) | Fuse structures formed of concentric fuse tubes to provide a maximum heat radiating surface and a novel venting means | |

| US2200608A (en) | Fuse | |

| US2859381A (en) | Fuse for incandescent lamp | |

| US2143038A (en) | Fuse | |

| US3523264A (en) | Fuse links | |

| US2409361A (en) | Seal for electric lamps and similar devices | |

| US2342320A (en) | Electric fuse | |

| US3152236A (en) | Fuse construction |