US1852540A - Signaling device - Google Patents

Signaling device Download PDFInfo

- Publication number

- US1852540A US1852540A US201802A US20180227A US1852540A US 1852540 A US1852540 A US 1852540A US 201802 A US201802 A US 201802A US 20180227 A US20180227 A US 20180227A US 1852540 A US1852540 A US 1852540A

- Authority

- US

- United States

- Prior art keywords

- signal

- shaft

- yoke

- housing

- electromagnets

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000011664 signaling Effects 0.000 title description 34

- 230000033001 locomotion Effects 0.000 description 34

- 239000012530 fluid Substances 0.000 description 7

- 230000007935 neutral effect Effects 0.000 description 6

- 230000004048 modification Effects 0.000 description 5

- 238000012986 modification Methods 0.000 description 5

- 241000271202 Juncus gerardii Species 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 210000004907 gland Anatomy 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 210000001364 upper extremity Anatomy 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G08—SIGNALLING

- G08G—TRAFFIC CONTROL SYSTEMS

- G08G1/00—Traffic control systems for road vehicles

- G08G1/09—Arrangements for giving variable traffic instructions

Definitions

- My invention relates to improvements in signaling devices and the object of my invention is to provide eiiicient means by which prearranged, mutually understood, signals may be produced to communicate desired information to persons within the range of Vision of the signaling device.

- My signaling device is especially well adapted to be installed on movable conveyances, as motor vehicles or air or water craft, for the purpose of giving signals required by law, or signals established by common usage, relative to the intentions and wishes of the person operating the vehicle or air or water crait.

- the signaling device may, however, be adapted for various other uses.

- Another object of my invention is to pro vide a signal embodying one or more arms or semaphores mounted for swinging movement from a neutral into various signaling positions and arranged to be moved by means that may be controlled by an operator located at any desired distance from the signal.

- a further object is to provide a signal having signal operating means arranged to be set in motion from a remote point and having stop means also controlled from a remote point for predetcrmining the amount of movement of the signal operating means to thereby predetermine the signal that will be given.

- a signaling device of this nature may be operated and controlled either by electric means, by fluid pressure means, or by hand power means; to provide a signal that is adapted, either for day or night use, the same being equipped with lamps by which it may be illuminated at night, to provide a signal having a transparent or light conductive housing that is equipped with automatically operated wiper means by which it will be kept clean and tree from dirt and moisture so that it will be readily visible under all weather conditions.

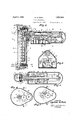

- Figs. 2, 3, 4, 5, 6 and 7 are sectional views of the same on broken lines 2-2, 3-3, t41-, 5-5, 6-6, and 7-7 respectively of Fig. 1, certain of said figures being on a larger scale than Fig. 1 and certain parts in said figures being shown in elevation.

- Fig. 8 is a somewhat diagrammatic View illustrating electric wiring and switch mechanism, electromagnet control and operating devices and fluid pressure control and operating means. i 1

- Figs. 9 and 10 are detached sectional views of one form of electric switches that may be used in connection with my invention.

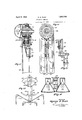

- Fig. 11 is a front elevation of modified form of the invention in which two signal arms or semaphores are used instead of one and in which rack and pinion means is used for operating the signal arms.

- Fig. 12 is a sectional view on broken line 12-12 of Fig. 11.

- Fig. 13 is a sectional view on broken line l313 of Fig. 12.

- Fig. 14 is a combined sectional view and wiring diagram of a modification of the de vices shown in Figs. 11 to 13 inclusive.

- Fig. 15 is a sectional view of one form of electric switch that may be used in connection with the device shown in Fig. 14.

- Fig. 16 is a plan View looking down into the switch housing shown in Fig. 15, the cover plate and switch throw member being removed.

- Fig. 17 is a sectional view on broken line 17-17 of Fig. 18 illustrating a modification of the invention adapted to be operated by hand by means of a cable control.

- Fig. 18 is a View partly in rear elevation and partly in section on broken line 18-18 of Fig. 17, certain parts being broken away.

- Fig. 19 is a sectional view on a larger scale on broken line 19-19 of Fig. 17.

- Fig. 20 is a somewhat diagrammatic detached elevation of a lever control for the cable operated devices shown in Figs. 17 18 and 19.

- Fig. 21 is a. fragmentary detached sectional view of said lever control devices taken substantially on broken line 2121 of Fig. 20.

- the numeral 1 designates a housing adapted to be secured to a fixed support, as to the frame, or to any fixed part, of a motor vehicle

- 2 designates,in a general way, a signaling member or semaphore, hereinafter termed a signal arm, that is arranged at right angles to the housing 1 and rotatably connected with what I shall hereinafter term the forward end of said housing 1.

- a rear frame member 7 of the signal arm 2 is provided with a hub 8 that fits over the end of the tubular shaft 3 and is secured thereto by pins 9 so that when the tubular shaft 3 is rotated the signal arm will be caused to swing into various signaling positions.

- a fitting or sleeve 10 is screwed over the end of the hub 8 as shown in Fig. 2 and is provided, on its end adjacent the housing 1 with an annular extension 11 that fits rotatably within a suitable groove the end a of the housing 1 thereby forming a neat and weatherproof connection at this location.

- a sleeve 12 to the rear of the bearing member 5 prevents the tubular shaft 3 from moving forward longitudinally.

- a relatively fixed, non-rotatable shaft 13 extends longitudinally within the tubular shaft 3 and projects from the forward end thereof.

- a disc member 14 is fixedly secured to the forward end of the shaft 13 within the signal arm 2 and is provided on its front and rear sides with mutilated or segmental gears 14 for purposes hereinafter explained.

- a signal arm housing 15 is secured to the rear signal arm frame member 7, and a relatively long transparent front lamp casing 16 is secured to the signal arm housing 15, said lamp casing 16 being arcuate in cross sectional shape.

- yoke 17 is a cylinder within the housing 1, and 18 is a piston reciprocable within the cylinder 17 and having a piston rod 19 that extends outwardly through a suitable gland in the front end of the cylinder and is secured to a yoke 20.

- the yoke 20 is guided for movement on the shaft 3 and on two guide rods 21 and said yoke 20 is provided with a finger or pawl 22 that fits within a spiral groove 23 in the shaft 3 and serves to rotate said shaft 3 as the yoke 20 is moved lengthwise within the housing 1, thereby rotating or swinging the signal arm into various angular signaling positions.

- Compression springs 20 on the shaft 3 abut against opposite sides of the yoke '20 and always serve to return said yoke to the initial or inoperative position after a signal has been given.

- the pitch of the spiral groove 23 is preferably of'such a degree as to cause the signal arm 2 to be moved through substantially one half of one complete turn, (180 degrees), when the piston'18 is moved from its initial mid way position, shown in Fig. 1, completely to either end of the cylinder.

- stop means are provided for arresting the movement of the yoke 20 at a plurality of different points as desired.

- stop means are illustrated as being in the form of electromagnets or solenoids 24, having plungers 25 adapted to extend upwardly in alignment with notches 26 in the yoke 20, one series of solenoids being provided on each side of the central or neutral position in which the yoke 20 is shown in Fig. 1.

- the electromagnets may be mounted on a base of insulating material that is secured within the bottom of housing 1.

- the plunger 25 of each electromagnet 24 has one end of a downwardly curved spring 27 secured to its upper extremity, the other end of each spring 27 being secured to a suitable support or bracket.

- the springs 27 of the series of electromagnets to one side of the central position of the yoke 20 are inclined in one direction while the springs 27 of the other series of electromagnets are inclined in the opposite direction. All of the plungers normally remain in the raised position ready to intercept the yoke 20 and arrest the movement of the same.

- One series of electromagnets is arranged to prevent movementof the yoke 20 in one direction while the other series of electromagnets is arranged to prevent movement of the yoke 20 in the opposite direction.

- the yoke 20 is arranged to ride over either series of inclined springs 26 and depress the plungers connected therewith as it returns toward the neutral or initial position.

- Suitable electric circuit and switch control means are provided for energizing any one or more of the electromagnets 2 1 to retract the plungers 25 connected therewith and permit unobstructed movement of the yoke 20 past said plunger as hereinafter described in connection with Fig. 8.

- the cylinder 17 has fluid conduit pipes 28 lit;

- Fig. 8 respectively connected with opposite ends thereof through which fluid under pressure, as compressed air, may enter or exhaust from the cylinder.

- the pipes 28 and 29 connect with a valve housing 30 that has a slide valve 31 therein.

- the slide valve 31 is arranged to be moved in opposite directions by two electromagnets 32 and 33 respectively that are connected with opposite ends of the same.

- Springs 34 exert a pressure against armatures 35 and return the slide valve 31 to the neutral position shown in Fig. 8 when neither of the electromagnets 32 or 33 is energized.

- a fluid pressure tank 36 is connected with the valve housing 30 at two spaced points by branched pipes 37 and 38.

- T ie slide valve 31 is provided with two spaced, diametrically arranged conduits 39 and 40 and is further provided with two spaced cavities 41 and 42 as shown in Fig. 8. lVhen the slide valve 31 is in the mid position shown in Fi 8 the cavities 41 and 42 will connect the respective pipes 28 and 29 with conduits 43 that open to the atmosphere leaving the cylinder 17 fully exhausted of all positive or negative fiuid pressure.

- It electromagnet 32 is energized slide valve 31 will be moved to the right Fig. 8, causing diametrical conduit 40 to register with pipes 37 and 29, admitting iiuid under pressure to one end of cylinder 17 for moving the piston 18 in one direction.

- the cavity 41 will connect the pipe 28 with an air outlet or exhaust pipe 44 relieving pressure that might otherwise be built up on the opposite side of the piston 18.

- electromagnet 33 is energized slide valve 31 will be moved to the left bringing passageway 39 into registration with conduits 38 and 28 and connecting conduit 29 with one of the exhaust pipes 44.

- Electromagnets 32 and .33 each have one terminal connected by circuit wire 45 with one side of a battery 46, the other terminal of 32 being connected by circuit wire with each individual switch of a group of switches 48, while the other terminal of 33 is connected by circuit wire 49 with each individual switch ot a group of switches 50.

- the electromagnet 32 When any switch of the group 48 is closed the electromagnet 32 will be energized and when any switch of the group 50 is closed the electromagnet 33 will be energized.

- the group of switches 48 is also used for controlling one series 01. the electromagnets 24 that govern the stopping and limit the movement of the yoke 20 in one direction while the group of switches 50 is similarly used for controlling the other series of electromagnets 24 that govern and limit the movement of the yoke 20 in the opposite direction.

- Each switch of both of the groups 48 and 50 has one terminal connected by common circuit wire 51 with the battery 46 and the other terminal or terminals connected by separate circuit wires 52 with one or more of the electromagnets 24. In Figs.

- 9 and 10 I have shown one form of a switch that may be used for this purpose, said switch being of the push button type and having one terminal 53 to which the common circuit wire 51 may be'connected and a plurality of terminals 54 for connection with one or more of the separate circuit wires to the electromagnets 24.

- one of the switches of each group will be connected with the first electromagnet 24 adjacent the yoke 20, the next switch of the group will be connected with the first two electromagnets 24, the third switch will be connected with the first three electromagnets and the fourth switch will be connected with all four electromagnets 24 of the group on one side of the position of rest of the yoke 20.

- the closing of the first switch of either group will retract the first plunger 25 and permit movement of the signal arm to the first signaling position while the closing of the second switch will retract the first two plungers 25, the closing of the third switch will retract the first three plungers and the closing of the fourth switch will retract all four plungers. More switches and more plungers may be provided if a greater number of signaling positions are desired. It will be apparent from the preceding description that the closing of any switch in either group 48 or 50 will simultaneously energize either electromagnet 32 or electromagnet 33 and the desired ones of the electromagnets 24. Thereby setting the stops for the yoke 20 and at thesame time admitting the compressed fiuid for moving said yoke inthe desired direction.

- the signal arm 2 is provided, in substantial alignment with the shaft 3, with a larger signal lamp 55 disposed in a curved reflector housing 56 and connected by suitable wires 57 with a switch contact ring 58 on the movable frame member 7.

- Another contact 59 is provided on the fixed end 4 of the housing 1 and is connected with suitable circuit wires by which current may be supplied for illuminating the lamp.

- the contact ring 58 may be interrupted at the lowermost point, corresponding to its position of engagement with the fixed contact 59, when at rest, so that the lamp or lamps will not be lighted when the signal arm is in the position of rest but will be lighted the instant the signal arm is moved in either direction toward a signaling position.

- a plurality of smaller lamps 60 may be provided in the transparent signal arm casing 16 below the larger lamp 55 and connected with the same circuit wires 57

- Two wiper members 61 and (52 each having squeegee strips 63 are adapted to be moved over the arcuate transparent front 16 of the signal arm to keep the same clean and insure maximum visibility under all weather conditions.

- the wiper members 61 and 62 have arms 64 on their ends, arranged at right angles thereto, one set of said arms being connected with tubular shaft 65, which, in turn, are connected through gear trains 66 with shafts 67 and 68 that are provided with bevel gears 69 on one side of the disc 14.

- the other set of wiper arms 64 are connected with shafts 70 that extend through the tubular shafts and are connected by gear trains 71 with shafts 72 and 73 having bevel gears 7% that mesh with the multilated gears 14' on the discl l.

- the tubular shafts 65 are journaled in the ends 15 of the signal arm frame and the shafts are journaled in the shafts 65.

- the respective gear trains 66 and 71 are shown in Figs. 4 and 5.

- the gear ratios are preferably such as to cause the wipers'to make their full travel while the signal arm is being moved to the first signaling position, the bevel gears running off of the mutilated gears at this point and no further movement of the wipers taking place until the signal arm is returned toward neutral whereupon the bevel gears will again engage the relatively fixed mutilated gears and the wipers will be returned to their initial less radius are smaller than the other two bevel gears to equalize the gear ratio at the two ends and prevent any tendency toward moving one end of the swipe members faster than the other.

- Figs. 11,12 and 13 I show amodilied form of the invention in which two signal arms 75 and 76 are provided, said signal arms being adapted to hang vertically when no signal is being given and to be swung in opposite directions in giving a signal.

- the arms 7 5 and 76 are independently movable to different signaling positions and make possible the display of a large number of different signals that can not be shown or displayed by the use of a single arm, it being obvious many different signals may be formed by varying the relative positions of the two arms.

- the signal arms 75 and 76 are similar to the previously described signal arm 2 and may, if desired, be provided with similar wipers although said Wipers are not herein shown or described.

- a single large lamp 77 common to the two arms 75 and 76 is provided at the top and a plurality of smaller lamps 78 are distributing longitudinally along said arms.

- Suitable electric-contact means 79 of a general form similar to that hereinbefore described is provided for transmitting electric current to the lamps 7 7 and 78.

- the signal arms 75 and 76 have hubs 80 and 81 respectively formed at their upper ends, the hub 80 being secured to a shaft 82 and the hub 81 being secured to a sleeve 83 that is rotatable on the shaft 82.

- the shaft 82 and sleeve 83 are both rotatably mounted in suitable bearings 84 in the upper portion of a housing 85 that arranged parallel with the signal arms, 7 5 and 76 and contains the means for operating said signal arms.

- the operating means disclosed in the drawings comprises two flanged gearwheels 86 and 87 secured to the shaft 82 and sleeve 83 respectively and engaged respectively by gear racks 88 and 89.

- the gear racks 88 and 89 are positioned on opposite sides of their respective gearwheels 86 and 87 for rotating the shaft 82 and the sleeve 88 oppositely to swing the signal arms upward in opposite directions, and said gear racks are respectively connected with pistons 90 and 91 in cylinders 92 and 93.

- the rack bars 88 and 89 each have a ratchet lug 96 provided thereon that is adapted to be engaged by a plurality of stop plungers 97 arranged in the path of movement of said lug to predetermine the position or the amount of movement of the rack bar.

- the plungers are slidable within electromagnets 98, one electromagnet being provided for each plunger, the electromagnets being adapted, when energized, to retract the plungers and the plungers being normally held outwardly in the path of the lug 96 by springs 99.

- the plungers 97 act as positive stops to limit the upward movement of the rack bars 88 and 89, except when they are retracted by the electromagnets 98, but the ends of said plungers are inclined on their upper sides as at 100 so that the inclined lower sides 101 of the ratchet lugs 96 will ride over and retract the plungers as the rack bars move downwardly.

- the operation of the signal shown in Figs. 11, 12 and 13 is similar to the operation of the previous ly described signal except that both signal arms may be used in giving a signal instead of only one, thus making possible the giving of a greater number of signals.

- Figs. 14, 15 and 16 I show a modified form of signal and operating mechanism therefor which conforms substantially with the signal shown in Figs. 11, 12 and 13 except that this device is entirely electrically operated.

- I show a housing 102 having two signal arms 103 and 104 connected therewith for swinging movement in opposite directions in the same manner as shown in Fig. 12, said arms being secured to a shaft 105 and a sleeve 106 respectively that have gear wheels 107, only one of which is shown secured thereon.

- Said gearwheels 107 are raclr bars 108 having pawls 109 arranged to be engaged by stop plungers 110 operated by electromagnets 111.

- the rack bars 108 extend downwardly into double electroi'nagnets or solenoids 112113 and are connected with cores 114 that are adapted to be moved by the electromagnets 112113 to transmit movement through the rack bars 108, gearwheels 107, and shaft 105 or sleeve 106, to one or both of the signal arms 103-104.

- each electromagnet there are upper and lower buffer springs 115 to cushion what otherwise might be a shock at the end of travel of the core 114.

- In this form of device I show three of the positioning electromagnets 111 in connection with each rack bar and provide positive lined stops 116, only one of which is shown to limit the upward movement of the rack bars.

- the switches for controlling the circuits to the electromagnets 112113 may be of the form shown in Figs. 15 and 16 so that the current may be conveniently switched from one to the other of said electromagnets to reverse the direction of movement of the core 114 or to return said core to the inoperative position.

- This switch comprises a housing 140 having an arcuate receptacle 141 in the bottom of which is embedded a common terminal or contact 142 and two sets of contacts 143 and 144.

- An oscillating contact member 145, pivoted at 146 and having finger piece 147 is provided with an insert of conductive material 148, adapted to bridge the common terminal 142 and either one of the sets of contacts 143 or 144 when said contact member moved to either side of the central position.

- a spring 149 normally holds the contact member 145 in the inoperative position shown in Fig. 15.

- Figs. 17 to 21 inclusive I have shown a 123 respectively that are rotatably mounted on a tubular bearing member 124 which is supported by a frame plate 125.

- the hubs 122 and 123 are each provided with grooves 126 around which, operating cables 127 and 128 respectively are looped.

- the operating cables 127 and 128 pass outwardly between the signal arms and 121, preferably to the rear, over guide sheaves 129 that are sup ported from the frame bracket and said operating cables are conducted to a remote point and there connected with the bottom ends of operating levers 130 and 131 that are movable between guides 132.

- the upper ends of operating levers 130 and 131 are connected with stub shafts 133, Fig. 21, on hand levers 134.

- the stub shafts 133 are pivotally mounted in fixed plates 135 and the hand levers 134 are provided with spring pressed detent members 136 movable over notched segments 137.

- the signal device of Figs. 17 to 21 has a relatively large axially arranged signal lamp 138 and the arms 120 and 121 are each provided with a plurality of smaller lamps 139, Fig. 19, contact means similar to that hereinbefore described is provided in connection with this form of the device as shown .111 Fig. 15 for supplying electric current to the lamps.

- the two arms of any of the double arm signals may be secured together and operated as a single arm.

- the lights in the several signals may be varied as to color, number, size, and arrangement as desired.

- WVhat I claim is 1.

- a signaling device a housing, a rotatable shaft disposed longitudinally within said housing and projecting fromone end of said housing, a yoke mounted on said shaft, means on said yoke and shaft for rotating said shaft, by movementof said yoke, a signal arm disposed at right angles to said housing and secured to the projecting end of said shaft, means for moving said yoke, and selective stop means arranged to be set so asto arrest the movement of said yoke at predetermined positions.

- a housing a rotatable shaft disposed longitudinally within said housing and extending from one end of the housing, a signal arm disposed at right angles to said housing and secured to the projecting end of said shaft, a yoke mounted on said shaft and arranged to rotate said shaft, means for moving said yoke, electromagnets disposed in said housing, pl-ungers in said electromagnets normally disposed in the path of movement of said yoke to stop said yoke in predetermined positions and means for selectively energizing said electromagnets to withdraw said plungers.

- a housing arranged to be secured to a fixed support, a shaft extending lengthwise of, and rotatable-in said housing and projecting from one end of the same, a signal arm disposed at right angles to said housing and secured to the projecting end of said shaft, a yoke mounted on said shaft and arranged to rotate said shaft, a cylinder, a piston in the cylinder, a piston rod connecting the piston with the yoke, means for admitting fluid under pressure to the cylinder, electromagnets disposed in said housing, plungers in said electromagnets normally disposed in the path. of movement of said yoke and arranged to stop said yoke in predetermined positions and means for selectively energizing said electromagnets to withdraw predetermined plungers.

- a housing a shaft rotatable and longitudinally disposed in said housing and projecting from one end thereof, a yoke arranged to fit over said shaft and slidable thereon, said yoke and said shaft having interfittingspiral groove and tongue means for rotating the shaft when the yoke is moved lengthwise thereof, a signal arm secured to the shaft external to the housing and at right angles to the shaft and'housi-ng, power operated devices for moving the yoke, and selective stop means for arresting the movement of the yoke in any predetermined position.

- a signal .arm mounted for swinging movement, a light conductive casing on the front side of said signal arm, means for illuminating said light conductive casing and wiper means for clean-- ing said light conductive casing in response to swinging movement ofsaid signal arm.

- a signal of the class described embodying a fixed casing, a shaft journaled longitudinally therein and projecting outwardly therefrom, a signal arm secured on the end of said shaft at right angles thereto, illuminating means within said casing, a piston operated element for rotating said shaft, piston means for selectively moving the piston operated element in two opposite directions, two series of spaced stop members arranged on opposite sides ,of the inoperative position of said piston operated shaft rotating element and normally positioned so as to block the movement of the same in a direction away from the inoperative position and means for moving any one or all of the stop members of either series out of the path of movement of said shaft rotating element, said stop members being arranged so as to permit the shaft rotating element to pass over the same in its return movement to an inoperative position.

- a movable signal arm In a signaling-device, a movable signal arm, means for moving said signal arm, means forming a light conductive section on said signal arm, means for illuminating said light conductive section, a wiper for wiping said light conductive section, and wiper operating means interconnecting the wiper and the signal mechanism whereby the wiper will be moved in response to movement of the si gal arm.

- a signaling device a movable signal arm, means for moving said signal arm, a transparent casing of arcuate cross sectional shape forming the front of said signal arm, means for illuminating said casing, wiper meansmovable over saidarcuate casing, supporting devices for said wiper means, said supporting devicesbeing pivoted .coaxially with said arcuate casing, and wiper operating means interconnecting the wiper and the signal mechanism whereby the wiper will be moved in response 'to'movement of the signal arm.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Lighting Device Outwards From Vehicle And Optical Signal (AREA)

Description

April 5,, 1932. u s. RUSH SIGNALING DEVICE Filed June 27, 1927 5 Sheets$heet l INVENTOR Ulysses ifiush ATTORNEY April 5, 1932. u. s. RUSH SIGNALING DEVICE Filed June 27, 1927 5 Sheets-Sheet 2 2% ATTORN EY m m6 m w. w

April 5, u 5 RUSH 1,852,540

SIGNALING DEVICE Filed June 27. 1927 5 Sheets-Sheet 3 INVENTOR 04% as 6, Bus/7 ATTORNEY April 5, 1932.

U. S. RUSH SIGNALING DEVICE Filed June 27, 1927 5 Sheets-Sheet 4 INVENTOR l/ysseg 5 [Push ATTOR N EY Fatented Apr. 5, 1932 PATENT ULYSSES S. RUSH, OF SALTCHUCK, ALASKA SIGNALING DEVICE Application filed June 27,

My invention relates to improvements in signaling devices and the object of my invention is to provide eiiicient means by which prearranged, mutually understood, signals may be produced to communicate desired information to persons within the range of Vision of the signaling device.

My signaling device is especially well adapted to be installed on movable conveyances, as motor vehicles or air or water craft, for the purpose of giving signals required by law, or signals established by common usage, relative to the intentions and wishes of the person operating the vehicle or air or water crait. The signaling device may, however, be adapted for various other uses.

Another object of my invention is to pro vide a signal embodying one or more arms or semaphores mounted for swinging movement from a neutral into various signaling positions and arranged to be moved by means that may be controlled by an operator located at any desired distance from the signal.

A further object is to provide a signal having signal operating means arranged to be set in motion from a remote point and having stop means also controlled from a remote point for predetcrmining the amount of movement of the signal operating means to thereby predetermine the signal that will be given.

Further objects are to provide a signaling device of this nature that may be operated and controlled either by electric means, by fluid pressure means, or by hand power means; to provide a signal that is adapted, either for day or night use, the same being equipped with lamps by which it may be illuminated at night, to provide a signal having a transparent or light conductive housing that is equipped with automatically operated wiper means by which it will be kept clean and tree from dirt and moisture so that it will be readily visible under all weather conditions.

it still iurther object is to provide a signal of this nature which may be equipped with two or more signal arms movable to various diil'erent signaling positions to thereby pro- 1927. Serial No. 201,802.

duce different signaling combinations which may conform to any predetermined signal code.

Other and more specific objects will be apparent from the following description taken in connection with the accompanying drawings, wherein- Figure 1 is a vertical mid-section of a signaling device constructed in accordance with my invention, parts being shown in elevation.

Figs. 2, 3, 4, 5, 6 and 7 are sectional views of the same on broken lines 2-2, 3-3, t41-, 5-5, 6-6, and 7-7 respectively of Fig. 1, certain of said figures being on a larger scale than Fig. 1 and certain parts in said figures being shown in elevation.

Fig. 8 is a somewhat diagrammatic View illustrating electric wiring and switch mechanism, electromagnet control and operating devices and fluid pressure control and operating means. i 1

Figs. 9 and 10 are detached sectional views of one form of electric switches that may be used in connection with my invention.

Fig. 11 is a front elevation of modified form of the invention in which two signal arms or semaphores are used instead of one and in which rack and pinion means is used for operating the signal arms.

Fig. 12 is a sectional view on broken line 12-12 of Fig. 11.

Fig. 13 is a sectional view on broken line l313 of Fig. 12.

Fig. 14 is a combined sectional view and wiring diagram of a modification of the de vices shown in Figs. 11 to 13 inclusive.

Fig. 15 is a sectional view of one form of electric switch that may be used in connection with the device shown in Fig. 14.

Fig. 16 is a plan View looking down into the switch housing shown in Fig. 15, the cover plate and switch throw member being removed.

Fig. 17 is a sectional view on broken line 17-17 of Fig. 18 illustrating a modification of the invention adapted to be operated by hand by means of a cable control.

Fig. 18 is a View partly in rear elevation and partly in section on broken line 18-18 of Fig. 17, certain parts being broken away.

Fig. 19 is a sectional view on a larger scale on broken line 19-19 of Fig. 17.

Fig. 20 is a somewhat diagrammatic detached elevation of a lever control for the cable operated devices shown in Figs. 17 18 and 19.

Fig. 21 is a. fragmentary detached sectional view of said lever control devices taken substantially on broken line 2121 of Fig. 20.

It will be noted that all of the modifications shown in the figures hereinbefore described embody one or more swingingly mounted signal arms arranged to operate in the same manner, the mechanism for moving the signal arms being different in the different modifications.

Like reference numerals designate like parts throughout the several views.

Referring first to Figs. 1 to 10 inclusive, the numeral 1 designates a housing adapted to be secured to a fixed support, as to the frame, or to any fixed part, of a motor vehicle, and 2 designates,in a general way, a signaling member or semaphore, hereinafter termed a signal arm, that is arranged at right angles to the housing 1 and rotatably connected with what I shall hereinafter term the forward end of said housing 1.

3 is a normally horizontal, tubular shaft that is supported for rotation in suitable bearings 4, 5 and 6 in the housing 1 and projects outwardly from the forward-end of said housing. A rear frame member 7 of the signal arm 2 is provided with a hub 8 that fits over the end of the tubular shaft 3 and is secured thereto by pins 9 so that when the tubular shaft 3 is rotated the signal arm will be caused to swing into various signaling positions. A fitting or sleeve 10 is screwed over the end of the hub 8 as shown in Fig. 2 and is provided, on its end adjacent the housing 1 with an annular extension 11 that fits rotatably within a suitable groove the end a of the housing 1 thereby forming a neat and weatherproof connection at this location. A sleeve 12 to the rear of the bearing member 5 prevents the tubular shaft 3 from moving forward longitudinally. A relatively fixed, non-rotatable shaft 13 extends longitudinally within the tubular shaft 3 and projects from the forward end thereof. A disc member 14: is fixedly secured to the forward end of the shaft 13 within the signal arm 2 and is provided on its front and rear sides with mutilated or segmental gears 14 for purposes hereinafter explained.

A signal arm housing 15 is secured to the rear signal arm frame member 7, and a relatively long transparent front lamp casing 16 is secured to the signal arm housing 15, said lamp casing 16 being arcuate in cross sectional shape.

17 is a cylinder within the housing 1, and 18 is a piston reciprocable within the cylinder 17 and having a piston rod 19 that extends outwardly through a suitable gland in the front end of the cylinder and is secured to a yoke 20. The yoke 20 is guided for movement on the shaft 3 and on two guide rods 21 and said yoke 20 is provided with a finger or pawl 22 that fits within a spiral groove 23 in the shaft 3 and serves to rotate said shaft 3 as the yoke 20 is moved lengthwise within the housing 1, thereby rotating or swinging the signal arm into various angular signaling positions. Compression springs 20 on the shaft 3 abut against opposite sides of the yoke '20 and always serve to return said yoke to the initial or inoperative position after a signal has been given. The pitch of the spiral groove 23 is preferably of'such a degree as to cause the signal arm 2 to be moved through substantially one half of one complete turn, (180 degrees), when the piston'18 is moved from its initial mid way position, shown in Fig. 1, completely to either end of the cylinder. To limit the movement of the signal arm 2 to less than 180 degrees, stop means are provided for arresting the movement of the yoke 20 at a plurality of different points as desired. These stop means are illustrated as being in the form of electromagnets or solenoids 24, having plungers 25 adapted to extend upwardly in alignment with notches 26 in the yoke 20, one series of solenoids being provided on each side of the central or neutral position in which the yoke 20 is shown in Fig. 1. The electromagnets may be mounted on a base of insulating material that is secured within the bottom of housing 1. The plunger 25 of each electromagnet 24 has one end of a downwardly curved spring 27 secured to its upper extremity, the other end of each spring 27 being secured to a suitable support or bracket. The springs 27 of the series of electromagnets to one side of the central position of the yoke 20 are inclined in one direction while the springs 27 of the other series of electromagnets are inclined in the opposite direction. All of the plungers normally remain in the raised position ready to intercept the yoke 20 and arrest the movement of the same. One series of electromagnets is arranged to prevent movementof the yoke 20 in one direction while the other series of electromagnets is arranged to prevent movement of the yoke 20 in the opposite direction. The yoke 20 is arranged to ride over either series of inclined springs 26 and depress the plungers connected therewith as it returns toward the neutral or initial position. Suitable electric circuit and switch control means are provided for energizing any one or more of the electromagnets 2 1 to retract the plungers 25 connected therewith and permit unobstructed movement of the yoke 20 past said plunger as hereinafter described in connection with Fig. 8.

The cylinder 17 has fluid conduit pipes 28 lit;

and 29 as shown in Fig. 8 respectively connected with opposite ends thereof through which fluid under pressure, as compressed air, may enter or exhaust from the cylinder. The pipes 28 and 29 connect with a valve housing 30 that has a slide valve 31 therein. The slide valve 31 is arranged to be moved in opposite directions by two electromagnets 32 and 33 respectively that are connected with opposite ends of the same. Springs 34 exert a pressure against armatures 35 and return the slide valve 31 to the neutral position shown in Fig. 8 when neither of the electromagnets 32 or 33 is energized.

A fluid pressure tank 36 is connected with the valve housing 30 at two spaced points by branched pipes 37 and 38. T ie slide valve 31 is provided with two spaced, diametrically arranged conduits 39 and 40 and is further provided with two spaced cavities 41 and 42 as shown in Fig. 8. lVhen the slide valve 31 is in the mid position shown in Fi 8 the cavities 41 and 42 will connect the respective pipes 28 and 29 with conduits 43 that open to the atmosphere leaving the cylinder 17 fully exhausted of all positive or negative fiuid pressure. It electromagnet 32 is energized slide valve 31 will be moved to the right Fig. 8, causing diametrical conduit 40 to register with pipes 37 and 29, admitting iiuid under pressure to one end of cylinder 17 for moving the piston 18 in one direction. At the same time the cavity 41 will connect the pipe 28 with an air outlet or exhaust pipe 44 relieving pressure that might otherwise be built up on the opposite side of the piston 18. In a similar manner, it electromagnet 33 is energized slide valve 31 will be moved to the left bringing passageway 39 into registration with conduits 38 and 28 and connecting conduit 29 with one of the exhaust pipes 44.

Electromagnets 32 and .33 each have one terminal connected by circuit wire 45 with one side of a battery 46, the other terminal of 32 being connected by circuit wire with each individual switch of a group of switches 48, while the other terminal of 33 is connected by circuit wire 49 with each individual switch ot a group of switches 50. When any switch of the group 48 is closed the electromagnet 32 will be energized and when any switch of the group 50 is closed the electromagnet 33 will be energized.

The group of switches 48 is also used for controlling one series 01. the electromagnets 24 that govern the stopping and limit the movement of the yoke 20 in one direction while the group of switches 50 is similarly used for controlling the other series of electromagnets 24 that govern and limit the movement of the yoke 20 in the opposite direction. Each switch of both of the groups 48 and 50 has one terminal connected by common circuit wire 51 with the battery 46 and the other terminal or terminals connected by separate circuit wires 52 with one or more of the electromagnets 24. In Figs. 9 and 10 I have shown one form of a switch that may be used for this purpose, said switch being of the push button type and having one terminal 53 to which the common circuit wire 51 may be'connected and a plurality of terminals 54 for connection with one or more of the separate circuit wires to the electromagnets 24. In practice one of the switches of each group will be connected with the first electromagnet 24 adjacent the yoke 20, the next switch of the group will be connected with the first two electromagnets 24, the third switch will be connected with the first three electromagnets and the fourth switch will be connected with all four electromagnets 24 of the group on one side of the position of rest of the yoke 20. hen the connections are made in this man her the closing of the first switch of either group will retract the first plunger 25 and permit movement of the signal arm to the first signaling position while the closing of the second switch will retract the first two plungers 25, the closing of the third switch will retract the first three plungers and the closing of the fourth switch will retract all four plungers. More switches and more plungers may be provided if a greater number of signaling positions are desired. It will be apparent from the preceding description that the closing of any switch in either group 48 or 50 will simultaneously energize either electromagnet 32 or electromagnet 33 and the desired ones of the electromagnets 24. Thereby setting the stops for the yoke 20 and at thesame time admitting the compressed fiuid for moving said yoke inthe desired direction.

The signal arm 2 is provided, in substantial alignment with the shaft 3, with a larger signal lamp 55 disposed in a curved reflector housing 56 and connected by suitable wires 57 with a switch contact ring 58 on the movable frame member 7. Another contact 59, preferably spring pressed, is provided on the fixed end 4 of the housing 1 and is connected with suitable circuit wires by which current may be supplied for illuminating the lamp. If desired the contact ring 58 may be interrupted at the lowermost point, corresponding to its position of engagement with the fixed contact 59, when at rest, so that the lamp or lamps will not be lighted when the signal arm is in the position of rest but will be lighted the instant the signal arm is moved in either direction toward a signaling position. A plurality of smaller lamps 60 may be provided in the transparent signal arm casing 16 below the larger lamp 55 and connected with the same circuit wires 57 Two wiper members 61 and (52 each having squeegee strips 63 are adapted to be moved over the arcuate transparent front 16 of the signal arm to keep the same clean and insure maximum visibility under all weather conditions. The wiper members 61 and 62 have arms 64 on their ends, arranged at right angles thereto, one set of said arms being connected with tubular shaft 65, which, in turn, are connected through gear trains 66 with shafts 67 and 68 that are provided with bevel gears 69 on one side of the disc 14. The other set of wiper arms 64: are connected with shafts 70 that extend through the tubular shafts and are connected by gear trains 71 with shafts 72 and 73 having bevel gears 7% that mesh with the multilated gears 14' on the discl l. The tubular shafts 65 are journaled in the ends 15 of the signal arm frame and the shafts are journaled in the shafts 65. The respective gear trains 66 and 71 are shown in Figs. 4 and 5. When the signal arm is moved away from the neutral position the bevel gears 69 and 74 are caused to move around the stationary disc ll and will be rotated by reason of their meshing with mutilated gear segments 14' thereby transmitting rotary movement through the interconnecting shafts and gear trains to the wiper members 61 and 62 which wiper members will be caused to move around the transparent shell 16 toward each other. The gear ratios are preferably such as to cause the wipers'to make their full travel while the signal arm is being moved to the first signaling position, the bevel gears running off of the mutilated gears at this point and no further movement of the wipers taking place until the signal arm is returned toward neutral whereupon the bevel gears will again engage the relatively fixed mutilated gears and the wipers will be returned to their initial less radius are smaller than the other two bevel gears to equalize the gear ratio at the two ends and prevent any tendency toward moving one end of the swipe members faster than the other.

In the operation of this device when any switch of the group 48 is closed the signal arm will be caused to swing upwardly in one direction through a predetermined angle and when any switch of the group 50 is closed the signal arm will be caused to swing upwardly in the opposite direction through a predetermined angle. In this way any desired signal may be given.

In Figs. 11,12 and 13 I show amodilied form of the invention in which two signal arms 75 and 76 are provided, said signal arms being adapted to hang vertically when no signal is being given and to be swung in opposite directions in giving a signal. The arms 7 5 and 76 are independently movable to different signaling positions and make possible the display of a large number of different signals that can not be shown or displayed by the use of a single arm, it being obvious many different signals may be formed by varying the relative positions of the two arms.

The signal arms 75 and 76 are similar to the previously described signal arm 2 and may, if desired, be provided with similar wipers although said Wipers are not herein shown or described. A single large lamp 77 common to the two arms 75 and 76 is provided at the top and a plurality of smaller lamps 78 are distributing longitudinally along said arms. Suitable electric-contact means 79 of a general form similar to that hereinbefore described is provided for transmitting electric current to the lamps 7 7 and 78. The signal arms 75 and 76 have hubs 80 and 81 respectively formed at their upper ends, the hub 80 being secured to a shaft 82 and the hub 81 being secured to a sleeve 83 that is rotatable on the shaft 82. The shaft 82 and sleeve 83 are both rotatably mounted in suitable bearings 84 in the upper portion of a housing 85 that arranged parallel with the signal arms, 7 5 and 76 and contains the means for operating said signal arms. In this form of signaling device the operating means disclosed in the drawings comprises two flanged gearwheels 86 and 87 secured to the shaft 82 and sleeve 83 respectively and engaged respectively by gear racks 88 and 89. The gear racks 88 and 89 are positioned on opposite sides of their respective gearwheels 86 and 87 for rotating the shaft 82 and the sleeve 88 oppositely to swing the signal arms upward in opposite directions, and said gear racks are respectively connected with pistons 90 and 91 in cylinders 92 and 93. Fluid under pressure is admitted to and exhausted from the cylinders 92 and 93 through conduit pipes 94 that are connected with electromagnetically operated valves 95 which may be controlled in a similar manner to the valve 30 shown in Fig. 8. The wiring and switch mechanism used in connection with this form of the invention is not shown in detail. The rack bars 88 and 89 each have a ratchet lug 96 provided thereon that is adapted to be engaged by a plurality of stop plungers 97 arranged in the path of movement of said lug to predetermine the position or the amount of movement of the rack bar. The plungers are slidable within electromagnets 98, one electromagnet being provided for each plunger, the electromagnets being adapted, when energized, to retract the plungers and the plungers being normally held outwardly in the path of the lug 96 by springs 99. The plungers 97 act as positive stops to limit the upward movement of the rack bars 88 and 89, except when they are retracted by the electromagnets 98, but the ends of said plungers are inclined on their upper sides as at 100 so that the inclined lower sides 101 of the ratchet lugs 96 will ride over and retract the plungers as the rack bars move downwardly. The operation of the signal shown in Figs. 11, 12 and 13 is similar to the operation of the previous ly described signal except that both signal arms may be used in giving a signal instead of only one, thus making possible the giving of a greater number of signals.

In Figs. 14, 15 and 16 I show a modified form of signal and operating mechanism therefor which conforms substantially with the signal shown in Figs. 11, 12 and 13 except that this device is entirely electrically operated. In said Fig. 14, I show a housing 102 having two signal arms 103 and 104 connected therewith for swinging movement in opposite directions in the same manner as shown in Fig. 12, said arms being secured to a shaft 105 and a sleeve 106 respectively that have gear wheels 107, only one of which is shown secured thereon. Said gearwheels 107 are raclr bars 108 having pawls 109 arranged to be engaged by stop plungers 110 operated by electromagnets 111. The rack bars 108 extend downwardly into double electroi'nagnets or solenoids 112113 and are connected with cores 114 that are adapted to be moved by the electromagnets 112113 to transmit movement through the rack bars 108, gearwheels 107, and shaft 105 or sleeve 106, to one or both of the signal arms 103-104. In each electromagnet there are upper and lower buffer springs 115 to cushion what otherwise might be a shock at the end of travel of the core 114. In this form of device I show three of the positioning electromagnets 111 in connection with each rack bar and provide positive lined stops 116, only one of which is shown to limit the upward movement of the rack bars. The wiring and electrical conmotions to the various electromagnets shown in Fig. 14 is not herein described in detail but may be made in substantially the manner shown in said Fig. 14. In the diagram a portion of the wiring is omitted. The switches for controlling the circuits to the electromagnets 112113 may be of the form shown in Figs. 15 and 16 so that the current may be conveniently switched from one to the other of said electromagnets to reverse the direction of movement of the core 114 or to return said core to the inoperative position. This switch comprises a housing 140 having an arcuate receptacle 141 in the bottom of which is embedded a common terminal or contact 142 and two sets of contacts 143 and 144. An oscillating contact member 145, pivoted at 146 and having finger piece 147 is provided with an insert of conductive material 148, adapted to bridge the common terminal 142 and either one of the sets of contacts 143 or 144 when said contact member moved to either side of the central position. A spring 149 normally holds the contact member 145 in the inoperative position shown in Fig. 15.

In Figs. 17 to 21 inclusive I have shown a 123 respectively that are rotatably mounted on a tubular bearing member 124 which is supported by a frame plate 125. The hubs 122 and 123 are each provided with grooves 126 around which, operating cables 127 and 128 respectively are looped. The operating cables 127 and 128 pass outwardly between the signal arms and 121, preferably to the rear, over guide sheaves 129 that are sup ported from the frame bracket and said operating cables are conducted to a remote point and there connected with the bottom ends of operating levers 130 and 131 that are movable between guides 132. The upper ends of operating levers 130 and 131 are connected with stub shafts 133, Fig. 21, on hand levers 134. The stub shafts 133 are pivotally mounted in fixed plates 135 and the hand levers 134 are provided with spring pressed detent members 136 movable over notched segments 137.

Movement of either hand lever 134 will move the operating lever that is connected therewith, causing it to transmit movement through the cable 127 or 128 to the signal arm 120 or 121 that is connected therewith. In this way the signal arms 120 and 121 are moved into various signaling positions. The signal device of Figs. 17 to 21 has a relatively large axially arranged signal lamp 138 and the arms 120 and 121 are each provided with a plurality of smaller lamps 139, Fig. 19, contact means similar to that hereinbefore described is provided in connection with this form of the device as shown .111 Fig. 15 for supplying electric current to the lamps.

In all of the modifications hereinbefore de-. scribed the same principle of operation is maintained, the signaling being accomplished by one or more swinging arms arranged to be held in different positions to give different signals.

If desired, the two arms of any of the double arm signals may be secured together and operated as a single arm. The lights in the several signals may be varied as to color, number, size, and arrangement as desired.

The foregoing description and accompanying drawings clearly disclose certain preferred embodiments of my invention but it will be understood that these disclosures are merely illustrative and that such changes in the device. may be resorted to as are fairly within the scope and spirit of the following claims.

WVhat I claim is 1. In a signaling device, a housing, a rotatable shaft disposed longitudinally within said housing and projecting fromone end of said housing, a yoke mounted on said shaft, means on said yoke and shaft for rotating said shaft, by movementof said yoke, a signal arm disposed at right angles to said housing and secured to the projecting end of said shaft, means for moving said yoke, and selective stop means arranged to be set so asto arrest the movement of said yoke at predetermined positions.

2. In a signaling device, a housing, a rotatable shaft disposed longitudinally within said housing and extending from one end of the housing, a signal arm disposed at right angles to said housing and secured to the projecting end of said shaft, a yoke mounted on said shaft and arranged to rotate said shaft, means for moving said yoke, electromagnets disposed in said housing, pl-ungers in said electromagnets normally disposed in the path of movement of said yoke to stop said yoke in predetermined positions and means for selectively energizing said electromagnets to withdraw said plungers.

3. In a signaling device, a housing arranged to be secured to a fixed support, a shaft extending lengthwise of, and rotatable-in said housing and projecting from one end of the same, a signal arm disposed at right angles to said housing and secured to the projecting end of said shaft, a yoke mounted on said shaft and arranged to rotate said shaft, a cylinder, a piston in the cylinder, a piston rod connecting the piston with the yoke, means for admitting fluid under pressure to the cylinder, electromagnets disposed in said housing, plungers in said electromagnets normally disposed in the path. of movement of said yoke and arranged to stop said yoke in predetermined positions and means for selectively energizing said electromagnets to withdraw predetermined plungers.

4. In a signaling device, a housing, a shaft rotatable and longitudinally disposed in said housing and projecting from one end thereof, a yoke arranged to fit over said shaft and slidable thereon, said yoke and said shaft having interfittingspiral groove and tongue means for rotating the shaft when the yoke is moved lengthwise thereof, a signal arm secured to the shaft external to the housing and at right angles to the shaft and'housi-ng, power operated devices for moving the yoke, and selective stop means for arresting the movement of the yoke in any predetermined position.

5. In a signaling device, a signal .arm mounted for swinging movement, a light conductive casing on the front side of said signal arm, means for illuminating said light conductive casing and wiper means for clean-- ing said light conductive casing in response to swinging movement ofsaid signal arm.

' *6. "*In a signaling device, a supporting member ra non-rotatable shaft extending outwardly there'from, a signal arm garranged to shaft, means for moving said signal arm into signaling positions, a transparent casing of arcuate cross sect onal shape forming the front of said signal arm, illuminating means within said casing, wiper members movable over said transparent casing for cleaning the exterior of the same, means pivotally supporting said wiper members, gear and shaft means connected with said pivotal supporting means and stationary means carried on the end of said non-rotatable shaft for coacting with said gear d a t means and moving said wiper members over said casing when said signal arm is moved,

7 A signal of the class described, embodying a fixed casing, a shaft journaled longitudinally therein and projecting outwardly therefrom, a signal arm secured on the end of said shaft at right angles thereto, illuminating means within said casing, a piston operated element for rotating said shaft, piston means for selectively moving the piston operated element in two opposite directions, two series of spaced stop members arranged on opposite sides ,of the inoperative position of said piston operated shaft rotating element and normally positioned so as to block the movement of the same in a direction away from the inoperative position and means for moving any one or all of the stop members of either series out of the path of movement of said shaft rotating element, said stop members being arranged so as to permit the shaft rotating element to pass over the same in its return movement to an inoperative position.

8, In a signaling-device, a movable signal arm, means for moving said signal arm, means forming a light conductive section on said signal arm, means for illuminating said light conductive section, a wiper for wiping said light conductive section, and wiper operating means interconnecting the wiper and the signal mechanism whereby the wiper will be moved in response to movement of the si gal arm.

9. 11 a signaling device, a movable signal arm, means for moving said signal arm, a transparent casing of arcuate cross sectional shape forming the front of said signal arm, means for illuminating said casing, wiper meansmovable over saidarcuate casing, supporting devices for said wiper means, said supporting devicesbeing pivoted .coaxially with said arcuate casing, and wiper operating means interconnecting the wiper and the signal mechanism whereby the wiper will be moved in response 'to'movement of the signal arm.

In 'witness whereof, I hereunto subscribe my name this fifteenth day of June, D.

UL'YSSES 'S. RUSH.

move about the axis of said n n-r tat ble

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201802A US1852540A (en) | 1927-06-27 | 1927-06-27 | Signaling device |

| US289706A US1965751A (en) | 1927-06-27 | 1928-07-02 | Signaling device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201802A US1852540A (en) | 1927-06-27 | 1927-06-27 | Signaling device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852540A true US1852540A (en) | 1932-04-05 |

Family

ID=22747362

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US201802A Expired - Lifetime US1852540A (en) | 1927-06-27 | 1927-06-27 | Signaling device |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852540A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2642489A (en) * | 1950-03-06 | 1953-06-16 | Twist Lee | Vehicle direction signal |

-

1927

- 1927-06-27 US US201802A patent/US1852540A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2642489A (en) * | 1950-03-06 | 1953-06-16 | Twist Lee | Vehicle direction signal |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1965751A (en) | Signaling device | |

| US1852540A (en) | Signaling device | |

| US2667545A (en) | Automatic direction signal | |

| US2201078A (en) | Safety light switch | |

| US1896495A (en) | Signal device for vehicles | |

| US1840213A (en) | Direction indicator | |

| US2057760A (en) | Motor vehicle signal | |

| US2158973A (en) | Automobile traffic signal | |

| US1997780A (en) | Control means for electrically actuated devices | |

| US2205048A (en) | Automobile turning signal | |

| US1320566A (en) | Direction-indicator fob motos-vehicles | |

| US1325146A (en) | de ford | |

| US2490585A (en) | Electrically operated time lapse traffic signal | |

| US1834882A (en) | Signal | |

| US1368095A (en) | Manual controlling means for vehicle-signals | |

| US2254078A (en) | Direction indicating signal | |

| US2197226A (en) | Directional signal | |

| US1362234A (en) | Safety-signal | |

| US1877438A (en) | Signaling device | |

| US1180278A (en) | Speed-limit indicator for automobiles, motor-cycles, and other vehicles. | |

| US1903692A (en) | Direction signal | |

| DE565397C (en) | Overhaul indicators for motor vehicles | |

| US1890961A (en) | Direction signal for vehicles | |

| US1494526A (en) | Direction indicator | |

| US1658975A (en) | Vehicle signal |