US1852527A - Carton - Google Patents

Carton Download PDFInfo

- Publication number

- US1852527A US1852527A US356956A US35695629A US1852527A US 1852527 A US1852527 A US 1852527A US 356956 A US356956 A US 356956A US 35695629 A US35695629 A US 35695629A US 1852527 A US1852527 A US 1852527A

- Authority

- US

- United States

- Prior art keywords

- flaps

- carton

- flap

- tongue

- handle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010276 construction Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000007306 turnover Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/46—Handles

- B65D5/46072—Handles integral with the container

- B65D5/46088—Handles integral with the container formed by extensions of closure flaps, by closure flaps or by extensions of side flaps of a container formed by folding a blank to form a tubular body

Definitions

- My invention is addressed to the production of a folding carton with flap closures which are adapted'to be used in the ordinary way, but where desired can be opened out and made into a handle or bail for carrying the carton.

- Such cartons are-conveniently used for shipping articles or groups of articles making up a moderately bulky package designed to be sold without division of the contents.

- My carton when filled, may be packed in the ordinary wooden, corrugated or solid fiber shipping case and shipped to the retail dealer.- When the sale is made, the customer or the dealer can form the top flaps of the carton into the aforementioned handle, making it convenient for the buyer to carry awa his purchase.

- Figure 1 is a plane view of the blank from which my cartons are cut.

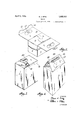

- Figure 2 is a perspective view showing the innermost top flaps engaged, but the outermost top flaps not yet closed.

- Figure 3 is a perspective view with portions of the top flaps cut away showing my closed positon for shipment.

- Figure 4 is a view showing my carton with the outermost top flaps set up into handle position for carrying.

- FIG 1 I have shown a blank having ordinary side and end wall forming portions indicated respectively as 1, 2, 3 and 4. It will be understood that the shape and size of the carton may vary and that my invention is not limited by dimensional restrictions.

- the blank has the ordinary glue flap, 5 and is provided with a series of side closing flaps 6 to 9 inclusive and end closing flaps 10 to 13 inclusive.

- I provide a flap construction particularly on the bottom designed to give greater strength.

- My invention is not restricted to this however and other types of closing flaps are equaly adaptable for use in my carton. I may for example, make the ordinary sealmg flaps on the carton bottom and cause these to be sealed on an automatic sealing machine in the well known manner..

- I have indicated end clos-- ing flaps 12 and 13 which are provided with hook engagement portions 14 and 15 so that when these flaps are folded over, they ma be engaged as will be readily understoo

- the flap 9 has an ordinary tuck end portion 16 which engages over the slanting edges of the flaps 12 and 13.

- the flap 8 is rovided wlth a tongue 17 which after the ot er flaps have been closed is adapted to be inserted into a slit 18 in the line of articulation between the side wall 3 and the flap 9.

- dotted lines indicate lines of score while solid lines indicate lines of cut. It will be clear that the flaps 8 and 9 are preferably to be made co-extensive in area with the bottom of the carton.

- the upper end closing flaps 10 and 11 are also preferably provided with hook or lock portions 19 and 20 so that these flaps when bent over (after the carton has been filled) may be engaged as shown clearly in Figure 2, to form a closure for the top of the earton irrespective of the other two top flaps.

- the closure flap 6 has a tuck end portion 21 serving the same function as the portion- 16 of the flap 9; and the flap 7 has a tongue 22 serving the same purpose as the tongue 17 on the flap 8 and operating through a slit 23 inthe line of articulation between the side wall 1 and the closing flap 6.

- Hand hole portions 24 and 25 are cut in the flaps 6 and 7, and in the tuck end portion 21 there is formed a corresponding cut out 26 for a purpose which will presently be described.

- a slit 27 adapted also toreceive the tongue 22.

- the tongue 22 is preferably made quite narrow so as not to weaken the handle forming portion of my carton.

- the flaps 6 and 7 will again be coextensive in area with the top of the carton.

- the flaps 6 and 7 are disengaged and brought up from their position in the plane of the top of the carton, until their top edges come together and they form two faces of a pyramidal figure above the carton top.

- the tuck end portion 21 now lies adjacent to and beneath the flap 7, and it will be clear that .the cut out portion 26 was made so that the member 21 would not cover a part or all of the hand hole 25.

- the tongue 22 is now inserted in the slot 27 instead of the slot 23 and the handle forming structure

- the fingers of the and 25 and the box carried as an ordinary basket or pail.

- Suflicient board is left between the tops of the flaps 6 and 7 and the hand holes 242 and 25, to give the necessary strength, and both strength and rigidity are imparted to the handle structure by the turn over of the tuck end porion 21, as well as by the interlocking structure.

- a carton formed from a blank having side and end wall portions and side and end closing flaps, atieast one end of said carton having a pair of locking flaps, a flap with a tuck end, and a flap witha tongue, the line of articulation between a wall and the flap having tuck end being provided with a slit for the reception of said tongue, and hand holes in said two last mentioned flaps whereby said flaps'may be positioned angularly above said carton end to form a bail-like handle.

- a carton formed from a blank having side and end wall portions and side and end having tuck end being provided with a slit for the reception of said tongue, and hand holes in said two last mentioned flaps closing flaps, at least one end of said cartonhaving a pair of locking flaps, a flap with a tuck end, and a flap with a tongue, the line of articulation between a'wall and the flap having tuck end being provided with a slit for the reception of said tonguei v and hand holes in said two last mentione flaps whereby said flaps may be positioned angularly above said carton end to -form a bail-like handle, the line of'articulation between said tuck end portion and the flap to which it is attached being provided with a slit to receive said tongue whereby said flaps may be locked in handle forming osition, said tuck end portion cut away to c ear said handle openings.

- said flaps may be positioned angularly above said carton end to form a bail-like handle, the line of articulation between said tuck end portion and the flap to which it is attached being 1provided with a slit to receive said tongue w ere-by said flaps may be locked in handle forming position, said tuck end portion cut away to clear said handle openings,

- the other end of said carton being formed with a pair of locking flaps, a tuck end flap and a flap provided with a tongue, the line of articulation between a wall and said tuck end flap being provided with a slit for the reception of said tongue.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

Description

E. J KING April 5, 1932.

CARTON Filed April 22, 1929 2 Sheets-Sheet l /INVENTOR ATTORNEYS E. J. KING April 5 11932..

CARTON Filed April 22, 1929 2 Sheetsheet 2 INlfENTOR. fl'um K BY (Him A TTORNEYS carton in a Patented Apr. 5,. 1932 UNITED TATE PATENT OFFICE ELEEB J. KINQOI CINCINNATI, OHIO, ASSIGNOB TO THE GLOBE FOLDING BOX 00., O1

CINCINNATI, 0310, A CORPORATION OF OHIO enroll Application flled .April 22, 1929. Serial I0. 858,956.

My invention is addressed to the production of a folding carton with flap closures which are adapted'to be used in the ordinary way, but where desired can be opened out and made into a handle or bail for carrying the carton. Such cartons are-conveniently used for shipping articles or groups of articles making up a moderately bulky package designed to be sold without division of the contents. My carton, when filled, may be packed in the ordinary wooden, corrugated or solid fiber shipping case and shipped to the retail dealer.- When the sale is made, the customer or the dealer can form the top flaps of the carton into the aforementioned handle, making it convenient for the buyer to carry awa his purchase.

It is In 0b]8Ct in such a carton to provide for satisfiactory strength when the box is closed as in shipment, and also when the first two top flaps are in the handle forming position.

These and other objects of my invention, I accomplish by that certain construction and arrangement of parts of which I shall now describe a preferred embodiment, reference being had to the drawings accompanying these specifications.

In the drawings:

Figure 1 is a plane view of the blank from which my cartons are cut.

Figure 2 is a perspective view showing the innermost top flaps engaged, but the outermost top flaps not yet closed.

Figure 3 is a perspective view with portions of the top flaps cut away showing my closed positon for shipment.

Figure 4 is a view showing my carton with the outermost top flaps set up into handle position for carrying.

In Figure 1, I have shown a blank having ordinary side and end wall forming portions indicated respectively as 1, 2, 3 and 4. It will be understood that the shape and size of the carton may vary and that my invention is not limited by dimensional restrictions. The blank has the ordinary glue flap, 5 and is provided with a series of side closing flaps 6 to 9 inclusive and end closing flaps 10 to 13 inclusive. Inasmuch as my carton may frequently be desired for use with heavy articles such for example as filled bottles, I provide a flap construction particularly on the bottom designed to give greater strength. My invention is not restricted to this however and other types of closing flaps are equaly adaptable for use in my carton. I may for example, make the ordinary sealmg flaps on the carton bottom and cause these to be sealed on an automatic sealing machine in the well known manner.. In the embodiment shown, I have indicated end clos-- ing flaps 12 and 13 which are provided with hook engagement portions 14 and 15 so that when these flaps are folded over, they ma be engaged as will be readily understoo The flap 9 has an ordinary tuck end portion 16 which engages over the slanting edges of the flaps 12 and 13. The flap 8 is rovided wlth a tongue 17 which after the ot er flaps have been closed is adapted to be inserted into a slit 18 in the line of articulation between the side wall 3 and the flap 9. In Figure 1, dotted lines indicate lines of score while solid lines indicate lines of cut. It will be clear that the flaps 8 and 9 are preferably to be made co-extensive in area with the bottom of the carton.

The upper end closing flaps 10 and 11 are also preferably provided with hook or lock portions 19 and 20 so that these flaps when bent over (after the carton has been filled) may be engaged as shown clearly in Figure 2, to form a closure for the top of the earton irrespective of the other two top flaps.

The closure flap 6 has a tuck end portion 21 serving the same function as the portion- 16 of the flap 9; and the flap 7 has a tongue 22 serving the same purpose as the tongue 17 on the flap 8 and operating through a slit 23 inthe line of articulation between the side wall 1 and the closing flap 6. Hand hole portions 24 and 25 are cut in the flaps 6 and 7, and in the tuck end portion 21 there is formed a corresponding cut out 26 for a purpose which will presently be described. In the line of articulation between the tuck end 21 and the closure flap 6 there is a slit 27 adapted also toreceive the tongue 22. It

will be-used as hereinafter described when T p is in set up position.

hand maybe inserted through the holes 2-1- angle thereto-when their upper edges are the upper closure flaps are set up to form a handle for the carton. The tongue 22 is preferably made quite narrow so as not to weaken the handle forming portion of my carton. The flaps 6 and 7 will again be coextensive in area with the top of the carton.

The manner of closing the bottom of the carton will be obvious and need not be described by me. After the carton has been filled the top flaps 10 and 11 may be interengaged as shown in Figure 2. For shipment, the flap 6 will then be folded over with the tuck end portions thrust down between the side wall 3 and the edges of the flaps 10 and 11. Then the flap 7 will be folded over andthe tongue 22 inserted in the slit 23. The box will now be in fully closed position as is illustrated in Figure 3. It will be noted that the handle openings 24 and 25, occurring'near the top edges of the flaps 6 and 7 are offset from each other so that the tightness of the closure of the carton top is not impaired. This feature is not,

necessary however inasmuch as the flaps 10 and 11 form a satisfactory closure for all but siftable bodies within the carton.

When itis desired to use the carton for carrying, as when a purchaser has bought the article or articles which it contains and desires to carry them home, the flaps 6 and 7 are disengaged and brought up from their position in the plane of the top of the carton, until their top edges come together and they form two faces of a pyramidal figure above the carton top. This is well illustrated in Figure 4. The tuck end portion 21 now lies adjacent to and beneath the flap 7, and it will be clear that .the cut out portion 26 was made so that the member 21 would not cover a part or all of the hand hole 25. The tongue 22 is now inserted in the slot 27 instead of the slot 23 and the handle forming structure The fingers of the and 25 and the box carried as an ordinary basket or pail. Suflicient board is left between the tops of the flaps 6 and 7 and the hand holes 242 and 25, to give the necessary strength, and both strength and rigidity are imparted to the handle structure by the turn over of the tuck end porion 21, as well as by the interlocking structure.

Various modifications in my invention may be made without departing from the spirit thereof.

Having thus described my invention, what I claim as new and desire to secure by Letters Patent, is

1. A carton formed from a blank having side and end wallsand side and end closure flaps, an opposite pair of said closure flaps being perforated to form handles, said flaps being of substantially the samearea as the top of said carton and adapted to'lie at an to the flap to which it is attached and form a stiffening part of the handle structure and means for locking said flaps together in handle forming position.

2. A carton formed from a blank having side and end Walls and side and end closure flaps, an opposite pair of said closure flaps being perforated to form handles, said flaps being ofsubstantially the same area as the top of said carton and adapted to lie at an angle thereto when their upper edges are brought together, a tuck end portion upon one of said flaps adapted when said flaps are in handle forming position to lie at an angle to the flap towhich it is attached and form a stiffening part of the handle structure and means for iolding said flaps together in handle forming position, said means comprising a tongue on one of said flaps and a slit to receive said tongue in the line of articulation between said tuck end portion and the flap to which it is a ttached.

3. A carton-formed from a blank having side and end walls and side and end closure flaps, an opposite pair of said closure flaps beingperforated to form handles, said flaps being of substantially the same area as the brought together, a tuck end portion upon one of said flaps adapted when said flaps are in handle forming position to lie at an angle to the flap to which it is attached and form a stiffening part'of the handle structure and means for holding said flaps together in handle forming position, said means comprising a tongue on one of said flaps and a slit to receive said tongue in the line of articulation between said tuck end portion and the flap to which it is attached and means upon the other pair of flaps to form a locking closure for said carton.

4. A carton formed from a blank having side and end wall portions and side and end closing flaps, atieast one end of said carton having a pair of locking flaps, a flap with a tuck end, and a flap witha tongue, the line of articulation between a wall and the flap having tuck end being provided with a slit for the reception of said tongue, and hand holes in said two last mentioned flaps whereby said flaps'may be positioned angularly above said carton end to form a bail-like handle.

5. A carton formed from a blank having side and end wall portions and side and end having tuck end being provided with a slit for the reception of said tongue, and hand holes in said two last mentioned flaps closing flaps, at least one end of said cartonhaving a pair of locking flaps, a flap with a tuck end, and a flap with a tongue, the line of articulation between a'wall and the flap having tuck end being provided with a slit for the reception of said tonguei v and hand holes in said two last mentione flaps whereby said flaps may be positioned angularly above said carton end to -form a bail-like handle, the line of'articulation between said tuck end portion and the flap to which it is attached being provided with a slit to receive said tongue whereby said flaps may be locked in handle forming osition, said tuck end portion cut away to c ear said handle openings.

7. A carton formed from a blank having side and end wall portions and side and end closing flaps, at least one end of said carton having a pair of locking flaps, a flap with a tuck end, and a flap with a tongue, the line of articulation between a wall and the flap having the tuck end being provided with a slit for the reception of said tongue and hand holes insaid two last mentioned flaps Whereby said flaps may be positioned angularly above said carton end to form a bail-like handle, the line of articulation between said tuck end portion and the flap to which it is attached being 1provided with a slit to receive said tongue w ere-by said flaps may be locked in handle forming position, said tuck end portion cut away to clear said handle openings,

the other end of said carton being formed with a pair of locking flaps, a tuck end flap and a flap provided with a tongue, the line of articulation between a wall and said tuck end flap being provided with a slit for the reception of said tongue.

ELMER J KING.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US356956A US1852527A (en) | 1929-04-22 | 1929-04-22 | Carton |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US356956A US1852527A (en) | 1929-04-22 | 1929-04-22 | Carton |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852527A true US1852527A (en) | 1932-04-05 |

Family

ID=23403668

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US356956A Expired - Lifetime US1852527A (en) | 1929-04-22 | 1929-04-22 | Carton |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852527A (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2444895A (en) * | 1944-06-02 | 1948-07-06 | Gardner Richardson Co | Sealed box |

| US2594394A (en) * | 1948-10-09 | 1952-04-29 | Polaroid Corp | Carton |

| US2596087A (en) * | 1949-10-12 | 1952-05-06 | California Container Corp | Edible material container |

| US2832527A (en) * | 1956-04-23 | 1958-04-29 | Alton Box Board Co | Folding box |

| US3126145A (en) * | 1964-03-24 | Article carrier | ||

| US4046311A (en) * | 1976-07-16 | 1977-09-06 | Westvaco Corporation | Return mail container |

| US4059221A (en) * | 1976-08-04 | 1977-11-22 | Packaging Corporation Of America | Shipping container and blank therefor |

| US4401255A (en) * | 1981-08-03 | 1983-08-30 | Federal Paper Board Co., Inc. | Distributor pack carton |

| US4830270A (en) * | 1988-05-19 | 1989-05-16 | Professional Packaging Limited | Mailing and shipping carton |

| EP0389254A1 (en) * | 1989-03-22 | 1990-09-26 | The Mead Corporation | Carton with divisible carrying handle for providing access to the carton contents |

| US5181651A (en) * | 1992-02-10 | 1993-01-26 | International Paper Company | Paperboard asparagus carton |

| FR2788492A1 (en) * | 1999-01-15 | 2000-07-21 | Charton Maurice Ets | PACKAGING AND PRESENTATION BOX |

| WO2016099251A1 (en) * | 2014-11-25 | 2016-06-23 | Thong Seng Engineering Sdn. Bhd. | A system for tucking interlocking dust flaps of a box |

| EP3623307A1 (en) * | 2018-09-14 | 2020-03-18 | José Vaz de Almada | Packaging |

| US10865009B1 (en) | 2019-08-06 | 2020-12-15 | Talal T. Al-Housseiny | Blank used for making a container with insertable tabs |

| US11511905B2 (en) | 2020-02-12 | 2022-11-29 | Talal T. Al-Housseiny | Blank used for making a container with interlocking flaps and a handle |

-

1929

- 1929-04-22 US US356956A patent/US1852527A/en not_active Expired - Lifetime

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3126145A (en) * | 1964-03-24 | Article carrier | ||

| US2444895A (en) * | 1944-06-02 | 1948-07-06 | Gardner Richardson Co | Sealed box |

| US2594394A (en) * | 1948-10-09 | 1952-04-29 | Polaroid Corp | Carton |

| US2596087A (en) * | 1949-10-12 | 1952-05-06 | California Container Corp | Edible material container |

| US2832527A (en) * | 1956-04-23 | 1958-04-29 | Alton Box Board Co | Folding box |

| US4046311A (en) * | 1976-07-16 | 1977-09-06 | Westvaco Corporation | Return mail container |

| US4059221A (en) * | 1976-08-04 | 1977-11-22 | Packaging Corporation Of America | Shipping container and blank therefor |

| US4401255A (en) * | 1981-08-03 | 1983-08-30 | Federal Paper Board Co., Inc. | Distributor pack carton |

| US4830270A (en) * | 1988-05-19 | 1989-05-16 | Professional Packaging Limited | Mailing and shipping carton |

| EP0389254A1 (en) * | 1989-03-22 | 1990-09-26 | The Mead Corporation | Carton with divisible carrying handle for providing access to the carton contents |

| US5181651A (en) * | 1992-02-10 | 1993-01-26 | International Paper Company | Paperboard asparagus carton |

| FR2788492A1 (en) * | 1999-01-15 | 2000-07-21 | Charton Maurice Ets | PACKAGING AND PRESENTATION BOX |

| WO2016099251A1 (en) * | 2014-11-25 | 2016-06-23 | Thong Seng Engineering Sdn. Bhd. | A system for tucking interlocking dust flaps of a box |

| EP3623307A1 (en) * | 2018-09-14 | 2020-03-18 | José Vaz de Almada | Packaging |

| US10865009B1 (en) | 2019-08-06 | 2020-12-15 | Talal T. Al-Housseiny | Blank used for making a container with insertable tabs |

| US11511905B2 (en) | 2020-02-12 | 2022-11-29 | Talal T. Al-Housseiny | Blank used for making a container with interlocking flaps and a handle |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1852527A (en) | Carton | |

| US2162089A (en) | Article container | |

| US2744622A (en) | Combination box and cradle for decorated easter eggs and the like | |

| US3119544A (en) | Composite package | |

| US3610512A (en) | Handheld food holder | |

| US2464951A (en) | Display box | |

| US2852177A (en) | Folding paperboard box construction | |

| US2791362A (en) | Partitioned shipping container | |

| US2151733A (en) | Container | |

| US2531255A (en) | Container and display insert | |

| US3019958A (en) | Hinge cover carton | |

| US2379665A (en) | Folding box | |

| US2822116A (en) | Combination bait box and carrier | |

| US3075683A (en) | Shockproof or cushioned carton | |

| US2307720A (en) | Collapsible box | |

| US2336655A (en) | Carton | |

| US2632595A (en) | Basket | |

| US2352994A (en) | Receptacle | |

| US3253769A (en) | Collapsible carton | |

| US2309134A (en) | Receptacle | |

| US1960947A (en) | Shipping container | |

| US3191818A (en) | Container with dispensing hopper means and blanks for making the same | |

| US1826962A (en) | Folding box | |

| US2292573A (en) | Bag or container | |

| US2686000A (en) | Receptacle with detachable compartments |