US1852435A - Grinding muller roller - Google Patents

Grinding muller roller Download PDFInfo

- Publication number

- US1852435A US1852435A US381105A US38110529A US1852435A US 1852435 A US1852435 A US 1852435A US 381105 A US381105 A US 381105A US 38110529 A US38110529 A US 38110529A US 1852435 A US1852435 A US 1852435A

- Authority

- US

- United States

- Prior art keywords

- muller

- grinding

- piston

- pressure

- roll

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000003190 augmentative effect Effects 0.000 description 4

- 239000011435 rock Substances 0.000 description 4

- 239000012530 fluid Substances 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 239000004927 clay Substances 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 241001272996 Polyphylla fullo Species 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C15/00—Disintegrating by milling members in the form of rollers or balls co-operating with rings or discs

- B02C15/14—Edge runners, e.g. Chile mills

Definitions

- the invention relates to grinding muller :rollers for dry pans, used for grinding or pulverizing ⁇ clay or other materials.

- the object of the present invention is to provide improved method and means 'for augmenting the pressure exerted by the mulu ler rolls.

- the muller rolls are adapted to rest by gravity upon the clay or other material contained in the revolving pan. In accordance with the present practice, usually the weight of the rolls is relied upon to secure the crushing' or grinding ⁇ effect.

- the pressure of the muller rolls is augmented by a Huid medium under pressure, such for example as compressed air or steam, exerted through a piston operating in a cylinder supplied with said medium.

- a Huid medium under pressure such for example as compressed air or steam

- Fig. 2 is a part elevation part section on line 2, 2 of Fig. 1, on an enlarged scale.

- Figi: 3 a fragmentary sectional view showingl a modification.

- the dry pan 5 is mounted upon the rotating shaft G, operated by the pulley 7 through the gears 8 and 9. in accordance with the present practice.

- the muller rolls 10 are mounted in the yoles 11, each yoke being connected to a rock shaft 12 so as to permit the rolls to rise and fall as they travel over the material in the rotating pan 5. This is also in accordance with the present practice.

- a piston rod 13 is pivotally secured, as at 1&1, to one arm of each yoke 11.y forming a bearing for the roll, at a point vertically above 'the axis of shaft 15 of the muller roll 10.

- the piston rod 13 is connected to a piston 16 i space beneath the piston is open to atmos- 1 phere.

- the space 18 in the cylinder 17, above the piston 16, is connected, as by pipe 19, with a source of air supply under pressure, such for example as contained in the tank 20.

- pressure may be communicated to the cylinder and piston through the medium of a liquid, as shown in Fig. 3, in which case the liquid is put under the pressure of a compressed elastic medium contained in the space 21 above the liquid 22.

- the pressure of the roll due to gravity will be augmented by the pressure of the compressed air or other elastic Huid medium, exerted in the cylinder 17, communicated through the piston 16 and piston rod 13 to the bearing carrying the roll.

- This augmented pressure will depend upon the pressure at which the elastic fluid medium is maintained, for example in the tank 20.

- This pressure can of course be varied at will, and the source of pressure, or the pressure tank, may be positioned at any convenient point irrespective of the position of the grinding mullers.

- dry pans are usually provided with two muller rolls, and the yokes mounted on the rock shafts usually provide a bearing, on each side of each muller roll. I do not however desire to limit the invention to any specific structure beyond that defined in the claims.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Grinding Of Cylindrical And Plane Surfaces (AREA)

- Crushing And Grinding (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Description

April 5, 1932 R. E. RATCHAE GRINDING MULLER ROLLER Filed July 26. 1929 ZJSheets-Sheet l Bf MKM L pri 5, 1932.

R. E. RnTcHlE 1,852,435

GBINDING MULLER ROLLER Filed July 26. 1929 2 Sheets-Sheet 2 Ilm - Arron/1H.

CSE

Patented Apr. 5, 1932 UNITED STATES PATENT or-rlcev RALPH E. IRITCHIE, OF BIRMINGHAM, ALABAMA, ASSIGNOR T()4 CHAMBERS BROTHERS COMPANY, A CORPORATION OF PENNSYLVANIA GRINDING MULLER ROLLER Application led July 26, 1929. Serial No. 381,105.

The invention relates to grinding muller :rollers for dry pans, used for grinding or pulverizing` clay or other materials.

The object of the present invention is to provide improved method and means 'for augmenting the pressure exerted by the mulu ler rolls.

In devices of this class now in common use, the muller rolls are adapted to rest by gravity upon the clay or other material contained in the revolving pan. In accordance with the present practice, usually the weight of the rolls is relied upon to secure the crushing' or grinding` effect.

In accordance with the present invention the pressure of the muller rolls is augmented by a Huid medium under pressure, such for example as compressed air or steam, exerted through a piston operating in a cylinder supplied with said medium.

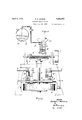

litefc-rring` to the drawings which illustrate merely by way of example suitable means for effecting the invention z- Fig. l is an elevation.

Fig. 2 is a part elevation part section on line 2, 2 of Fig. 1, on an enlarged scale.

Figi: 3 a fragmentary sectional view showingl a modification.

Similar numerals refer to similar parts throughout the several views.

The dry pan 5 is mounted upon the rotating shaft G, operated by the pulley 7 through the gears 8 and 9. in accordance with the present practice. The muller rolls 10 are mounted in the yoles 11, each yoke being connected to a rock shaft 12 so as to permit the rolls to rise and fall as they travel over the material in the rotating pan 5. This is also in accordance with the present practice.

In accordance with the present invention. a piston rod 13 is pivotally secured, as at 1&1, to one arm of each yoke 11.y forming a bearing for the roll, at a point vertically above 'the axis of shaft 15 of the muller roll 10.

The piston rod 13 is connected to a piston 16 i space beneath the piston is open to atmos- 1 phere. The space 18 in the cylinder 17, above the piston 16, is connected, as by pipe 19, with a source of air supply under pressure, such for example as contained in the tank 20.

It will be understood. that pressure may be communicated to the cylinder and piston through the medium of a liquid, as shown in Fig. 3, in which case the liquid is put under the pressure of a compressed elastic medium contained in the space 21 above the liquid 22.

In operation, it will be seen that the pressure of the roll due to gravity will be augmented by the pressure of the compressed air or other elastic Huid medium, exerted in the cylinder 17, communicated through the piston 16 and piston rod 13 to the bearing carrying the roll. This augmented pressure will depend upon the pressure at which the elastic fluid medium is maintained, for example in the tank 20. This pressure can of course be varied at will, and the source of pressure, or the pressure tank, may be positioned at any convenient point irrespective of the position of the grinding mullers. In accordance with the present practice dry pans are usually provided with two muller rolls, and the yokes mounted on the rock shafts usually provide a bearing, on each side of each muller roll. I do not however desire to limit the invention to any specific structure beyond that defined in the claims.

What I claim is 1. The combination of a plurality of muller rolls, movable bearings for each roll and means for applying the force of a compressed elastic :Huid medium directly to each bearing independently.

2. The combination of a muller roll, a shaft, a rocking yoke connected to the shaft provided with a bearing for the muller roll, a. cylinder and a piston operating therein, means for communicating the force of a compressed elastic fluid medium to the piston 5 Within the cylinder and a rod connecting the piston to said bearing.

3. The combination of :L muller roll, a rock shaft, a yoke connected to the rock shaft provided With a bearing for the muller roll, a

pivotally supported cylinder and a piston operating therein, means for communicating the force of a compressed elastic fluid medium to the piston Within the cylinder and a rod connecting the piston to said bearing.

RALPH E. RI'ICHIE.`

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US381105A US1852435A (en) | 1929-07-26 | 1929-07-26 | Grinding muller roller |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US381105A US1852435A (en) | 1929-07-26 | 1929-07-26 | Grinding muller roller |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852435A true US1852435A (en) | 1932-04-05 |

Family

ID=23503667

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US381105A Expired - Lifetime US1852435A (en) | 1929-07-26 | 1929-07-26 | Grinding muller roller |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852435A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2610802A (en) * | 1948-09-14 | 1952-09-16 | Simpson Herbert Corp | Variable unit pressure muller |

| US2680571A (en) * | 1945-11-20 | 1954-06-08 | Bjarme Johan Alfred | Pneumatic release means for gyratory crushers |

| US2691339A (en) * | 1949-10-12 | 1954-10-12 | Edwards Eng Corp | Automatic pressure control of sugar cane mills |

| US2787425A (en) * | 1952-12-12 | 1957-04-02 | Nordberg Manufacturing Co | Pneumatic release for gyratory crushers |

| US2909330A (en) * | 1954-09-30 | 1959-10-20 | Hardinge Harlowe | Pulverizing mill and process of pulverizing material |

| US2982481A (en) * | 1957-02-04 | 1961-05-02 | Osborne Associates | Crushing apparatus |

-

1929

- 1929-07-26 US US381105A patent/US1852435A/en not_active Expired - Lifetime

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2680571A (en) * | 1945-11-20 | 1954-06-08 | Bjarme Johan Alfred | Pneumatic release means for gyratory crushers |

| US2610802A (en) * | 1948-09-14 | 1952-09-16 | Simpson Herbert Corp | Variable unit pressure muller |

| US2691339A (en) * | 1949-10-12 | 1954-10-12 | Edwards Eng Corp | Automatic pressure control of sugar cane mills |

| US2787425A (en) * | 1952-12-12 | 1957-04-02 | Nordberg Manufacturing Co | Pneumatic release for gyratory crushers |

| US2909330A (en) * | 1954-09-30 | 1959-10-20 | Hardinge Harlowe | Pulverizing mill and process of pulverizing material |

| US2982481A (en) * | 1957-02-04 | 1961-05-02 | Osborne Associates | Crushing apparatus |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1852435A (en) | Grinding muller roller | |

| US2319616A (en) | Inking roller for printing presses | |

| US1428687A (en) | Tube mill | |

| US2656120A (en) | Material feed device for gyratory crushers | |

| US2610802A (en) | Variable unit pressure muller | |

| US2021895A (en) | Crusher | |

| US2265752A (en) | Apparatus for charging concrete mixers | |

| US1748102A (en) | Crusher | |

| US1889555A (en) | Air pressure dry pan | |

| US2470400A (en) | Doctor blade mounting | |

| US1776318A (en) | Means for reducing friable materials | |

| US199605A (en) | Improvement in machines for preparing and treating middlings | |

| US1788964A (en) | Color-grinding machine | |

| US2082498A (en) | Roller mill | |

| US1327300A (en) | Machine for coating blanks with paraffin | |

| US1718347A (en) | Grinding head | |

| US2224330A (en) | Roller grinding mill | |

| US1937030A (en) | Grinding mill | |

| US591644A (en) | Wood-pulp grinder | |

| US1772640A (en) | Apparatus for treating and mixing comminuted or finely-divided materials | |

| US1578590A (en) | Paper-pulp screen | |

| US2606080A (en) | Roller grinding mill | |

| GB331499A (en) | Improvements in or relating to motor vehicle chassis | |

| US525023A (en) | Fruit or lard press | |

| US1652410A (en) | Sheet-glass-abrading means |