US1852322A - System and apparatus for handling bottles - Google Patents

System and apparatus for handling bottles Download PDFInfo

- Publication number

- US1852322A US1852322A US258259A US25825928A US1852322A US 1852322 A US1852322 A US 1852322A US 258259 A US258259 A US 258259A US 25825928 A US25825928 A US 25825928A US 1852322 A US1852322 A US 1852322A

- Authority

- US

- United States

- Prior art keywords

- conveyor

- bottles

- conveyors

- onto

- pasteurizer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G47/00—Article or material-handling devices associated with conveyors; Methods employing such devices

- B65G47/52—Devices for transferring articles or materials between conveyors i.e. discharging or feeding devices

- B65G47/68—Devices for transferring articles or materials between conveyors i.e. discharging or feeding devices adapted to receive articles arriving in one layer from one conveyor lane and to transfer them in individual layers to more than one conveyor lane or to one broader conveyor lane, or vice versa, e.g. combining the flows of articles conveyed by more than one conveyor

- B65G47/71—Devices for transferring articles or materials between conveyors i.e. discharging or feeding devices adapted to receive articles arriving in one layer from one conveyor lane and to transfer them in individual layers to more than one conveyor lane or to one broader conveyor lane, or vice versa, e.g. combining the flows of articles conveyed by more than one conveyor the articles being discharged or distributed to several distinct separate conveyors or to a broader conveyor lane

Definitions

- This invention relates to a system and ap- Earatus for conveying a plurality of filled ottles, or other receptacles, from a capplng machine through a pasteurizer and thence removing the bottles or receptacles from the pasteurizer and delivering the same to a labeling machine in single file.

- the main object of the invention is to provide a system and apparatus of the character described by means of which a quantity of liquid, such as beer, near beer, milk, or any beverage containing milk, may be bottled, pasteurized and labeled in a continuous operation, all of the above operations being accomplished with a minimum loss of time and by automatic machinery.

- a quantity of liquid such as beer, near beer, milk, or any beverage containing milk

- Another object of the invention is to provide a system and apparatus of the character described by means of which a plurality of tiers of filled receptacles may be simultaneously passed through a pasteurizer whereby a given size pasteurizer may be operated continuously and at maximum elficiency.

- Another object of the invention is to provide a system and apparatus of the purpose set forth, which apparatus is simple and de-' pendable in operation and will occupy a minimum amount of floor s ace and yet handle a maximum number 0 receptacles in a given period.

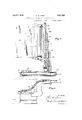

- Fig. 1 is a top plan view and apparatus;

- Fig. 2 is a side elevation of the same;

- Fig. 3 is a fragmenta top plan view showin the mechanism for ceding the bottles into t e lower tier of the pasteurizer;

- Fig. 4 is a top lan view similar to Fig. 3 showing the mec anism for feeding the bottles into the upper tier of the pasteurizer;

- Fig. 5 is a top plan view showing the mechanism for removing the bottles from the lower tier of the pasteurizer;

- Fig. dis a fragmentary view in side elevation of the mechanism illustrated in Fig. 5;

- Fig. 7 is a to Ian view of the mechanism for removingt e ottles from the lower tier of the pasteurizer pasteurizer P are'a showing the general layout of my system 1 1928. Serial No. 258,259.

- Fig. 8 is a vertical sectional view of the pasteurizer showing the mechanism for delivering the bottles therethrough in a plurality of superposed tiers.

- Fig. 1 illustrates the general plan or la out of my system and apparatus.

- the bottles are delivered from the capping machine onto the conveyors 2 and 3 in double file.

- a rail 4 separates the two files and guide rails 5 and Gare disposed along the outside edges of the conveyors.

- the conveyor 2 delivers onto a rotary trans-' fer plate 6 which receives the bottles and delivers the same onto an endless conveyor 7.

- Disposed along the opposite sides of the conveyor 7 are guide rails 8 and 9 which serve to hold the bottles in upright position.

- the guide rail 8 is bent inwardly as shown at 8. and extends across the conveyor 7 at an angle thereto, the purpose of which will hereinafter appear.

- the guide rail 9 is bent inwardly as shown at 9' and both guide rails Breferably extend through the asteurizer.

- a pasteurizer designated generally by the reference character P.

- the conveyor 3 delivers onto an upwardly inclined conve or 12, and disposed adjacent the delivery end of conveyor 12 is another u wardly inclined conveyor 13 which travels in the direction of the arrow in Fig. 4 and onto which the conveyor 12 delivers.

- another conveyor 14 Disposed adjacent the delivery end of the conveyor 13 and at right angles thereto is another conveyor 14 which'is arranged above the con veyor 7.

- the conveyor 14 is provided with guide rails 15 and 16 on op to sides thereof and the guide rail 15 is .t inwardly as shown at 15' and extends across the conveyor 14 at an angle thereto and thence through the spection of Fig. 8, it will be seen that the conveyors 7 and 14 are disposed-one above the other. Disposed between the conveyor 7 and the conveyor 10 is a dead plate 17 and disposed between the conveyor 14 and the conveyor 11 is a dead plate 18.

- the bottles on the conveyor 7 are directed onto the dead plate 17 by means of the guide rail 8 and the succeeding bottles force the forward bottles onto the conveyor 10.

- the bottles on the conveyor 14 are directed onto the dead plate 18 by the guide rail 15 and the succeeding bottles force the forward bottles onto the conveyor 11.

- the conveyors 7 and 14 move considerably faster than the conveyors 10 and 11 so that the conveyors 10 and 11 are kept substantially filled with bottles.

- the conveyors 10 and 11 are driven at a very slow speed so that the contents of the bottles are pasteurized while passing through the pasteurizer.

- a plurality of conveyors 19, 20, 21 and 22 Arranged at the delivery end of the pasteurizer P are a plurality of conveyors 19, 20, 21 and 22 and disposed between these conveyors and the conveyor 10 is a dead plate 23 onto which the bottles from the conveyor 10 are delivered.

- a dead plate 23 Arranged at the delivery end of the pasteurizer P and above the conveyors 19,'

- 20,21 and 22 are a lurality of conveyors 24, 25, 26 and 27 andisposed between the conveyor 11 and the last mentioned conveyor is a dead plate 28 onto which the bottles from the conveyor 11 are delivered.

- the guide rails 8 and 9 extend all the way through the pasteurizer andvacross the conveyors 19, 20, 21 and 22 at an angle thereto as most clearly shown in Fig. 7.

- the guide rails 15 and 16 extend through the pasteurizer and across the conveyors 24, 25, 26 and 27 as shown most clearly in Fi 5.

- the conveyors 19, 20, 21 and 22 are driven at different speeds, the conveyor .19 being driven at the slowest speed and the conveyor 22 being driven at the fastest speed.

- the conveyors 24, 25, 26 and 27 are driven at difierent speeds, the con veyor 24 being driven at the slowest speed and the conveyor 27 being driven at the fastest speed.

- Disposedad] acent the delivery end of the conveyor 27 isanother conveyor 29 onto which the bottles from the conveyor 27 are delivered.

- the conveyor 29 travels in the direction of the arrow shown in Fig. 5 and delivers the bottles onto another conveyor 30 which travels in the direction of the arrows shown in Fi .”5.

- the bottles on the conveyor 11 are delivered onto the dead plate 28 and the succeeding bottles force the forward bottles onto the conveyors 24, 25, 26 and .27 in succession.

- a pair of conveyors 31 and 32 Disposed adjacent the delivery end of the conveyor 22 are a pair of conveyors 31 and 32 both of which travel in the dlrection of the arrows shown in Fig. 7

- the guide rails 15 and 16 extend across the conveyors 31 and 32 at an angle thereto and serve to guide the bottles first onto the conveyor 31 and thence' onto the conveyor 32.

- the delivery end of the conveyor 30 is disposed adjacent one end of the conveyors 31 and 32 and the guide rails serve to direct the bottles from the conveyor 30 first onto the conveyor 31 and then onto the conve or 32.

- the conveyors 19, 20, 21 and 22 are moving at diflerent speeds and due to the arrangement of the guide rails 8 and 9, it will be seen that the bottles are removed from the lower conveyor 10 in single file and delivered onto the conveyor 30.

- the bottles from the upper conveyor 11 are delivered onto the -conveyors 24, 25, 26 and 27 and the' arrangement of the guide rails 15 and 16 causes the bottles to be delivered onto the conveyor 32 in single file.

- the conveyor 30 also delivers onto the conveyor 32 which moves at a comparatively.

- it container handling system adapted to convey containers from a sealing machine through a heating apparatus to a labeling machine, said system including a plurality oil narrow conveyors moving at a relatively speed, a plurality of considerably Wider conveyors moving through said heating apparatus at a relatively slow speed and to which said first conveyors deliver whereby to reduce the speed of said containers moving through said heating apparatus, the said vvider conveyors being disposed in difi'erent planes, and a plurality of conveyors moving at a relatively high speed for removing the containers from said slow speed conveyors, said last mentioned conveyors being of substantially the same capacity as said slow speed conveyors and delivering to said labeling machine in single file.

- a conveyor system for conveying containers from a capping machine through a heating apparatus and to a labeling machine, said system including a plurality of narrow conveyors moving at a relatively high speed and a lurality of conveyors arranged within the eating apparatus and disposed in difiterent planes and to which said high speed conveyors deliver, the conveyors in said heating apparatus being considerably wider than said first conveyors and moving at a relative- I ly low speed, a pluralit of narrow conveyors moving at a relatively igh speed for removing the containers from the heating apparathe and delivering the same to the labeling machine in single file, all of the above operations being accomplished in a continuous op eration.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Labeling Devices (AREA)

Description

April 5, 1932. c. H. LOEW 1,852,322

SYSTEM AND APPARATUS FOR HANDLING BOTTLES Filed March 1, 1928 6 Sheets-Sheet l I N VEN TOR.

WWWK A TTORNE Y.

A ril 5, 1932.

c. H. LOEW 1,852,322

SYSTEM AND APPARATUS FOR HANDLING BOTTLES Filed-March 1, 1928 6 Sheets-Sheet 2 A/ 4N V EN TOR /MM W- A TTORNE Y.

April 5, 1932.. c. H. LOEW 1,852,322

SYSTEM AND APPARATUS FOR HANDLING BOTTLES Filed March 1, 1928 6 Sheets-Sheet 5 gumxl'ullllmmzwiiilglHIllll-H fiil IIIIIIIIIIIIIIIIIIII A TTOR VE Y.

C. H. LOEW SYSTEM AND APPARATUS FOR HANDLING BOTTLES 6 Sheets-Sheet Filed March 1, 1928 INVENTOR.

' ATTORNEY.

A ril 5, 1932.

April 5, 1932. c H, LOEW 1,852,322

SYSTEM AND APPARATUS FOR HANDLING BOTTLES Filed March 1, 1928 6 Sheets-Sheet 5 INVENTOR.

MW K A TTORNE Y.

April 5, 1932. c. H. LOEW 1,

SYSTEM AND APPARATUS FOR HANDLING BOTTLES Filed March 1, 1928 6 Sheets-Sheet 6 HHHHHHIIIHII jih- "Hmilllh INVENTOR.

fw/w/mq I A TTORNE Y.

Patented Apr. 5, 1932 UNITED STATES PATENT OFFICE mums H. LGEW, OI AVON LAKE, OHIO, ASSIGNOR TO LIQUID CABIBONIC, CORPORA- T1017, OF CHICAGO, ILLINOIS, A COBYOBATION OI ILLINOIS SYSTEM AND .AIPARATUS FOB HANDLING BOTTLES Application filed larch 1,

This invention relates to a system and ap- Earatus for conveying a plurality of filled ottles, or other receptacles, from a capplng machine through a pasteurizer and thence removing the bottles or receptacles from the pasteurizer and delivering the same to a labeling machine in single file.

The main object of the invention is to provide a system and apparatus of the character described by means of which a quantity of liquid, such as beer, near beer, milk, or any beverage containing milk, may be bottled, pasteurized and labeled in a continuous operation, all of the above operations being accomplished with a minimum loss of time and by automatic machinery.

Another object of the invention is to provide a system and apparatus of the character described by means of which a plurality of tiers of filled receptacles may be simultaneously passed through a pasteurizer whereby a given size pasteurizer may be operated continuously and at maximum elficiency.

Another object of the invention is to provide a system and apparatus of the purpose set forth, which apparatus is simple and de-' pendable in operation and will occupy a minimum amount of floor s ace and yet handle a maximum number 0 receptacles in a given period.

Further and more limited objects of the invention will appear as the description proceeds and by re erence to the accompanying drawings in which Fig. 1 is a top plan view and apparatus; Fig. 2 is a side elevation of the same; Fig. 3 is a fragmenta top plan view showin the mechanism for ceding the bottles into t e lower tier of the pasteurizer; Fig. 4 is a top lan view similar to Fig. 3 showing the mec anism for feeding the bottles into the upper tier of the pasteurizer; Fig. 5 is a top plan view showing the mechanism for removing the bottles from the lower tier of the pasteurizer; Fig. dis a fragmentary view in side elevation of the mechanism illustrated in Fig. 5; Fig. 7 is a to Ian view of the mechanism for removingt e ottles from the lower tier of the pasteurizer pasteurizer P are'a showing the general layout of my system 1 1928. Serial No. 258,259.

and also illustrating the mechanism for de livering the bottles to the labeling machine; and Fig. 8 is a vertical sectional view of the pasteurizer showing the mechanism for delivering the bottles therethrough in a plurality of superposed tiers.

Referring now to the drawings, Fig. 1 illustrates the general plan or la out of my system and apparatus. The bott es'are filled by any suitable mechanism (not own) and are delivered to the capping machme 1 where they are hermetically sealed. Leading from the capping machine are a pair of endless conveyors 2 and 3. The bottles are delivered from the capping machine onto the conveyors 2 and 3 in double file. A rail 4 separates the two files and guide rails 5 and Gare disposed along the outside edges of the conveyors.

The conveyor 2 delivers onto a rotary trans-' fer plate 6 which receives the bottles and delivers the same onto an endless conveyor 7. Disposed along the opposite sides of the conveyor 7 are guide rails 8 and 9 which serve to hold the bottles in upright position. The guide rail 8 is bent inwardly as shown at 8. and extends across the conveyor 7 at an angle thereto, the purpose of which will hereinafter appear. The guide rail 9 is bent inwardly as shown at 9' and both guide rails Breferably extend through the asteurizer.

isposed adjacent the conveyor and with its longitudinal axis at right angles thereto is a pasteurizer designated generally by the reference character P. Arranged wlthin the Cpair of superposed endess conveyors 10 an 11 which extend longitudinally through the pasteurizer and operate in a manner to be hereinafter described. The conveyor 3 delivers onto an upwardly inclined conve or 12, and disposed adjacent the delivery end of conveyor 12 is another u wardly inclined conveyor 13 which travels in the direction of the arrow in Fig. 4 and onto which the conveyor 12 delivers. Disposed adjacent the delivery end of the conveyor 13 and at right angles thereto is another conveyor 14 which'is arranged above the con veyor 7. The conveyor 14 is provided with guide rails 15 and 16 on op to sides thereof and the guide rail 15 is .t inwardly as shown at 15' and extends across the conveyor 14 at an angle thereto and thence through the spection of Fig. 8, it will be seen that the conveyors 7 and 14 are disposed-one above the other. Disposed between the conveyor 7 and the conveyor 10 is a dead plate 17 and disposed between the conveyor 14 and the conveyor 11 is a dead plate 18. The bottles on the conveyor 7 are directed onto the dead plate 17 by means of the guide rail 8 and the succeeding bottles force the forward bottles onto the conveyor 10. In a like manner the bottles on the conveyor 14 are directed onto the dead plate 18 by the guide rail 15 and the succeeding bottles force the forward bottles onto the conveyor 11. The conveyors 7 and 14 move considerably faster than the conveyors 10 and 11 so that the conveyors 10 and 11 are kept substantially filled with bottles. The conveyors 10 and 11 are driven at a very slow speed so that the contents of the bottles are pasteurized while passing through the pasteurizer.

Arranged at the delivery end of the pasteurizer P are a plurality of conveyors 19, 20, 21 and 22 and disposed between these conveyors and the conveyor 10 is a dead plate 23 onto which the bottles from the conveyor 10 are delivered. Arranged at the delivery end of the pasteurizer P and above the conveyors 19,'

20,21 and 22 are a lurality of conveyors 24, 25, 26 and 27 andisposed between the conveyor 11 and the last mentioned conveyor is a dead plate 28 onto which the bottles from the conveyor 11 are delivered. The guide rails 8 and 9 extend all the way through the pasteurizer andvacross the conveyors 19, 20, 21 and 22 at an angle thereto as most clearly shown in Fig. 7. Likewise the guide rails 15 and 16 extend through the pasteurizer and across the conveyors 24, 25, 26 and 27 as shown most clearly in Fi 5. The conveyors 19, 20, 21 and 22 are driven at different speeds, the conveyor .19 being driven at the slowest speed and the conveyor 22 being driven at the fastest speed. Likewise the conveyors 24, 25, 26 and 27 are driven at difierent speeds, the con veyor 24 being driven at the slowest speed and the conveyor 27 being driven at the fastest speed. Disposedad] acent the delivery end of the conveyor 27 isanother conveyor 29 onto which the bottles from the conveyor 27 are delivered. The conveyor 29 travels in the direction of the arrow shown in Fig. 5 and delivers the bottles onto another conveyor 30 which travels in the direction of the arrows shown in Fi ."5. 'The bottles on the conveyor 11 are delivered onto the dead plate 28 and the succeeding bottles force the forward bottles onto the conveyors 24, 25, 26 and .27 in succession. Disposed adjacent the delivery end of the conveyor 22 are a pair of conveyors 31 and 32 both of which travel in the dlrection of the arrows shown in Fig. 7 The guide rails 15 and 16 extend across the conveyors 31 and 32 at an angle thereto and serve to guide the bottles first onto the conveyor 31 and thence' onto the conveyor 32. The delivery end of the conveyor 30 is disposed adjacent one end of the conveyors 31 and 32 and the guide rails serve to direct the bottles from the conveyor 30 first onto the conveyor 31 and then onto the conve or 32.

It will thus be seen that all 0 the bottles from the paste'urizer are finally delivered onto the conveyor 32 in single file. Disposed adjacent the end of the conveyor 32 is another conveyor 33 onto which the bottles from the conveyor 32 are delivered. The conveyor 33 delivers the bottles into the labeling machine 34 in single file where the labeling operation is performed and after which the bottles are packed in suitable containers. Disposed adj acent the conveyor 31 and projecting thereover is a wheel 35 which is driven in any suitable manner and which projects over the conveyor 31. Disposed adjacent this wheel is a lever 36 which is pivotally secured at one end as shown at 37 and the opposite end of which is provided with a roller38. Thislivered from the capping machine in double file and thence separated, one file going to thelower conveyor of the pasteurizer and the other file goin to the upper conveyor of the pasteurizer. lhe conveyors 7 and 14 are driven at a rapid speed in comparison to'the movement of the conveyors 10 and 11 with the result that the conveyors 10 and 11 are kept substantially filled with bottles. The bottles are carried slowly through the pasteurizer by means of the conveyors 10 and 11 and are delivered onto the dead lates 23 and 28 from whence the succeeding ottles push the forward bottles onto the conveyors for removing the same. Due to the fact that the conveyors 19, 20, 21 and 22 are moving at diflerent speeds and due to the arrangement of the guide rails 8 and 9, it will be seen that the bottles are removed from the lower conveyor 10 in single file and delivered onto the conveyor 30. The bottles from the upper conveyor 11 are delivered onto the - conveyors 24, 25, 26 and 27 and the' arrangement of the guide rails 15 and 16 causes the bottles to be delivered onto the conveyor 32 in single file. The conveyor 30 also delivers onto the conveyor 32 which moves at a comparatively.

high speed and delivers onto'the conveyor 33 recesses which delivers the bottles into the labeling machine in single file.

The specific construction of the conveyors as Well as the specific driving mechanism may he modified without departing from the spirit of my invention and the details of these mechanisms form no part of this invention. Various other changes may be made in the details of my construction Without departing from the spirit of my invention and l therefore wish my invention to be limited only in accordance with the scope of the appended claims it will now be clear that ll have provided a system and apparatus of the character described which will accom lish the objects oi the invention as hereinbe' ore stated.

Having thus described my invention,-vvhat l claim is:-

1. it container handling system adapted to convey containers from a sealing machine through a heating apparatus to a labeling machine, said system including a plurality oil narrow conveyors moving at a relatively speed, a plurality of considerably Wider conveyors moving through said heating apparatus at a relatively slow speed and to which said first conveyors deliver whereby to reduce the speed of said containers moving through said heating apparatus, the said vvider conveyors being disposed in difi'erent planes, and a plurality of conveyors moving at a relatively high speed for removing the containers from said slow speed conveyors, said last mentioned conveyors being of substantially the same capacity as said slow speed conveyors and delivering to said labeling machine in single file.

2. A conveyor system for conveying containers from a capping machine through a heating apparatus and to a labeling machine, said system including a plurality of narrow conveyors moving at a relatively high speed and a lurality of conveyors arranged within the eating apparatus and disposed in difiterent planes and to which said high speed conveyors deliver, the conveyors in said heating apparatus being considerably wider than said first conveyors and moving at a relative- I ly low speed, a pluralit of narrow conveyors moving at a relatively igh speed for removing the containers from the heating apparathe and delivering the same to the labeling machine in single file, all of the above operations being accomplished in a continuous op eration.

in testimony whereof, I hereunto afix my signature.

CHARLES H. LOE'W.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US258259A US1852322A (en) | 1928-03-01 | 1928-03-01 | System and apparatus for handling bottles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US258259A US1852322A (en) | 1928-03-01 | 1928-03-01 | System and apparatus for handling bottles |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852322A true US1852322A (en) | 1932-04-05 |

Family

ID=22979774

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US258259A Expired - Lifetime US1852322A (en) | 1928-03-01 | 1928-03-01 | System and apparatus for handling bottles |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852322A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2466693A (en) * | 1944-06-03 | 1949-04-12 | Hartford Empire Co | Crate unloader |

| US2763359A (en) * | 1951-08-07 | 1956-09-18 | Allen S Rose | Arranging apparatus for cans and similar containers |

| US3256971A (en) * | 1960-03-28 | 1966-06-21 | Lillian F Arnett | Apparatus for regimenting articles |

| US3310151A (en) * | 1966-04-08 | 1967-03-21 | Meyer Geo J Mfg Co | Article combiner |

| US3465868A (en) * | 1967-09-18 | 1969-09-09 | Solar Eng & Equipment Co | Single file column forming apparatus |

| FR2064300A1 (en) * | 1969-10-13 | 1971-07-23 | Anchor Hocking Corp | |

| US4222813A (en) * | 1979-01-22 | 1980-09-16 | Dennison Manufacturing Company | Bottle transport system |

| US20060151292A1 (en) * | 2004-12-29 | 2006-07-13 | Fleetwood, Inc. | Accumulation table |

| US20070251806A1 (en) * | 2004-12-29 | 2007-11-01 | Fleetwood, Inc. | Accumulation table |

| US10259658B2 (en) | 2016-11-02 | 2019-04-16 | NJM Packaging Inc. | Conveyor with accumulation table |

-

1928

- 1928-03-01 US US258259A patent/US1852322A/en not_active Expired - Lifetime

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2466693A (en) * | 1944-06-03 | 1949-04-12 | Hartford Empire Co | Crate unloader |

| US2763359A (en) * | 1951-08-07 | 1956-09-18 | Allen S Rose | Arranging apparatus for cans and similar containers |

| US3256971A (en) * | 1960-03-28 | 1966-06-21 | Lillian F Arnett | Apparatus for regimenting articles |

| US3310151A (en) * | 1966-04-08 | 1967-03-21 | Meyer Geo J Mfg Co | Article combiner |

| US3465868A (en) * | 1967-09-18 | 1969-09-09 | Solar Eng & Equipment Co | Single file column forming apparatus |

| FR2064300A1 (en) * | 1969-10-13 | 1971-07-23 | Anchor Hocking Corp | |

| US3604551A (en) * | 1969-10-13 | 1971-09-14 | Anchor Hocking Corp | Article conveyor flow control and unscrambling apparatus |

| US4222813A (en) * | 1979-01-22 | 1980-09-16 | Dennison Manufacturing Company | Bottle transport system |

| US20060151292A1 (en) * | 2004-12-29 | 2006-07-13 | Fleetwood, Inc. | Accumulation table |

| US7252186B2 (en) | 2004-12-29 | 2007-08-07 | Garvey Corporation | Accumulation table |

| US20070251806A1 (en) * | 2004-12-29 | 2007-11-01 | Fleetwood, Inc. | Accumulation table |

| US7441645B2 (en) | 2004-12-29 | 2008-10-28 | Garvey Corporation | Accumulation table |

| US10259658B2 (en) | 2016-11-02 | 2019-04-16 | NJM Packaging Inc. | Conveyor with accumulation table |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2219827A (en) | Bottle packing machine | |

| US3342012A (en) | Egg packer | |

| US3872647A (en) | Carton loader | |

| US1852322A (en) | System and apparatus for handling bottles | |

| US2071859A (en) | Magnetic transfer device | |

| US3142371A (en) | Spotting device for bottles and the like | |

| US5147023A (en) | Method and apparatus for converting a multi-row container into, a single row stream | |

| US2501367A (en) | Device for drying traveling articles | |

| US2570198A (en) | Container transfer mechanism | |

| US2684799A (en) | Casing machine | |

| US2763359A (en) | Arranging apparatus for cans and similar containers | |

| US2264348A (en) | Can conveyer | |

| US2953234A (en) | Conveying and arranging system for containers | |

| US2840224A (en) | Conveying devices for accelerating and timing articles | |

| US1886896A (en) | Can positioning and feeding machine | |

| US3575713A (en) | Method and apparatus for cleaning containers | |

| US3425530A (en) | Machine for stowing bottles or flasks in an orderly position from a batch of bottles or flasks in bulk | |

| US2684147A (en) | Can unscrambling machine | |

| US2609109A (en) | Case unloader | |

| US4273236A (en) | Method and apparatus for handling bottles | |

| US3559563A (en) | Bottling apparatus and method | |

| US3069823A (en) | Case filling and stacking machine | |

| US1754047A (en) | Counting and grouping machine | |

| US1875423A (en) | T daniels | |

| US1445797A (en) | Best available cop |