US1663265A - Hook - Google Patents

Hook Download PDFInfo

- Publication number

- US1663265A US1663265A US85644A US8564426A US1663265A US 1663265 A US1663265 A US 1663265A US 85644 A US85644 A US 85644A US 8564426 A US8564426 A US 8564426A US 1663265 A US1663265 A US 1663265A

- Authority

- US

- United States

- Prior art keywords

- cable

- socket

- hook

- groove

- sockets

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000010276 construction Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- JHIVVAPYMSGYDF-UHFFFAOYSA-N cyclohexanone Chemical compound O=C1CCCCC1 JHIVVAPYMSGYDF-UHFFFAOYSA-N 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 210000005182 tip of the tongue Anatomy 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16G—BELTS, CABLES, OR ROPES, PREDOMINANTLY USED FOR DRIVING PURPOSES; CHAINS; FITTINGS PREDOMINANTLY USED THEREFOR

- F16G11/00—Means for fastening cables or ropes to one another or to other objects; Caps or sleeves for fixing on cables or ropes

- F16G11/14—Devices or coupling-pieces designed for easy formation of adjustable loops, e.g. choker hooks; Hooks or eyes with integral parts designed to facilitate quick attachment to cables or ropes at any point, e.g. by forming loops

Definitions

- the invention is a hook which is made in one solid casting and in which a cable or the like may be positively locked.

- the object of the invention is to provide a self locking logging hook that has no moving parts.

- Anothemobjects of the invention is to provide a logging hook in which the cable is locked and held by itself.

- a turther object :of the invention is to provide a self locking logging hook through which a cable may be threaded, twisted and positively held.

- a still further object of the invention is to provide a self locking log-ginghook which is of a simple and economical construction.

- I V p v With these ends in view the invention .embodies a hook having a socket at the upper end in which a button at the end of t'he cable may be held, and a slotted irregular member at the lower end through which the cable may be passed, and into which. it will be held.

- Figure 2- is a front View of the device.

- Figure 3' is aside view of'the device.

- Figure 1 is a plan view-of the device.

- Figure 5 is a view looking toward the lower end of the device.

- FIG. 6 is another front view of the device showing an alternate design.

- Figure 7 is a sile view of thevdesign shown in Figure 6..

- Figure 8 is a plan view of the device shown in Figure 6. 1

- Figure 10 is a front view showing another alternate design.

- Figure 11 is a side view of the design shown in Figure 10.

- Figure 12 is a View looking at the lower end of the device shown in Figure 10.

- numeral 1 indicates the socket at the upper end

- numeral 2 the grooved member at the lower end

- numeral 3 the groove between the two members.

- FIG 9 is a sectional plan on line 9-9

- the socket 1 inall designs is made with a cylindrical shaped hub 5 having a slot 4 in one side and which extends 1nto an opening

- a button is indicated by the numeral 8 which may be attachedto the end of a cable which is indicated by'the numeral 9, and be placed into the. socket 1 with the cable passingthrough theslot 4,

- the cable may then be drawn through” the opening 13 and pass that the button 8 n socket 1.

- the end of The groove 3 islformed as shown in Figures 2 and 3 wlth a curved web 15'having a reinforcing web 16 and in, the upper side of the groove is an overhanging shoulder as shown in Figures 337 and 11. It will-be noted: that the groove is large enough to hold the cable so that the cable may first be passed through itbetore the end of the cable is lockedin the device as shown in Figure 1.

- the lower 7 made in .the tormof ing 17 in the upper side and an opening 18 part of the 'device is a sphere with an open in one side both of which are of such a size that the button 8 may pass through them.

- the button laced straight into the opening may be 18 and then twisted through a horizontal plane through an angle of degrees with the cable passingthrough a slot 19. The button may then be twisted downward with the cable passingthrough a slot 20 until the button will pass through an opening 17.

- the cable will rest in a notch with a curved back 22, and a tongue 23 with projections 24 and 25 at the lower end and another projection 26 at the upper end.

- the tongue 23 is also provided with a projecting member 27 behind which the button 8 may rest when the cable is held in the lower part of the device.

- the cable may, be placed across the lower end of the device or between the lug 25 and the edgeiof the tongue 23, and then pas-sing the cable below the tip of the tongue 23 and Cover the lug 26, at the same time permitting it-to pass over the lug 25 andinto the recess between the lugs 24 and 25.

- the button at the upper end of the cable v may then be placed into the socket 1 as hereinbet'ore described.

- a cylindrical shaped socket with one end'open and the other closed, said socket having a slot in one side and extendinginto the center of the closed end.

- another member in combination with the said socket,

- said latter member'having grooves arranged therein and said grooves being so arranged that a cable may be placed in them, twisted and then substantially straightened sothat it may also pass through the slot in the socket, said socket and member having a transverse eye between them.

- a cylindrical shaped socket with one end open and the other closed, said I said latter member having grooves arranged therein and said grooves being so arranged that a cable may be placed in them. twisted and thensubstantially straightened so that it may also pass through the slot inthe socket, said socket and member having a transverse eye between them, and said lower member having projections co-operating with the said grooves to hold the cablein the grooves.

- a choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight groove in one side and the other having a distorted groove requiring the cable to be doubled upon itself or to pass through an I 8 formation when being placed therein.

- choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight V groove in one side and the other having a vwinding aperture in the side thereof.

- a choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight groove in one sideand the other having an S shaped groove in the side thereof.

- a choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight groove in one side and the/other having an S shaped groove in the side thereof, and an aperture adaptable to receive the ferrule on thecable at the upper end of'the said 8 shaped groove.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Installation Of Indoor Wiring (AREA)

Description

March 20, 1928.

H. R. BENSON HOOK 2 Sheets-Sheet 1 Filegi Feb. 5. 1926 anon Mo's Illll. ll-lINl-ll Match 20, 1928. 1,663,265

H. R. BENSQN HOOK Filed Feb. 5, 19 26 2 Sheets-Sheet 2 flan/75560500 attain Fatented Mar. 20, 1928.;

"Hook.

an a 1 Application filed. February 3, 1926. Serial No. 85,644.

The invention is a hook which is made in one solid casting and in which a cable or the like may be positively locked.

The object of the invention is to provide a self locking logging hook that has no moving parts. p I

Anothemobjects of the invention is to provide a logging hook in which the cable is locked and held by itself.

0 A turther object :of the invention is to provide a self locking logging hook through which a cable may be threaded, twisted and positively held. v i

And a still further object of the invention is to provide a self locking log-ginghook which is of a simple and economical construction. I V p v With these ends in view the invention .embodies a hook having a socket at the upper end in which a button at the end of t'he cable may be held, and a slotted irregular member at the lower end through which the cable may be passed, and into which. it will be held.

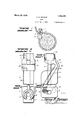

Other features and advantages of the in ventionwill appear from the following description taken connectionwtih the drawings, wherein r Figure 1 is a View showing the device as it may be used for locking the end or a cable around a log. 7

Figure 2- is a front View of the device. Figure 3' is aside view of'the device. Figure 1 is a plan view-of the device. Figure 5 is a view looking toward the lower end of the device. V

Figure 6 is another front view of the device showing an alternate design. V

Figure 7 is a sile view of thevdesign shown in Figure 6.. I

Figure 8 is a plan view of the device shown in Figure 6. 1

of Figure 7. i Figure 10 is a front view showing another alternate design.

Figure 11 is a side view of the design shown in Figure 10.

Figure 12 is a View looking at the lower end of the device shown in Figure 10.

Tnthe drawings the device is shown as it would be made wherein numeral 1 indicates the socket at the upper end, numeral 2 the grooved member at the lower end, and numeral 3 the groove between the two members.

Figure 9 is a sectional plan on line 9-9 The socket 1 inall designs is made with a cylindrical shaped hub 5 having a slot 4 in one side and which extends 1nto an opening It will be noted that a button is indicated by the numeral 8 which may be attachedto the end of a cable which is indicated by'the numeral 9, and be placed into the. socket 1 with the cable passingthrough theslot 4,

as shown in Figure 3p cable in the opening. It will be noted that the cable may'first be passed through the diagonal slot 10 andthen twisted longitud'ia nally through the openings 11 and12 to the straight position so that it will pass directly through the opening 13. It will be noted that as it passes into the upper end of the opening 18 it will be bent over the projection 14 which will lock it in place.

the cable may then be drawn through" the opening 13 and pass that the button 8 n socket 1..

through the slot hso ay beplaced into the '6 in the center of the base 7 of the socket. .60

The end of The groove 3islformed as shown in Figures 2 and 3 wlth a curved web 15'having a reinforcing web 16 and in, the upper side of the groove is an overhanging shoulder as shown in Figures 337 and 11. It will-be noted: that the groove is large enough to hold the cable so that the cable may first be passed through itbetore the end of the cable is lockedin the device as shown in Figure 1.

In the design shown in Figures '6 to 9 inclusive. the lower 7 made in .the tormof ing 17 in the upper side and an opening 18 part of the 'device is a sphere with an open in one side both of which are of such a size that the button 8 may pass through them.

It will be observed that the button laced straight into the opening may be 18 and then twisted through a horizontal plane through an angle of degrees with the cable passingthrough a slot 19. The button may then be twisted downward with the cable passingthrough a slot 20 until the button will pass through an opening 17. The

cable may then be dr member so that the awn through the lower button may be placed into the socket as hereinbefore described.

In this position the cable will rest in a notch with a curved back 22, and a tongue 23 with projections 24 and 25 at the lower end and another projection 26 at the upper end. The tongue 23 is also provided with a projecting member 27 behind which the button 8 may rest when the cable is held in the lower part of the device.

It will be noted that in this design the cable may, be placed across the lower end of the device or between the lug 25 and the edgeiof the tongue 23, and then pas-sing the cable below the tip of the tongue 23 and Cover the lug 26, at the same time permitting it-to pass over the lug 25 andinto the recess between the lugs 24 and 25. The button at the upper end of the cable vmay then be placed into the socket 1 as hereinbet'ore described.

7 It is also understood that other changes may be made in the construction without departing from the spirit of the invention. One of which changes may be in the use of other arrangements of the slots or projections in the lower portion of the device, an-

other may be in the design or arrangement of the socket, and still another may be in the design or arrangement of the groove.

Having thus fully described the invention, what I claim as new and desire to secure by Letters Patent, is 2-- 1. In a hook, a cylindrical shaped socket with one end open and the other closed. said socket having a slot in one side and extending into the center of the closed end. another member in combination with the said socket. said latter member having grooves arranged therein and said grooves being so arranged that a cable may be placed in them, twisted and then substantially straightened so that it may also pass through the slot in the socket.

2. In a hook, a cylindrical shaped socket with one end'open and the other closed, said socket having a slot in one side and extendinginto the center of the closed end. another member in combination with the said socket,

, said latter member'having grooves arranged therein and said grooves being so arranged that a cable may be placed in them, twisted and then substantially straightened sothat it may also pass through the slot in the socket, said socket and member having a transverse eye between them. i

3. In a hook, a cylindrical shaped socket with one end open and the other closed, said I said latter member having grooves arranged therein and said grooves being so arranged that a cable may be placed in them. twisted and thensubstantially straightened so that it may also pass through the slot inthe socket, said socket and member having a transverse eye between them, and said lower member having projections co-operating with the said grooves to hold the cablein the grooves.

4:. In a device of the class described, a choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight groove in one side and the other having a distorted groove requiring the cable to be doubled upon itself or to pass through an I 8 formation when being placed therein.

'5. In a device. of the class described, a-

choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight V groove in one side and the other having a vwinding aperture in the side thereof.

6. In a device of the class described, a choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight groove in one sideand the other having an S shaped groove in the side thereof.

7. In a device of the class described, a choker hook having sockets in axial alignment with a transverse groove between the sockets, one of said sockets having a straight groove in one side and the/other having an S shaped groove in the side thereof, and an aperture adaptable to receive the ferrule on thecable at the upper end of'the said 8 shaped groove.

In testimony whereofhe afiixes' his signa-

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US85644A US1663265A (en) | 1926-02-03 | 1926-02-03 | Hook |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US85644A US1663265A (en) | 1926-02-03 | 1926-02-03 | Hook |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1663265A true US1663265A (en) | 1928-03-20 |

Family

ID=22192997

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US85644A Expired - Lifetime US1663265A (en) | 1926-02-03 | 1926-02-03 | Hook |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1663265A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4107825A (en) * | 1974-08-05 | 1978-08-22 | Brawand Franklin M | Tag line and butt hook constructions |

-

1926

- 1926-02-03 US US85644A patent/US1663265A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4107825A (en) * | 1974-08-05 | 1978-08-22 | Brawand Franklin M | Tag line and butt hook constructions |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1426537A (en) | Cordage hitching device | |

| US3353421A (en) | Steel link chain | |

| US2085333A (en) | Rope socket | |

| US2151664A (en) | Rope fastener | |

| US2174192A (en) | Wire rope fitting | |

| US1685489A (en) | Lace for footwear | |

| US1663265A (en) | Hook | |

| US1406560A (en) | Sheave block | |

| US1579719A (en) | Hose clamp | |

| US1567719A (en) | Butt-line-rigging plate | |

| US1672419A (en) | Corner joint | |

| US1976089A (en) | Lock | |

| US2240510A (en) | Logging choker and fitting therefor | |

| US2375719A (en) | Shackle | |

| US1118915A (en) | Adjusting member for car-brakes. | |

| US1601270A (en) | Auto tow hook | |

| US1493285A (en) | Hook | |

| US1808636A (en) | Cord fastener | |

| US1470481A (en) | George popps | |

| US1782307A (en) | Crate attachment | |

| US1560638A (en) | Combined cotter pin and washer | |

| US1550784A (en) | Safety lock | |

| US1688293A (en) | Double-swivel hook | |

| US2700200A (en) | Deadend and yoke therefor | |

| US1461498A (en) | Rope hitch |