US166321A - Improvement in knitting-machines - Google Patents

Improvement in knitting-machines Download PDFInfo

- Publication number

- US166321A US166321A US166321DA US166321A US 166321 A US166321 A US 166321A US 166321D A US166321D A US 166321DA US 166321 A US166321 A US 166321A

- Authority

- US

- United States

- Prior art keywords

- screw

- burr

- knitting

- tompkins

- machines

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004744 fabric Substances 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B13/00—Circular knitting machines with fixed spring or bearded needles, e.g. loop-wheel machines

Definitions

- WITN ESSES WITN ESSES.

- This invention pertains to that portion of a rotary knittingmachine that supports the burrs; and,as they require the greatest nicety of adjustment relatively to the needles, the object of this invention is to provide an efficient means for such a purpose, and in the simplest possible manner; and the invention consists in a double-threaded screw with right and left hand threads, in combination with the burrstems and the bracket that supports the burr or burrs, as the case may be, said screw being mounted so that it may be regulated from under the cylinder without opening the cloth, and having no lost motion in its threads, as will hereafter appear, and also by a reference to the accompanying drawings, in which Figure 1 represents a side elevation of the burr-supports and the burr-adjuster, and Fig. 2 a plan or top view of the same.

- the bracket for supporting the burrs mounted concentrically with the cylinders, and it is held in proper position upon a central rod by a set-screw, as at B.

- the burr-support Upon the outer arc of said bracket A is mounted the burr-support, as at Oone or more, as the case may be.

- Said support or supports in the present case, consist of a hollow axis for the burrdisk to revolve upon, and said axis is mounted on a portion of a tube, as at H, which serves as an oil-chamber, from which oil is drawn by capillary attraction to the burr-bearing, as in the Maxwell patent.

- a projection, as at E through which is tapped a nut to receive the adjusting-screw F, which works through a screwnut in the bracket A.

- the threads on said adjusting-screw are cut right and left, and the diameter of one thread may be smaller than the other, so as to readily pass through the first nut, if desired; and said screw extends down sufficiently far below the bracket A to be turned by a key below the cylinder without opening the web, as is now often done to make such adjustments.

- the studD is held in a fixed position by a set-screw, as at G.

- the adjustment of the burr may thereby be easily efl'ected, and it is then held in position by the set-screw K.

- the angular, radial, and vertical position of the burr may be readily secured before the cloth is put on the needles, and when, as generally is the case, a nicety of adjustment is required, (say to fractional hundredths of an inch,) it maybe accomplished by the use of the adjusting-screw F.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Sewing Machines And Sewing (AREA)

- Corsets Or Brassieres (AREA)

Description

|. a A. TOMPKINS. Knitting-Machine.

No. 166,321. PatentedAug.3,1875.

WITN ESSES.

INVENTORS ".PETERS. PHVUWUTHOGRAPHER, WASHINGTON, 01C.

UNITED STATES PATENT OFFICE.

lRA TOMPKINS AND ALBERT TOMPKINS, OF TROY, NEW YORK.

IMPROVEMENT IN KNITTING-MACHIN ES.

Specification forming part of Letters Patent No. 166,321, dated August 3, 1875; application filed March 25, 1875.

To all whom it may concern:

Be it known that we, IRA ToMPKINs and ALBERT ToMPKINs, of the city of Troy, county of Rensselaer and State of New York. have invented certain Improvements in Knitting- Machines, of which the following is a specification:

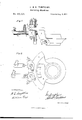

This invention pertains to that portion of a rotary knittingmachine that supports the burrs; and,as they require the greatest nicety of adjustment relatively to the needles, the object of this invention is to provide an efficient means for such a purpose, and in the simplest possible manner; and the invention consists in a double-threaded screw with right and left hand threads, in combination with the burrstems and the bracket that supports the burr or burrs, as the case may be, said screw being mounted so that it may be regulated from under the cylinder without opening the cloth, and having no lost motion in its threads, as will hereafter appear, and also by a reference to the accompanying drawings, in which Figure 1 represents a side elevation of the burr-supports and the burr-adjuster, and Fig. 2 a plan or top view of the same.

At A is seen the bracket for supporting the burrs, mounted concentrically with the cylinders, and it is held in proper position upon a central rod by a set-screw, as at B. Upon the outer arc of said bracket A is mounted the burr-support, as at Oone or more, as the case may be. Said support or supports, in the present case, consist of a hollow axis for the burrdisk to revolve upon, and said axis is mounted on a portion of a tube, as at H, which serves as an oil-chamber, from which oil is drawn by capillary attraction to the burr-bearing, as in the Maxwell patent. This, however, is immaterial, as the burr-axis may rest in the oilchamber, as in the Allardice patent, provided in either case they are attached to an adjustable stud, as shown at D, which works through a hole in the outer arc of the bracket A. Up-

on said stud D is formed a projection, as at E, through which is tapped a nut to receive the adjusting-screw F, which works through a screwnut in the bracket A. The threads on said adjusting-screw are cut right and left, and the diameter of one thread may be smaller than the other, so as to readily pass through the first nut, if desired; and said screw extends down sufficiently far below the bracket A to be turned by a key below the cylinder without opening the web, as is now often done to make such adjustments. After the adjustment is made the studD is held in a fixed position by a set-screw, as at G.

If the shank of the burr-support, as at H, is made round where it passes through the stud D, the adjustment of the burr, as its angle or inclined position, may thereby be easily efl'ected, and it is then held in position by the set-screw K.

By the use of such a combination of parts the angular, radial, and vertical position of the burr may be readily secured before the cloth is put on the needles, and when, as generally is the case, a nicety of adjustment is required, (say to fractional hundredths of an inch,) it maybe accomplished by the use of the adjusting-screw F.

We are aware that a screw, having a right and left screw-thread, is not of itself new, but such is not claimed by us.

We therefore claim The combination, with the bracket A, the burr-support (l, and stud D, having the pro jection E, provided with the nut, of the adj usting-screw P, provided with the right and left screw-threads and the set-screw G, the whole constructed and arranged to operate as herein shown and described.

IRA TOMPKINS. ALBERT TOMPKINS. Witnesses:

W. O. TOMPKINS, WILLIAM 00x.

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US166321A true US166321A (en) | 1875-08-03 |

Family

ID=2235730

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US166321D Expired - Lifetime US166321A (en) | Improvement in knitting-machines |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US166321A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030060011A1 (en) * | 2001-09-25 | 2003-03-27 | Seiko Epson Corporation | Semiconductor device and method of manufacturing the same |

| US20040129972A1 (en) * | 2002-10-30 | 2004-07-08 | Seiko Epson Corporation | Semiconductor device and method of manufacturing the same |

-

0

- US US166321D patent/US166321A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030060011A1 (en) * | 2001-09-25 | 2003-03-27 | Seiko Epson Corporation | Semiconductor device and method of manufacturing the same |

| US20040129972A1 (en) * | 2002-10-30 | 2004-07-08 | Seiko Epson Corporation | Semiconductor device and method of manufacturing the same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1132554A (en) | Device for dimming the headlights of automobiles. | |

| US166321A (en) | Improvement in knitting-machines | |

| US1164608A (en) | Crutch and the like. | |

| US163738A (en) | Improvement in cylinder-cams | |

| US853394A (en) | Bur-wheel support for knitting-machines. | |

| US752666A (en) | Eobeet w | |

| US1451744A (en) | Spindle | |

| US1446926A (en) | Micrometer | |

| US170122A (en) | Improvement in compensation-journals for sewing-machine balance-wheels | |

| US818082A (en) | Spindle. | |

| US324639A (en) | Manttfactubebs | |

| US1075860A (en) | Sewing-machine shuttle. | |

| US172597A (en) | Improvement in knitting-burrs | |

| US415336A (en) | Spindle and bearing therefor | |

| US510998A (en) | Wickandfeederick j | |

| US169262A (en) | Improvement in ratchet-drills | |

| US709831A (en) | Bur-wheel support for knitting-machines. | |

| US916134A (en) | Reamer. | |

| US1269650A (en) | Needle-lever support for sewing-machines. | |

| US1209972A (en) | Sewing-machine slack-thread controller. | |

| US784414A (en) | Spindle. | |

| US248062A (en) | Spindle for spinning-machines | |

| US109414A (en) | Improvement in shuttles for sewing-machines | |

| US235238A (en) | Head for circular-knitting machines | |

| US333822A (en) | Sleeve-whirl spindle for spinning-frames |