US1285280A - Grader. - Google Patents

Grader. Download PDFInfo

- Publication number

- US1285280A US1285280A US21180718A US21180718A US1285280A US 1285280 A US1285280 A US 1285280A US 21180718 A US21180718 A US 21180718A US 21180718 A US21180718 A US 21180718A US 1285280 A US1285280 A US 1285280A

- Authority

- US

- United States

- Prior art keywords

- drum

- grader

- grading

- holes

- openings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 235000002595 Solanum tuberosum Nutrition 0.000 description 7

- 244000061456 Solanum tuberosum Species 0.000 description 7

- 235000012015 potatoes Nutrition 0.000 description 5

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 235000013399 edible fruits Nutrition 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

- B07B1/4609—Constructional details of screens in general; Cleaning or heating of screens constructional details of screening surfaces or meshes

- B07B1/4636—Regulation of screen apertures

Definitions

- This invention relates to improvements in graders.

- My improved grader is especially designed by me for grading potatoes although it is advantageous for use in grading fruit.

- the main obj ectsof this invention are:

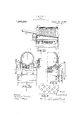

- Figure I is a sideeleva-tion of a structure embodying the features of my invention.

- Fig. II is an elevation of the opposite side from that shown in Fig. I.

- Fig. III is a vertical longitudinal section on a line corresponding to line 3-3 of Fig. IV.

- Fig. IV is a front view with the feed chute omitted.

- Fig. V is a detail transverse section on a line corresponding to line 55 f Fig. I.

- Fig. VI is a rear view. 7

- Fig. VII is a detail transverse section on a line corresponding to line 77 of Fig. I.

- Fig. VIII is an enlarged detailview of the grader showing one adjustment of the grading openings.

- Fig. X is an enlarged detail view showing still another adjustment of the grading openings.

- Fig. XII is an enlarged detail section on a linev corresponding to line 1212 of Fig. II.

- the grading drum 2 consists of an outer member 13 and an inner member" 14, the inner ,member. being. arranged within the outer for rotative and longitudinal'"adjustment, being secured in its adj usted. position by the set screw 15.

- the inner and outer drum members have rows of holes 16 and 17 therein preferably arranged with the holes of adjacent rows alternated.

- the holes of the members areof the same size and adapted to be brought into register or adjusted to bring the holes of the inner member partially out of register with those of the outer, thereby decreasing the size of the grading openings.

- the screen in the structure illustrated consisting of a series of bars 18 arranged in an inclined position below the drum, a defiector 19 being positioned above the screen to guide the potatoes discharged at one side toward the screen so that they will travel over the same and aiiord an opportunity for separation from the dirt.

- a teed chute 23 is arranged at the front so as to discharge into the front, end of the drum.

- the potatoes to be graded are poured or shoveled into the feed chute from which they roll into the drum and as the drum is rotated the smaller-potatoes drop through the grading openings, the larger ones being discharged at the rear end of the drum 'i

- My improved grader is of large capacity and the potatoes arenot bruised or: injured inpassing therethrough.

- a potato grader in a potato grader; the combination with a frame, of a toraminated drum comprising inner and outer members having registering holes therein, the inner member being rotatively and longitudinally adjustable within the outer member to regulate the size of the grading openings, and means tor rotatively supporting said drum.

- a potato grader the combination with a frame, of a toraminated drum com prising an outer member and a plurality of inner members, said members having registering holes, the inner members being supported for independent rotative longitudinal adjustment within the outer member to facilitate the regulating of the size or" the gradingopenings, and means for rotatively supporting said drum.

Landscapes

- Seasonings (AREA)

Description

J. N. MCCARTY.

HEADER,

APPLICATION FILED IAN.14. 1916.

1 ,285,280. Patented Nov. 19, 1918.

3 SHEETS-SHEET I- lil Ii Ill-Ill awe/MM haves/107% wi fweooe ,7

J. N. MCCARTY.

GRADER,

APPLICATION FILED JAN. 14. 1918.

1,285,280, Patented Nov. 19, 1918.

a SHEETS-SHEET 2 AW: 1* m. F- amea 07/ dbfomsuf J. N. McCARTY.

GRADER.

APPLICATION FILED JAN.I4.1918.

Patented Nov. 19, 1918.

3 SHEETS-SHEET 3.

S A S JAMES n. MeoAnrY, on PAW' Pnmuurciirenri. I

ennnnn. 7

Specification of Letters Patent. Patented NOV. 19, 1918.

Application filed January 14, 1918. Serial No. 211,807.

To all whom it may concern:

Be it known that I, JAMES-N. -N[OOARTY, a citizen of the United States, residing. at Paw Paw, in the county of Van Buren and State'of Michigan, have inventedc'ertain new and useful Improvements in Graders,

of which the following is a specification.

This invention relates to improvements in graders.

My improved grader, is especially designed by me for grading potatoes although it is advantageous for use in grading fruit.

The main obj ectsof this invention are:

. First to provide an improved grader-in which the size of the be varied; I

Second, to provide an improved grader which is of large capacity. I I

Third, to provide an improved; grader which does not become clogged. T 1

Further objects, and objects relating to structural details, will definitely appear from the detailed 'descriptionto, follow.

I accomplish the objectsof my invention by the devices and means described in-the following specification. The invention is clearly defined and'pointed out in the claims.

A structure which is a preferred embodiment of my invention is clearly illustrated in the accompanying d-rawing;-forming a part of this specification, in which:

Figure I is a sideeleva-tion of a structure embodying the features of my invention.

Fig. II is an elevation of the opposite side from that shown in Fig. I.

Fig. III is a vertical longitudinal section on a line corresponding to line 3-3 of Fig. IV.

Fig. IV is a front view with the feed chute omitted.

Fig. V is a detail transverse section on a line corresponding to line 55 f Fig. I.

Fig. VI is a rear view. 7

Fig. VII is a detail transverse section on a line corresponding to line 77 of Fig. I.

Fig. VIII is an enlarged detailview of the grader showing one adjustment of the grading openings.

Fig. IX is an enlarged detail view showing another adjustment of the grader.

Fig. X is an enlarged detail view showing still another adjustment of the grading openings.

Fig. XI is a detail view of a modified construction showing means for providing grading openings may grading openings of different shape and size in the same grading drum.

.Fig. XII is an enlarged detail section on a linev corresponding to line 1212 of Fig. II.

In the drawing, similar reference characters refer to similar parts throughout the several-views, and the sectional views are taken looking, in the direction. of the little arrows at the ends of thesection lines.

Referring to the drawing, the frame 1 is of suitable.structure to Support'the grading drum 2 in an elevated position. The grading drum 2 iscarried by pairs of rollers, 3, 3 and 4, 4 positioned so that the drum is supported in a rearwardly' inclined position; -The drum isprovided with rings or collars .5-resting on the rollers and at its front end. with a wormgear 6. The'driving shaft 7 is disposed transversely below the drum and provided with a worm 8 meshing with the gearfi. At one end the driving shaft is provided with a balance wheel 9 and at the other with a pinion 10 meshing with the gear 11 of the gearingzl2. r

The grading drum 2 consists of an outer member 13 and an inner member" 14, the inner ,member. being. arranged within the outer for rotative and longitudinal'"adjustment, being secured in its adj usted. position by the set screw 15. The inner and outer drum members have rows of holes 16 and 17 therein preferably arranged with the holes of adjacent rows alternated. The holes of the members areof the same size and adapted to be brought into register or adjusted to bring the holes of the inner member partially out of register with those of the outer, thereby decreasing the size of the grading openings. By arranging the inner member so that it may be adjusted both longitudinally and rotatively, and the shape as well as the size of the openings may be considerably varied.

In Fig. VII the inner member is shown adjusted longitudinally so that the oval holes are provided, the diameter being circumferential of the drum. In Fig. IX the inner member is adjusted rotatively so that the greatest diameter of the holes is longitudinally of the drum. In Fig. X the inner drum is adjusted both rotatively and longitudinally so that the greatest diameter of the holes is diagonally of the cylinder.

In the modification shown in Fig. XI

the screen in the structure illustrated consisting of a series of bars 18 arranged in an inclined position below the drum, a defiector 19 being positioned above the screen to guide the potatoes discharged at one side toward the screen so that they will travel over the same and aiiord an opportunity for separation from the dirt.

To tree the grading openings from potatoes which become wedged therein 1 provide a plurality of tappets consisting of heads 20 and spring supports 21 mounted on. the frame so that the heads ride on the drum and pass into and out of the grading holes as the drum rotates. The heads 20 are pret erably formed of rubber, the spring supports 21 being rod springs having coils 22 formed therein.

A teed chute 23 is arranged at the front so as to discharge into the front, end of the drum. The potatoes to be graded are poured or shoveled into the feed chute from which they roll into the drum and as the drum is rotated the smaller-potatoes drop through the grading openings, the larger ones being discharged at the rear end of the drum 'i My improved grader is of large capacity and the potatoes arenot bruised or: injured inpassing therethrough.

I have illustrated and described my improvements as Lhave embodied the same. 1 have not attempted to illustrate or describe certain adaptations or modifications of which my invention is capable as I believe the disclosure made will enable those skilled in the art to which my invention relates to embody or adapt the same as may be required. 7

Having thus described may invention, what I claim as new and desire to secure by Letters Patent is:

l. in a potato grader; the combination with a frame, of a toraminated drum comprising inner and outer members having registering holes therein, the inner member being rotatively and longitudinally adjustable within the outer member to regulate the size of the grading openings, and means tor rotatively supporting said drum.

2. In a potato grader, the combination with a frame, of a toraminated drum com prising an outer member and a plurality of inner members, said members having registering holes, the inner members being supported for independent rotative longitudinal adjustment within the outer member to facilitate the regulating of the size or" the gradingopenings, and means for rotatively supporting said drum.

in witness whereof I have hereunto set my hand and seal in the presence of two witnesses.

AliiES N; MCCARTY.

iVitnesses J. B. WARNER, ESTHER S'rnvmvson.

this patent may be obtained for five cents each, by addressing the Go'mmissioner or" Eatents,

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US21180718A US1285280A (en) | 1918-01-14 | 1918-01-14 | Grader. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US21180718A US1285280A (en) | 1918-01-14 | 1918-01-14 | Grader. |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1285280A true US1285280A (en) | 1918-11-19 |

Family

ID=3352855

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US21180718A Expired - Lifetime US1285280A (en) | 1918-01-14 | 1918-01-14 | Grader. |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1285280A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2465632A (en) * | 1947-04-08 | 1949-03-29 | Paul P Burns | Tumble barrel |

| US2520718A (en) * | 1946-07-12 | 1950-08-29 | David R Mckinley | Material spreading apparatus |

-

1918

- 1918-01-14 US US21180718A patent/US1285280A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2520718A (en) * | 1946-07-12 | 1950-08-29 | David R Mckinley | Material spreading apparatus |

| US2465632A (en) * | 1947-04-08 | 1949-03-29 | Paul P Burns | Tumble barrel |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1285280A (en) | Grader. | |

| US3820618A (en) | Axle adjusting mechanism for agricultural machines | |

| US2464305A (en) | Root crop digger | |

| US785748A (en) | Fruit-grader. | |

| US1668157A (en) | Beet harvester | |

| DE723657C (en) | Potato harvester with two sieve drums arranged behind the share | |

| US2161705A (en) | Agricultural machine | |

| DE297352C (en) | ||

| US664811A (en) | Screen or riddle for separators. | |

| DE442051C (en) | Pea sorting machine with several sieve cylinders arranged one inside the other | |

| US2169527A (en) | Seed harvester | |

| US1319925A (en) | Punooiurn | |

| AT86726B (en) | Shaking floor for threshing machines. | |

| US1334761A (en) | Grain-cleaning sieve | |

| DE729869C (en) | Cylinder sieve for grains | |

| US95242A (en) | Improvement in potato-diggers | |

| US1098079A (en) | Wheat-grader for fanning-mills. | |

| DE244932C (en) | ||

| DE6609C (en) | Picking and sorting machine for grain | |

| DE533073C (en) | Seed machine with cell wheels swinging back and forth around its axis | |

| US5410A (en) | Winnowina-machine | |

| US127788A (en) | Improvement in grain-separators | |

| US1814992A (en) | Potato digger conveyer shaker | |

| AT130367B (en) | Device for sieving and conveying bulk goods. | |

| DE524295C (en) | Potato harvester with shaftless sieve drum rotating behind the share |