JP6730975B2 - Electric connector and method of locking connection terminals in the electric connector - Google Patents

Electric connector and method of locking connection terminals in the electric connector Download PDFInfo

- Publication number

- JP6730975B2 JP6730975B2 JP2017226899A JP2017226899A JP6730975B2 JP 6730975 B2 JP6730975 B2 JP 6730975B2 JP 2017226899 A JP2017226899 A JP 2017226899A JP 2017226899 A JP2017226899 A JP 2017226899A JP 6730975 B2 JP6730975 B2 JP 6730975B2

- Authority

- JP

- Japan

- Prior art keywords

- terminal

- locking

- locking plate

- holder

- housing body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 12

- 238000003780 insertion Methods 0.000 claims description 90

- 230000037431 insertion Effects 0.000 claims description 90

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 8

- 230000007246 mechanism Effects 0.000 claims description 5

- 238000003825 pressing Methods 0.000 claims description 3

- 239000000758 substrate Substances 0.000 claims description 3

- 238000012790 confirmation Methods 0.000 claims 1

- 230000001105 regulatory effect Effects 0.000 claims 1

- 238000005192 partition Methods 0.000 description 13

- 230000013011 mating Effects 0.000 description 9

- 238000002788 crimping Methods 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 238000007789 sealing Methods 0.000 description 4

- 239000003566 sealing material Substances 0.000 description 3

- 210000000078 claw Anatomy 0.000 description 2

- 239000003381 stabilizer Substances 0.000 description 2

- 238000004078 waterproofing Methods 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 229920002379 silicone rubber Polymers 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 239000005061 synthetic rubber Substances 0.000 description 1

Images

Landscapes

- Connector Housings Or Holding Contact Members (AREA)

Description

本発明は、例えば自動車の電気回路に用いられ、小さな接続端子でも確実にハウジング内に保持し得る電気コネクタ及び該電気コネクタ内の接続端子の係止方法に関するものである。 The present invention relates to an electric connector that is used in an electric circuit of an automobile, for example, and can securely hold even a small connection terminal in a housing, and a method of locking the connection terminal in the electric connector.

従来から、電気コネクタのハウジングに内蔵した接続端子は、ハーネス加工時や自動車の車体への取付時に外部に引き出された電線に強い力が加わると、接続端子がハウジングから引き抜かれる所謂後抜けが生じ易い。この接続端子の後抜けは、電気コネクタとしての機能を損ねるので、ハウジング内に設けた係止機構により防止しており、一般にはハウジング内に設けた可撓性を有するケースランスによって係止している。 Conventionally, the connection terminal built in the housing of the electrical connector causes a so-called rear disconnection in which the connection terminal is pulled out from the housing when a strong force is applied to the electric wire pulled out during the processing of the harness or the attachment to the vehicle body of the automobile. easy. Since the pulling-out of this connection terminal impairs the function as an electric connector, it is prevented by a locking mechanism provided in the housing. Generally, it is locked by a flexible case lance provided in the housing. There is.

しかし、近年のように接続端子が小型化するにつれて、ハウジングも小型化されてケースランスも小型とならざるを得ず、ケースランスだけでは十分な係止力が得られないことが多い。 However, as the connection terminals have been downsized as in recent years, the housing has to be downsized and the case lance has to be downsized, and in many cases, sufficient locking force cannot be obtained only with the case lance.

このことから、特許文献1のように、ハウジングの内部でケースランスにより接続端子を係止すると共に、ハウジングの側方から幅広のサイドホルダを挿入して、ハウジング内で接続端子を係止する電気コネクタが知られている。

From this, as in

この電気コネクタでは、サイドホルダはその主体部がハウジングの側部からハウジング内に挿入されており、ハウジング内で接続端子を係止する場合に、接続端子に付設された係止片を挿入したサイドホルダにより係止している。 In this electrical connector, the main body of the side holder is inserted into the housing from the side of the housing, and when locking the connection terminal in the housing, the side holder has the locking piece attached to the connection terminal inserted. It is locked by the holder.

しかし、この特許文献1の電気コネクタでは、サイドホルダ挿入用の大きな孔部を、ハウジングの側部に形成しなければならず、この孔部からハウジング内に浸水が生じ易く、接続端子同士の接続時の防水性を目的とした電気コネクタには不適である。

However, in the electrical connector of

また、サイドホルダの端部は常時、ハウジングの外面に露出しているので、他部材との不時の接触により、サイドホルダが抜け出す虞れがある。 Further, since the end portion of the side holder is always exposed to the outer surface of the housing, there is a possibility that the side holder may come off due to accidental contact with other members.

本発明の目的は、上述の課題を解消し、ハウジング内に内装した係止板部を操作部材によってハウジング内で移動することにより、内装した接続端子を確実に係止して、接続端子の後方への抜け出しを防止する電気コネクタ及び該電気コネクタ内の接続端子の係止方法を提供することにある。 An object of the present invention is to solve the above-mentioned problems and to reliably lock the internal connection terminal by moving the locking plate part installed inside the housing by the operation member within the housing, and to the rear of the connection terminal. An object of the present invention is to provide an electric connector that prevents the electric connector from being pulled out and a method of locking a connection terminal in the electric connector.

上記目的を達成するための本発明に係る電気コネクタは、ハウジング本体と、該ハウジング本体の後方から該ハウジング本体内に挿入する端子ホルダと、該端子ホルダの前端に連結され、前記端子ホルダの挿入する方向に直交する横方向に移動自在の係止板部と、前記端子ホルダと共に前記ハウジング本体内に挿入した前記係止板部を、前記横方向に移動させる操作部材とを備え、係止片を有する複数個の接続端子を内装可能とする電気コネクタであって、前記ハウジング本体には、後部に前記端子ホルダを保持するホルダ保持部が設けられていると共に、前部に前記接続端子の接続部を保持する端子保持部が設けられ、前記端子ホルダの後部には、前記接続端子をそれぞれ挿入する複数個の開孔が設けられ、前記係止板部には、基板部に前記接続端子の係止片を通過させる挿通溝が形成され、前記基板部の後部に前記端子ホルダに対して、前記横方向に移動可能に連結する挿込板が設けられ、前記基板部の一部に前記操作部材による前記横方向に移動のための被操作端が設けられ、前記操作部材には、前記ハウジング本体の端子保持部に設けられた押込口から押し込んで前記係止板部の被操作端に作用する操作部が設けられ、前記操作部材の操作部により、前記端子保持部において前記係止板部を前記横方向に移動させ、前記接続端子の係止片に対し前記係止板部により前記係止片の後抜けを規制することを特徴とする。

An electrical connector according to the present invention for achieving the above object includes a housing body, a terminal holder that is inserted into the housing body from the rear of the housing body, and a terminal holder that is connected to a front end of the terminal holder. a locking plate portion of the movable laterally perpendicular to the direction in which, the locking plate portion which is inserted into the housing body with the terminal holder, and an operating member for moving the transverse direction, the locking piece And a holder holding portion for holding the terminal holder in a rear portion of the housing body, and a connecting portion of the connecting terminal in a front portion. A terminal holding portion for holding the connecting portion is provided, a plurality of openings for respectively inserting the connection terminals are provided at a rear portion of the terminal holder, and the locking plate portion has a board portion for connecting the connection terminals. An insertion groove through which the locking piece passes is formed, an insertion plate that is movably connected to the terminal holder in the lateral direction is provided at a rear portion of the board portion, and the operation portion is provided at a part of the board portion. An operated end for moving in the lateral direction by a member is provided, and the operating member is pushed into the operated end of the locking plate portion by being pushed in from a push opening provided in a terminal holding portion of the housing body. An operating portion for operating the operating member, the operating portion of the operating member moves the locking plate portion in the lateral direction in the terminal holding portion, and the locking plate portion causes the locking plate portion to engage with the locking piece of the connection terminal. It is characterized by restricting the slip-out of the stopper.

また、本発明に係る接続端子の係止方法は、ハウジング本体と、該ハウジング本体の後方から該ハウジング本体内に挿入する端子ホルダと、該端子ホルダの前端に連結され、前記端子ホルダの挿入する方向に直交する横方向に移動自在の係止板部と、前記端子ホルダと共に前記ハウジング本体内に挿入した前記係止板部を、前記横方向に移動させる操作部材とを備え、係止片を有する複数個の接続端子を内装可能とする電気コネクタの係止方法において、前記係止板部は後部を前記端子ホルダに対し横方向に移動可能に連結し、前記接続端子を挿入するに際して、前記接続端子に設けられた係止片を、前記係止板部に形成した挿通溝を前進させて挿入し、前記接続端子の挿入後に、前記ハウジング本体に設けた押込口から前記操作部材を前記ハウジング本体内に押し込んで、前記係止板部を前記横方向に移動させることにより前記接続端子の係止片の後部を係止して、前記接続端子の後方への移動を規制することを特徴とする。

Further, a method of locking a connection terminal according to the present invention includes a housing main body, a terminal holder inserted into the housing main body from the rear of the housing main body, and a front end of the terminal holder, which is connected to the terminal holder. a locking plate portion of the movable laterally perpendicular to the direction, the locking plate portion which is inserted into the housing body with the terminal holder, and an operating member for moving the transverse direction, the locking piece In the method of locking an electric connector capable of incorporating a plurality of connection terminals, the locking plate portion has a rear portion movably connected to the terminal holder in a lateral direction, and when the connection terminals are inserted, The locking piece provided on the connection terminal is inserted by advancing the insertion groove formed on the locking plate portion, and after the connection terminal is inserted, the operation member is moved from the pushing port provided on the housing body to the housing. By pushing in the main body and moving the locking plate part in the lateral direction, the rear part of the locking piece of the connection terminal is locked, and the rearward movement of the connection terminal is restricted. To do.

本発明に係る電気コネクタ及び該電気コネクタ内の接続端子の係止方法は、ハウジング本体の内部に設けた可動の係止板部を、別部材の操作部材により移動させて、接続端子を係止するので、ハウジング内で接続端子を確実に保持可能である。 An electrical connector according to the present invention and a method for locking a connection terminal in the electrical connector are provided in which a movable locking plate portion provided inside a housing body is moved by an operating member which is a separate member to lock the connection terminal. Therefore, the connection terminal can be reliably held in the housing.

また、防水部材を備え、ハウジング本体の前面に操作部材を押し込むための押込口を形成することにより、相手側電気コネクタとの連結状態において防水構造が実現される。 Further, by providing a waterproof member and forming a pushing port for pushing the operation member on the front surface of the housing main body, a waterproof structure is realized in a connected state with the mating electric connector.

本発明を図示の実施例に基づいて詳細に説明する。

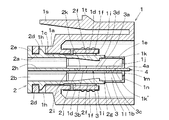

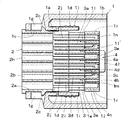

図1は組み立てた状態の実施例の電気コネクタを前方から見た斜視図、図2は後方から見た斜視図、図3は分解した状態の後方から見た斜視図である。図4は組み立てた状態の電気コネクタを鉛直方向に切断した縦断面図、図5は水平方向に切断した縦断面図である。

The present invention will be described in detail with reference to the illustrated embodiments.

FIG. 1 is a perspective view of an electric connector of an embodiment in an assembled state as seen from the front, FIG. 2 is a perspective view as seen from the rear, and FIG. 3 is a perspective view as seen from the rear in an exploded state. FIG. 4 is a vertical cross-sectional view of the assembled electrical connector taken in the vertical direction, and FIG. 5 is a vertical cross-sectional view taken in the horizontal direction.

電気コネクタは、ハウジング本体1と、このハウジング本体1の後方から該ハウジング本体1内に挿入する端子ホルダ2と、この端子ホルダ2の前端に連結され、端子ホルダ2を挿入する方向と直交する横方向に移動自在の係止板部3と、ハウジング本体1内で係止板部3を横方向に移動させる操作部材4とから構成されている。

The electrical connector includes a

ハウジング本体1には、端子ホルダ2、係止板部3を挿入すると共に接続端子を内装し、端子ホルダ2はハウジング本体1の後部から嵌合し、接続端子の後端部を保持する。また、係止板部3は、端子ホルダ2の先端に横方向に移動可能に連結され、端子ホルダ2と共にハウジング本体1内に挿入され、ハウジング本体1の前部から押し込まれた操作部材4により操作される。この操作により、係止板部3は端子ホルダ2に対して係止板部3の挿入する方向に直交する横方向に移動し、内装の接続端子の係止片の後端を係止する。

The

電気コネクタは、例えば上下2段に6列ずつ計12個の受型の接続端子である所謂雌端子を後方側から内装可能とし、同数の挿入型接続端子である所謂雄端子を内蔵した相手側電気コネクタと前方側で連結して、接続端子同士の電気的な接続を行うものである。 The electrical connector can accommodate, for example, 12 so-called female terminals, which are 6 receiving terminals in total in 6 rows in the upper and lower rows, from the rear side, and a mating side in which so-called male terminals, which are the same number of inserting-type connecting terminals, are incorporated. The electric connector is connected to the front side to electrically connect the connection terminals.

この小型の電気コネクタの大きさは、組み立てた状態で、例えば幅24mm、高さ14mm、長さ24mmとされており、接続端子の個数等に応じて適宜の大きさのものを採用することができる。 The size of this small electrical connector is, for example, 24 mm in width, 14 mm in height, and 24 mm in length in the assembled state, and an appropriate size may be adopted according to the number of connecting terminals and the like. it can.

先ず、ハウジング本体1に内装される接続端子について説明すると、この接続端子は、図6の斜視図に示すように、例えば厚さ0.15mmの黄銅などの導電金属板を打ち抜き折曲して形成された、例えば全長が15mmの受型接続端子である。接続端子Tの前方部には、幅1.1mm、高さ1.6mm、長さ4.8mm程度の角筒状の受用の接続部Taが形成されている。

First, the connection terminal installed in the

接続部Taの底面Tbの後端の幅方向の片側には、底面Tbへの切り込みにより形成され、係止板部3により係止される係止片Tcが、下方に向け、かつ前後方向に沿って突出されている。この係止片Tcは、ひれ状に切り出された辺部の先端が一旦、下方に向けられ、再び上方にU字状に折り返されて、例えば高さ0.4mmに形成されている。

On one side of the rear end of the bottom surface Tb of the connecting portion Ta in the width direction, a locking piece Tc formed by cutting into the bottom surface Tb and locked by the locking

この係止片Tcは接続端子Tの挿入時におけるガイドの役割を果たすと共に、挿入後の接続端子Tの姿勢安定のためのスタビライザとしての役割、更には接続端子T自体の後方への抜け出し防止の機能を兼ねている。更に、接続部Taの後部上端は、端子ホルダ2に形成されたケースランスが後方から当接する被押当部Tdとされている。

The locking piece Tc plays a role of a guide when the connection terminal T is inserted, a role of a stabilizer for stabilizing the posture of the connection terminal T after insertion, and a prevention of the connection terminal T itself from coming out backward. It also has a function. Furthermore, the upper end of the rear portion of the connecting portion Ta is a pressed portion Td with which the case lance formed on the

接続端子Tの後端部には、被覆部Teの外径1mm程度の電線Tfが接続されており、被覆部Teから剥き出された芯線部Tgが、U字状の芯線圧着部Thを折り曲げることにより圧着接続されている。更に、芯線圧着部Thの後方には、被覆部Teの外側に挿着された防水用の合成ゴム製の円筒シール材Tiが、被覆部Teと共に、U字状の被覆圧着部Tjを折り曲げることにより圧着固定されている。 An electric wire Tf having an outer diameter of about 1 mm of the covering portion Te is connected to the rear end portion of the connection terminal T, and the core wire portion Tg exposed from the covering portion Te bends the U-shaped core wire crimping portion Th. It is crimped and connected. Further, behind the core wire crimping portion Th, a cylindrical sealing material Ti made of synthetic rubber for waterproofing, which is attached to the outside of the covering portion Te, bends the U-shaped covering crimping portion Tj together with the covering portion Te. It is fixed by crimping.

ハウジング本体1は、中央部に中筒1aが設けられ、その外側に中筒1aを大きく囲むように、間隙を設けて外筒1bが配置され、外筒1bの後部は中筒1aの後方に連結され、中筒1aと外筒1bは一体に成型されている。中筒1aの後部は後方に向けて開口され、端子ホルダ2の後方の枠部を保持する筒状のホルダ保持部1cとされ、中筒1aの外筒1b内の前端は、外径を稍々小さくした防水部1dとされている。

The

防水部1dの内側から更に前方に、中筒1aよりも小径で筒状の端子保持部1eが形成されており、端子保持部1eは防水部1dの内側から複数のリブ1fにより支持されている。なお、リブ1f間は後述する端子ホルダ2のケースランスが進入するための間隙とされている。端子保持部1eはその内部に接続端子Tの接続部Taを保持するためのものであり、前端部は閉塞されている。

A tubular

ホルダ保持部1cの両側部には、端子ホルダ2の仮挿入時に端子ホルダ2の仮挿入用係止突起が嵌入する長溝状の仮挿入用溝部1gが形成されている。また、ホルダ保持部1cの上下部には、端子ホルダ2の本挿入時に端子ホルダ2の本挿入用係止突起を受け入れる2個ずつの本挿入用溝部1hが形成されている。

On both sides of the

中筒1aの先端の防水部1dにはシール部1iが周状に付設され、このシール部1iは防水部1dに設けた小孔を介して内外両面で接続され、内外両面においては水の浸入を阻止するために断面は波状とされている。このシール部1iは、ハウジング本体1の射出成型時に、シリコンゴムを二色成型して付設し、更に架橋することが好ましい。

A sealing

端子保持部1e内には、接続端子Tの接続部Taを個々に収納する断面角型の接続部収容室1jが、上下2段に計12個設けられている。上下の接続部収容室1jの間には、接続端子Tの底面Tbをそれぞれ支持するための底板1k、1k’が間隙をおいて背中合わせに配置されており、底板1k、1k’の間隙を含めた全体の厚みは1.4mmである。

In the

底板1k、1k’の上下両面には、左右に隣接する接続端子T間を仕切るため、2枚1組で計10組の隔壁1l、1l’が長手方向に十分に長く延在されており、隔壁1l、1l’同士の間には間隙が設けられている。そして、底板1k、1k’、隔壁1l、1l’により囲まれた空間が、接続部Taを個々に収納する接続部収容室1jとされている。なお、底板1k、1k’間の間隙に後述する操作部材4の水平板が挿入され、隔壁1l、1l’間の間隙に操作部材4の縦板が挿入される。

On the upper and lower surfaces of the

また、端子保持部1eの前面は前壁1mにより閉塞され、この前壁1mには挿入された個々の接続端子Tに対応して、相手側の挿入型接続端子の挿入端がそれぞれ挿入される上下6個ずつの開口部1nが形成されている。更に、前壁1mにはハウジング本体1内に挿入し、係止板部3を横方向に移動させるための操作部材4用の押込口1oが設けられている。なお、押込口1oとして、1個の水平溝1pと複数個の縦溝1qが形成されており、水平溝1pは上下の開口部1n間、縦溝1qは左右の開口部1n間に設けられており、水平溝1pは端子保持部1eの底板1k、1k’の間の間隙に連通され、縦溝1qは隔壁1l、1l’の間隙に連通されている。

Further, the front surface of the

端子保持部1eの両外側には、操作部材4の両側の側板が嵌合する凹部1rが設けられている。更に、ハウジング本体1の外筒1bの上側中央部には、相手側コネクタと連結状態で錠止するための弾発性を有する錠止アーム1sが形成され、その上部に錠止爪1tが突出されている。

端子ホルダ2の後部には、中筒1aのホルダ保持部1cに内挿される枠部2aが設けられ、この枠部2aには、接続端子Tを個々に挿入する例えば径2.3mm程度の円形断面を有する開孔2bが、接続端子Tごとに2段6列に設けられている。

A

枠部2aの両側部には、端子ホルダ2の仮挿入状態において、ホルダ保持部1cの仮挿入用溝部1gに嵌合する仮挿入用係止突起2cが、1個ずつ外側に向けて突出されている。また、枠部2aの上下部には、本挿入状態において端子ホルダ2をハウジング本体1に固定する本挿入用係止突起2dが上下方向に向けて2個ずつ設けられている。更に、端子ホルダ2の後端部には、中筒1aに対する端子ホルダ2の本挿入時における挿入を、所定位置で停止するためのストッパ2eが上下方向に設けられている。

Temporary

枠部2aの前部の上部及び下部から、各6本の弾発性を有するケースランス2fが、内装される接続端子Tごとに前方に向けて突出されている。接続端子Tは端子保持部1eの上段と下段との接続部収容室1j内にそれぞれ6個ずつの接続部Taが上下対称に内装されるために、上下のケースランス2fは上下対称に設けられている。また、各ケースランス2fの先端には、接続端子Tの接続部Taの被押当部Tdに、後方から当接しながら押圧するための鉤部2gが形成されている。

Six elastic case lances 2f project forward from the upper and lower portions of the front portion of the

枠部2aの上下の開孔2b間には、開孔2b間を上下に仕切り、開孔2bに連続し、内断面を半円弧状とした仕切部2hが設けられており、仕切部2hの最も薄い部分は厚さ0.45mmとされている。そして、仕切部2hの前方には平板状の端子載置板2iが延在されている。端子載置板2iは厚さ1.4mmとされ、各接続端子Tの底面Tbを上下両面においてそれぞれ載置するようにされている。

Between the upper and

端子載置板2iの上下両面には、接続端子Tの挿入に際して、係止片Tcを前方に通過させるための幅0.6mm、深さ0.4mmの6本ずつの挿通溝2jが前後方向に向けて形成されている。なお、係止片Tcは接続部Taの幅方向の片側に寄せて形成されており、上下2段の接続端子Tを上下対称に配置するために、上下の挿通溝2jは互いに左右方向にずれて配置されている。

Six

このことは、後述する図8に示す係止板部3の上下両面における挿通溝についても同様である。また、端子載置板2iの前端には、係止板部3の挿込板を横方向に移動可能に受け入れるために、幅広のスリット状の連結穴2kが形成されている。

This also applies to the insertion grooves on the upper and lower surfaces of the locking

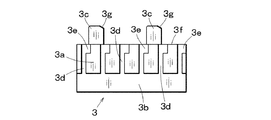

係止板部3は図7の平面図、図8の正面図にも示すように、基板部3aと、後方に突出する挿込板3bと、前方に突出する被操作端3cとから成っている。基板部3aの厚みは、端子保持部1eの底板1k、1k’の間隙、及び端子ホルダ2の端子載置板2iの間隙と同じ1.4mmの略矩形状の板体である。基板部3aの上下両面には、係止板部3の端子ホルダ2への挿入連結位置において、端子載置板2iに設けられた挿通溝2jと連通し、挿通溝2jと同じ幅0.6mm、深さ0.4mmの6個ずつの挿通溝3dが前後方向に向けて形成されている。また、各挿通溝3dの前端側部には、幅方向に向けて設けた矩形状の切込みが形成され、接続端子Tが後方に抜け出さないように、係止片Tcを係止するための係止部3eとされている。

As shown in the plan view of FIG. 7 and the front view of FIG. 8, the locking

なお、図8は接続端子Tの係止片Tcが、係止板部3の挿通溝3dに挿通されている状態を一点鎖線で示している。

Note that FIG. 8 shows a state in which the locking piece Tc of the connection terminal T is inserted into the

挿込板3bは端子ホルダ2の連結穴2kに嵌合され、連結穴2kよりも幅が狭く、厚さ0.6mm程度の板体状とされている。また被操作端3cは、基板部3aの前縁3fから前方に突出された厚さ0.6mm程度の2個の条板部とされている。被操作端3cの先端片側には、操作部材4により係止板部3をハウジング本体1、端子ホルダ2に対し、横方向に移動させるための方向変換用のくさび機構となる受斜面部3gが形成されている。

The

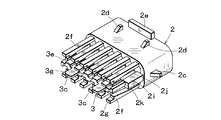

操作部材4は、ハウジング本体1の前壁1mの押込口1oから端子保持部1e内に押し込み、内部の係止板部3を横方向に移動させるための部材である。図9に示すように、操作部材4は、底板1k、1k’の間隙に入り込む厚さ0.6mmの水平板4a、隔壁1l、1l’の間隙に入り込む厚さ0.6mmの複数の縦板4b、及び両側の一対の側板4cから成っている。

The

水平板4aの前端には、係止板部3の被操作端3cを受け入れる2個の凹部4dが形成され、凹部4dの入口の片側には被操作端3cの受斜面部3gと共働して、係止板部3を横方向に移動させるための操作部となる押斜面部4eが設けられている。また、水平板4aの後端部には、操作部材4を押し込み、また必要に応じて操作部材4を引き抜くための押込片4fが設けられている。

At the front end of the

電気コネクタの組立時には、図10に示すように端子ホルダ2の先端の連結穴2kに係止板部3の挿込板3bを嵌合して横方向に移動自在に連結しておく。この場合に、挿込板3bは端子載置板2iの連結穴2kに対し、片側に寄せた状態とする。これにより、係止板部3の挿通溝3dは端子載置板2iの挿通溝2jと連通され、接続端子Tの係止片Tcがこれらの挿通溝2j、3dを順次に通過可能となる。

At the time of assembling the electric connector, as shown in FIG. 10, the

このようにして、端子ホルダ2と係止板部3とを一体化して、ハウジング本体1の後方から、中筒1aのホルダ保持部1c内に、図示しない案内機構に沿って挿入する。この挿入により、図11、図12に示すように、端子ホルダ2の枠部2aがホルダ保持部1cに仮挿入状態として組付けられる。

In this way, the

この仮挿入状態においては、係止板部3の被操作端3cの前端が、端子保持部1eの底板1k、1k’同士の間隙の近傍に位置する状態となる。また、この仮挿入状態で係止板部3を挿入可能にし、後述する本挿入状態で係止板部3を挿入可能とすると共に横方向に移動可能にするために、端子保持部1eの側面にはスリットが形成されている。

In this temporary insertion state, the front end of the operated

端子ホルダ2、係止板部3を仮挿入するに際して、端子ホルダ2の仮挿入用係止突起2cは、ハウジング本体1のホルダ保持部1cを押し拡げて仮挿入用溝部1gに嵌合し、また本挿入用係止突起2dの前端がホルダ保持部1cの後端に当接する。この状態で、ケースランス2fは端子保持部1eと防水部1dの間のリブ1f同士の間に位置している。

When the

端子ホルダ2の仮挿入状態において、仮挿入用係止突起2cと本挿入用係止突起2dとにより、ホルダ保持部1cの後端が挟着されるので、端子ホルダ2、係止板部3はハウジング本体1から脱落することがなくなり、仮挿入状態が維持される。このように、ハウジング本体1に対し端子ホルダ2、係止板部3が仮挿入状態とされた組付体を、次工程の接続端子Tの挿入作業場に運搬しても、これらの組立体の組付状態が崩れることはない。

In the temporary insertion state of the

次いで図13に示すように、接続端子Tを接続部Taを先にして、個々に端子ホルダ2の開孔2bから端子ホルダ2の内部に一次挿入する。個々の接続部Taは、端子保持部1eから後方に延在された隔壁1l、1l’により案内されながら端子載置板2i上を進み、これに伴い接続部Taの係止片Tcは、端子載置板2iの挿通溝2j、更に係止板部3の挿通溝3d内を前進する。

Next, as shown in FIG. 13, the connection terminals T are first inserted into the inside of the

この接続端子Tの一次挿入過程で、上段の接続端子Tのように、先端の接続部Taがケースランス2fを押し上げて、ケースランス2fの鉤部2gを潜り抜け、接続部Taは接続部収容室1j内に入り込む。ケースランス2fと中筒1aの防水部1dとの間は若干の間隙があり、ケースランス2fは外側に変形可能とされている。接続部Taが鉤部2gを潜り抜けると、ケースランス2fは復元して、鉤部2gは接続部Taの被押当部Tdに当接する。そして、下段の接続端子Tに示すように、各接続端子Tはこの一次挿入位置で停止する。

In the primary insertion process of the connection terminal T, the connection portion Ta at the tip pushes up the

全ての接続端子Tの一次挿入が終了した後に、更に端子ホルダ2を係止板部3と共に中筒1a内に押し込む。これにより、図14に示すように、ケースランス2fの鉤部2gが接続部Taの被押当部Tdを押して、接続端子Tを一次挿入位置から二次挿入位置に前進させることにより、全ての接続端子Tの接続部Taを接続部収容室1j内の所定位置まで押し込まれる。

After completing the primary insertion of all the connection terminals T, the

同時に、係止板部3の被操作端3cは底板1k、1k’同士の間隙に挿入され、端子ホルダ2のストッパ2eがハウジング本体1の後端部に当接し、端子ホルダ2、係止板部3はこの位置で前進を停止する。この本挿入過程では、端子ホルダ2の本挿入用係止突起2dがハウジング本体1のホルダ保持部1cを押し拡げて本挿入用溝部1h内に嵌合し、端子ホルダ2はハウジング本体1に対し本挿入状態で結合される。この本挿入状態において、端子ホルダ2の本挿入用係止突起2dとストッパ2eとにより、ホルダ保持部1cの後端を挟着することにより、端子ホルダ2、係止板部3はハウジング本体1に対して前後方向に不動となる。

At the same time, the operated

また、接続端子Tはこの二次挿入状態において、接続部収容室1j内の接続部Taの前端が前壁1mの内側に当接し位置が定まる。この接続端子Tの停止状態において、ケースランス2fの鉤部2gが接続端子Tの被押当部Tdを後方から当接して、接続端子Tの後抜けが防止される。このとき、接続端子Tの係止片Tcは、スタビライザとして端子載置板2iの挿通溝2jを経由して、係止板部3の挿通溝3dの先端において停止している。

Further, the position of the connecting terminal T is determined by the front end of the connecting portion Ta in the connecting

このような端子ホルダ2、係止板部3の本挿入状態において、別体の操作部材4を、図15に示すようにハウジング本体1の前壁1mに設けられた押込口1oから、水平板4a、縦板4bを底板1k、1k’、隔壁1l、1l’の間隙にそれぞれ押し込む。また、操作部材4の両側の側板4cを端子保持部1eの凹部1rに嵌合する。

In such a state that the

これにより、ハウジング本体1内で、図16(a)に示すように係止板部3と操作部材4とは対向する。なお、接続端子Tの接続部Ta、係止片Tcは、一点鎖線で示している。ここで、操作部材4を矢印Aで示すように強く押し込むと、図16(b)に示すように、操作部材4の水平板4aの凹部4d内に、係止板部3の被操作端3cが入り込む。操作部材4の更なる押圧力により、押斜面部4eは被操作端3cの受斜面部3gに対し、斜面同士のくさび作用により係止板部3に矢印Bの横方向に進む力を加える。

As a result, in the

係止板部3の挿込板3bが端子載置板2iの連結穴2k内で、また被操作端3cが底板1k、1k’の間隙内で横方向に移動することにより、係止板部3は端子ホルダ2、ハウジング本体1に対して前方から見て右方向の横方向に移動する。そして、係止板部3は操作部材4により、この位置において左方向への動きが規制されるので、係止板部3が不時に元の位置に戻ることはない。

The

この係止板部3の横方向への移動により、接続端子Tを動かすことなく、係止板部3の挿通溝3dの前端に位置していた係止片Tcが、挿通溝3dの先端脇に設けられた係止部3e内に相対的に横方向に移行する。これにより、係止片Tcの後部は係止部3eにより係止されることになり、係止片Tcの後方への移動が規制されることになる。この係止板部3の横方向に移動距離は、係止片Tcの幅よりも大きい0.6mm程度である。このように、操作部材4が挿入されている限り、係止板部3が元の位置に戻ることはなく、係止片Tcの係止状態は係止部3eにより維持される。

By moving the

なお、図16における説明は、係止板部3の上面における動作の説明であるが、下面においても同様に、下面側に配置された接続端子Tの係止片Tcの後部は、下面側の係止部3eにより係止される。操作部材4が押し込まれていれば、係止板部3の横方向に移動が確実になされているはずであり、係止片Tcの係止を確認することができる。ここで、操作部材4を例えばハウジング本体1とは異なる色に着色しておくと、操作部材4の装着状態が更に容易に視認できる。なお、操作部材4による係止板部3を移動させる機構は他の方式であってもよい。

Although the description in FIG. 16 is for the operation on the upper surface of the locking

このように、接続端子Tは被押当部Tdがケースランス2fにより係止され、更に係止片Tcが係止板部3の係止部3eにより係止されるという2つの係止手段によって、接続端子Tの後方への電線Tfの引き抜きなどに起因する後抜けが防止される。

In this way, the connection terminal T is locked by the two locking means in which the pressed portion Td is locked by the

また、本挿入位置において、図15に示すように、接続端子Tの後端部は端子ホルダ2の開孔2b内に位置し、接続端子Tに取り付けた円筒シール材Tiが開孔2bの内壁に密着して、端子ホルダ2、中筒1a内への後方からの水の浸入が防止される。更に、防水部1dに設けたシール部1iの内側部分により、中筒1aの内側と端子ホルダ2の外側との間が密封され、中筒1aと端子ホルダ2との隙間から内部への水の浸入が防止される。

Further, at the main insertion position, as shown in FIG. 15, the rear end portion of the connection terminal T is located in the

このように構成された実施例の電気コネクタは、使用に際して相手側の電気コネクタのハウジングと結合され、ハウジング同士は錠止アーム1sの錠止爪1tにより錠止される。相手側の接続端子の挿入端が、前壁1mの開口部1nから挿入されて、接続端子Tの接続部Taに嵌入され、両接続端子の電気的な接続がなされる。

In use, the electric connector of the embodiment thus configured is connected to the housing of the mating electric connector, and the housings are locked by the locking

相手側の電気コネクタも防水構造とされており、相手側の電気コネクタの外筒が、ハウジング本体1の外筒1bと中筒1aの間に挿入され、中筒1aに設けたシール部1iの外側部分により、中筒1aと相手側コネクタの外筒との間をシールし、これらの間から内部に水が浸入しないように密封される。このように、シール部1i及び円筒シール材Tiによる密封構造により、ホルダ保持部1cの内部に水が浸入することがなく、相手側の防水構造の電気コネクタと結合することにより、防水コネクタとして機能することになる。

The mating electric connector also has a waterproof structure, and the outer cylinder of the mating electric connector is inserted between the

実施例においては、接続端子Tを電気コネクタの上下2段に、その底面Tb同士を向き合わせて挿入することを前提としているために、端子ホルダ2の端子載置板2i、係止板部3にそれぞれ形成された係止片Tcの挿通溝は、上下両面に形成されている。しかし、接続端子Tを1段に内装する電気コネクタであれば、挿通溝は片面のみに形成すればよい。

In the embodiment, since it is premised that the connection terminals T are inserted in the upper and lower two stages of the electric connector with their bottom surfaces Tb facing each other, the

また、例えば修理等において、ハウジング本体1から接続端子Tを取り出すには、操作部材4を押込片4fにより抜き出して、治具により係止板部3を左方向に横移動させると、係止片Tcに対する規制が解除される。次いで、前壁1mの開口部1nから専用治具を挿入して、当該接続端子Tに対するケースランス2fの係止を外して、接続端子Tを後方に引き出せばよい。

In order to take out the connection terminal T from the

上述の実施例においては、係止板部3に接続端子Tの係止片Tcを係止する係止部3eを設けている。しかし、底板1k、1k’の前後方向の長さを大きくして、接続端子Tの二次挿入時に接続部Taの全てが底板1k、1k’上に至るようにし、底板1k、1k’にも係止片Tcの挿通溝を設け、接続端子Tの二次挿入時には、係止片Tcを底板1k、1k’に設けた挿通溝まで押し込むことが可能である。そして、係止片Tcの係止は係止部3eによることなく、横方向に移動させた係止板部3の前縁3fにより、底板1k、1k’に設けた挿通溝を閉塞することにより係止を行うこともできる。

In the above embodiment, the locking

また、端子ホルダ2の端子載置板2iにも挿通溝2jを設けたが、接続端子Tの挿入時において、接続端子Tの係止片Tcを係止板部3の挿通溝3dに直接案内できれば、端子ホルダ2の挿通溝2jを省略することもできる。

Further, the

実施例においては、接続端子Tを受型接続端子としたが、接続端子を挿入型接続端子とした電気コネクタに適用することもできる。更に、接続端子Tの数を変更したり、段数を1段又は3段以上とすることも可能である。 In the embodiment, the connection terminal T is the receiving type connection terminal, but it can be applied to an electric connector in which the connection terminal is an insertion type connection terminal. Furthermore, it is possible to change the number of the connection terminals T or to set the number of stages to one or three or more.

なお、実施例における上下左右とは、図面に対しての説明であり、実際の電気コネクタにおける上下左右とは異なることがある。 It should be noted that the terms “upper, lower, left, right” in the embodiments are only for the drawings and may be different from “up, down, left, right” in an actual electrical connector.

1 ハウジング本体

1a 中筒

1b 外筒

1c ホルダ保持部

1e 端子保持部

1i シール部

1j 接続部収容室

1k、1k’ 底板

1l、1l’ 隔壁

1m 前壁

1n 開口部

1o 押込口

2 端子ホルダ

2a 枠部

2b 開孔

2f ケースランス

2i 端子載置板

2j、3d 挿通溝

3 係止板部

3a 基板部

3b 挿込板

3c 被操作端

3g 受斜面部

4 操作部材

4a 水平板

4b 縦板

4e 押斜面部

T 接続端子

Ta 接続部

Tc 係止片

Tf 電線

Ti 円筒シール部材

1

Claims (11)

前記ハウジング本体には、後部に前記端子ホルダを保持するホルダ保持部が設けられていると共に、前部に前記接続端子の接続部を保持する端子保持部が設けられ、

前記端子ホルダの後部には、前記接続端子をそれぞれ挿入する複数個の開孔が設けられ、

前記係止板部には、基板部に前記接続端子の係止片を通過させる挿通溝が形成され、前記基板部の後部に前記端子ホルダに対して、前記横方向に移動可能に連結する挿込板が設けられ、前記基板部の一部に前記操作部材による前記横方向に移動のための被操作端が設けられ、

前記操作部材には、前記ハウジング本体の端子保持部に設けられた押込口から押し込んで前記係止板部の被操作端に作用する操作部が設けられ、

前記操作部材の操作部により、前記端子保持部において前記係止板部を前記横方向に移動させ、前記接続端子の係止片に対し前記係止板部により前記係止片の後抜けを規制することを特徴とする電気コネクタ。

A housing body, a terminal holder to be inserted into said housing body from the rear of the housing body, is connected to the front end of the terminal holder, the terminal locking plate of the movable laterally perpendicular to the direction of insertion of the holder And an operating member for moving the locking plate portion inserted into the housing body together with the terminal holder in the lateral direction, the electrical connector capable of internally mounting a plurality of connection terminals having locking pieces. There

The housing main body is provided with a holder holding portion for holding the terminal holder at a rear portion, and a terminal holding portion for holding a connecting portion of the connection terminal is provided at a front portion,

A plurality of openings for inserting the connection terminals are provided in the rear portion of the terminal holder,

An insertion groove is formed in the base plate of the locking plate to allow the locking pieces of the connection terminals to pass therethrough, and an insertion groove is movably connected to the terminal holder in the rear of the base of the base. An insert plate is provided, and an operated end for moving in the lateral direction by the operation member is provided in a part of the substrate portion,

The operation member is provided with an operation portion that is pushed in from a pressing opening provided in the terminal holding portion of the housing body and acts on the operated end of the locking plate portion.

The operation portion of the operation member moves the locking plate portion in the lateral direction in the terminal holding portion, and the locking plate portion restricts rearward removal of the locking piece with respect to the locking piece of the connection terminal. An electrical connector characterized by:

前記係止板部は後部を前記端子ホルダに対し横方向に移動可能に連結し、前記接続端子を挿入するに際して、前記接続端子に設けられた係止片を、前記係止板部に形成した挿通溝を前進させて挿入し、前記接続端子の挿入後に、前記ハウジング本体に設けた押込口から前記操作部材を前記ハウジング本体内に押し込んで、前記係止板部を前記横方向に移動させることにより前記接続端子の係止片の後部を係止して、前記接続端子の後方への移動を規制することを特徴とする電気コネクタ内の接続端子の係止方法。

A housing body, a terminal holder to be inserted into said housing body from the rear of the housing body, is connected to the front end of the terminal holder, the terminal locking plate of the movable laterally perpendicular to the direction of insertion of the holder And an operating member for moving the locking plate portion inserted into the housing main body together with the terminal holder in the lateral direction, the electrical connector capable of incorporating a plurality of connection terminals having locking pieces. In the locking method,

The locking plate portion has a rear portion movably connected to the terminal holder in a lateral direction, and when inserting the connection terminal, a locking piece provided on the connection terminal is formed on the locking plate portion. After inserting the insertion groove by advancing and inserting the connection terminal, the operation member is pushed into the housing body from a pushing opening provided in the housing body to move the locking plate portion in the lateral direction. A method of locking a connection terminal in an electric connector, characterized in that the rear portion of the locking piece of the connection terminal is locked by means of which the rearward movement of the connection terminal is restricted.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017226899A JP6730975B2 (en) | 2017-11-27 | 2017-11-27 | Electric connector and method of locking connection terminals in the electric connector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017226899A JP6730975B2 (en) | 2017-11-27 | 2017-11-27 | Electric connector and method of locking connection terminals in the electric connector |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2019096548A JP2019096548A (en) | 2019-06-20 |

| JP2019096548A5 JP2019096548A5 (en) | 2019-07-25 |

| JP6730975B2 true JP6730975B2 (en) | 2020-07-29 |

Family

ID=66973111

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017226899A Active JP6730975B2 (en) | 2017-11-27 | 2017-11-27 | Electric connector and method of locking connection terminals in the electric connector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6730975B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2020198277A (en) * | 2019-06-05 | 2020-12-10 | 株式会社デルタプラス | Electrical connector and locking method of connection terminal in electrical connector |

| JP7202531B2 (en) * | 2019-10-25 | 2023-01-12 | 株式会社オートネットワーク技術研究所 | connector |

-

2017

- 2017-11-27 JP JP2017226899A patent/JP6730975B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019096548A (en) | 2019-06-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006253017A (en) | Joint connector | |

| US7086910B2 (en) | Connector | |

| JP5789494B2 (en) | Connector and connector manufacturing method | |

| KR100709086B1 (en) | A divided connector and method of assembling it | |

| JP2008543026A (en) | Connector assembly having terminal position assurance device | |

| JP4304474B2 (en) | connector | |

| JP6730975B2 (en) | Electric connector and method of locking connection terminals in the electric connector | |

| JP2007012352A (en) | Connector | |

| JP4544065B2 (en) | connector | |

| CN111213287B (en) | Connector, jig, and method for assembling terminal to connector | |

| WO2021079590A1 (en) | Connector | |

| JP2014207102A (en) | Connector | |

| WO2021182093A1 (en) | Connector and method for manufacturing connector | |

| JP5217974B2 (en) | connector | |

| WO2020246428A1 (en) | Electrical connector and method for locking connection terminal in said electrical connector | |

| JP2021082419A (en) | connector | |

| JP5711625B2 (en) | Terminal mating confirmation structure | |

| WO2023021858A1 (en) | Connector | |

| JP2005183340A (en) | Joint connector | |

| JP2008198392A (en) | Joint connector | |

| JP4492442B2 (en) | connector | |

| JPH11354185A (en) | Connector | |

| JP2022127024A (en) | connector | |

| JPH08273741A (en) | Connector | |

| JP2000150052A (en) | Connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20171127 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190619 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190619 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200514 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200616 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200703 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6730975 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |