JP6233781B2 - Cooling system - Google Patents

Cooling system Download PDFInfo

- Publication number

- JP6233781B2 JP6233781B2 JP2014023798A JP2014023798A JP6233781B2 JP 6233781 B2 JP6233781 B2 JP 6233781B2 JP 2014023798 A JP2014023798 A JP 2014023798A JP 2014023798 A JP2014023798 A JP 2014023798A JP 6233781 B2 JP6233781 B2 JP 6233781B2

- Authority

- JP

- Japan

- Prior art keywords

- battery

- holder

- inflow

- flow path

- electrode terminal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000001816 cooling Methods 0.000 title claims description 64

- 239000002826 coolant Substances 0.000 claims description 53

- 239000000463 material Substances 0.000 claims description 33

- 239000000110 cooling liquid Substances 0.000 claims description 24

- 239000007769 metal material Substances 0.000 claims description 23

- 229920003002 synthetic resin Polymers 0.000 claims description 22

- 239000000057 synthetic resin Substances 0.000 claims description 22

- 230000002093 peripheral effect Effects 0.000 description 26

- 229920005989 resin Polymers 0.000 description 22

- 239000011347 resin Substances 0.000 description 22

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 description 10

- 229910001416 lithium ion Inorganic materials 0.000 description 10

- -1 polypropylene Polymers 0.000 description 10

- 229910052782 aluminium Inorganic materials 0.000 description 8

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 8

- 238000002347 injection Methods 0.000 description 6

- 239000007924 injection Substances 0.000 description 6

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 4

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 4

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 4

- 239000000853 adhesive Substances 0.000 description 4

- 230000001070 adhesive effect Effects 0.000 description 4

- 229910052802 copper Inorganic materials 0.000 description 4

- 239000010949 copper Substances 0.000 description 4

- 239000011737 fluorine Substances 0.000 description 4

- 229910052731 fluorine Inorganic materials 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 238000005192 partition Methods 0.000 description 4

- 229910001220 stainless steel Inorganic materials 0.000 description 4

- 239000010935 stainless steel Substances 0.000 description 4

- 239000012809 cooling fluid Substances 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- 239000004696 Poly ether ether ketone Substances 0.000 description 2

- 239000004734 Polyphenylene sulfide Substances 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000000498 cooling water Substances 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 2

- 238000001746 injection moulding Methods 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 229910052759 nickel Inorganic materials 0.000 description 2

- 239000005011 phenolic resin Substances 0.000 description 2

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 2

- 229920001707 polybutylene terephthalate Polymers 0.000 description 2

- 229920005668 polycarbonate resin Polymers 0.000 description 2

- 239000004431 polycarbonate resin Substances 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 229920002530 polyetherether ketone Polymers 0.000 description 2

- 239000011112 polyethylene naphthalate Substances 0.000 description 2

- 229920013716 polyethylene resin Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 229920000069 polyphenylene sulfide Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 229920005990 polystyrene resin Polymers 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 229920005992 thermoplastic resin Polymers 0.000 description 2

- 229920001187 thermosetting polymer Polymers 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000003507 refrigerant Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Description

本発明は、冷却液の流路を有する電池ケースに複数個の電池を収容して、各電池を冷却する冷却装置に関する。The present invention relates to a cooling device in which a plurality of batteries are accommodated in a battery case having a coolant flow path and each battery is cooled.

リチウムイオン電池などの二次電池を電気自動車などの車両に使用できるようにするために、単電池を複数個接続して大きな電流容量を得るようにした電池パックまたは組電池においては、発熱量が大きいので、電池の温度上昇を抑制するために冷却液にて電池を冷却する冷却装置が使用されており、この冷却装置としては、例えば、特許文献1に開示されているように、複数個の長円筒形のリチウムイオン二次電池を箱状の組電池ケースに収納して外部に正極および負極の電極端子を突出させた組電池において、組電池ケース内に直接冷却液を通してリチウムイオン二次電池の冷却を行うことにより、温度上昇を効率よく抑制することができる冷却装置が提案されている。In order to make it possible to use a secondary battery such as a lithium ion battery in a vehicle such as an electric vehicle, a battery pack or an assembled battery in which a plurality of single cells are connected to obtain a large current capacity has a heat generation amount. Since it is large, a cooling device that cools the battery with a cooling liquid is used to suppress the temperature rise of the battery. As this cooling device, for example, as disclosed in

しかし、特許文献1にて提案された組電池の冷却装置では組電池ケース内で、冷却液が直接電池に接触されているので、前記電極端子の温度上昇に対して冷却効率はよいが、冷却液による電極端子の腐食を防止させる処置を講ずる必要がある。However, in the assembled battery cooling device proposed in

一方、電池ケースに複数個の電池を収容して、その電池ケースの外周に冷却液の流路を形成することにより冷却液が直接電池に接触されないようにして各電池を冷却する冷却装置として、例えば、特許文献2に開示されている。すなわち、円筒形蓄電池を例とする電池を収容する円筒形の開口部(電池収容室)に電池の外表面が密着して接触する隔壁を形成して、この隔壁に液体の冷媒(冷却液)を流す冷却溝を形成して電池を冷却する冷却装置が提案されている。On the other hand, as a cooling device that houses a plurality of batteries in a battery case and cools each battery so that the coolant does not come into direct contact with the battery by forming a coolant flow path on the outer periphery of the battery case, For example, it is disclosed in

しかし、特許文献2にて提案された冷却装置では、電極端子が配慮されておらず、また、電池に密着させ、電池に面する隔壁の厚みを薄くして熱伝達性を向上させ効率よい冷却をさせるようにしているが、冷却液を循環させて隔壁を冷却させるに際し、冷却液が滞留することなく円滑に流れるようにすることが配慮されていない。However, in the cooling device proposed in

本発明は、上記の問題点を解消するために、冷却液の流路を有する電池ケースに複数個の電池を収容して、各電池を冷却する冷却装置において、電池ケースの外周において冷却液が滞留することなく円滑に流れるようにして、各電池の電極端子がと冷却液と接触せずに各電池を効率よく冷却することができる冷却装置を提供することを目的とする。In order to solve the above-described problems, the present invention provides a cooling device in which a plurality of batteries are accommodated in a battery case having a coolant flow path, and each battery is cooled. An object of the present invention is to provide a cooling device that can smoothly flow without stagnation and efficiently cool each battery without the electrode terminals of each battery coming into contact with the coolant.

本発明の請求項1に記載の冷却装置は、冷却液の流路を有し、正極および負極の電極端子を設けた電池ケース内に複数個の電池を収容して、各電池を冷却する冷却装置において、前記電池ケース内に複数個の筒状の電池収容室を設け、各電池収容室の外周に螺旋状の流路を形成して、前記電池収容室の外周に冷却液を流して各電池を冷却する冷却装置であって、前記電池ケースは下端が開口した筒状の上側ホルダと上端が開口した筒状の下側ホル ダとの密着接合により形成されてできており、前記上側ホルダまたは前記下側ホルダには前記電極端子から離れた部位に冷却液を前記流路に流入させる流入口および冷却液を前記流路から流出させる流出口を有することを特徴とする。請求項2に記載の冷却装置は、請求項1に記載の冷却装置において、前記上側ホルダおよび下側ホルダは合成樹脂材でできており、前記上側ホルダに金属材でできた複数個の筒状の電池収容室を一体に形成したことを特徴とする。請求項3に記載の冷却装置は、請求項1または2に記載の冷却装置において、前記上側ホルダには冷却液を流入させる流入部を有し、前記下側ホルダには前記冷却液を流出させる流出部を有することを特徴とする。請求項4に記載の冷却装置は、請求項1または2に記載の冷却装置において、前記上側ホルダには冷却液を流入させる流入部と前記冷却液を流出させる流出部とを有することを特徴とする。The cooling device according to

本発明の冷却装置は、冷却液の流路を有し、正極および負極の電極端子を設けた電池ケース内に複数個の電池を収容して、各電池を冷却する冷却装置において、前記電池ケース内に複数個の筒状の電池収容室を設け、各電池収容室の外周に螺旋状の流路を形成して、前記電池収容室の外周に冷却液を流して各電池を冷却する冷却装置であって、前記電池ケースは下端が開口した筒状の上側ホルダと上端が開口した筒状の下側ホルダとの密着接合により形成されてできており、前記上側ホルダまたは前記下側ホルダには前記電極端子から離れた部位に冷却液を前記流路に流入させる流入口および冷却液を前記流路から流出させる流出口を有して、前記電池収容室の外周に冷却液を流して各電池を冷却するので、各電池の電極端子が冷却液と接触させないようにすることができ、電池ケースの外周詳しくは各電池収容室の外周において冷却液が滞留することなく円滑に流れるようにして各電池を効率よく冷却することができるなどの効果がある。Cooling device of the present invention has a flow path of the cooling liquid, and accommodates a plurality of batteries in a battery case provided with electrode terminals of the positive electrode and the negative electrode, in a cooling device for cooling the batteries, the battery case A cooling device in which a plurality of cylindrical battery housing chambers are provided, a spiral flow path is formed on the outer periphery of each battery housing chamber, and a cooling liquid is allowed to flow on the outer periphery of the battery housing chamber to cool each battery. The battery case is formed by tightly joining a cylindrical upper holder having a lower end opened and a cylindrical lower holder having an upper end opened, and the upper holder or the lower holder includes and possess an outlet for outflow of the inlet and the cooling fluid for flowing the cooling fluid in the flow path at a site distant from the electrode terminal from the flow path, each battery by flowing a cooling fluid to the outer periphery of the battery housing chamber So that the electrode terminals of each battery are in contact with the coolant. Can prevent not, such an effect can detail the outer circumference of the battery case is efficiently cool each battery was smoothly flow so without coolant stagnates at the outer periphery of the battery housing chamber .

以下、本発明の実施形態について図面を参照して説明する。Embodiments of the present invention will be described below with reference to the drawings.

(実施形態1)

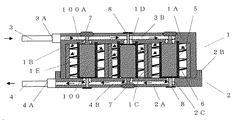

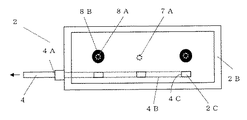

図1から図10は、本発明の実施形態1を示し、電池ケースは箱状で、上側ホルダ1と下側ホルダ2とが接合されてできており、上側ホルダ1には冷却液を流入させる流入部3を有し、下側ホルダ2には流路6から冷却液を流出させる流出部4を有し、電池ケースに収容される電池100は円筒形を例示する筒形のリチウムイオン電池などの二次電池で、正極の電極端子100Aおよび負極の電極端子100Bがそれぞれ上端および下端に設けられている。この場合、電極端子100Aおよび電極端子100Bはそれぞれ正極および負極を例示しているが、アルミニウム材の筒形のリチウムイオン電池においては、負極の電極端子100Aおよび正極の電極端子100Bであり、7および7Aはそれぞれ負極端子および負極端子接続部で、8、8Aおよび8Bはそれぞれ正極端子、正極端子接続部および電池接触負極板である。(Embodiment 1)

FIG. 1 to FIG. 10

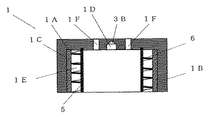

図1、図2および図4において、上側ホルダ1は、下端が開口した箱状で、上端壁1Aと筒状の周壁1Bとで空間部を形成し、この空間部には上端壁1Aの内面に複数個(図では3個)の筒状でその下端が開口した環状壁1Cが一直線状に形成されている。これら上端壁1A、周壁1Bおよび環状壁1Cは合成樹脂材で一体に形成されている。その合成樹脂材としては、ポリフェニレンサルファイド系樹脂、ポリエチレン系樹脂、ポリプロピレン系樹脂、ポリスチレン系樹脂、ポリカーボネート系樹脂、ポリ塩化ビニル系樹脂、ポリエチレンテレフタレート系樹脂、ポリブチレンテレフタレート系樹脂、ポリエチレンナフタレート系樹脂、ポリブチレンナフタレート系樹脂、フッ素系樹脂、ポリエーテルエーテルケトン系樹脂などの熱可塑性樹脂およびフェノール系樹脂やエポキシ系樹脂などの熱硬化性樹脂が例示できる。1, 2 and 4, the

各筒状の環状壁1Cの内部には上下端が開口した筒状の電池収容室5が上端壁1Aと一体に形成されている。この電池収容室5の素材は、熱伝導性がよい素材で、例えばアルミニウム、銅、鉄などの金属材または前記金属材表面にニッケル膜形成などの表面処理をした金属材またはステンレスなどの金属材であり、合成樹脂材であれば、他の部位よりも薄肉とすることが好ましい。また、形状は、電池100を収容する大きさで、図においては、リチウムイオン電池などの二次電池で円筒形の電池を例示しているので、円筒状である。各電池収容室5と環状壁1Cとの間は流路形成空間部1Eとなり、上端壁1Aの後述する流入ガイド孔1Dから下端方向に螺旋状に延びる流路6が形成されている。流路6を螺旋状に形成する方法としては、フッ素系樹脂などの合成樹脂材やアルミニウムやステンレスなどの金属材を螺旋状に形成した螺旋状成形品をもちいて、図7に示すように電池収容室5の外周の流路形成空間部1Eに装着する方法を例示する。なお、この螺旋状の流路6の形成法においては、螺旋状成形品の装着ではなく、電池収容室5の外周に一体成形などで予め固着しておけば、螺旋状成形品の装着作業は不要となる。また、各電池収容室5の内部の上端面のほぼ中央の部位にはアルミニウムや銅などの金属材でできた正極端子接続部7Aまたは負極端子接続部8Aが形成されており、負極端子接続部8Aについては、電池収容室5の上端面の内面に電池接触負極板8Bが形成されているが、この電池接触負極板8Bは、上側ホルダ1の上端壁1Aの内面に形成してもよい。Inside each cylindrical annular wall 1C, a cylindrical

また、上端壁1Aには、冷却液を流路6に流入させる流入部3が形成されている。この流入部3は、流入口3Aと流入路3Bとからなり、流入口3Aは流入路3Bに連通して上端壁1Aで周壁1Bの外方向に突出して形成されており、流入路3Bは、合成樹脂材の上端壁1Aに埋設するように一体に成形可能な金属材でできた中空管で、複数個の流入孔3Cが形成されて各流路6に冷却液を流入させるように形成されている。この流入孔3Cの部位には、図10に示すように、流入路3Bの内壁面が部分的に突出されるように流入路3Bを局所的に狭窄する絞り部3Dが形成されることにより、冷却液を各流路6に導いて流入しやすくしている。In addition, an

さらに、上端壁1Aにおいて各電池収容室5の上端面側のほぼ中央の部位に形成された正極端子接続部7Aおよび負極端子接続部8Aのそれぞれに接続された電池100の電極端子である正極端子7および負極端子8が図4に示すように、並設されている。この場合、負極端子8については、電池接触負極板8Bを介して負極端子接続部8Aに接続されている。また、上端壁1Aで中央の部位から離れた部位、すなわち、正極端子7および負極端子8から離れた部位には、流入路3Bの流入孔3Cと連通した流入ガイド孔1Dが形成されている。従って、冷却液は、電池収容室5の外周に流入されており、電池収容室5の内部には流入されないので、電池100の電極端子が冷却液と接触しないようにすることができる。Furthermore, the positive electrode terminal which is an electrode terminal of the

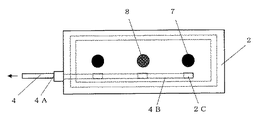

一方、図1、図2および図5において、下側ホルダ2は、上端が開口した箱状で、上側ホルダ1に接合して、上側ホルダ1の下端の開口を閉塞させるように、下端壁2Aと筒状の周壁2Bとで空間部を有し、これら下端壁2Aおよび周壁2Bは合成樹脂材でできており、その素材は上側ホルダ1の上端壁1A、周壁1Bおよび環状壁1Cと同じ素材が例示できる。下端壁2Aのほぼ中央の部位には、正極端子接続部7Aおよび負極端子接続部8Aに接続された電池100の電極端子である正極端子7および負極端子8が図5に示すように設けられており、正極端子7および負極端子8はそれぞれ上端壁1Aの正極端子7および負極端子8と正極および負極の対になるように並設されている。この場合、負極端子8については、下端壁2Aの上面(上側ホルダ1の電池収容室5に対面する面)に形成された電池接触負極板8Bを介して負極端子接続部8Aに接続されている。また、下端壁2Aには、中央の部位から離れた部位、すなわち、これら正極端子7および負極端子8から離れた部位には、複数個の流出ガイド孔2Cが形成されている。On the other hand, in FIG. 1, FIG. 2 and FIG. 5, the

さらに、下端壁2Aには、中央の部位から離れた部位、すなわち、正極端子7および負極端子8から離れた部位には、冷却液を流路6から流出させる流出部4が形成されている。この流出部4は、流出路4Bと、この流出路4Bと連通した周壁2Bの外方向に突出した流出口4Aとからなる。この流出路4Bは、合成樹脂材の下端壁2Aに埋設するように一体に成形可能な金属材でできた中空管で、各流路6から冷却液を流出させるように流出ガイド孔2Cと連通した流出孔4Cが形成されている。従って、冷却液は、電池収容室5の内部に流出入されないので、冷却液が電池100の正極の電極端子100Aおよび負極の電極端子100Bに接触しないようにすることができる。Furthermore, the

次に、図7から図9を参照して、上側ホルダ1と下側ホルダ2とを接合して電池ケースを形成する手順を以下、説明する。Next, a procedure for joining the

先ず、下端が開口した箱状で、上端壁1Aと筒状の周壁1Bとで空間部を有し、この空間部において複数個の筒状の環状壁1Cが直線状に配列するようにした形状の成形型を用意し、この成形型に合成樹脂材を充填するに際し、矢印A方向に複数個の筒状の電池収容室5、中空管状の流入路3B、正極端子接続部7Aおよび負極端子接続部8Aの金属材をインサートして射出成形して環状壁1Cと電池収容室5との間の流路形成空間部1Eを形成する。この場合、複数個の筒状の電池収容室5の一部、図では3個のうち、1番目および3番目には正極端子接続部7Aが形成されており、2番目(真中)には電池接触負極板8Bを介して負極端子接続部8Aが形成されている。また、これら正極端子接続部7Aおよび負極端子接続部8Aから離れた部位に流入ガイド孔1Dが形成されており、この流入ガイド孔1Dに連通して流入孔3Cを有する流入路3Bが上端壁1Aに埋設されている。次に、この流路形成空間部1Eに螺旋状に形成した螺旋状成形品を矢印B方向に挿入して筒状の電池収容室5の外周に装着することにより、上側ホルダ1が形成される。一方、下側ホルダ2においても、上端が開口した箱状で、下端壁2Aと筒状の周壁2Bとで空間部を有する形状の成形型に合成樹脂材を充填するに際し、矢印A方向に中空管状の流出路4B、正極端子接続部7Aおよび負極端子接続部8Aの金属材をインサートして射出成形して上側ホルダ1の3個の筒状の電池収容室5と対応してその1番目および3番目に電池接触負極板8Bを形成して下側ホルダ2が形成される。このようにして上側ホルダ1と下側ホルダ2とを用意して、この上側ホルダ1の電池収容室5に電池100を1番目および3番目においては正極が上方で、2番目(真中)においては正極が下方となるようにして矢印C方向に挿入させて後、下側ホルダ2の開口した上端を上側ホルダ1の開口した下端に矢印D方向に重合するようにして接着剤などで接合することにより、螺旋状の流路6を有し複数個の電池100が密閉して収容され電池ケースが得られる。この場合、電池100を交換するために電池100を着脱できるように、上側ホルダ1と下側ホルダ2との接合を接着剤や溶着などではなく取り外し可能なバンドなどをもちいてもよい。First, a box-like shape having an open lower end has a space portion between an upper end wall 1A and a cylindrical peripheral wall 1B, and a plurality of cylindrical annular walls 1C are linearly arranged in this space portion. When the mold is filled with a synthetic resin material, a plurality of cylindrical

次に、図1および図2を参照して、電池100を冷却する冷却液の流れ動作を以下、説明する。Next, with reference to FIG. 1 and FIG. 2, the flow operation of the cooling liquid for cooling the

冷却液については、冷却水を例示しており、この冷却液が流入部3の流入口3Aから上側ホルダ1の流入路3Bに流入されると、流入された冷却液は流入路3Bに形成された流入孔3C(図10参照)から流入ガイド孔1Dを経て各電池収容室5の流路形成空間部1Eにある螺旋状の流路6に流入されて、冷却液は螺旋状に流れて、下側ホルダ2の流出ガイド孔2Cから流出部4の流出孔4Cを経て流出路4Bに流れて流出口4Aから排出される。このような流入部3から流路6を経て流出部4に流れる冷却液は冷却液供給装置(図示せず)で循環され、冷却液は螺旋状の流路6により、各電池収容室5の外周に相当する流路形成空間部1Eに滞留することなく円滑に流れて各電池100が電池収容室5を介して効率よく冷却される。As for the cooling liquid, cooling water is illustrated, and when this cooling liquid flows into the inflow path 3B of the

(実施形態2)

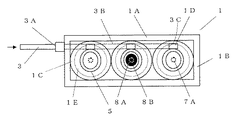

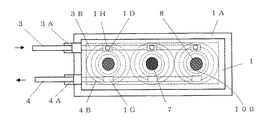

図11から図16は、本発明の実施形態2を示し、実施形態1と同様に電池ケースは箱状で、上側ホルダ1と下側ホルダ2とが接合されてできており、上側ホルダ1には冷却液を流路6に流入させる流入部3を有し、下側ホルダ2には流路6から冷却液を流出させる流出部4を有し、電池ケースに収容される電池101は実施形態1と異なり、長円筒形を例示する筒形のリチウムイオン電池などの二次電池で、正極の電極端子101Aおよび負極の電極端子101Bが上端に並設されている。(Embodiment 2)

FIGS. 11 to 16 show a second embodiment of the present invention. Like the first embodiment, the battery case has a box shape, and the

上側ホルダ1は、下端が開口した箱状で、上端壁1Aと筒状の周壁1Bとで空間部を形成し、この空間部には上端壁1Aの内面に複数個(図では3個)の筒状でその下端が開口した環状壁1Cが一直線状に形成されている。これら上端壁1A、周壁1Bおよび環状壁1Cは合成樹脂材で一体に形成されている。その合成樹脂材としては、ポリフェニレンサルファイド系樹脂、ポリエチレン系樹脂、ポリプロピレン系樹脂、ポリスチレン系樹脂、ポリカーボネート系樹脂、ポリ塩化ビニル系樹脂、ポリエチレンテレフタレート系樹脂、ポリブチレンテレフタレート系樹脂、ポリエチレンナフタレート系樹脂、ポリブチレンナフタレート系樹脂、フッ素系樹脂、ポリエーテルエーテルケトン系樹脂などの熱可塑性樹脂およびフェノール系樹脂やエポキシ系樹脂などの熱硬化性樹脂が例示できる。The

各筒状の環状壁1Cの内部には筒状の電池収容室5が上端壁1Aと一体に形成されている。この電池収容室5の素材は、実施形態1と同様に熱伝導性がよい素材で、例えばアルミニウム、銅、鉄などの金属材または前記金属材表面にニッケル膜形成などの表面処理をした金属材またはステンレスなどの金属材であり、また、形状は、電池101を収容する大きさで、図においては、長円筒形の電池を例示しているので、長円筒状で、上端壁1Aと一体に成形されている。電池収容室5の外周において、環状壁1Cとの間の流路形成空間部1Eには下端方向に螺旋状に延びる流路6が形成されている。流路6を螺旋状に形成するには、実施形態1と同様な方法で、例えば、フッ素系樹脂などの合成樹脂材やアルミニウムやステンレスなどの金属材を螺旋状に形成した螺旋状成形品を電池収容室5の外周の流路形成空間部1Eに装着すればよい。また、上端壁1A、周壁1Bおよび環状壁1Cを合成樹脂材とし、金属材の電池収容室5と一体に成形するに際し、図16に示すように、上端壁1Aに電池収容室5と連通した一対の端子貫挿孔1F、1Fを成形型で形成させる。その結果、電池101を電池収容室5に収容する際に、図11に示すように各電池収容室5の上端面の部位の端子貫挿孔1F、1Fのそれぞれに電池101の正極の電極端子101Aおよび負極の電極端子101Bを貫挿して上端壁1Aの外部に突出させ、ボルト締めなどで接続固定されてそれぞれ正極端子9および負極端子10を形成する。A cylindrical

さらに、上端壁1Aには、ほぼ中央の部位で端子貫挿孔1F、1Fの間、すなわち、正極端子9と負極端子10との間に冷却液を流路6に流入させる流入部3が形成されている。この流入部3は、流入路3Bと流入口3Aとからなり、流入口3Aは流入路3Bに連通して上端壁1Aで周壁1Bの外方向に突出して形成されている。この流入路3Bは、合成樹脂材の上端壁1Aに埋設するように一体に成形可能な金属材でできた中空管でできている。この場合、流入路3Bを合成樹脂材の上端壁1Aに埋設するには、上端壁1Aと筒状の周壁1Bとで空間部を有し、この空間部において複数個の筒状の環状壁1Cが直線状に配列するようにした形状の成形型を用意し、この成形型に合成樹脂材を充填するに際し、複数個の筒状の電池収容室5および中空管状の流入路3Bの金属材をインサートして射出成形して得られる。また、流入路3Bは、実施形態1と同様で図10に示すように、複数個の流入孔3Cが形成されて各流路6に冷却液を流入させるようにしている。流入孔3Cの部位には流入路3Bの内壁面が部分的に突出されるように流入路3Bを局所的に狭窄する絞り部3Dが形成されることにより、冷却液を流路6に流入しやすくして、この流入路3Bの流入孔3Cと連通した流入ガイド孔1Dが上端壁1Aで各電池収容室5の上端面の部位に形成されている。従って、冷却液は、電池収容室5の内部に流入されないので、電池101の正極の電極端子101Aおよび負極の電極端子101Bが冷却液と接触しないようにすることができる。Further, the upper end wall 1A is formed with an

一方、下側ホルダ2は、上端が開口した箱状で、上側ホルダ1に接合して、上側ホルダ1の下端の開口を閉塞させるように、下端壁2Aと筒状の周壁2Bとで空間部を有し、これら下端壁2Aおよび周壁2Bは合成樹脂材でできており、その素材は上側ホルダ1の上端壁1A、周壁1Bおよび環状壁1Cと同じ素材が例示できる。下端壁2Aのほぼ中央の部位には、複数個の流出ガイド孔2Cおよび冷却液を流路6から流出させる流出部4が形成されている。この流出部4は、流出路4Bと、この流出路4Bと連通した周壁2Bの外方向に突出した流出口4Aとからなる。流出路4Bは、合成樹脂材の下端壁2Aに埋設するように一体に成形可能な金属材でできた中空管でできている。この場合、流出路4Bを合成樹脂材の下端壁2Aに埋設するには、下端壁2Aと筒状の周壁2Bとで空間部を有する形状の成形型に合成樹脂材を充填するに際し、中空管状の流出路4Bの金属材をインサートして射出成形して得られる。流出路4Bには、各流路6から冷却液を流出させるように流出ガイド孔2Cと連通した流出孔4Cが形成されている。従って、冷却液は、電池収容室5の内部に流出入されないので、電池101の正極の電極端子101Aおよび負極の電極端子101Bが冷却液と接触しないようにすることができる。On the other hand, the

上側ホルダ1と下側ホルダ2とにおいて、下側ホルダ2の開口した上端を上側ホルダ1の開口した下端に重合するようにして実施形態1と同様に接着剤やバンドなどで接合することにより、上側ホルダ1の下端の開口を閉塞させるようにして、螺旋状の流路6を有し複数個の電池101を収容した電池ケースが得られ、冷却水を例示する冷却液が流入部3の流入口3Aから上側ホルダ1の流入路3Bに流入されると、流入された冷却液は流入路3Bに形成された流入孔3C(図10参照)から流入ガイド孔1Dを経て各電池収容室5の流路形成空間部1Eにある螺旋状の流路6にて冷却液は螺旋状に流れて下側ホルダ2の流出ガイド孔2Cから流出部4の流出孔4Cを経て流出路4Bに流れて流出口4Aから排出される。その際、流入部3および流出部4は冷却液供給装置(図示せず)で循環されて、各電池収容室5を介して各電池101を効率よく冷却することができる。In the

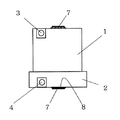

(実施形態3)

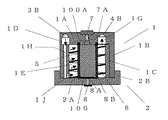

図17から図21は、本発明の実施形態3を示し、電池ケースは箱状で、上側ホルダ1と下側ホルダ2とが接合されてできており、上側ホルダ1には冷却液を流入させる流入部3および冷却液を流出させる流出部4とを有し、電池ケースに収容される電池100は実施形態1と同じ円筒形を例示する筒形のリチウムイオン電池などの二次電池で、正極の電極端子100Aおよび負極の電極端子100Bがそれぞれ上端および下端に設けられているが、流入部3および流出部4の部位が実施形態1と異なり、以下、説明する。(Embodiment 3)

FIGS. 17 to 21

図17、図18および図19はそれぞれ冷却装置の正面図、側面図および平面であり、上側ホルダ1には、流入部3および流出部4が形成されており、実施形態1とは異なり、下側ホルダ2には流出部4が形成されていない。図20および図21は、それぞれ冷却装置の側面部位の断面図および正面部位の断面図であり、上側ホルダ1は下端が開口した箱状で、その素材は、実施形態1と同じ合成樹脂材でできており、上端壁1Aと筒状の周壁1Bとで空間部を形成し、この空間部には上端壁1Aの内面に複数個(例えば3個)の筒状でその下端が開口した環状壁1Cが一直線状に形成されている。各筒状の環状壁1Cの内部には上下端が開口した筒状の電池収容室5が実施形態1と同様な素材および形状で上端壁1Aと一体に形成されており、各電池収容室5と環状壁1Cとの間は流路形成空間部1Eとなる。上側ホルダ1には、実施形態1と異なり、流入路3Bおよび流出路4Bが設けられている。周壁1Bおよび環状壁1Cとの間には貫通孔でできた注入路1Hが形成されており、この注入路1Hは、上端が上側ホルダ1の流入ガイド孔1Dと連通して下側ホルダ2の方向に延び、下端が下側ホルダ2で閉塞されている。さらに、この注入路1Hの下端には流路形成空間部1Eと連通した孔部1Jが形成されている。この流路形成空間部1Eには実施形態1と同様な螺旋状成形品でできた流路6が形成されており、この螺旋状成形品の螺旋形状は実施形態1とは逆方向で上側方向に延びて、孔部1Jから流入された冷却液が下側ホルダ2の方向から上側ホルダ1の方向に流れて流出ガイド孔1Gから流出されるように形成されている。また、各電池収容室5の内部の上端面のほぼ中央の部位にはアルミニウムや銅などの金属材でできた正極端子接続部7Aまたは負極端子接続部8Aが形成されている。そのうち、負極端子接続部8Aについては、電池収容室5の上端面の内面に電池接触負極板8Bが形成されている。従って、流入路3Bおよび流出路4Bは上端壁1Aにおいて正極端子7および負極端子8から離れた部位に形成されている。なお、電極端子100Aおよび電極端子100Bはそれぞれ正極および負極を例示しているが、アルミニウム材の筒形のリチウムイオン電池においては、負極の電極端子100Aおよび正極の電極端子100Bである。FIGS. 17, 18 and 19 are a front view, a side view and a plan view of the cooling device, respectively, and the

一方、下側ホルダ2は、上端が開口した箱状で、上側ホルダ1に接合して、上側ホルダ1の下端の開口を閉塞させるように、下端壁2Aと筒状の周壁2Bとで空間部を有し、これら下端壁2Aおよび周壁2Bは合成樹脂材でできており、その素材は上側ホルダ1の上端壁1A、周壁1Bおよび環状壁1Cと同じ素材が例示できる。下端壁2Aの部位には、正極端子接続部7Aおよび負極端子接続部8Aに接続された電池100の電極端子である正極端子7および負極端子8が設けられており、正極端子7および負極端子8はそれぞれ上端壁1Aの正極端子7および負極端子8と正極および負極の対になるように並設されている。この場合、負極端子8は、下端壁2Aの上面(上側ホルダ1の電池収容室5に対面する面)に形成された電池接触負極板8Bを介して負極端子接続部8Aに接続されている。On the other hand, the

このように形成された上側ホルダ1と下側ホルダ2とを実施形態1と同様に接着剤や溶着または取り外し可能なバンドなどで接合することにより、螺旋状の流路6を有し複数個の電池100が収容された電池ケースが得られ、冷却液が流入ガイド孔1Dから注入路1Hに流れ、孔部1Jから矢印で示すように流路6に流入し、流出ガイド孔1Gに流出することにより、この流路6は螺旋状であるので、冷却液が滞留することなく円滑に流れて、各電池収容室5を介して各電池100を効率よく冷却することができる。しかも、冷却液が各電池収容室5の内部に流出入しないので、各電池の電極端子100A、100Bが冷却液と接触しないようにすることができ、さらに、流入路3Bおよび流出路4Bは上側ホルダ1に並設されているので、下側ホルダ2に流出路4Bを設けるスペースを必要とせず、コンパクトな冷却装置を提供することができる。The

なお、この実施形態3においては冷却液が流入路3Bのある上側ホルダ1の流入ガイド孔1Dから下側ホルダ2の方向に流入し、下側ホルダ2の上面から螺旋状の流路6を経て流出ガイド孔1Gから上側ホルダ1にある流出路4Bに流出するようにするために注入路1Hを使用しているが、このような注入路1Hに代えて、上側ホルダ1の流入ガイド孔1Dから直接、流路形成空間部1Eに冷却液を流入させてもよい。例えば、図示しないが、冷却液が流入ガイド孔1Dから螺旋状の流路6に流入させ、流出ガイド孔1Gに流出されるように、螺旋状の流路6を上方(上側ホルダ1の位置)から下方(下側ホルダ2の位置)に螺旋状に冷却液が流れるようにし、続いて、冷却液が下方(下側ホルダ2の位置)から折り返して上方(上側ホルダ1の位置)に螺旋状に冷却液が流れるように形成してもよい。In the third embodiment, the coolant flows in the direction of the

本発明において上側ホルダ1および下側ホルダ2は上下方向の位置が逆でもよいし、左右方向の位置でもよい。また、上記実施形態1、2および3において、上側ホルダ1および下側ホルダ2が何れも筒状の周壁1B、2Bを有し、一端が開口した箱状を示すが、何れか一方が筒状の周壁1B、2Bを有せず、上端壁1Aもしくは下端壁2Aのみで上側ホルダ1と下側ホルダ2との組み合わせにより箱状としてもよい。In the present invention, the

本発明の冷却装置は、電池ケースには電池パックまたは組電池となるように複数個の電池を収容して各電池を冷却することができるように冷却液の流路を有しているので、リチウムイオン電池などの二次電池を複数個接続して大電力を必要とする自動車等のモータ駆動用電源装置の冷却として利用できる。The cooling device of the present invention has a coolant flow path so that the battery case can accommodate a plurality of batteries so as to become a battery pack or a battery pack and cool each battery. A plurality of secondary batteries such as lithium ion batteries can be connected to cool a power supply device for driving a motor such as an automobile that requires high power.

1 上側ホルダ

2 下側ホルダ

3 流入部

4 流出部

5 電池収容室

6 流路DESCRIPTION OF

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014023798A JP6233781B2 (en) | 2014-01-23 | 2014-01-23 | Cooling system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014023798A JP6233781B2 (en) | 2014-01-23 | 2014-01-23 | Cooling system |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015138773A JP2015138773A (en) | 2015-07-30 |

| JP2015138773A5 JP2015138773A5 (en) | 2017-02-09 |

| JP6233781B2 true JP6233781B2 (en) | 2017-11-22 |

Family

ID=53769619

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014023798A Active JP6233781B2 (en) | 2014-01-23 | 2014-01-23 | Cooling system |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6233781B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109599640A (en) * | 2018-11-27 | 2019-04-09 | 南京航空航天大学 | A kind of cylindrical power battery mould group liquid thermal management scheme |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017065762A1 (en) * | 2015-10-14 | 2017-04-20 | Covestro Llc | Phosphazene modified polycarbonate molded battery cooling device |

| KR102066701B1 (en) | 2016-03-03 | 2020-01-15 | 주식회사 엘지화학 | Battery pack case improved in coolong performance |

| WO2018025559A1 (en) * | 2016-08-02 | 2018-02-08 | パナソニックIpマネジメント株式会社 | Battery cover and battery pack |

| DE102017128878A1 (en) * | 2017-12-05 | 2019-06-06 | Schaeffler Technologies AG & Co. KG | Battery module and module housing |

| JP7137360B2 (en) * | 2018-06-04 | 2022-09-14 | 株式会社Subaru | battery module |

| CN108767371B (en) * | 2018-08-16 | 2023-08-25 | 南京工程学院 | Automotive battery thermal management system for liquid medium |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3493896B2 (en) * | 1996-04-25 | 2004-02-03 | トヨタ自動車株式会社 | Fuel cell and fuel cell system |

| FR2833759B1 (en) * | 2001-12-13 | 2004-02-27 | Cit Alcatel | ELECTROCHEMICAL GENERATOR MODULE |

| DE10223782B4 (en) * | 2002-05-29 | 2005-08-25 | Daimlerchrysler Ag | Battery with at least one electrochemical storage cell and a cooling device and use of a battery |

| JP2005285454A (en) * | 2004-03-29 | 2005-10-13 | Sanyo Electric Co Ltd | Power supply apparatus |

| CN102362388B (en) * | 2009-11-25 | 2013-09-25 | 松下电器产业株式会社 | Battery module |

| WO2012069054A1 (en) * | 2010-11-25 | 2012-05-31 | Danfoss Drives A/S | An energy transfer device |

| JP2014194906A (en) * | 2013-03-29 | 2014-10-09 | Fuji Heavy Ind Ltd | Cooling structure of battery module and cooling structure of battery pack |

-

2014

- 2014-01-23 JP JP2014023798A patent/JP6233781B2/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109599640A (en) * | 2018-11-27 | 2019-04-09 | 南京航空航天大学 | A kind of cylindrical power battery mould group liquid thermal management scheme |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015138773A (en) | 2015-07-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6233781B2 (en) | Cooling system | |

| JP6374603B2 (en) | Battery pack | |

| JP6254658B2 (en) | Battery module | |

| CN111971815B (en) | Battery cell comprising a built-in temperature control device | |

| JP5294575B2 (en) | Pack battery and manufacturing method thereof | |

| US10236546B2 (en) | Method for producing a plate-shaped heat exchanger, plate-shaped heat exchanger, and assembly comprising plate-shaped heat exchangers | |

| WO2016059751A1 (en) | Battery pack | |

| JP6407997B2 (en) | Battery pack and manufacturing method thereof | |

| KR101608853B1 (en) | Frame for secondary battery and battery module including the same | |

| JP2014078471A (en) | Secondary battery and secondary battery system | |

| JP2011049011A (en) | Battery pack | |

| CN112204808A (en) | Battery unit with temperature control device integrated into housing | |

| JP2011083744A (en) | Ion exchanger of cooling water supply device | |

| JP2020500409A (en) | Battery module | |

| JP2014082069A (en) | Temperature control bag and temperature control system | |

| JP6017139B2 (en) | battery | |

| JP2019504448A (en) | Secondary battery cartridge and battery module including the same | |

| JP2012043767A (en) | Energy conservation device module | |

| JP2014194906A (en) | Cooling structure of battery module and cooling structure of battery pack | |

| KR20140147979A (en) | Frame for secondary battery and battery module including the same | |

| CN105684189A (en) | Hollow type secondary battery and connector for hollow type secondary battery | |

| JP2016103378A (en) | Battery pack | |

| JP2022529795A (en) | Battery module including cell frame | |

| JP6244646B2 (en) | Heat exchanger | |

| TWI765076B (en) | Battery packs and power batteries |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161201 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20161201 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170926 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20171010 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20171016 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6233781 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |