JP5889715B2 - Method of raising washing machine on waterproof pan and raising platform with rod - Google Patents

Method of raising washing machine on waterproof pan and raising platform with rod Download PDFInfo

- Publication number

- JP5889715B2 JP5889715B2 JP2012117191A JP2012117191A JP5889715B2 JP 5889715 B2 JP5889715 B2 JP 5889715B2 JP 2012117191 A JP2012117191 A JP 2012117191A JP 2012117191 A JP2012117191 A JP 2012117191A JP 5889715 B2 JP5889715 B2 JP 5889715B2

- Authority

- JP

- Japan

- Prior art keywords

- washing machine

- waterproof pan

- raising

- row

- pedestal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005406 washing Methods 0.000 title claims description 92

- 238000000034 method Methods 0.000 title claims description 17

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 claims description 49

- 238000012423 maintenance Methods 0.000 description 14

- 238000004140 cleaning Methods 0.000 description 8

- 238000009434 installation Methods 0.000 description 5

- 238000007689 inspection Methods 0.000 description 4

- 235000008429 bread Nutrition 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 210000001364 upper extremity Anatomy 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Landscapes

- Main Body Construction Of Washing Machines And Laundry Dryers (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

Description

本発明は、防水パン上に設置された洗濯機を、該防水パンの上方に移動させておくための防水パン上の洗濯機の嵩上げ方法に関する。 The present invention relates to a method for raising a washing machine on a waterproof pan for moving a washing machine installed on the waterproof pan above the waterproof pan.

近年の集合住宅事情では、設備機器の設置用に充てるスペースを縮小し、その縮小分を室内空間の拡大用に充てる傾向にあって、設備機器の一つである洗濯機の設置スペースも縮小されている。 In recent apartment housing circumstances, there is a tendency to reduce the space allocated for installation of equipment and use the reduced portion for expansion of indoor space, and the installation space for washing machines, one of the equipment, has also been reduced. ing.

そして、洗濯機の設置スペースに設置されて階下への漏水を防止するための防水パンにおいても、縮小された洗濯機の設置スペースに対応するよう縮小されている。 And the waterproof pan installed in the installation space of the washing machine to prevent water leaking downstairs is also reduced to correspond to the reduced installation space of the washing machine.

これにより、防水パンに備える排水管内の臭気の逆流を防止するための排水トラップが、防水パンの四隅に設けられる洗濯機の脚を載せる台座を避けて、防水パンの中央付近に移っている。 Thereby, the drain trap for preventing the reverse flow of the odor in the drain pipe provided in the waterproof pan has moved to the vicinity of the center of the waterproof pan, avoiding the pedestal on which the legs of the washing machine provided at the four corners of the waterproof pan are placed.

したがって、排水トラップやこれに接続する排水管の手入れや点検洗浄等のメンテナンスを行う場合には、防水パンの上から洗濯機を移動させて排水トラップの上方を空けてからでないとメンテナンスを行うことができなかった。 Therefore, when performing maintenance such as cleaning the drain trap and the drain pipe connected to it, checking and cleaning, etc., it is necessary to move the washing machine from the top of the waterproof pan and leave the top of the drain trap for maintenance. I could not.

しかしながら、防水パンの上から洗濯機を移動させるにしても、乾燥機能を備えるドラム式の洗濯機は重量が100kgになる機種もあり、そして、洗濯機の設置スペースも3方が壁に囲まれ、かつ洗濯機の外面と壁面との隙間が5cm以下の場所が多くあって、これらのことから、洗濯機の移動は少なくとも3人以上の作業者を必要とする非常に困難な作業となっていた。 However, even if the washing machine is moved from above the waterproof pan, some drum-type washing machines with a drying function can weigh up to 100kg, and the installation space for the washing machine is surrounded by three walls. In addition, there are many places where the gap between the outer surface and the wall surface of the washing machine is 5 cm or less, and for these reasons, the movement of the washing machine is a very difficult task requiring at least three workers. It was.

そして、集合住宅における排水管の洗浄作業は一棟まとめて実施するのが普通であり、しかも限られた予算の中で実施しなければならないため、作業人員や作業時間を簡単に増やすことができず、したがって、前述のような大重量の機種が設置されている場合には、防水パンの排水トラップやこれに接続する排水管の手入れや点検洗浄等のメンテナンスが実施できない事もあった。 In addition, it is common to carry out the cleaning work of drain pipes in an apartment house as a whole, and since it must be carried out within a limited budget, it is possible to easily increase the workforce and work time. Therefore, when a heavy-weight model as described above is installed, maintenance such as maintenance, inspection and cleaning of the drain pan trap of the waterproof pan and the drain pipe connected thereto may not be performed.

また、防水パンの上から洗濯機を移動させる場合、組み立て式のリフト装置を使用すれば1人での作業も可能ではあるが、被作業宅への該リフト装置の運び入れや作業場所での組み立て、且つ作業終了後の分解や運び出しの手間を考慮すると、リフト装置を使用しての洗濯機移動作業は非現実的であった。 In addition, when the washing machine is moved from the top of the waterproof pan, it is possible to work alone by using an assembly-type lift device. However, the lift device can be carried into the work house or at the work place. Considering the labor of assembling and disassembling and carrying out the work after completion of the work, the washing machine moving work using the lift device has been unrealistic.

他の方法としては、防水パン上から洗濯機を移動させずに洗浄用ホースの引き回し等によって排水トラップを洗浄する方法もあるが、この方法では、排水トラップは細い隙間を排水が流通する構造のため、該隙間から糸くずやゴミ等の撤去状態が確認できず洗浄が十分でない可能性もあり不安が残るものであった。 As another method, there is a method of cleaning the drain trap by moving a washing hose without moving the washing machine from the waterproof pan, but in this method, the drain trap has a structure in which drainage flows through a narrow gap. Therefore, the state of removal of lint, dust, etc. from the gap cannot be confirmed, and there is a possibility that the cleaning is not sufficient.

そして、上述するように3人以上の作業者を要して洗濯機を移動させる際も、該洗濯機の外面と壁面とが接近しているために洗濯機の外面と壁面とが接触して壁面を傷付けてしまう恐れがあり、いずれにしても、防水パンの排水トラップやこれに接続する排水管の手入れや点検洗浄等のメンテナンス作業は非常に困難であった。 As described above, when the washing machine is moved by requiring three or more workers, the outer surface and the wall surface of the washing machine are in contact with each other because the outer surface and the wall surface of the washing machine are close to each other. There is a risk of damaging the wall surface, and in any case, maintenance work such as maintenance, inspection and washing of the drain pan trap of the waterproof pan and the drain pipe connected thereto is very difficult.

本発明の目的とするところは、防水パンの排水トラップ上方にメンテナンスを行うに十分な空間が空けられるように、重い洗濯機でも1人乃至2人で防水パン上に設置された洗濯機を、該防水パンの上方に移動させておくための防水パン上の洗濯機の嵩上げ方法を提供できるようにすることにある。 The purpose of the present invention is to install a washing machine installed on the waterproof pan by one or two people even in a heavy washing machine so that a sufficient space for maintenance is provided above the drain trap of the waterproof pan. An object of the present invention is to provide a method for raising the washing machine on the waterproof pan for moving the waterproof pan above the waterproof pan.

上述した課題を解決するために、本発明に係る防水パン上の洗濯機の嵩上げ方法は、防水パンの前列および後列の台座に脚を載せた洗濯機の後列の脚を支点に背面側に傾けて洗濯機の前列の脚を防水パンの前列の台座の上方に浮かせ、次いで、防水パンの前列の台座上面と、防水パンの前方に置いた外部台座上面との間にブリッジを架けてこのブリッジ上に洗濯機の前列の脚を下ろし、次いで、洗濯機の前列の脚を支点にして洗濯機を前面側に傾けて防水パンの後列の台座に載る洗濯機の後列の脚を上方に浮かせて支持し、次いで、この支持状態のまま洗濯機の前列の脚を外部台座方向におけるブリッジ上の所定の位置まで移動させて保持し、次いで、防水パンの後列の台座位置にロッド付き嵩上げ台をセットし、次いで、ブリッジ上の洗濯機の前列の脚を略移動前の位置に後退させると共に洗濯機の後列の脚をロッド付き嵩上げ台上に下ろし、次いで、ロッド付き嵩上げ台上の洗濯機の後列の脚を支点に洗濯機を背面側に傾けて洗濯機の前列の脚をブリッジの上方に浮かせ、次いで、防水パンの前列の台座上からブリッジを撤去すると共に防水パンの前列の台座位置に嵩上げ台をセットし、次いで、この嵩上げ台上に洗濯機の前列の脚を下ろすことにより行うことを特徴とする防水パン上の洗濯機の嵩上げ方法であって、 ロッド付き嵩上げ台のロッドは、上方へ伸びているロッドであることを特徴とする。 In order to solve the above-described problem, the method for raising the washing machine on the waterproof pan according to the present invention is configured such that the legs of the rear row of the washing machine with the legs placed on the pedestal of the front row and the rear row of the waterproof pan are tilted to the back side. The front leg of the washing machine is floated above the pedestal of the front row of the waterproof pan, and then this bridge is bridged between the top of the pedestal of the front row of the waterproof pan and the top of the external pedestal placed in front of the waterproof pan. Lower the front row legs of the washing machine up, then tilt the washing machine to the front side with the front row legs of the washing machine as a fulcrum and lift the rear row legs of the washing machine on the back row base of the waterproof pan upward Next, move the front row leg of the washing machine to a predetermined position on the bridge in the direction of the external pedestal while maintaining this support state, and then set the lifting platform with the rod at the pedestal position on the back row of the waterproof pan And then washing on the bridge Lower the front row of the leg rear row of legs of the washing machine causes retracted position before substantially moved onto the raised platform with rods, then the washers back to fulcrum rear leg of the washing machine on the raised platform with rod Tilt to the side and lift the legs of the front row of the washing machine above the bridge, then remove the bridge from the pedestal of the front row of the waterproof pan and set the raised platform at the pedestal position of the front row of the waterproof pan, and then raise this raised level A method of raising a washing machine on a waterproof pan characterized by lowering a leg of the front row of the washing machine on a table, wherein the rod of the raising table with a rod is a rod extending upward Features .

そして、防水パンの前列および後列の台座に脚を載せた洗濯機の後列の脚を支点に背面側に傾けて洗濯機の前列の脚を防水パンの前列の台座の上方に浮かせる場合は、防水パンの前列の台座上面と洗濯機の前列の脚下面との間に、該台座上面と、防水パンの前方に置いた外部台座上面との間に架け渡すブリッジが進入できる隙間が生じる程度に浮かせればよい。 If the legs of the rear row of the washing machine with the legs placed on the front row and rear row of the waterproof pan are tilted to the back side with the legs of the rear row of the washing machine as fulcrums, the front row of the washing machine is floated above the front row of the waterproof pan. Float to the extent that a bridge can be inserted between the top surface of the pedestal in the front row of bread and the bottom surface of the legs in the front row of the washing machine between the top surface of the pedestal and the top surface of the external pedestal placed in front of the waterproof pan. Just do it.

上記、防水パンの台座上面と、防水パンの前方に置いた外部台座上面との間に架け渡すブリッジは、簡単に台座上面と外部台座上面から外れないように構成するのが望ましく、公知の形態や構造を利用すればよい。 The bridge spanning between the upper surface of the waterproof pedestal pedestal and the upper surface of the outer pedestal placed in front of the waterproof pan is preferably configured so as not to be easily detached from the upper surface of the pedestal and the upper surface of the external pedestal. And the structure can be used.

また、ブリッジと外部台座とを一体的に形成した専用の外部部材を用いてもよく、なお、このブリッジ一体形の外部台座を用いる場合は、本出願人が既に出願している洗濯機用の引き出し台(特許第5302906号)を用いることで、本発明に係る防水パン上の洗濯機の嵩上げをより安全に行うことができる。 Alternatively, it is also possible to use external member dedicated to integrally form the bridge and an external base, In the case of using this bridge integral external pedestal for a washing machine in which the present applicant has already filed By using the drawer stand (Japanese Patent No. 5302906) , the washing machine on the waterproof pan according to the present invention can be raised more safely.

また、嵩上げ台には、該嵩上げ台の上方に伸長するロッドを着脱自在に設けておくのが望ましく、これにより、嵩上げ台を室内の壁側となる防水パンの後列の台座位置にセットする際、ロッドを持って行うことにより容易にセットすることが可能になる。

なお、ロッドを該嵩上げ台に固定的に設ける場合は、ロッドを伸縮可能に構成するのが望ましい。

In addition, it is desirable that the raising base is provided with a detachable rod extending above the raising base, so that the raising base is set at the pedestal position in the rear row of the waterproof pan on the indoor wall side. It can be easily set by holding the rod.

In addition, when providing a rod fixedly to this raising base, it is desirable to comprise a rod so that expansion-contraction is possible.

そして、防水パンの台座位置に嵩上げ台をセットする場合は、該嵩上げ台を防水パンの台座上に重置可能に、もしくは、被装可能に構成すればよい。

上記、防水パンの台座上に重置可能な嵩上げ台とは、少なくとも台座上面に接する下面を有する形態のもので、防水パンの台座上面によって嵩上げ台が支持されるものである。

また、形状は特に限定するものではないが、台座の側壁たる立ち上がり面に回り込んで嵩上げ台のずれを抑制するためのガイドを設ける場合がある。

And when setting a raising base in the base position of a waterproof pan, what is necessary is just to comprise this raising base so that it can be placed on the base of a waterproof pan, or it can be equipped.

The raised platform that can be placed on the pedestal of the waterproof pan has a form having at least a lower surface in contact with the upper surface of the pedestal, and the raised platform is supported by the upper surface of the pedestal of the waterproof pan.

In addition, the shape is not particularly limited, but a guide may be provided to suppress the displacement of the raised base by going around the rising surface as the side wall of the base.

また、防水パンの台座に被装可能な嵩上げ台とは、少なくとも台座上面に接触乃至台座上面の上方に位置する天面部を有すると共に、防水パンの内底面に接触する底面を有する形態のもので、主に、防水パンの内底面によって嵩上げ台が支持されるものである。

また、形状は特に限定するものではないが、嵩上げ台の任意の部位に、台座の側壁たる立ち上がり面に回り込んで嵩上げ台のずれを抑制するためのガイドを設ける場合がある。

Further, the raised base that can be mounted on the base of the waterproof pan has at least a top surface portion that is in contact with or above the top surface of the base and a bottom surface that contacts the inner bottom surface of the waterproof pan. The raising base is mainly supported by the inner bottom surface of the waterproof pan.

Further, the shape is not particularly limited, but a guide may be provided at any part of the raising table so as to go around the rising surface that is the side wall of the pedestal and suppress the deviation of the raising table.

なお、上記嵩上げ台は、防水パンのそれぞれの台座ごとにセットする形態に形成したり、あるいは、後列の左右台座、前列の左右台座に一度にセットできる形態、例えば、左右台座を一体的に形成したり、さらには、嵩上げ台どうしを重ねることができるようにする場合がある。 In addition, the raising base is formed in a form that is set for each pedestal of the waterproof pan, or a form that can be set on the left and right pedestals in the rear row and the left and right pedestals in the front row, for example, integrally forming the left and right pedestals In some cases, the raising bases can be stacked one on another.

本発明の防水パン上の洗濯機の嵩上げ方法によれば、重い洗濯機でも1人乃至2人で、短時間且つ容易に防水パンの上方に移動させておくことができる。

これにより、この後に行う防水パンの排水トラップやこれに接続する排水管の手入れや点検洗浄等のメンテナンス作業の時間を充分に確保できる。

According to the method for raising the washing machine on the waterproof pan of the present invention, even a heavy washing machine can be moved by one or two people above the waterproof pan in a short time and easily.

As a result, it is possible to secure sufficient time for maintenance work such as the maintenance and inspection cleaning of the drain pan of the waterproof pan and the drain pipe connected thereto.

また、洗濯機を上方に移動させることで、該洗濯機前方のスペースをほぼ全てメンテナンススペースに使用できるので、近年の集合住宅事情で狭くなったランドリースペースでも十分にメンテナンス作業を行うことができ、安全に作業を行うことができる。 In addition, by moving the washing machine upward, almost all the space in front of the washing machine can be used as a maintenance space, so maintenance work can be sufficiently performed even in a laundry space that has become narrow due to recent housing complex circumstances. You can work safely.

また、洗濯機の嵩上げ作業に使用する部材もコンパクトに形成できるので、該部材の被作業宅への運び入れや運び出しも簡単にでき、メンテナンス作業を行う作業者の負担も軽減できる。 In addition, since the member used for raising the washing machine can be formed compactly, the member can be easily carried into and out of the work house, and the burden on the operator performing the maintenance work can be reduced.

さらに、自社において嵩上げ作業用の部材を保管する場合も、保管に必要なスペースが小なるスペースですむ。 In addition, when storing materials for raising work in-house, the space required for storage can be reduced.

以下、本発明に係る防水パン上の洗濯機の嵩上げ方法を、以下、添付図面に基づいて説明する。 Hereinafter, a method for raising a washing machine on a waterproof pan according to the present invention will be described with reference to the accompanying drawings.

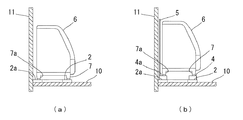

図1は、防水パンの一例を示していて、図中の符号1は、防水パンの本体、符号2は、洗濯機の前列に備える脚を載置するための前列の台座、符号2aは、洗濯機の後列に備える脚を載置するための後列の台座、符号3は、防水パンの内底に設けられた排水トラップである。

FIG. 1 shows an example of a waterproof pan. In the figure,

図2は、防水パンの前列および後列の台座2、2aにセットする嵩上げ台の一例を示していて、図中の符号4は、防水パンの前列の台座2にセットする嵩上げ台、符号4aは、防水パンの後列の台座2aにセットするロッド5を設けている嵩上げ台である。

また、本嵩上げ台4、4aは、防水パンの前列および後列の台座2、2aに重置するタイプのものである。

FIG. 2 shows an example of the raising base set on the

Further, the raised

以下、防水パンの前列および後列の台座2、2aに載置している洗濯機6の前列および後列の脚7、7aの下に嵩上げ台4、4aを入れて、洗濯機6を嵩上げする(図3中の(a)に示した状態から図3中の(b)に示した状態にする)本発明の嵩上げ方法を図4により説明する。

Hereinafter, the raising

洗濯機6は、図4中の(a)に示すように、防水パンの前列および後列の台座2、2aにそれぞれ前列の脚7と後列の脚7aが載っている。

なお、洗濯機6の前列の脚7とは、洗濯機6の前面側の左右端部寄りにそれぞれ配置される少なくとも2つの脚であり、また、洗濯機6の後列の脚7aとは、洗濯機6の背面側の左右端部寄りにそれぞれ配置される少なくとも2つの脚のことである。

As shown in FIG. 4A, the

The

まず、図4中の(b)に示すように、洗濯機6を、後列の脚7aを支点に背面側に傾けて、洗濯機6の前列の脚7を防水パンの前列の台座2の上方に浮かせる。

First, as shown in FIG. 4 (b), the

次いで、図4中の(c)に示すように、防水パンの前列の台座2上面と、防水パンの前方に置いた外部台座8の上面との間にブリッジ9を架け、図4中の(d)に示すように、このブリッジ9上に洗濯機6の前列の脚7を下ろす。

Next, as shown in FIG. 4 (c), a bridge 9 is laid between the upper surface of the

次いで、図4中の(e)に示すように、洗濯機6の前列の脚7を支点にして洗濯機6を前面側に傾けて防水パンの後列の台座2aに載る洗濯機6の後列の脚7aを上方に浮かせると共に洗濯機6を安定する傾き角度で支持する。

Next, as shown in FIG. 4 (e), the

次いで、図4中の(f)に示すように、この支持状態のまま洗濯機6の前列の脚7を外部台座8の方向におけるブリッジ9上の所定の位置まで移動させて保持する。

Next, as shown in (f) in FIG. 4, the

次いで、図4中の(g)に示すように、防水パンの後列の台座2a上に嵩上げ台4aをセットする。

Next, as shown in FIG. 4G, the raising

次いで、図4中の(h)に示すように、ブリッジ9上の洗濯機6の前列の脚7を略移動前の位置に後退させ、図4中の(i)に示すように、洗濯機6の後列の脚7aを嵩上げ台4a上に下ろす。

Next, as shown in FIG. 4 (h), the

次いで、図4中の(j)に示すように、嵩上げ台4a上の洗濯機の後列の脚7aを支点に洗濯機6を背面側に傾けて洗濯機6の前列の脚7をブリッジ9の上方に浮かせる。

Next, as shown in (j) in FIG. 4, the

次いで、図4中の(k)に示すように、防水パンの前列の台座2上からブリッジ9を撤去すると共に防水パンの前列の台座2上に嵩上げ台4をセットする。

Next, as shown in (k) in FIG. 4, the bridge 9 is removed from the

次いで、図4中の(l)に示すように、この嵩上げ台4上に洗濯機6の前列の脚7を下ろす。

Next, as shown in (l) in FIG. 4, the

以上の動作により、防水パンの前列および後列の台座2、2aに載置した洗濯機6を嵩上げすることができる。

With the above operation, the

そして、防水パンの排水トラップ3やこの排水トラップ3に接続する排水管(図示は省略)の手入れや点検洗浄等のメンテナンス作業が終了し、嵩上げ台4、4a上の洗濯機6を防水パンの前列および後列の台座2、2a上に戻す場合は、前述の嵩上げ動作と反対の動作をすることにより洗濯機6を防水パンの前列および後列の台座2、2a上に戻すことができる。

Then, maintenance work such as maintenance of the

図5は、防水パンの台座に被装可能に構成した嵩上げ台の一例を示したものであり、図5中の(a)は、防水パンの前列の台座2に被装する嵩上げ台4で、図5中の(b)は、防水パンの後列の台座2aに被装する嵩上げ台4aで、該嵩上げ台4aの上方に伸長するロッド5を設けているもので、また、図5中の(a)、(b)に示すものは、防水パンの後列の台座2aの正面向かって左側に被装するものである。

図5中の(c)は、嵩上げ台4、4aを防水パンの前列および後列の台座2、2aに被装した状態を示している。

FIG. 5 shows an example of a raised base that can be mounted on the base of the waterproof pan. FIG. 5A shows the raised

(C) in FIG. 5 shows a state in which the raising

また、防水パンの前列および後列の台座2、2a上が凹所状になっている場合は、例えば、適当なスペーサ部材を防水パンの前列の台座2の凹所内にセットするようにして、防水パンの前列の台座2の凹所にセットしたスペーサ部材の上面と、防水パンの前方に置いた外部台座8の上面との間に架け渡したブリッジ9が安定するようにすればよい。

When the front and

実施例における図中の符号10は、ランドリースペースの床、符号11は、ランドリースペースの壁である。

1…本体

2…前列の台座

2a…後列の台座

3…排水トラップ

4…嵩上げ台

4a…嵩上げ台

5…ロッド

6…洗濯機

7…前列の脚

7a…後列の脚

8…外部台座

9…ブリッジ

10…床

11…壁

DESCRIPTION OF

Claims (3)

上記ロッド付き嵩上げ台のロッドは、上方へ伸びているロッドであることを特徴とする、防水パン上の洗濯機の嵩上げ方法。 Tilt the back row of the washing machine with legs on the pedestal of the front and back rows of the waterproof pan to the rear side with the legs of the back row of the washing machine as a fulcrum, and then float the front row of the washing machine above the pedestal of the front row of the waterproof pan. A bridge is built between the upper surface of the pedestal in the front row and the upper surface of the outer pedestal placed in front of the waterproof pan, and the legs of the front row of the washing machine are lowered on the bridge. Tilt the machine to the front side to support the rear row legs of the washing machine on the pedestal in the rear row of the waterproof pan, and then support the legs of the front row of the washing machine on the bridge in the direction of the external pedestal in this supported state. Move to a predetermined position and hold it, then set the lifting platform with a rod in the rear row of the waterproof pan, and then move the front row leg of the washing machine on the bridge back to the position before the movement and wash the back row of the legs of the machine with the rod Lowered into the raised bench, then floated front row leg of the washing machine above the bridge washing machine fulcrum rear leg of the washing machine on the raised platform with the rod by tilting the back side, then the waterproof pan On the waterproof pan, the bridge is removed from the pedestal in the front row, a raising base is set at the pedestal position in the front row of the waterproof pan, and then the legs of the front row of the washing machine are lowered on the raising base. A method for raising the washing machine of

The method of raising a washing machine on a waterproof pan, wherein the rod of the raising platform with a rod is a rod extending upward .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012117191A JP5889715B2 (en) | 2012-05-23 | 2012-05-23 | Method of raising washing machine on waterproof pan and raising platform with rod |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012117191A JP5889715B2 (en) | 2012-05-23 | 2012-05-23 | Method of raising washing machine on waterproof pan and raising platform with rod |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013240545A JP2013240545A (en) | 2013-12-05 |

| JP2013240545A5 JP2013240545A5 (en) | 2015-12-10 |

| JP5889715B2 true JP5889715B2 (en) | 2016-03-22 |

Family

ID=49842054

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012117191A Active JP5889715B2 (en) | 2012-05-23 | 2012-05-23 | Method of raising washing machine on waterproof pan and raising platform with rod |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5889715B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5970634B2 (en) * | 2012-06-13 | 2016-08-17 | ヨコイテック株式会社 | Raising tools for washing machines |

| CN108239842B (en) * | 2016-12-26 | 2021-04-16 | 青岛胶南海尔洗衣机有限公司 | Clothes dryer stacking support |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3150645U (en) * | 2009-03-06 | 2009-05-28 | 東京電設サービス株式会社 | Safety belt support pole for scaffolding |

| JP5579399B2 (en) * | 2009-04-06 | 2014-08-27 | 新生産業株式会社 | Raising platform for washing machine in waterproof pan for washing machine installation |

| JP2011041745A (en) * | 2009-08-24 | 2011-03-03 | Toshiba Corp | Leg cover for washing machine |

| JP5302906B2 (en) * | 2010-01-21 | 2013-10-02 | 有限会社ベルテックス | Drawer base for washing machine and method for pulling out washing machine using this drawer base |

-

2012

- 2012-05-23 JP JP2012117191A patent/JP5889715B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013240545A (en) | 2013-12-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2015024047A (en) | Cleaning tool | |

| JP5302906B2 (en) | Drawer base for washing machine and method for pulling out washing machine using this drawer base | |

| KR20060005849A (en) | Domestic appliances having a stacking structure | |

| JP5889715B2 (en) | Method of raising washing machine on waterproof pan and raising platform with rod | |

| KR101142839B1 (en) | Working cage apparatus for construcion | |

| JP2013018618A (en) | Working platform device for inspection of equipment in hoistway | |

| JP5970634B2 (en) | Raising tools for washing machines | |

| JP4826847B2 (en) | Drum washing machine | |

| KR100817229B1 (en) | Lifting device for cone of electric generator and fabricating method thereof | |

| JP2013074922A (en) | Base and base assembly for support of article including the same | |

| JP5892442B2 (en) | Method and method for raising washing machine | |

| KR20190037971A (en) | Device for brick hoist | |

| KR20190001635A (en) | Moving type scaffold for boiler | |

| JP3204547U (en) | Raising platform of washing machine | |

| JP6598498B2 (en) | Washing machine lift device | |

| JP2013240545A5 (en) | ||

| JP5706228B2 (en) | Elevator equipment inspection workbench | |

| JP2011080334A (en) | Scaffold support base, scaffold, and method of renewing scaffold | |

| JP2007111480A (en) | Drum type washing machine | |

| JP6306464B2 (en) | How to install bathroom and bathtub | |

| JP3177081U (en) | Auxiliary tools used when moving furniture | |

| JP6302252B2 (en) | Building equipment mounting method and building manufacturing method | |

| KR102484487B1 (en) | Submerged foreign matter cleaning apparatus | |

| CN203699020U (en) | Hydraulic tray | |

| CN105098623A (en) | Power distribution cabinet with pedestal |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150421 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151022 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20151022 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20151118 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20151124 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160122 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20160209 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20160217 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5889715 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |