JP5462744B2 - Interceptor - Google Patents

Interceptor Download PDFInfo

- Publication number

- JP5462744B2 JP5462744B2 JP2010189882A JP2010189882A JP5462744B2 JP 5462744 B2 JP5462744 B2 JP 5462744B2 JP 2010189882 A JP2010189882 A JP 2010189882A JP 2010189882 A JP2010189882 A JP 2010189882A JP 5462744 B2 JP5462744 B2 JP 5462744B2

- Authority

- JP

- Japan

- Prior art keywords

- drainage

- trap

- plate

- container body

- box

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229940004975 interceptor Drugs 0.000 title 1

- 238000000926 separation method Methods 0.000 claims description 24

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 22

- 239000003921 oil Substances 0.000 claims description 14

- 238000007789 sealing Methods 0.000 claims description 9

- 239000003925 fat Substances 0.000 claims description 8

- 235000019645 odor Nutrition 0.000 claims description 8

- 230000005484 gravity Effects 0.000 claims description 5

- 238000007689 inspection Methods 0.000 claims description 5

- 238000004140 cleaning Methods 0.000 claims description 4

- 230000004888 barrier function Effects 0.000 claims description 3

- 241000251730 Chondrichthyes Species 0.000 claims 1

- 239000004519 grease Substances 0.000 description 23

- 238000005192 partition Methods 0.000 description 9

- 239000002351 wastewater Substances 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 239000003818 cinder Substances 0.000 description 2

- 235000014593 oils and fats Nutrition 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 239000004071 soot Substances 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 241000233866 Fungi Species 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 241000607479 Yersinia pestis Species 0.000 description 1

- 238000004378 air conditioning Methods 0.000 description 1

- 239000003657 drainage water Substances 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

Images

Landscapes

- Sewage (AREA)

Description

本発明は、排水に含まれる厨芥や土砂、油脂分を除去・分離する阻集器に関する。 The present invention relates to a interceptor that removes and separates dredging, earth and sand, and oil and fat contained in waste water.

近年、図4に示すようなシンダーコンクリート2内に収まり、床の防火区画を貫通することなく、施工時にスラブコンクリート3を開口する手間を省く施工性・リニューアル性にすぐれた浅型グリース阻集器の需要が増加している。

従来、この種のグリース阻集器は、四角い形状の容器本体6の一方側に排水流入部7を、他方に排水流出部8が形成されており、容器本体6内は、仕切板9、10によって、排水流入部7側を排水に含まれる厨芥を除去するバスケット11を設けた第一分離室A、中央部を水と油の比重差を利用して油脂分を浮上分離させる第二分離室B、排水流出部8側を第3分離室Cと区画し、各分離室を仕切板9、10の下方で連通させた構成を有している。

そして第3分離室C内には排水流出部8下流からの臭いや菌の発生・害虫(以下「臭い等」という)の逆流を封じるトラップ部12が構成されており、具体的には配管用90°エルボなどのトラップ管13を使用している。そしてトラップ管13の一方側を排水流出部8に接続し、他方の端をトラップ部の水位より下方になるように下向きに開口させたトラップ管入口13aとする(以下、第1従来例という)。

In recent years, a shallow grease interceptor that fits within the cinder concrete 2 as shown in FIG. Demand is increasing.

Conventionally, a grease interceptor of this type has a drainage inflow portion 7 formed on one side of a

In the third separation chamber C, there is a

また、図5に示すグリース阻集器では、第3分離室C内のトラップ管13の手前に容器本体6の幅一杯に堰板14を設けている。この堰板14を設けることにより第3分離室C内へ排水のみを越流させ、容器本体6の底に堆積する残さがトラップ部に入り込まないようにしている(以下、第2従来例という)。

Further, in the grease interceptor shown in FIG. 5, a

さらに、図6に示すグリース阻集器では、第3分離室内にトラップ管13の代わりに仕切板10側にトラップ板15を設け、排水流出部8側に容器本体6の幅一杯に堰板14を設けている。この構成では、トラップ板15の下端と堰板14の上端との高低差が封水深Dとなり、浅い容器本体においてもSHASE−S(空気調和・衛生工学会規格)等で定められる基準以上の封水深を保つことが容易となる。

しかしながら、トラップ板15から排水流出部8側のトラップ部上方が開放されるため、このままでは、下流の排水管側からの臭い等が厨房内に逆流してしまう。そこで、その対策として、図7に示すように、別途トラップ部上方全体をすきまなく覆う蓋部16を設ける。さらに、トラップ部内を点検・清掃できるように開閉可能な点検口を設けることが望ましいため、蓋部16には、蓋17や蝶番18、蓋17を密閉状に保持するためパッキン19や押え金具20などが取付けられる(以下、第3従来例という。特許文献1)。

Further, in the grease interceptor shown in FIG. 6, a

However, since the upper part of the trap part on the

上述した第1従来例によれば、トラップ管入口13aと容器本体6底面とのすき間が小さく、また狭いトラップ管入口13aで流速を増した排水の勢いで、容器本体6の底に堆積している残さが排水と一緒に流出する危険がある。また、トラップ管13は排水流出部8に固定されトラップ管入口13aは下方に開口しているため、トラップ管13内部を清掃するのは非常に難しい。

そこで、第1従来例の問題を解決するため、第2従来例のような堰板14を設けたグリース阻集器が存在するが、堰板14を超えた側の水位は排水流出部8の内径下面部と等しくなるため、この水位とトラップ管入口13aとの深さD(封水深)がSHASE−S等で求められる50mmぎりぎりかそれ以下になる危険性がある。

また、上述した第3従来例によれば、堰板14は容器本体6の幅一杯に設けられているため、この堰板14を越流する排水速度が抑えられ、第1従来例のものと比べて堆積している残さを吸い出すおそれが少ないという効果がある。しかし、通常、グリース阻集器の本体や仕切板・堰板はステンレスやFRPなどで製造され、前記蓋部を含めたトラップ部も本体に使われたものと同じ素材を用いることがほとんどであるため、トラップ部にポリ塩化ビニルなどで作られたエルボ管などのトラップ管を用いるよりも製造に手間もかかり製造コストが比較的高くなる。

According to the first conventional example described above, the gap between the trap tube inlet 13a and the bottom surface of the

Therefore, in order to solve the problem of the first conventional example, there is a grease interceptor provided with the

In addition, according to the above-described third conventional example, since the

したがって、本発明は、上述した問題点に鑑みなされたもので、その目的とするところは、浅型・小型の阻集器でも比較的大量の排水が処理でき、容器本体の底に堆積した残さが排水と一緒に流出せず、かつ清掃しやすい上に、製造も簡単で低コストなトラップ部を備えた阻集器を提供するところにある。 Therefore, the present invention has been made in view of the above-mentioned problems, and the object of the present invention is to treat a relatively large amount of wastewater even with a shallow and small interceptor, and to leave a residue deposited on the bottom of the container body. It is an object of the present invention to provide a trap with a trap part that does not flow out together with drainage, is easy to clean, is easy to manufacture, and is low-cost.

阻集器の容器本体に、少なくとも、排水が流れ込むバスケットを設けた第一分離室と、水と油の比重差を利用して油脂分を浮上分離させる第二分離室と、排水流出部下流からの臭い等の逆流を防ぐトラップ部とを備えた阻集器であって、前記トラップ部は、前記排水流出部に片持ちされ、封水深さDを持って前記排水流出部の下部よりも低く位置する下端が容器本体内の排水に浸かり前記排水流出部に排水を案内する囲繞形状であって、上端が前記排水流出部の下部よりも高く位置され、前記容器本体内の排水の標準水位面を決める堰板であって、前記堰板は排水流出部の内径より大きい幅を有することを特徴とする。 At least a first separation chamber provided with a basket into which drainage flows into the container body of the interceptor, a second separation chamber that floats and separates fats and oils using the difference in specific gravity between water and oil, A trap having a trap part for preventing a reverse flow of odor or the like, wherein the trap part is cantilevered by the drainage outflow part and is located lower than the lower part of the drainage outflow part with a sealing depth D The lower end is immersed in the drainage in the container body and has a surrounding shape that guides the drainage to the drainage outflow part, and the upper end is positioned higher than the lower part of the drainage outflow part, and determines the standard water level surface of the drainage in the container body A dam plate, characterized in that the dam plate has a width larger than the inner diameter of the drainage outflow portion .

本発明によれば、トラップ入口での局部的な流速の増大を抑える効果のある越流式の堰板を備えたコンパクトな箱型にしたことで、小型や浅型の阻集器でも比較的大量の排水が処理できるようになり、狭い業務用厨房にも、阻集効率の高い適正な阻集器を設置しやすくなる。 According to the present invention, a compact box shape having an overflow type weir plate that has an effect of suppressing an increase in local flow velocity at the trap inlet enables a relatively large amount of small and shallow type interceptors. Wastewater can be treated, and it becomes easy to install appropriate interceptors with high interception efficiency even in narrow commercial kitchens.

以下、本発明の実施の形態を図面に基づいて説明する。尚、図面において従来例と同一の符号で表示した部分は、同一又は相当の部分を示している。 Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the drawings, the parts indicated by the same reference numerals as those in the conventional example indicate the same or corresponding parts.

図1は、本実施例のグリース阻集器1が、厨房の床下などに埋設された状態を示すものである。グリース阻集器1は、建物内の防火区画を画すスラブコンクリート3を開口することなく表層部であるシンダーコンクリート2内に収まる深さを有しており、シンダーコンクリート2上に設けられた排水溝(又は排水管)4から流入してくる排水を受け入れるように設置されている。排水溝4やグリース阻集器1の上には、グレーチングや鋼鈑等の蓋部材5が設けられている。

FIG. 1 shows a state in which the grease interceptor 1 of this embodiment is buried under the floor of a kitchen. The grease interceptor 1 has a depth that can be accommodated in the cinder concrete 2 that is a surface layer portion without opening the slab concrete 3 that defines a fire prevention section in the building, and a drainage groove ( (Or drain pipe) 4 is installed so as to receive the waste water flowing in. On the drainage groove 4 and the grease interceptor 1, a

前記グリース阻集器1は、四角い形状の容器本体6の一方側に排水流入部7を、他方に排水流出部8が形成されており、容器本体6内は、仕切板9によって、排水流入部7側を排水に含まれる厨芥を除去するバスケット11を設けた第一分離室A、それに続いて水と油の比重差を利用して油脂分を浮上分離させる第二分離室Bとを有しており、分離室Aと分離室Bは、仕切板9の下方で連通している。

The grease interceptor 1 is formed with a drainage inflow portion 7 on one side of a square-

排水流出部8下流からの臭い等の逆流を封じるトラップ部12は、前記第二分離室内に設けられており、具体的には、図1〜図3に示すようにヒシャクをひっくり返したような箱体形状のトラップ21が排水流出部8に接続されており、厨芥や油脂分が取り除かれた排水が排水流出部8下流に案内される。

The

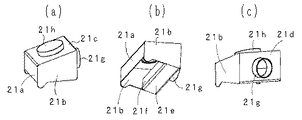

前記トラップ21は、仕切り板9に平面視平行に設けられた前板21a、前記前板21a両側に左右側板21b、上面には点検・清掃のための開口を有する天板21c、排水流出部8側には流出口を有する後板21d、前記後板21dとつながっている底板21eに囲まれた箱体である。さらに、前記底板21eの前方には堰板21fが側面視上方に向けて設けられており、堰板21fの上端は排水流出部8の下部よりも高く位置させて、前記左右側板21bと前記底板21eと後板21dとこの堰板21fとで囲まれた水溜部Pを形成する。

The

そして前記トラップ21は、トラップ21内に流れ込んだ排水を排水流出部8下流に案内する接続管21gを備え、排水流出部8に接続固定されている。

The

さて、前記前板21aの下端は、上流から流れてくる排水が箱体内に流れ込むように容器本体6底面より少し上方に位置しているが、前記左右側板21bは、接続管21gで片持ちされたトラップ21を支えるために前方下端部の一部を容器本体6の底面につけてトラップ21を支持させている。それ以外の左右側板21b下端は、前記前板21aと同様に上流から流れてくる排水がトラップ21内に流れ込むように容器本体6底面より少し上方に位置させているが、排水流出部8の下部よりも低く位置している。その位置は前板21aの下端高さと同じ高さであるとともに、前記水溜部Pを形成する底板21fの底面高さでもある。但し、前記水溜部Pの底面高さは前板21aの下端高さより低くてもかまわない。

Now, the lower end of the

前記堰板21f上端の高さは、グリース阻集器内に油脂分が浮上していない状態での水位である標準水位面WLを決め、ここを排水が越流して排水流出部8下流へ流れ出る。そして、前記堰板21f上端の高さと前記前板21a下端の高さの差が本実施例のグリース阻集器における封水深Dを決めるとともに、前板21aと左右側板21bと堰板21fとで囲まれた箇所で封水部SWを形成している。

The height of the upper end of the weir plate 21f determines a standard water level surface WL which is a water level in a state where no oil or fat has floated in the grease interceptor, and the drainage water flows over the

さらに、前記堰板21fの左右幅は排水流出部8の内径よりも広くすることが望ましい。堰板21fの左右幅が狭いと、前記封水部SWからトラップ21内に流入した排水の前記堰板21fを越流する速度が速くなり、分離室の底に堆積している残さや浮上分離されている油脂分を巻き込んで流出する危険があるため、少なくとも前記内径の1.5倍以上の幅を確保することにより、こうした問題を回避できる。

Furthermore, it is desirable that the left-right width of the dam plate 21f be wider than the inner diameter of the

グリース阻集器の容器本体6が小さいものしか設置できない狭い厨房であっても、前記堰板21fの幅が広いものを採用することにより、グリース阻集器の処理能力を向上させることができる。

Even in a narrow kitchen in which only a

前記トラップ21内を点検・清掃するための開口を設けた天板21cは点検・清掃しやすいように前板側に向かって低くなる斜面となっているが、もちろん傾斜をつけなくても構わない。さらに、前記開口には臭い等がトラップ部から漏れないようにキャップ21hが取付けられているが、キャップの形状や取付け方は周知の方法を選ぶことができる。

The

また、前記トラップ21は箱体に限らず、必要な封水深Dと標準水位面WLが確保でき、堰板を越流する排水の速度を抑えられる幅を有するものであれば、お椀のような形状をしたものも可能であり、容器本体6内の排水を排水流出部8下流へ排他的に案内する囲繞形状であればよい。また、本実施例では接続部21gで片持ちされているトラップ21を左右側板21b下端部の一部を容器本体6底につけて支持させているが、この支持部はその他の箇所に設けてもよい。

In addition, the

また、本実施例ではトラップ21を囲む外壁が第二分離室で浮上分離した油脂分を仕切る仕切板の役割を果たしているため、容器本体6内の仕切板を一枚のみとしたが、このような仕切板はニ枚以上であってもよい。

Further, in this embodiment, the outer wall surrounding the

また、前記トラップ21を、トラップ部にエルボ配管などのトラップ管を使用していた従来型のグリース阻集器のトラップ管と交換することもでき、この交換により、同じ大きさのグリース阻集器容器本体でありながら、阻集効率を向上させることができる。

Further, the

前記トラップ21はポリ塩化ビニルで形成することも可能であり、製造コストを抑えることができる。

The

実施例ではグリース阻集器を例に挙げて説明をしたが、オイル阻集器として使用することができ、同様の効果をあげることができる。 In the embodiment, the grease interceptor has been described as an example, but it can be used as an oil interceptor, and the same effect can be obtained.

1 グリース阻集器

6 容器本体

7 排水流入部

8 排水流出部

9 仕切板

11 バスケット

21 トラップ

21a 前板

21f 堰板

A 第一分離室

B 第二分離室

D 封水深

SW 封水部

WL 標準水位面

1 Grease

Claims (5)

前記トラップ部は、前記排水流出部に片持ちされ、封水深さDを持って前記排水流出部の下部よりも低く位置する下端が容器本体内の排水に浸かり前記排水流出部に排水を案内する囲繞形状であって、上端が前記排水流出部の下部よりも高く位置され、前記容器本体内の排水の標準水位面を決める堰板であって、前記堰板は排水流出部の内径より大きい幅を有することを特徴とする阻集器。

At least a first separation chamber provided with a basket into which drainage flows into the container body of the interceptor, a second separation chamber that floats and separates fats and oils using the difference in specific gravity between water and oil, A trap with a trap that prevents backflow of odors,

The trap part is cantilevered by the drainage outflow part, and a lower end positioned below the lower part of the drainage outflow part with a sealing depth D is immersed in the drainage in the container body to guide the drainage to the drainage outflow part. A dam plate having a top shape and an upper end positioned higher than a lower portion of the drainage outflow portion and determining a standard water level surface of the drainage in the container body, the dam plate having a width larger than an inner diameter of the drainage outflow portion The interceptor characterized by having .

前記トラップ部は、前記排水流出部に片持ちされ、封水深さDを持って前記排水流出部の下部よりも低く位置する下端が容器本体内の排水に浸かり前記排水流出部に排水を案内するヒシャクをひっくり返したような箱型形状もしくはお椀のような形状であって、上端が前記排水流出部の下部よりも高く位置され、前記容器本体内の排水の標準水位面を決める堰板であって、前記堰板は排水流出部の内径より大きい幅を有することを特徴とする阻集器。

At least a first separation chamber provided with a basket into which drainage flows into the container body of the interceptor, a second separation chamber that floats and separates fats and oils using the difference in specific gravity between water and oil, A trap with a trap that prevents backflow of odors,

The trap part is cantilevered by the drainage outflow part, and a lower end positioned below the lower part of the drainage outflow part with a sealing depth D is immersed in the drainage in the container body to guide the drainage to the drainage outflow part. It is a box shape or bowl-like shape that turns over the shark, and its upper end is positioned higher than the lower part of the drainage outflow part, and is a weir plate that determines the standard water level surface of the drainage in the container body. The barrier plate has a width larger than the inner diameter of the drainage outflow portion .

Cantilevered drainage outlet portion of the interceptor device, the seal water portion a box-shape as tipped human scepters lower ends positioned lower than the lower of the drainage outflow portion, the upper end of the drainage outflow portion And a weir plate positioned higher than the lower part of the box-type trap.

On the top surface of the box-shaped shape of the water-sealing part, there is a top plate provided with an openable / closable inspection port for inspection and cleaning, and the top plate is directed toward the front plate side of the box-shaped shape. The box-shaped trap according to claim 4, wherein the box-shaped trap has a lower slope.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010189882A JP5462744B2 (en) | 2010-08-26 | 2010-08-26 | Interceptor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010189882A JP5462744B2 (en) | 2010-08-26 | 2010-08-26 | Interceptor |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012046953A JP2012046953A (en) | 2012-03-08 |

| JP2012046953A5 JP2012046953A5 (en) | 2013-10-31 |

| JP5462744B2 true JP5462744B2 (en) | 2014-04-02 |

Family

ID=45902106

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010189882A Active JP5462744B2 (en) | 2010-08-26 | 2010-08-26 | Interceptor |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5462744B2 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101755113B1 (en) * | 2015-09-07 | 2017-07-06 | 남홍선 | Grease Trap |

| JP6795325B2 (en) * | 2016-04-16 | 2020-12-02 | ホーコス株式会社 | Blocker |

| JP6850519B2 (en) * | 2017-02-20 | 2021-03-31 | ホーコス株式会社 | Blocker |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000005778A (en) * | 1998-06-23 | 2000-01-11 | Sekisui Plant System Kk | Waste water treating apparatus |

| JP3060606U (en) * | 1998-12-28 | 1999-09-07 | ホーコス株式会社 | Grease trap |

-

2010

- 2010-08-26 JP JP2010189882A patent/JP5462744B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2012046953A (en) | 2012-03-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017208218A2 (en) | Grease interceptor and residue separator for catering wastewater | |

| JP4719261B2 (en) | Separation device | |

| JP5462744B2 (en) | Interceptor | |

| JP5065567B2 (en) | Solid-liquid separator | |

| JPS61412A (en) | Oil/water separator | |

| JP6795325B2 (en) | Blocker | |

| JP6768436B2 (en) | Drainage chamber | |

| KR101710061B1 (en) | Intercepting Chamber of Sewage Line | |

| CN110578407A (en) | Assembled integrated bathroom | |

| US10279284B2 (en) | Waste water separation vessel | |

| JP5069802B2 (en) | Sewage underground structure | |

| JP2012046953A5 (en) | ||

| CN211774415U (en) | Assembled integrated bathroom | |

| KR20050080171A (en) | The manhole which has an offensive odor interception function | |

| KR101342860B1 (en) | Drainpipe system | |

| JP3195658U (en) | Interceptor | |

| JP6688541B2 (en) | Drain trap, interceptor with drain trap | |

| KR20090003585A (en) | A drain trap | |

| JP6850519B2 (en) | Blocker | |

| JP2024087599A (en) | Interceptor | |

| KR20140003514U (en) | Drain apparatus for ocean structure | |

| CN211899842U (en) | Assembled integrated bathroom | |

| JP7344691B2 (en) | drainage structure | |

| KR101096795B1 (en) | Interceptor | |

| JP2019085728A (en) | Interceptor and trap tank |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20130619 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130620 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130621 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20130619 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130903 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130912 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20130912 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20131007 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20131022 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131212 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140114 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140117 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5462744 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |