JP5286959B2 - Cylindrical roller bearing - Google Patents

Cylindrical roller bearing Download PDFInfo

- Publication number

- JP5286959B2 JP5286959B2 JP2008158098A JP2008158098A JP5286959B2 JP 5286959 B2 JP5286959 B2 JP 5286959B2 JP 2008158098 A JP2008158098 A JP 2008158098A JP 2008158098 A JP2008158098 A JP 2008158098A JP 5286959 B2 JP5286959 B2 JP 5286959B2

- Authority

- JP

- Japan

- Prior art keywords

- raceway surface

- cylindrical roller

- roller bearing

- cage

- lubricant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Rolling Contact Bearings (AREA)

Description

本発明は、内輪と外輪との間に設けた保持器に複数の円筒ころを転動可能に配置している円筒ころ軸受に関する。 The present invention relates to a cylindrical roller bearing in which a plurality of cylindrical rollers are arranged so as to roll on a cage provided between an inner ring and an outer ring.

円筒ころ軸受は、内輪の外周面の略中央部に形成した軌道面と、外輪の内周面の略中央部に形成した軌道面との間に複数の円筒ころを転動可能に配置している。

上記円筒ころは、外輪と内輪との間に設けた保持器によって円周方向に沿って所定間隔に保持されている。具体的には上記保持器は軸方向に所定間隔離して対向配置した一対の環状部と、一対の環状部を軸方向に延びて連結する柱部とにより複数のポケットを形成してあり、このポケット内に各円筒ころを円周方向に沿って所定間隔に保持するようにしてある。

上記円筒ころ軸受として、上記各環状部の外周側に、外輪の内周面の軸方向両端部に摺接可能な案内部をそれぞれ設け、軸受の回転中に上記案内部が外輪の内周面に摺接することによって保持器の回転を案内するものが知られている(例えば、特許文献1参照)。

The cylindrical roller bearing is configured such that a plurality of cylindrical rollers can roll between a raceway surface formed at a substantially central portion of the outer peripheral surface of the inner ring and a raceway surface formed at a substantially central portion of the inner peripheral surface of the outer ring. Yes.

The cylindrical rollers are held at predetermined intervals along the circumferential direction by a cage provided between the outer ring and the inner ring. Specifically, the cage has a plurality of pockets formed by a pair of annular portions arranged opposite to each other in the axial direction and a column portion extending and connecting the pair of annular portions in the axial direction. Each cylindrical roller is held in the pocket at a predetermined interval along the circumferential direction.

As the cylindrical roller bearing, guide portions that can be slidably contacted with both axial end portions of the inner peripheral surface of the outer ring are provided on the outer peripheral side of each annular portion, and the guide portion is the inner peripheral surface of the outer ring during rotation of the bearing. A device that guides the rotation of the cage by sliding contact with is known (for example, see Patent Document 1).

しかし、上記円筒ころ軸受装置は、各案内部によって円筒ころが挟まれた状態となるので、外輪の軌道面上に供給されたグリースや潤滑油等の潤滑剤が保持器の軸方向外側へ移動するのが当該案内部により規制される。このため潤滑剤が軌道面上に滞留しやすく、この滞留する潤滑剤が円筒ころの転動抵抗となって軸受トルクが上昇し易いという問題があった。

上記潤滑剤の滞留を防止するために、案内部の外形を小さくして、案内部と上記軌道面との間に隙間を形成し、この隙間から潤滑剤を逃がすことが考えられる。しかし、この場合は上記隙間の存在によって保持器が偏心し易く、その回転を良好に案内することができなくなるという新たな問題が生じる。

本発明はこのような事情に鑑みてなされたものであり、保持器の回転を良好に案内することができるとともに、軌道面上に潤滑剤が滞留することに起因して軸受トルクが上昇するのを防止することができる円筒ころ軸受を提供することを目的とする。

However, the cylindrical roller bearing device is in a state in which the cylindrical roller is sandwiched between the guide portions, so that the lubricant such as grease or lubricating oil supplied on the raceway surface of the outer ring moves outward in the axial direction of the cage. This is regulated by the guide section. For this reason, there is a problem that the lubricant easily stays on the raceway surface, and the staying lubricant becomes a rolling resistance of the cylindrical roller and the bearing torque is likely to increase.

In order to prevent the lubricant from staying, it is conceivable that the outer shape of the guide portion is reduced to form a gap between the guide portion and the raceway surface, and the lubricant is allowed to escape from the gap. However, in this case, a new problem arises that the cage is likely to be eccentric due to the existence of the gap and the rotation cannot be guided well.

The present invention has been made in view of such circumstances, and can satisfactorily guide the rotation of the cage, and the bearing torque increases due to the retention of the lubricant on the raceway surface. It is an object of the present invention to provide a cylindrical roller bearing capable of preventing the above.

上記目的を達成するための本発明の円筒ころ軸受は、外周面に軌道面を有する内輪と、内周面に軌道面を有する外輪と、前記内輪の軌道面と外輪の軌道面との間に転動可能に配置された複数の円筒ころと、前記円筒ころを円周方向に沿って所定間隔に保持する保持器と、を備えた円筒ころ軸受において、前記保持器に、当該保持器の周面より突出し、前記内輪及び外輪のいずれか一方の軌道面に摺接して当該保持器の回転を案内するとともに、軌道面上の余剰潤滑剤を除去する案内片を周方向に沿って所定間隔毎に設け、前記案内片の軸方向両端部に、前記保持器の周面側から、前記軌道面と摺接する部分の軸方向中央に向かって傾斜するテーパ面が形成され、前記摺接する部分の軸方向全長が、前記軌道面の軸方向全長よりも短いことを特徴としている。 In order to achieve the above object, a cylindrical roller bearing of the present invention includes an inner ring having a raceway surface on an outer peripheral surface, an outer ring having a raceway surface on an inner peripheral surface, and a raceway surface of the inner ring and a raceway surface of the outer ring. In a cylindrical roller bearing comprising a plurality of cylindrical rollers arranged to be rollable and a cage for holding the cylindrical rollers at a predetermined interval along a circumferential direction, the cage is provided with a circumferential surface of the cage. A guide piece that protrudes from the surface and slides in contact with one of the inner race surface and the outer race surface to guide the rotation of the cage, and removes the excess lubricant on the raceway surface at predetermined intervals along the circumferential direction. Provided at both ends in the axial direction of the guide piece from the peripheral surface side of the cage, and tapered surfaces inclined toward the axial center of the portion in sliding contact with the raceway surface are formed. direction overall length, especially shorter than the axial length of said raceways It is set to.

上記のように構成された円筒ころ軸受によれば、案内片を内輪または外輪の軌道面に摺接させるようにしたので、保持器の回転を良好に案内することができる。また、保持器の回転に伴って軌道面上の余剰の潤滑剤を上記案内片によって除去することができる。しかも上記案内片が、保持器の周方向に沿って所定間隔毎に設けられているので、外輪又は内輪の軸方向両端部に余剰の潤滑剤を逃がすことができる。このため、軌道面上に余剰の潤滑剤が滞留することに起因して、軸受トルクが上昇するのを防止することができる。 According to the cylindrical roller bearing configured as described above, since the guide piece is brought into sliding contact with the raceway surface of the inner ring or the outer ring, the rotation of the cage can be guided well. In addition, surplus lubricant on the raceway surface can be removed by the guide piece as the cage rotates. And since the said guide piece is provided for every predetermined interval along the circumferential direction of a holder | retainer, an excess lubricant can be escaped to the axial direction both ends of an outer ring | wheel or an inner ring | wheel. For this reason, it is possible to prevent the bearing torque from increasing due to the excessive lubricant remaining on the raceway surface.

また、円筒ころ軸受の回転中に案内片が軌道面に対して軸方向のいずれか一方側に偏っても、軌道面の他方側には案内片が摺接しない領域すなわち潤滑剤を除去しない領域が常に存在することになるため、軌道面上に潤滑剤を適度に残留させることができる。このため、軌道面の軸方向全長に亘って余剰の潤滑剤を除去することによって潤滑剤の供給が不足し易い条件下でも、潤滑剤の供給不足が生じるのを回避することできるとともに、軌道面の軸方向における少なくとも一方側に残留させた潤滑剤が表面張力等により軌道面上に広がることで、円筒ころが転走する軌道面の内の転走面に、適度な量の潤滑剤を供給することができる。 In addition , even if the guide piece is biased to one side in the axial direction with respect to the raceway surface during the rotation of the cylindrical roller bearing, the region where the guide piece does not slide on the other side of the raceway surface, that is, the region where the lubricant is not removed. Therefore, the lubricant can be appropriately left on the raceway surface. For this reason, it is possible to avoid occurrence of insufficient supply of lubricant even under conditions where supply of lubricant is likely to be insufficient by removing excess lubricant over the entire axial length of the track surface, and the raceway surface. The lubricant remaining on at least one side in the axial direction of the roller spreads on the raceway surface due to surface tension, etc., so that an appropriate amount of lubricant is supplied to the rolling surface of the raceway surface on which the cylindrical roller rolls. can do.

また、上記案内片の上記軌道面と摺接する部分の軸方向全長は、上記円筒ころの軸方向全長よりも短いことが好ましい。この場合、円筒ころ軸受の回転中に円筒ころが転走する軌道面の内の転走面の軸方向における少なくとも一方側には、潤滑剤を除去しない領域が常に存在することになるため、転走面上に潤滑剤を適度に残留させることができる。このため、転走面の軸方向全長に亘って余剰の潤滑剤を除去することによって潤滑剤の供給が不足し易い条件下でも、潤滑剤の供給不足が生じるのを回避することができるとともに、転走面の軸方向における少なくとも一方側に残留させた潤滑剤を円筒ころが転動により引き伸ばすことで、適度な量の潤滑剤を転走面に供給することができる。 Moreover, it is preferable that the axial direction full length of the part which slidably contacts with the said track surface of the said guide piece is shorter than the axial direction full length of the said cylindrical roller. In this case, a region where the lubricant is not removed always exists on at least one side in the axial direction of the rolling surface of the raceway surface on which the cylindrical roller rolls during rotation of the cylindrical roller bearing. The lubricant can be left moderately on the running surface. For this reason, it is possible to avoid the occurrence of insufficient supply of lubricant even under conditions where supply of lubricant is likely to be insufficient by removing excess lubricant over the entire axial length of the rolling surface, An appropriate amount of lubricant can be supplied to the rolling surface by the cylindrical roller extending the lubricant remaining on at least one side in the axial direction of the rolling surface by rolling.

また、上記案内片は上記軌道面に線接触していることが好ましい。この場合、案内片の摺接抵抗を小さくすることができるため、保持器の案内部が面接触する従来の円筒ころ軸受に比べて軸受トルクを減少させることができる。

また上記案内片の先端部に上記軌道面上の潤滑剤を溜める窪みを有することが好ましい。この場合、上記窪み内に潤滑剤を一時的に溜めておくことができるため、潤滑剤の供給が不足し易い条件下でも、窪み内の潤滑剤を供給することができ、潤滑剤の供給不足を防止することができる。

Further, it is preferable that the guide piece is in line contact with the raceway surface. In this case, since the sliding contact resistance of the guide piece can be reduced, the bearing torque can be reduced as compared with the conventional cylindrical roller bearing in which the guide portion of the cage is in surface contact.

Moreover, it is preferable to have the hollow which accumulate | stores the lubricant on the said track surface in the front-end | tip part of the said guide piece. In this case, since the lubricant can be temporarily stored in the recess, the lubricant in the recess can be supplied even under conditions where the supply of the lubricant is likely to be insufficient, and the supply of lubricant is insufficient. Can be prevented.

本発明の円筒ころ軸受によれば、案内片により保持器の回転を良好に案内しつつ、余剰潤滑剤が軌道面に滞留することに起因して軸受トルクが上昇するのを防止することができる。 According to the cylindrical roller bearing of the present invention, it is possible to prevent the bearing torque from increasing due to the excess lubricant remaining on the raceway surface while guiding the rotation of the cage satisfactorily by the guide piece. .

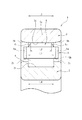

次に、本発明の好ましい実施形態について添付図面を参照しながら説明する。図1は本発明の第1の実施形態に係る内輪鍔付きタイプの円筒ころ軸受を示す断面図である。

図1において、円筒ころ軸受1は、図示しない回転軸に固定される内輪2と、図示しないハウジングに固定される外輪3と、内輪2と外輪3との間に転動可能に配置された複数の円筒ころ4と、各円筒ころ4を円周方向に沿って等間隔に保持するための保持器5とを備えている。

Next, preferred embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is a sectional view showing a cylindrical roller bearing of an inner ring flange type according to the first embodiment of the present invention.

In FIG. 1, a cylindrical roller bearing 1 includes an inner ring 2 fixed to a rotating shaft (not shown), an

内輪2は、外周面の軸方向中央部に円筒ころ4が転動する軌道面2aを形成し、軌道面2aの軸方向両端部の側方には、外輪3側に突出する鍔部2bを一体形成している。

外輪3は、内周面の軸方向中央部に円筒ころ4が転動する軌道面3aを形成し、軌道面3aの軸方向両端部には、軸方向外側に向かって漸次拡径するテーパ面3bを形成している。

各軌道面2a、3aには全周にわたって潤滑剤としてのグリースGを塗布している。

The inner ring 2 forms a

The

Grease G as a lubricant is applied to each

図2は保持器5の一部を示す斜視図である。この保持器5は、軸方向に離間して配置された一対の環状部5a、5aと、この環状部の周方向に沿って等間隔おきに配置して環状部5a、5a同士を連結する複数の柱部5bと、保持器5の回転を案内する案内片6とを備え、隣接する柱部5bと一対の環状部5aとによって囲まれるポケット5c内に、各円筒ころ4を配置し、円筒ころ4を円周方向に沿って所定間隔に保持している。

FIG. 2 is a perspective view showing a part of the

案内片6は、全ての柱部5bの外周面に外輪3の軌道面3a側に突出して形成され、その先端部には軌道面3aに摺接する摺接部6aを備えている。

また、案内片6は、軸方向に延びる一対の側面に、柱部5b側から摺接部6aの周方向略中央部に向けて傾斜する第一テーパ面6bが形成された断面三角形状のものであり、摺接部6aの軸方向全長が先鋭になっている(図3参照)。

The

The

上記構成により、円筒ころ軸受1の回転中に案内片6の摺接部6aが軌道面3aに摺接するため、保持器5の回転を良好に案内することができる。また、保持器5が軌道面3aに対して図3の矢印X方向に回転することに伴って、軌道面3a上のグリースGのうち余剰のグリースGb(図3の斜線部分)を摺接部6aにより掻き取って除去することができるとともに、外輪3の軸方向両端側に余剰グリースGbを逃がすことができる。このため、適量のグリースGa(図3の非斜線部分)を軌道面3a全体に薄く均一な厚みにして残留させつつ軌道面3a上に余剰グリースGbが滞留するのを防止することができる。したがって、余剰潤滑剤Gbが軌道面3aに滞留することに起因して軸受トルクが上昇するのを防止することができる。しかも、摺接部6aが一対の第一テーパ面6bによって先鋭に形成されているため、摺接部6aの軸方向全長が軌道面3aに対して線接触となり、摺接部6aの摺接抵抗を小さくすることができる。このため、保持器の案内部が面接触する従来の円筒ころ軸受に比べて軸受トルクを減少させることができる。

With the above configuration, since the sliding

また、図1に示すように案内片6の基端部の軸方向全長L1を、外輪3の軌道面3aの軸方向全長L3と同一長さに形成するとともに、案内片6の軸方向両端部に、柱部5b側から摺接部6aの軸方向略中央に向かって傾斜する第二テーパ面6cを形成して、案内片6の先端部である摺接部6aの軸方向全長L2を軌道面3aの軸方向全長L3および軌道面3aの軸方向全長L3以下(本実施形態では軌道面3aの軸方向全長L3と同じ)の円筒ころ4の軸方向全長L4より短く形成している。

これにより、円筒ころ軸受1の回転中に摺接部6aが軌道面3aに対して軸方向のいずれか一方側に偏っても、軌道面3aの他方側には摺接部6aが摺接しない領域(L3−L2、L4−L2)、すなわちグリースGを除去しない領域が常に存在することから、軌道面3a上に適量のグリースGaを残留させることができ、軌道面3aの軸方向全長に亘って余剰の潤滑剤Gbを除去することによって適量グリースGaの供給が不足し易い条件下であっても適量グリースGaの供給不足が生じるのを回避することできる。

Further, as shown in FIG. 1, the axial total length L1 of the base end portion of the

Thereby, even if the sliding

図4は、第2の実施形態に係る円筒ころ軸受1における案内片6の軸方向略中央部の断面図であり、第1の実施形態における図3に対応する図である。図4において第2の実施形態が第1の実施形態と相違する点は、案内片6の摺接部6aを平坦面とし、この摺接部6aにグリースGを一時的に溜める窪み6dを備えている点である。

本実施形態によれば、円筒ころ軸受1の回転中に適量グリースGaの供給が不足し易い条件下であっても、窪み6d内に溜められたグリースGを軌道面3aに供給することができ、適量グリースGaの供給不足を防止することができる。

FIG. 4 is a cross-sectional view of a substantially central portion in the axial direction of the

According to the present embodiment, the grease G stored in the

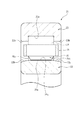

図5は、第3の実施形態に係る外輪鍔付きタイプの円筒ころ軸受21を示す断面図である。第3の実施形態が第1の実施形態と相違する点は、外輪23を鍔部付きとし、内輪22を鍔部なしとし、保持器25の案内片26を内輪22の軌道面22a側に形成した点である。図5において、内輪22は、外周面の軸方向中央部に円筒ころ24が転動する軌道面22aを形成し、軌道面22aの軸方向両端部には、軸方向内側に向かって漸次拡径するテーパ面22bを形成している。外輪23は、外周面の軸方向中央部に円筒ころ24が転動する軌道面23aを形成し、軌道面23aの軸方向両端部には内輪22側に突出する鍔部23bを一体形成している。

FIG. 5 is a cross-sectional view showing a

案内片26は、各柱部25bの内周面から内輪22の軌道面22a側に突出しており、その先部には内輪22の軌道面22aに摺接する摺接部26aを備えている。この摺接部26aが円筒ころ軸受21の回転中に軌道面22aに摺接することにより保持器25の回転を良好に案内することができる。

また、この第3の実施形態においては、保持器25と軌道面22aとの相対回転に伴って軌道面22a上の余剰のグリース(図示せず)を摺接部26aにより掻き取って除去することができるとともに、内輪22の軸方向両端側に余剰グリースを逃がすことができる。このため、適量のグリース(図示せず)を軌道面22a全体に薄く均一な厚みにして残留させることができるとともに、軌道面22a上に余剰グリースが滞留するのを防止することができる。したがって、余剰潤滑剤が軌道面に滞留することに起因して軸受トルクが上昇するのを防止することができる。

The

Further, in the third embodiment, excess grease (not shown) on the

なお、本発明は上記各実施形態に限定されるものではなく、例えば上記各実施形態では案内片6、26を鍔なし側の軌道輪の軌道面に摺接させているが、鍔あり側の軌道輪の軌道面に摺接させることも可能である。また、上記各実施形態では案内片6、26の摺接部6a、26aを軌道面に線接触させているが、面接触させることも可能である。

The present invention is not limited to the above-described embodiments. For example, in each of the above-described embodiments, the

さらに、上記各実施形態では案内片6、26を保持器5、25の全ての柱部5b、25bに形成してあるが、一部の柱部5b、25bのみに形成することも可能である。要するに案内片6、26は保持器5、25の周方向に所定間隔毎に、好ましくは等配に形成されていれば良い。

Furthermore, the above-described embodiments is formed a draft in

1、21 円筒ころ軸受

2、22 内輪

3、23 外輪

3a、22a 軌道面

4、24 円筒ころ

5、25 保持器

6、26 案内片

6d 窪み

Gb 余剰グリース(余剰潤滑剤)

1,21

Claims (4)

内周面に軌道面を有する外輪と、

前記内輪の軌道面と外輪の軌道面との間に転動可能に配置された複数の円筒ころと、

前記円筒ころを円周方向に沿って所定間隔に保持する保持器と、を備えた円筒ころ軸受において、

前記保持器に、当該保持器の周面より突出し、前記内輪及び外輪のいずれか一方の軌道面に摺接して当該保持器の回転を案内するとともに、軌道面上の余剰潤滑剤を除去する案内片を周方向に沿って所定間隔毎に設け、

前記案内片の軸方向両端部に、前記保持器の周面側から、前記軌道面と摺接する部分の軸方向中央に向かって傾斜するテーパ面が形成され、前記摺接する部分の軸方向全長が、前記軌道面の軸方向全長よりも短いことを特徴とする円筒ころ軸受。 An inner ring having a raceway surface on the outer peripheral surface;

An outer ring having a raceway surface on the inner peripheral surface;

A plurality of cylindrical rollers arranged to roll between the raceway surface of the inner ring and the raceway surface of the outer ring;

In a cylindrical roller bearing provided with a cage that holds the cylindrical roller at a predetermined interval along the circumferential direction,

A guide that protrudes from the circumferential surface of the cage to the cage and slides against one of the raceways of the inner ring and the outer ring to guide the rotation of the cage and to remove excess lubricant on the raceway surface. A piece is provided at predetermined intervals along the circumferential direction ,

Tapered surfaces are formed at both axial ends of the guide piece from the peripheral surface side of the cage toward the axial center of the portion that is in sliding contact with the raceway surface, and the axial total length of the sliding contact portion is A cylindrical roller bearing characterized by being shorter than the total axial length of the raceway surface .

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008158098A JP5286959B2 (en) | 2008-06-17 | 2008-06-17 | Cylindrical roller bearing |

| US12/737,120 US8616776B2 (en) | 2008-06-17 | 2009-06-09 | Cylindrical roller bearing |

| EP09766554.1A EP2287482B1 (en) | 2008-06-17 | 2009-06-09 | Cylindrical roller bearing |

| PCT/JP2009/060544 WO2009154106A1 (en) | 2008-06-17 | 2009-06-09 | Cylindrical roller bearing |

| CN2009801132397A CN102007311B (en) | 2008-06-17 | 2009-06-09 | Cylindrical roller bearing |

| EP14151444.8A EP2722542B1 (en) | 2008-06-17 | 2009-06-09 | Cylindrical roller bearing |

| EP17182801.5A EP3279490B1 (en) | 2008-06-17 | 2009-06-09 | Cylindrical roller bearing |

| US14/074,794 US9022661B2 (en) | 2008-06-17 | 2013-11-08 | Cylindrical roller bearing |

| US14/580,440 US20150110428A1 (en) | 2008-06-17 | 2014-12-23 | Cylindrical roller bearing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008158098A JP5286959B2 (en) | 2008-06-17 | 2008-06-17 | Cylindrical roller bearing |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009299874A JP2009299874A (en) | 2009-12-24 |

| JP2009299874A5 JP2009299874A5 (en) | 2011-10-27 |

| JP5286959B2 true JP5286959B2 (en) | 2013-09-11 |

Family

ID=41546971

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008158098A Active JP5286959B2 (en) | 2008-06-17 | 2008-06-17 | Cylindrical roller bearing |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5286959B2 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5803099B2 (en) * | 2010-12-21 | 2015-11-04 | 日本精工株式会社 | Cylindrical roller bearings and spindles for machine tools |

| JP5644474B2 (en) * | 2010-12-21 | 2014-12-24 | 日本精工株式会社 | Cylindrical roller bearings and spindles for machine tools |

| JP5691490B2 (en) * | 2010-12-21 | 2015-04-01 | 日本精工株式会社 | Cylindrical roller bearings and spindles for machine tools |

| JP5909893B2 (en) * | 2011-06-30 | 2016-04-27 | 日本精工株式会社 | Radial needle bearing |

| JP2016070470A (en) * | 2014-10-02 | 2016-05-09 | Ntn株式会社 | Rolling bearing |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3971202B2 (en) * | 2002-02-21 | 2007-09-05 | 三菱電線工業株式会社 | Plastic seal |

| JP2006112584A (en) * | 2004-10-18 | 2006-04-27 | Jtekt Corp | Roller bearing cage |

| JP2008064184A (en) * | 2006-09-06 | 2008-03-21 | Nsk Ltd | Thrust needle roller bearing |

-

2008

- 2008-06-17 JP JP2008158098A patent/JP5286959B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2009299874A (en) | 2009-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2009154106A1 (en) | Cylindrical roller bearing | |

| EP2386772B1 (en) | Rolling bearing with internal lubrication | |

| WO2015041109A1 (en) | Bearing structure | |

| JP2005321049A (en) | Roller bearing | |

| JP5286959B2 (en) | Cylindrical roller bearing | |

| US20190257354A1 (en) | Cylindrical roller bearing | |

| JP4618197B2 (en) | Cylindrical roller bearings and cages for cylindrical roller bearings | |

| JP2007321802A (en) | Conical roller bearing | |

| JP5610013B2 (en) | Cylindrical roller bearing | |

| WO2013084724A1 (en) | Rolling bearing | |

| JP2006226306A (en) | Oil lubricating type roller bearing device | |

| JP5315905B2 (en) | Cylindrical roller bearing | |

| JP2009299874A5 (en) | ||

| JP2009275722A (en) | Rolling bearing | |

| JP2008002495A (en) | Automatic aligning roller bearing | |

| JP2004316670A (en) | Retainer for roller bearing | |

| JP6759838B2 (en) | Roller bearing | |

| JP2007332996A (en) | Double row roller bearing | |

| JP2006077905A (en) | Rolling bearing | |

| JP2007327518A (en) | Cylindrical roller bearing and its cage | |

| JP2010002027A (en) | Cylindrical roller bearing and cylindrical roller bearing device | |

| JP2007309455A (en) | Ball bearing | |

| JP2024002516A (en) | Bearing with cage | |

| JP6606903B2 (en) | Rolling bearing | |

| JP6094637B2 (en) | Roller bearing cage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110221 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110818 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110912 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121127 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130507 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130520 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5286959 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |