JP5100552B2 - 塀 Panel mounting structure - Google Patents

塀 Panel mounting structure Download PDFInfo

- Publication number

- JP5100552B2 JP5100552B2 JP2008186669A JP2008186669A JP5100552B2 JP 5100552 B2 JP5100552 B2 JP 5100552B2 JP 2008186669 A JP2008186669 A JP 2008186669A JP 2008186669 A JP2008186669 A JP 2008186669A JP 5100552 B2 JP5100552 B2 JP 5100552B2

- Authority

- JP

- Japan

- Prior art keywords

- lower frame

- panel

- bent

- support column

- support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910052751 metal Inorganic materials 0.000 description 29

- 239000002184 metal Substances 0.000 description 29

- 239000000463 material Substances 0.000 description 12

- 239000011162 core material Substances 0.000 description 5

- 229910000838 Al alloy Inorganic materials 0.000 description 4

- -1 polyethylene Polymers 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 238000005452 bending Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 238000009434 installation Methods 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000010935 stainless steel Substances 0.000 description 3

- 229910001220 stainless steel Inorganic materials 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 229920003002 synthetic resin Polymers 0.000 description 3

- 239000000057 synthetic resin Substances 0.000 description 3

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 229910010272 inorganic material Inorganic materials 0.000 description 2

- 239000011147 inorganic material Substances 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 239000004925 Acrylic resin Substances 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- WNROFYMDJYEPJX-UHFFFAOYSA-K aluminium hydroxide Chemical compound [OH-].[OH-].[OH-].[Al+3] WNROFYMDJYEPJX-UHFFFAOYSA-K 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 238000004898 kneading Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- VTHJTEIRLNZDEV-UHFFFAOYSA-L magnesium dihydroxide Chemical compound [OH-].[OH-].[Mg+2] VTHJTEIRLNZDEV-UHFFFAOYSA-L 0.000 description 1

- 229910001862 magnesium hydroxide Inorganic materials 0.000 description 1

- 239000000347 magnesium hydroxide Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000010422 painting Methods 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

Images

Landscapes

- Fencing (AREA)

- Connection Of Plates (AREA)

Description

本発明は、住宅や工場等の敷地境界部や隣地境界部に沿って取付けられる塀パネルの取付構造に関するものであり、特に下枠を備えた塀パネルの取付構造に関するものである。 The present invention relates to a mounting structure for a saddle panel that is attached along a site boundary or a neighboring land boundary in a house or factory, and particularly relates to a mounting structure for a saddle panel that includes a lower frame.

住宅、工場、公園等の敷地境界部や隣地境界部に沿って取付けられる塀は、一般に設置される境界部等に沿って複数本の支柱が立設され、この支柱間にネットフェンスや縦格子パネルや塀パネル等のパネル体が架設されている。この支柱とパネル体との取付構造においては、主にパネル体と支柱とが同一面内に位置するものとパネル体が支柱の正面側に位置するものとが用いられており、必要となる強度や施工性、意匠性等を考慮して様々な形態が提案されている。 A fence attached along the boundary of a site, such as a house, factory, or park, or the boundary of an adjacent land, has a plurality of pillars erected along the boundary that is generally installed. Panel bodies such as panels and fence panels are installed. In this mounting structure of the column and the panel body, mainly the panel body and the column are positioned in the same plane and the panel body is positioned on the front side of the column, and the required strength is used. Various forms have been proposed in consideration of the workability, designability, and the like.

例えば、パネル体が支柱の正面側に位置する塀においては、塀パネルの下端部に設けられた枠材やビーム材を、支柱の下方からL字状に突設した受け金具で支持し、押さえ金具等を介してパネル体の上端部の枠材やビーム材を支柱の上方に固定することによって、パネル体を支柱に固定するネットフェンスやフェンスの支持構造が提案されている(例えば、特許文献1、特許文献2参照。)。 For example, in a coffin where the panel body is located on the front side of the column, the frame material or beam material provided at the lower end of the coffin panel is supported by a receiving metal fitting protruding in an L shape from below the column and pressed. There has been proposed a support structure for a net fence or a fence for fixing the panel body to the support by fixing the frame material or beam material of the upper end of the panel body to the upper side of the support through a metal fitting or the like (for example, Patent Documents) 1, see Patent Document 2.).

これらのネットフェンスやフェンスの支持構造においては、予め支柱の下方に受け金具を設けておけば、フェンスの下端部を受け金具に嵌合させて仮置きした状態でフェンスの上端部を押さえ金具で固定することにより、支柱に対するフェンスの取付作業が容易となるものである。又、押さえ金具をフェンス上端部の枠材の外形に沿った横J字状に形成することにより、該枠材を強固に保持することができ、併せてフェンスの上下方向に対する位置ずれやがたつきを抑えることができる。

しかしながら、前記のネットフェンスやフェンスの支持構造には次のような問題点があった。すなわちフェンス等のパネル体の通風性が見込めない平板状である場合はは、強風によりパネル体が弓形に変形すると、パネル体の下枠等を支える受け金具も外向きに開くように変形して受け金具から下枠が抜け出し、パネル体が支柱から外れる恐れがあった。又、この受け金具を下枠の外形に沿って横J字状にした場合、下枠が抜け出しにくくなり強度向上が図れるものの、パネル体をこの受け金具に取付ける場合は、支柱に取付けた受け金具の側方から下枠を挿入する必要があり、施工性が大幅に低下する点が問題であった。 However, the net fence and the support structure for the fence have the following problems. In other words, if the panel body such as a fence cannot be expected to be ventilated, if the panel body is deformed into a bow shape due to strong wind, the bracket that supports the lower frame of the panel body will be deformed to open outward. There was a risk that the lower frame would come out of the bracket and the panel body could come off the support. In addition, when this bracket is made in a horizontal J shape along the outer shape of the lower frame, the lower frame is difficult to come out and the strength can be improved. However, when mounting the panel body to this bracket, the bracket attached to the column It was necessary to insert a lower frame from the side of the side, and the problem was that the workability was greatly reduced.

本発明は、前記の如き問題点を解消し、塀パネルが風荷重等により弓形に変形した場合であっても、塀パネルの下枠が支柱の受け金具から容易に外れないようになされた塀パネルの取付構造を提供せんとするものである。 The present invention solves the above-described problems, and even when the heel panel is deformed into a bow shape by a wind load or the like, the heel panel has a lower frame that is not easily detached from the support metal of the column. It is intended to provide a panel mounting structure.

上記目的を達成するために、本発明は次のような構成としている。

すなわちこの発明に係る塀パネルの取付構造は、下端部に沿って下枠が設けられた塀パネルが、支柱の正面側に設けられた受け金具を介して支柱に取付けられる塀パネルの取付構造において、前記受け金具は、支柱の正面側に突出し前記下枠が載置される底板部と、この底板部から上方に立ち上がる縦板部と、該縦板部の上部から支柱側に向けて斜め上方に折り曲げられた折曲部とを備え、該下枠は、前記支柱と前記折曲部との間に上方から挿入可能となされると共に、下枠の抜け方向に対して、下枠の外側の隅角部が前記折曲部の折曲基部に係止されるようになされたことを特徴とするものである。

In order to achieve the above object, the present invention is configured as follows.

In other words, the saddle panel mounting structure according to the present invention is a saddle panel mounting structure in which the saddle panel provided with the lower frame along the lower end is attached to the support via the support fitting provided on the front side of the support. The support bracket protrudes from the front side of the column and the bottom frame is placed on the bottom plate, the vertical plate rising upward from the bottom plate, and obliquely upward from the top of the vertical plate toward the column The lower frame can be inserted between the support column and the bent portion from above, and the outer side of the lower frame with respect to the removal direction of the lower frame. The corner portion is configured to be locked to the bent base portion of the bent portion.

本発明に係る塀パネルの取付構造において、下枠が支柱と縦板部との間に挿入された状態において、折曲部の折曲基部が、下枠の外側隅角部より上方に位置させ構成としてもよい。 In the saddle panel mounting structure according to the present invention, in a state where the lower frame is inserted between the support column and the vertical plate portion, the bent base portion of the bent portion is positioned above the outer corner portion of the lower frame. It is good also as a structure.

本発明によれば、受け金具は、支柱の正面側に突出し前記下枠が載置される底板部と、この底板部から上方に立ち上がる縦板部と、該縦板部の上部から支柱側に向けて斜め上方に折り曲げられた折曲部とを備え、該下枠は、前記支柱と前記折曲部との間に上方から挿入可能となされると共に、下枠の抜け方向に対して、下枠の外側の隅角部が前記折曲部の折曲基部に係止されるようになされているので、塀パネルが風荷重により弓形に変形した場合、下枠は支柱と受け金具との間から抜け方向に移動しようとするが、下枠の外側の隅角部が折曲部の折曲基部に係止されるため、下枠の抜けが阻止され、塀パネルが支柱から外れることを防ぐことができる。 According to the present invention, the receiving bracket protrudes from the front side of the support column and on which the lower frame is placed, the vertical plate unit that rises upward from the bottom plate unit, and from the upper part of the vertical plate unit to the support column side. The lower frame can be inserted from above between the support column and the bent portion, and the lower frame has a lower portion with respect to the direction in which the lower frame is pulled out. Since the outer corner of the frame is locked to the bent base of the bent portion, the lower frame is located between the support and the bracket when the heel panel is deformed into a bow shape by wind load. Trying to move in the direction of pulling out, but the corners on the outside of the lower frame are locked to the bent base of the bent part, so that the lower frame is prevented from coming off and the heel panel is prevented from coming off the column. be able to.

本発明に係る塀パネルの取付構造において、下枠が支柱と縦板部との間に挿入された状態において、折曲部の折曲基部が、下枠の外側の隅角部より上方に位置させれば、塀パネルが風荷重等により弓形に変形した場合、下枠の外側の隅角部は、前記高さ位置の寸法差の分に応じて受け金具から抜け方向に移動した後で折曲部の折曲基部に係止されるため、前記移動により風荷重により塀パネルに生じる応力を緩和することができ、下枠から受け金具に係る荷重を抑え、塀パネルが支柱からより外れにくくなる。 In the saddle panel mounting structure according to the present invention, in a state where the lower frame is inserted between the support column and the vertical plate portion, the bent base portion of the bent portion is positioned above the corner portion on the outer side of the lower frame. If the heel panel is deformed into an arc due to wind load or the like, the outer corners of the lower frame are folded after moving in the removal direction from the metal fittings according to the dimensional difference of the height position. Because it is locked to the bent base of the bent part, it can relieve the stress generated in the heel panel due to the wind load due to the movement, suppress the load on the receiving bracket from the lower frame, and the heel panel is less likely to come off the column Become.

次に、本発明を実施するための最良の形態について図面を参照し、具体的に説明する。 Next, the best mode for carrying out the present invention will be specifically described with reference to the drawings.

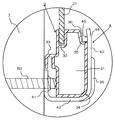

すなわち、図1〜5は本発明に係る塀パネルの取付構造における実施の一形態を示すものであり、1は支柱、2は塀パネル、3は塀パネル2の下端部に設けられた下枠、4は支柱1に取付けられ下枠3を受ける受け金具であり、本発明に係る塀パネルの取付構造は、支柱1、塀パネル2、下枠3、及び受け金具4から主に構成されている。

That is, FIGS. 1 to 5 show an embodiment of the installation structure of the eaves panel according to the present invention, where 1 is a column, 2 is an eaves panel, and 3 is a lower frame provided at the lower end of the eaves panel 2.

図1は本発明に係る塀パネルの取付構造の正面図、図2は図1のA−A断面における縦断面図である。先ず、支柱1は、地表に間隔をおいて複数立設されたものである。支柱1は、一般には断面が矩形状で、アルミニウム合金、ステンレス鋼や鋼材からなる金属管により作成され、その表面にはめっきや塗装等の表面処理が施されている。

FIG. 1 is a front view of a saddle panel mounting structure according to the present invention, and FIG. 2 is a longitudinal sectional view taken along the line AA of FIG. First, a plurality of

塀パネル2は、矩形平板状のパネル本体21と、このパネル本体21の下端部に沿って取付けられた下枠3とを備えている。パネル本体21は、本実施形態においては、平板状の芯材22の表裏に金属薄板23、24が貼着されたものである。芯材22は、一般には、ポリエチレンやポリプロピレン等のポリオレフィン系熱可塑性合成樹脂から作製されるものであり、ポリエチレン、ポリプロピレン単独のもの、或いはこれらを適宜混練されたものを用いてもよく、発泡させた形態でもよく、これらに水酸化アルミニウム、水酸化マグネシウム等の無機材料を適宜混練したものを用いてもよい。

The eaves panel 2 includes a

金属板23,24は、一般にはアルミニウム合金、ステンレス鋼、銅等の金属箔からなり、その前面には、装飾性を高めるために塗装が施されてもよく、装飾用のシートやフィルムを貼着されてもよいが、そのまま用いてもよい。 The metal plates 23 and 24 are generally made of a metal foil such as an aluminum alloy, stainless steel, or copper. The front surface of the metal plates 23 and 24 may be painted to enhance decorativeness, and a decorative sheet or film is pasted thereon. It may be worn but may be used as it is.

パネル本体21は、本実施形態では、芯材22及び金属板23,24からなる積層体であるが、金属板は芯材22の一方のみに貼着されたものでもよく、或いは芯材22、或いは金属板23を単独で用いる形態でもよく、透光性を付与するためにポリカーボネートやアクリル樹脂等からなる透光材料からなる形態でもよい。

In this embodiment, the panel

塀パネル2は、本実施形態では、塀パネル2の上端部に沿って上枠5が取付けられている。上枠5は、パネル2の上端部に沿って略矩形の中空部51が設けられると共に、中空部51の下面に挿入溝52が形成され、塀パネル2の上端部が挿入されている。又、中空部51の支柱1側の側面には、支柱1と接続するための接続金具53が水平方向に摺動可能となされたガイド部54が設けられ、ガイド部54の支柱1側の側板部には長手方向に沿って隙間55が形成され側板部が上下に分けられている。そして、支柱1を貫通する取付ボルトBの螺子先端が隙間55を経て接続金具53に螺着されることにより、接続金具53を介して上枠5が支柱1に固定される。

In the present embodiment, the heel panel 2 has an upper frame 5 attached along the upper end portion of the heel panel 2. In the upper frame 5, a substantially rectangular hollow portion 51 is provided along the upper end portion of the panel 2, an insertion groove 52 is formed on the lower surface of the hollow portion 51, and the upper end portion of the eaves panel 2 is inserted. Further, a

又、塀パネル2は、本実施形態では、塀パネル2の両側端部に縦枠56が設けられ、パネル本体21の外周部に沿って設けられた下枠3、上枠5及び縦枠56により、塀パネル2の外周部を覆って装飾性を高めると共に、塀パネル2の剛性を高めることができる。

Further, in the present embodiment, the vertical panel 2 is provided with

図3は、図2の主要部の拡大図であり、支柱1に対する塀パネル2の下部の取付構造を示すものである。下枠3は、パネル本体21の下端部に沿って取付けられたものであり、水平方向に沿って設けられた中空部31と、中空部31の上面に設けられパネル本体21の下端部が挿入される挿入溝32と、中空部31の支柱1側の側面に設けられ、支柱1と中空部31との間隔を保持するための当たり部33とを備えている。そして、挿入溝32及び当たり部33は、中空部31の長手方向に向けて延設されている。

FIG. 3 is an enlarged view of the main part of FIG. The

下枠3は、一般にはアルミニウム合金や合成樹脂等を押出成型して得られる長尺体を適宜長さに切断した部材からなるものであるが、アルミニウム以外の金属、または金属や無機材料と合成樹脂との複合材料、例えば合成樹脂に金属フィルムをラミネートしたもの、表面に着色がなされたもの、装飾性を向上させるために表面に凹凸が形成されたもの等、必要な強度に応じて、適宜使用できる。

The

受け金具4は、図1〜3に示すように、支柱1の正面に設けられて、塀パネル2の下枠3を受けるものである。図4は、受け金具4の説明図であり、(a)は平面図、(b)は正面図、(c)は右側面図である。受け金具4は、支柱1に固定される固定部41と、固定部41から正面側に向けて突設され下枠3が載置される底板部42と、底板部42の先端部から立ち上がる縦板部43と、縦板部43の上部が支柱1側に向け斜め上方に折り曲げられた折曲部44からなる断面略J字状に形成されたものである。固定部41は、支柱1を貫通する固定ボルトB2の螺子先端により螺着され支柱1の正面側に固定されている。

1-3, the

受け金具4は、一般には鋼材等をプレス成形して得られる部材からなるものであるが、鋼材以外の金属、例えば、ステンレス鋼やアルミニウム合金等の他の金属を加工したものでもよく、又、1の金属部材から成型されてもよく、複数の金属部材から形成されるものでもよく、耐候性や耐食性を向上させるためにめっきや塗装を施したものを用いてもよい。

The

図5は、受け金具4に対する下枠3の固定方法の説明図であり、(a)は下枠3を支柱1と受け金具4の縦板部43との間に挿入する状態、(b)は下枠3が受け金具4の底板部42の上に載置された状態、(c)は下枠3が支柱1と受け金具4との間で固定された状態を示すものである。(a)において、支柱1と受け金具4の折曲部44の上端との離間寸法は、下枠3の前後寸法と同程度となされているので、下枠3は支柱1と縦板部43との間に挿入することができる。尚、本実施形態のように、下枠3の中空部31において、外側の下隅角部34の角を取って円弧状の曲面を形成しておけば、下枠3の挿入時に、支柱1と折曲部44の上端との離間寸法が下枠3の前後寸法よりやや狭い場合、円弧状の下隅角部34が折曲部44の先端45に接触しても、この先端45が円弧状部上を滑って折曲部44が外側に向けて反る方向に弾性的に変形することができるため、折曲部44に抗して下枠3を支柱1と縦板部43との間に挿入することができる。

FIG. 5 is an explanatory view of a fixing method of the

又、下枠3から支柱1側に向けて突出する当たり部33の突出寸法は、受け板部4を支柱1に固定する固定ボルトB2において支柱1の外周面から縦板部42に向けて突出した螺子先端部の突出寸法よりも大きくなっている。これにより、下枠3の下部が固定ボルトB2の螺子先端部に接触することなく、下枠3を底板部42の上に載置することができる。

Further, the projecting dimension of the

更に、図5の(b)において、固定ボルトB2を更に螺入させると、螺子先端が下枠の中空部31を縦板部43側に押圧して、(c)に示すように、枠体3の外側部が縦板部43の内側面に押し付けられて、下枠3を確実に固定することができる。そして、底板部42の外側面から縦板部43の外側面にかけては、厚肉部46が形成されており、前記下枠3の外側面が縦板部43の内側面に押し付けられた時に、縦板部43が外側に向けて発生する反りを抑えることができる。

Further, in FIG. 5B, when the fixing bolt B2 is further screwed in, the screw tip presses the

図6は、台風等の暴風や突風により背面側から正面側に向けて塀パネル2に風荷重がかかり、パネル本体21が正面側に向けて撓みが生じた状態を示す説明図であり、パネル本体21に風荷重がかかった状態を示す縦断面図である。パネル本体21が正面側に弓形になる場合、下枠3は、前記弓形のパネル本体21により正面側に傾斜した形態となって、受け金具4の縦板部43を正面側に押圧すると共に、支柱1と受け金具4との間から斜め上方に引き抜かれる方向に移動する。この時、下枠3の外側上方の上隅角部35は、縦板部43の上部から折曲部44が形成される折曲基部45の内側に引っ掛かり、この状態で下枠3が更に抜け方向に移動しようとしても、上隅角部35は折曲基部45から相対的に押圧を受けるため、これ以上の抜け方向の移動が抑えられ、これにより、上隅角部35は折曲基部45に係止され、下枠3はこれ以上の引き抜きが阻止される。上隅角部35及び折曲基部45は、角部が角張った形態でもよいが、本形態のように、角を取って丸みを帯び、これら曲面と曲面とが合わさって係止する形態でもよい。要は、上隅角部35が折曲基部45に係止されやすい形態であればよい。

FIG. 6 is an explanatory view showing a state in which a wind load is applied to the eaves panel 2 from the back side to the front side due to a storm such as a typhoon or a gust, and the

枠材3の外側壁は、上部が内部に向けて窪んだ凹み部36が形成され、凹み部36の外側の端部が前記上隅角部35となされている。これにより、下枠3の上部が凹み部36が形成されていない略矩形状に形成された場合に比べると、上隅角部35の剛性を高めることができると共に、図1に示すように、上枠3の上端と折曲部44の上端との高さ位置を合わせることができるので、下枠3の上端から折曲部44が突出することをなるべく抑え、意匠性を高めることができる。

The outer wall of the

折曲部44の折曲基部45は、図3に示すように、下枠3が支柱と縦板部との間に挿入された状態において、下枠3の外側の上隅角部35より上方に位置している。これにより、下枠3の外側壁は上下方向に亘って受け金具4の縦板部43の内側面に押し付けられたられた状態で強固に固定することができる。又、通常の設置状態では、上隅角部35は折曲基部45に係止されていないので、通常の設置状態で上隅角部35が折曲基部45に係止されている場合に比べて、通常塀パネル2が受ける風荷重により撓みが生じても折曲基部45には上隅角部35から負荷を受けることは少なく、折曲部44が起き上がる方向に変形するような不具合は起こりにくくなる。更に、図5に示すように、塀パネル2のパネル本体21が正面側に向けて比較的大きな撓みが生じた場合は、下枠3が抜けの方向に移動する際に、上隅角部35が折曲基部45に係止されるまで移動することができるので、この下枠3の前記移動により塀パネル2に生じる応力を緩和することができ、上隅角部35が折曲基部45に係止された際に、折曲基部45に掛かる応力を低減させることができる。

As shown in FIG. 3, the

本発明によれば、塀パネルが風荷重等により弓形に変形した場合であっても、塀パネルの下枠が支柱の受け金具から容易に外れないので、新規に塀パネルを取付ける場合だけではなく、既に設置された塀パネルに対する補強の場合や、既に設置された塀パネルを新しい塀パネルと交換する場合であっても、取付金具の取付作業及びその後の塀パネルの取付作業が容易であり、且つ塀パネルの取付構造をより強固なものとすることができるので、好適に利用できる。 According to the present invention, even when the heel panel is deformed into an arc due to wind load or the like, the lower frame of the heel panel is not easily detached from the support bracket of the support column. Even when reinforcing a previously installed fence panel or replacing an already installed fence panel with a new fence panel, the mounting work of the mounting bracket and the subsequent work of installing the fence panel are easy. And since the attachment structure of a heel panel can be made stronger, it can utilize suitably.

1 支柱

2 塀パネル

3 下枠

34 下隅角部

35 上隅角部

36 凹み部

4 受け金具

42 底板部

43 縦板部

44 折曲部

45 折曲基部

B2 固定ボルト

DESCRIPTION OF

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008186669A JP5100552B2 (en) | 2008-07-18 | 2008-07-18 | 塀 Panel mounting structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008186669A JP5100552B2 (en) | 2008-07-18 | 2008-07-18 | 塀 Panel mounting structure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010024694A JP2010024694A (en) | 2010-02-04 |

| JP5100552B2 true JP5100552B2 (en) | 2012-12-19 |

Family

ID=41730776

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008186669A Active JP5100552B2 (en) | 2008-07-18 | 2008-07-18 | 塀 Panel mounting structure |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5100552B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018145736A (en) * | 2017-03-08 | 2018-09-20 | Ykk Ap株式会社 | Partition unit |

| JP7560339B2 (en) * | 2020-12-01 | 2024-10-02 | 積水樹脂株式会社 | wall |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4112823B2 (en) * | 2000-12-01 | 2008-07-02 | 積水樹脂株式会社 | fence |

-

2008

- 2008-07-18 JP JP2008186669A patent/JP5100552B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010024694A (en) | 2010-02-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5500946B2 (en) | handrail | |

| JP5100552B2 (en) | 塀 Panel mounting structure | |

| KR101222115B1 (en) | Roof structure | |

| JP2008175033A (en) | Exterior wall | |

| JP2022009705A (en) | Simplified structure | |

| JP2014125727A (en) | Fence | |

| CN203878782U (en) | Board connecting structure and board | |

| JP2009007819A (en) | Fence | |

| JP5926207B2 (en) | Simple structure | |

| JP5890201B2 (en) | 塀 | |

| JP2006016820A (en) | Panel fence | |

| JP6367688B2 (en) | fence | |

| JP6334949B2 (en) | Tile-type support fixture for articles installed on tile roofs | |

| JP2010112104A (en) | Pent-roof | |

| JP6851931B2 (en) | fence | |

| JP2015175202A (en) | fence | |

| JP2010043466A (en) | Mounting structure of gable decorative plate | |

| JP3129221U (en) | Long starter metal fittings for outer wall materials and foundation construction using the same | |

| JP2009197523A (en) | Upper-hanging type eave | |

| CN218852226U (en) | Skirting line structure of integrated basin | |

| JP2011163015A (en) | Eaves | |

| JP4860282B2 (en) | Simple roof | |

| JP3137021U (en) | Vertical support member | |

| CN214169614U (en) | Adjusting plate installation modeling structure | |

| JP2008303654A (en) | Simple building |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110326 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120904 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120925 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151005 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5100552 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |