JP5073731B2 - Socks knitting method - Google Patents

Socks knitting method Download PDFInfo

- Publication number

- JP5073731B2 JP5073731B2 JP2009245317A JP2009245317A JP5073731B2 JP 5073731 B2 JP5073731 B2 JP 5073731B2 JP 2009245317 A JP2009245317 A JP 2009245317A JP 2009245317 A JP2009245317 A JP 2009245317A JP 5073731 B2 JP5073731 B2 JP 5073731B2

- Authority

- JP

- Japan

- Prior art keywords

- knitted fabric

- knitted

- knitting

- heel

- annular

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000009940 knitting Methods 0.000 title claims description 56

- 238000000034 method Methods 0.000 title claims description 20

- 239000004744 fabric Substances 0.000 claims description 100

- 210000002683 foot Anatomy 0.000 claims description 14

- 210000003423 ankle Anatomy 0.000 claims description 13

- 238000009958 sewing Methods 0.000 description 5

- 210000001217 buttock Anatomy 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 239000002699 waste material Substances 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 210000002414 leg Anatomy 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

Images

Landscapes

- Socks And Pantyhose (AREA)

Description

環状の穿口部分において足首部を固定し、爪先部を足指部分に係止することで着用するソックスであって、足の胛の部分が大きく開き外見上身に着けているのがわかりにくいソックスの編成方法に関する。 A sock that is worn by fixing the ankle part at the ring-shaped mouth part and locking the toe part to the toe part. It relates to the organization method.

靴底部から胛部開口までの高さの低い胛部開口が大きく開いた靴を履いた際に、外部からソックスの着用が目立たないようにするために胛部の生地を大きく取り除いたソックスが使用されている。これらソックスは足首部の環状の口ゴム部を残し足胛部の生地を大きく取り去っているが、もともとは足胛部にも生地の有る足部全体を編地で覆っている製品の胛部を切り取って縁部をかがり縫いしたりしているもので、その材料に無駄が生じ手間も要した(特許文献1参照)。 When wearing shoes with a wide open heel opening from the sole to the heel opening, socks with a large removal of the heel fabric are used to prevent the sock from being visible from the outside. Has been. These socks leave the annular rubber part of the ankle part and largely remove the fabric of the toe part, but originally the foot part of the product that covers the entire foot part with the fabric also on the toe part with knitted fabric The material is cut off and the edge portion is over-stitched, and the material is wasted and troublesome (see Patent Document 1).

本発明は、穿口部,踵部,足部,爪先部を有するソックスにあって、編み上げたソックスの胛部を切り去り周縁を縫製することにより胛部を大きく開いたソックスを得る従来の製作法を改良し、必要個所の編地のみを編成し、該編地を編成の途次編綴することで縫製により切除しなければならない廃棄物を無くし、更に、縫製の手間を要することなくソックスを完成させるソックス編成方法を提供することを目的とする。 The present invention relates to a sock having a mouth portion, a buttock portion, a foot portion, and a toe portion, and a conventional sock having a widened heel portion by cutting off the heel portion of the knitted socks and sewing the periphery. By improving the law, knitting only the necessary knitted fabric, and knitting the knitted fabric in the course of knitting eliminates the waste that must be cut off by sewing, and socks without the need for sewing An object of the present invention is to provide a sock knitting method that completes the process.

請求項1記載の発明は、ソックスの編成方法であって、短辺2gで連続し対称形をなしている胛側台形編地2cと足底側台形編地2dを前記短辺2gを折り線として折り重ねると共に、重なった斜辺2caと2da、重なった斜辺2cbと2dbとをそれぞれ編綴じしてなる袋状の爪先部2の足底側台形編地2dに続いて、同台形編地2dの長辺2fと等しい編幅の足底部編地3aを編成した後、該足底部編地3aに連なり足部を囲うように胛部から足底部にかけて環状に環状部編地5aを編成して、足底部上面に胛部開口4を形成し、環状部編地5aの最終コースの一部ウエール5bに続いて袋状の踵部6を編成し、次に該環状部編地5aの最終コースの残余のウエール5cと踵部6の最終コース6fの全ウエール6gとに続いて環状に足首部7及びそれに続く環状の穿口部8を連続して編成している。

請求項2記載の発明は、請求項1記載の発明において、胛部開口4の爪先側開口縁9には、爪先部2の胛側台形編地2cの編出し時に編出コース2aに続いて管状編地2bを編み込んでいる。

請求項3記載の発明は、請求項1記載の発明において、足部を囲うよう胛部から足底部にかけて環状に設けた環状部編地5aの、胛部開口4の足首側開口縁10に対位するコースには、管状編地3bを編み込んでいる。

The invention according to

The invention according to

The invention according to

本発明ソックスは、その編成に際して爪先部,足底部,踵部,穿口部と連続して一連に編成し足胛部の編成は行わないので、足胛部の開いたパンプス等を履いた際に好ましく使用できる胛部の生地の無いソックスが、縫製等の副次的作業を全く必要とせず完成させることが出来る。

従って、本発明方法によれば、一旦編成した靴下等を縫製にかけ不要部分を切除し、かがり縫いをするなどの手間を全く要せず作業効率を高めることができると共に、編成した編地を切除するが如き材料の無駄を無くし、廃棄すべきものも生じない。

また、胛部開口の爪先側開口縁と脚側開口縁とに管状編地を編み込んでいるために、ソックス着用時、着用者の肌とソックスとの間でフィット性を良くし、またクッション性を高めることにもなる。

The socks of the present invention are continuously knitted in succession to the toe part, the sole part, the heel part, and the mouth opening part in the knitting, and the heel part is not knitted. The socks having no heel fabric that can be preferably used can be completed without any additional work such as sewing.

Therefore, according to the method of the present invention, once knitted socks are sewn and the unnecessary portions are cut off and unnecessary work such as over-stitching is not required, and the work efficiency can be improved, and the knitted fabric is cut off. However, such waste of material is eliminated, and nothing to be discarded occurs.

In addition, because a tubular knitted fabric is knitted into the toe side opening edge and leg side opening edge of the buttock opening, the fit between the wearer's skin and the socks is improved when wearing socks, and cushioning properties It will also increase.

本発明方法によるソックス1の編成は、シリンダーを有する丸編靴下編機で行われている。その編成過程の概要を次に説明する。

先ず爪先部2を袋状に編成し、爪先部2に続いて足底部3のみの編成を足底部編地3aにより行い、足底部3の上面には胛部開口4を形成する。足底部編地3aの編成が終了してから足底部編地3aと胛部開口4とに接して管状編地3bを有する環状部5を編成した後、踵部6を公知手段により編成し次に足首部7,穿口部8を編成する。

The knitting of the

First, the

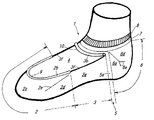

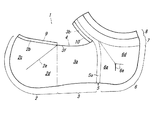

本発明ソックス編成方法の詳細を図3を主に用い次に説明する。前記丸編靴下編機において、概ね半数の針を用い編成を開始し、爪先部2の編出しコース2aから適宜コース数編成し、その最終コースを編出しコース2aに編み綴じすることにより編出しコース2aから前記最終コースまでの編地を管状編地2bとする。管状編地2bに続いて、編み幅を次第に少なくし短辺2gとした胛側台形編地2cと、編地2cと対称形の次第に編幅が大となる形の足底側台形編地2dとを編成し、それらの編成の途次台形編地2c,2dの両斜辺2caと2da,2cbと2dbとをそれぞれ編み綴じし、ゴアライン2eを発現して袋状の爪先部2とする(図1に図示)。

Details of the sock knitting method of the present invention will be described below mainly using FIG. In the circular sock knitting machine, knitting is started by using approximately half of the needles, knitting the number of courses as appropriate from the set-

足底部3の編地3aの各コースは、爪先部2の足底側台形編地2dの長辺2fに続いて同一幅で所定コース数耳編み3fを編成して往復編成され、足底部編地3aを矩形の編地とする。

この足底部編地3aの編成が終了する際に、それまで足底部編地3aを編成していた針以外の、編成を休止していた残余の針を使用し足底部編地3aに並ぶ管状編地3bを編成する。管状編地3bの編成は管状編地2bの編成と同様にして編成される。上記編成を休止していた針によって管状編地3bの編出しコース3cから適宜コース数編成し、管状編地3bの最終コース3dを編出しコース3cに編み綴じすることにより編出しコース3cから前記最終コース3dまでの編地を管状編地3bとする。

上記管状編地3bの最終コース3dと足底部の編地3aの最終コース3dに続いて足部を周回する環状部5の環状部編地5aの編成を行う。

上記編成によって足底部3は足底部編地3aが上方が開いたU字形をなし、該開いた部分を胛部開口4としている。胛部開口4は、爪先側開口縁9(図1,図2に図示)を爪先側の管状編地2bとし、爪先部2の内縁を円弧状に囲って胛部開口4の先端に位置し、足首側開口縁10を足首側の管状編地3bとし、管状編地2b,3b間を耳編3fで連続している。

Each course of the knitted

When the knitting of the sole knitted

Following the

As a result of the knitting, the sole 3 has a U-shape in which the sole knitted

次いで、管状編地3bと足底部3の編地3aとに続いて全針で足部を環状に取り巻く環状部5を環状部編地5aにより編成する。前記までの編成により、足底部3は断面U字形に上方に開いた胛部開口4を形成し、胛部開口4の前縁に位置する管状編地2bは爪先側開口縁9となり、胛部開口4の管状編地3bは足首側開口縁10となる。

Next, following the tubular knitted

次に踵部6の編成を行う。

環状部5の編地5aに続いて同編地5aの半数程度の針を用い編成を開始し、編み進むにつれその編幅を減じ台形の編地6aを編成し、それに続いて台形編地6aと頂辺を同じくし、底辺を大とした台形編地6bを数コース編成する。そして、台形編地6bの底辺に続いて、台形編地6b,6aと対称形をなした台形編地6c,6dを編成し、それらの編成の途次台形編地6aと6bの斜辺同士、同6cと6dの斜辺同士、同6aと6dの残余の斜辺同士を編み綴じしてゴアライン6eを発現する上記各台形編地は、編綴じした部位においては一体に綴じられているが、その他の部位にあっては一連に連続した組織で編成されている。この例にあっては、ゴアライン6eはY字形となるが、踵の形状,大きさ等によって、それ以外のライン形状でも差し支えない。上記ゴアライン6eは台形編地6b,6aの両側に作られる。

Next, the

Following the knitted

踵部6の台形編地6dの最終コース6fの編成が終了したときは踵部の編成は終わり、次に足首部7の編成に移る。足首部7は、図3に展開図で示す如く、踵部6が連続して袋状に編成された際、かかとの編成とはかかわり無く編成を休止していた環状編地5aの端部コースの台形の編地6aの長辺を編成した際の針の残余が連続して編成された部分以外の環状部編地5aの残余のウエール幅5cのコースと踵部6の台形編地6dの最終コース6fに続いて足首部7の最初のコースが編成され、以下所定コース数編成後、穿口部8が続いて編成される。

以上展開図に従って編成手順を述べたが、特に同図に限定するものではなく、編み幅、踵部前後の環状部の位置、更にはゴアラインの形状等応用幅を有するのは勿論である。

When the knitting of the

The knitting procedure has been described in accordance with the developed drawings. However, the knitting procedure is not particularly limited to the drawing, and it is needless to say that the knitting width, the position of the annular portion before and after the heel portion, and the shape of the gore line are applicable.

上記編成方法で編成されたソックスは、袋状の爪先部と踵部との間は、上方に開き胛部開口を形成した縦断面U字形の編地3aよりなる足底部であるために、ソックスが爪先側開口縁9の編出しコース2aから編成を開始され穿口部8で編成が終了したときにソックスは完成品として製作は終了している。従って、編成工程以外の例えば裁断工程,縫製工程等は全く行わなくて良いと言う効果を有する。更に、上述の裁断等を行わないために編成品からカットされた廃棄すべき部材等の出ることも防止できる。

The socks knitted by the above knitting method are the soles of the knitted

本発明方法によるソックスは、胛部開口4の爪先側開口縁9及び足首側開口縁10に管状編地2b,3bをそれぞれ編み込んでいるために、爪先或は足首部等とのフィット性を高め、更にはクッション性を良好にする作用も有する。胛部開口4を形成する足底部の編地3が、開口部の端部の耳編みで薄く形成されている点も管状編地により補強している。

The sock according to the method of the present invention has the tubular

1 ソックス

2 爪先部

2a 編出しコース

2b 管状編地

2c 胛側台形編地

2d 足底側台形編地

2e ゴアライン

2f 長辺

2g 短辺

3 足底部

3a 足底部編地

3b 管状編地

3c 編出しコース

3d 最終コース

3f 耳編み

4 胛部開口

5 環状部

5a 環状部編地

5b 環状部編地5aの最終コースの一部ウエール

5c 残余のウエール

6 踵部

6a,6b,6c,6d 台形編地

6e ゴアライン

6f 踵部6の台形編地6dの最終コース

6g 台形編地6dの最終コースの全ウエール

7 足首部

8 穿口部

9 爪先側開口縁

10 足首側開口縁

DESCRIPTION OF

5b A part of the final course of the annular knitted

5c

6f Final course of trapezoid knitted

6g All wales of the final course of trapezoidal knitted

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009245317A JP5073731B2 (en) | 2009-10-26 | 2009-10-26 | Socks knitting method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009245317A JP5073731B2 (en) | 2009-10-26 | 2009-10-26 | Socks knitting method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2011089234A JP2011089234A (en) | 2011-05-06 |

| JP5073731B2 true JP5073731B2 (en) | 2012-11-14 |

Family

ID=44107722

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009245317A Expired - Fee Related JP5073731B2 (en) | 2009-10-26 | 2009-10-26 | Socks knitting method |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5073731B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3225731U (en) * | 2020-01-20 | 2020-03-26 | イイダ靴下株式会社 | socks |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5930901A (en) * | 1982-08-06 | 1984-02-18 | 新宅 光男 | Sandal-shaped socks |

| JPH03112115U (en) * | 1990-02-28 | 1991-11-15 | ||

| JPH03123605U (en) * | 1990-03-27 | 1991-12-16 | ||

| JP2001011702A (en) * | 1999-06-30 | 2001-01-16 | Paarusutaa:Kk | Socks and socks cover |

| JP3700148B2 (en) * | 2002-05-24 | 2005-09-28 | 株式会社ナイガイ | Socks and knitting method thereof |

-

2009

- 2009-10-26 JP JP2009245317A patent/JP5073731B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011089234A (en) | 2011-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3308666B1 (en) | Shoe upper and method for manufacturing shoe upper | |

| JP6065243B2 (en) | Outer socks | |

| JP6223604B2 (en) | Footwear knitting method, footwear manufacturing method, and footwear | |

| WO2014013790A1 (en) | Shoe upper and method for producing shoe upper | |

| JP6335072B2 (en) | Foot cover | |

| JP5073731B2 (en) | Socks knitting method | |

| JP2014047433A (en) | Foot cover | |

| JP6199509B2 (en) | Shoe upper knitting method and shoe upper | |

| JP2010174425A (en) | Method for producing sock, and sock | |

| JP2016083110A (en) | Shoe upper knitting method | |

| US20160278439A1 (en) | Leg garment with expansive panel | |

| JP3700147B2 (en) | Socks provided with first and second mouth opening edges on the upper and lower sides and a knitting method thereof | |

| JP2004218131A (en) | Sock | |

| JP6618300B2 (en) | shoes | |

| JP2010121227A (en) | Sock, and method for making sock | |

| JP6253257B2 (en) | Foot cover | |

| JP6171130B2 (en) | socks | |

| US20190029330A1 (en) | Leg garment with expansive panel | |

| JP6315968B2 (en) | Socks | |

| JP2010261112A (en) | Lower body garment | |

| JP6042145B2 (en) | Socks knitting method | |

| JP5232094B2 (en) | Foot cover | |

| JP3154190U (en) | Foot cover | |

| JP6952969B2 (en) | socks | |

| JP3641634B1 (en) | Seamless stretch boot and manufacturing method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110930 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111004 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111129 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120509 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120706 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120726 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120822 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5073731 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150831 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |