JP4581803B2 - Rolled recording medium support device and support method - Google Patents

Rolled recording medium support device and support method Download PDFInfo

- Publication number

- JP4581803B2 JP4581803B2 JP2005111452A JP2005111452A JP4581803B2 JP 4581803 B2 JP4581803 B2 JP 4581803B2 JP 2005111452 A JP2005111452 A JP 2005111452A JP 2005111452 A JP2005111452 A JP 2005111452A JP 4581803 B2 JP4581803 B2 JP 4581803B2

- Authority

- JP

- Japan

- Prior art keywords

- roll

- recording medium

- shaped recording

- support

- unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Handling Of Continuous Sheets Of Paper (AREA)

- Unwinding Webs (AREA)

- Replacement Of Web Rolls (AREA)

Description

本発明は、ロール状記録媒体支持装置及び支持方法に関し、詳しくはロール状記録媒体を支持部材に固定する際のユーザ負担を軽減し、さらに多種のロール状記録媒体に対してもユーザ負担を軽減するロール状記録媒体支持装置及び支持方法に関する。 The present invention relates to a roll-shaped recording medium support device and a support method, and more particularly, reduces the user burden when fixing the roll-shaped recording medium to a support member, and further reduces the user burden for various types of roll-shaped recording media. The present invention relates to a roll-shaped recording medium support device and a support method.

一般に記録媒体は、1枚毎記録を行うシート状記録媒体の他に、記録媒体がロール状に巻かれたロール状記録媒体がある。ロール状記録媒体は、記録面積が大きい画像記録を行う際でも記録媒体を収納する寸法を小さくできるため、大型の記録装置によく用いられている。このときユーザはロール状記録媒体を記録装置にセットして記録動作を行わせるが、ロール状記録媒体は何層にも巻かれているので重い欠点があり、また大型の記録装置にセットする場合では細長くなっているため取扱いに負担がかかる欠点がある。 In general, the recording medium includes a roll-shaped recording medium in which the recording medium is wound into a roll, in addition to a sheet-shaped recording medium that records each sheet. A roll-shaped recording medium is often used in a large-sized recording apparatus because the size for accommodating the recording medium can be reduced even when image recording with a large recording area is performed. At this time, the user sets the roll-shaped recording medium in the recording apparatus to perform the recording operation. However, the roll-shaped recording medium has many disadvantages because it is wound in multiple layers, and is set in a large-sized recording apparatus. However, since it is long and thin, there is a drawback in that handling is burdensome.

従来、ロール状記録媒体のセット装置には、特許文献1、2に記載の装置が知られている。

Conventionally, apparatuses disclosed in

特許文献1に記載の装置は、両側板と底部にある巻き出しローラによって構成された凹部に、ロール状記録媒体を入れる装置である。このセット方法は投げ込み方式とも呼ばれている。この装置において、ロール状記録媒体の多種に及ぶ幅に対しては、側板がスライド溝によってロール状記録媒体の幅方向に移動することで対応可能となっている。また、スライドする側板はバネによってスライド溝を押圧することで、側板とスライド溝との摩擦力でスライドを固定できるので、容易にロール状記録媒体を固定することができる。

The apparatus described in

しかし、この装置ではロール状記録媒体の底部から巻き出しローラによってロール状記録媒体を巻き出すが、巻き出しローラとロール状記録媒体との摩擦が小さいと、巻き出しが良好に行えずにロールから記録媒体が弛む問題が起こり、また、この装置では巻き出しローラの重量によりロール状記録媒体との摩擦を得るので弛む問題が起こりやすい欠点がある。また、ロール状記録媒体の固定はユーザ自身が行うので、ユーザに負担がかかる欠点がある。 However, in this apparatus, the roll-shaped recording medium is unwound from the bottom of the roll-shaped recording medium by the unwinding roller. However, if the friction between the unwinding roller and the roll-shaped recording medium is small, unwinding cannot be performed satisfactorily and The problem of loosening of the recording medium occurs, and this apparatus has a drawback that the problem of loosening is likely to occur because friction with the roll- shaped recording medium is obtained by the weight of the unwinding roller. Further, since the roll recording medium is fixed by the user himself / herself, there is a disadvantage that a burden is imposed on the user.

次に、特許文献2に記載されている装置は、ロール状記録媒体の中空部に両端から支持部材を嵌め込ませ、支持部材を両端から懸架することで、ロール状記録媒体を支持するものである。この装置は、ロール状記録媒体の両端に支持部材をそれぞれ嵌め込ませるだけでよいのでユーザ負担を低減できる。

Next, the apparatus described in

しかし、この装置を使用する際、ユーザは片手でロール状記録媒体を持つ必要があるため、不安定な態勢となり、ユーザに負担がかかる欠点がある。また、ロール状記録媒体の多種の幅に対して、それぞれの幅に対応する支持部材が必要になるので、ユーザから見て不便であり、やはりユーザ負担がかかる欠点がある。

本発明は、上記の課題に鑑みなされたものであり、ロール状記録媒体を支持部材に固定する際のユーザ負担を軽減しさらに多種のロール状記録媒体に対してもユーザ負担を軽減するロール状記録媒体支持装置及び支持方法を提供することにある。 The present invention has been made in view of the above problems, and reduces the burden on the user when fixing the roll-shaped recording medium to the support member, and further reduces the burden on the user for various types of roll-shaped recording media. To provide a recording medium support device and a support method.

上記課題は、以下の各発明によって解決される。 The above problems are solved by the following inventions.

(請求項1)

ロール状記録媒体のロール中空部に嵌め込んで該ロール状記録媒体を支持する支持手段を備えたロール状記録媒体支持装置において、

前記ロール状記録媒体を所定位置に置くための仮置き部と、該仮置き部に所定の太さの前記ロール状記録媒体が置かれたことを検知する検知手段を備え、該検知手段の検知結果を入力した制御部が前記支持手段を所定時間だけ駆動することで前記ロール状記録媒体を支持することを特徴とするロール状記録媒体支持装置。

(Claim 1)

In a roll-shaped recording medium support device provided with a support means that is fitted into a roll hollow portion of a roll-shaped recording medium and supports the roll-shaped recording medium,

A temporary placement unit for placing the roll-shaped recording medium at a predetermined position; and a detection unit configured to detect that the roll-shaped recording medium having a predetermined thickness is placed on the temporary storage unit. A roll-shaped recording medium support device, wherein the control unit that inputs the result supports the roll-shaped recording medium by driving the support means for a predetermined time.

(請求項2)

前記仮置き部は前記ロール状記録媒体を支持する1対の支持部を有し、

前記検知手段は、前記1対の支持部の間に設けられ、該1対の支持部に置かれた前記ロール状記録媒体が所定の太さであることを検出するセンサからなる検出部と、該検出部を上下動することにより、前記検出部の前記1対の支持部に対する高さ位置を調整する検知位置調整部を有することを特徴とする請求項1記載のロール状記録媒体支持装置。

(Claim 2)

The temporary placement part has a pair of support parts for supporting the roll-shaped recording medium,

The detection means is provided between the pair of support parts , and a detection part comprising a sensor for detecting that the roll-shaped recording medium placed on the pair of support parts has a predetermined thickness ; 2. The roll-shaped recording medium support device according to

(請求項3)

前記支持手段は、押圧軸と該押圧軸の周囲に配置された中空部押圧部材からなることを特徴とする請求項1又は2記載のロール状記録媒体支持装置。

(Claim 3)

3. The roll-shaped recording medium support device according to

(請求項4)

前記支持手段は、前記ロール状記録媒体が巻き出す方向の略垂直方向に往復動可能な押圧駆動手段に接続され、前記制御部は該押圧駆動手段を駆動制御することを特徴とする請求項1、2又は3記載のロール状記録媒体支持装置。

(Claim 4)

2. The support unit is connected to a pressing drive unit that can reciprocate in a direction substantially perpendicular to a direction in which the roll-shaped recording medium is unwound, and the control unit drives and controls the pressing drive unit. 2. The roll-shaped recording medium support device according to 2 or 3.

(請求項5)

前記支持手段を所定位置で固定する固定手段を有することを特徴とする請求項1〜4の何れかに記載のロール状記録媒体支持装置。

(Claim 5)

5. The roll-shaped recording medium support device according to

(請求項6)

前記仮置き部が、前記支持手段が前記ロール状記録媒体を支持終了後に前記ロール状記録媒体から離間する機構を有することを特徴とする請求項1〜5の何れかに記載のロール状記録媒体支持装置。

(Claim 6)

The roll-shaped recording medium according to

(請求項7)

前記制御部は、前記支持手段が前記ロール状記録媒体を支持した旨の終了信号を受信し、前記仮置き部の駆動手段を駆動制御して前記ロール状記録媒体から離間することを特徴とする請求項6記載のロール状記録媒体支持装置。

(Claim 7)

The control unit receives an end signal indicating that the support unit has supported the roll-shaped recording medium, and controls the drive unit of the temporary placement unit to move away from the roll-shaped recording medium. The roll-shaped recording medium support apparatus according to

(請求項8)

ロール状記録媒体のロール中空部に嵌め込んで該ロール状記録媒体を支持する支持手段を用いたロール状記録媒体の支持方法において、

前記ロール状記録媒体を所定位置に置く仮置き工程と、

仮置き工程で所定の太さの前記ロール状記録媒体が置かれたことを検知する検知工程と、

該検知結果に基づき前記支持手段を所定時間だけ駆動することで前記ロール状記録媒体を支持する工程を有することを特徴とするロール状記録媒体の支持方法。

(Claim 8)

In a method of supporting a roll-shaped recording medium using a supporting means that is fitted into a roll hollow portion of the roll-shaped recording medium and supports the roll-shaped recording medium,

Temporarily placing the roll-shaped recording medium in a predetermined position;

A detection step of detecting that the roll-shaped recording medium having a predetermined thickness is placed in the temporary placement step;

A method for supporting a roll-shaped recording medium, comprising: supporting the roll-shaped recording medium by driving the support means for a predetermined time based on the detection result.

(請求項9)

前記仮置き工程は前記ロール状記録媒体を1対の支持部により支持し、

前記検知工程は、前記1対の支持部に仮置かれた前記ロール状記録媒体が所定の太さであることを、該1対の支持部の間に設けられたセンサからなる検出部によって検出する検出位置検知工程と、前記検出部を上下動することにより、前記検出部の前記1対の支持部に対する高さ位置を調整する検知位置調整工程を有することを特徴とする請求項8記載のロール状記録媒体の支持方法。

(Claim 9)

The temporary placing step supports the roll-shaped recording medium by a pair of support portions,

The detecting step detects that the roll-shaped recording medium temporarily placed on the pair of support parts has a predetermined thickness by a detection unit including a sensor provided between the pair of support parts. The detection position detection step of performing and a detection position adjustment step of adjusting the height position of the detection unit with respect to the pair of support units by moving the detection unit up and down . A method for supporting a roll-shaped recording medium.

(請求項10)

前記ロール状記録媒体を支持する工程が、前記支持手段を前記ロール状記録媒体が巻き出す方向の略垂直方向に往復動するように駆動制御する工程を有することを特徴とする請求項8又は9記載のロール状記録媒体の支持方法。

(Claim 10)

10. The step of supporting the roll-shaped recording medium includes a step of driving and controlling the support means so as to reciprocate in a direction substantially perpendicular to a direction in which the roll-shaped recording medium is unwound. A method for supporting the roll-shaped recording medium according to the description.

(請求項11)

前記支持手段を所定位置で固定する工程を有することを特徴とする請求項8〜10の何れかに記載のロール状記録媒体の支持方法。

(Claim 11)

The method for supporting a roll-shaped recording medium according to any one of claims 8 to 10, further comprising a step of fixing the supporting means at a predetermined position.

(請求項12)

前記仮置き工程が、前記ロール状記録媒体を支持終了後に前記ロール状記録媒体から離間する工程を有することを特徴とする請求項8〜11の何れかに記載のロール状記録媒体の支持方法。

(Claim 12)

The method for supporting a roll-shaped recording medium according to any one of claims 8 to 11, wherein the temporary placing step includes a step of separating the roll-shaped recording medium from the roll-shaped recording medium after the support is completed.

請求項1、8記載の発明によれば、ユーザがロール状記録媒体を検知手段が検知できる位置に持っていくだけで、ロール状記録媒体の中空部に両端から支持部材が嵌め込まれて支持でき、さらに、仮置き部を設けることによって、ロール状記録媒体を手で支える必要がなくなり、ユーザ負担を低減することができる。 According to the first and eighth aspects of the present invention, the user can bring the roll-shaped recording medium into a position where the detecting means can detect it, and the support member can be fitted and supported from both ends into the hollow portion of the roll-shaped recording medium. Furthermore, by providing the temporary placement section, it is not necessary to support the roll-shaped recording medium by hand, and the burden on the user can be reduced.

請求項2、9記載の発明によれば、ロール状記録媒体の太さが種々変化しても対応でき、ユーザ負担を軽減できる。 According to the second and ninth aspects of the invention, it is possible to cope with various changes in the thickness of the roll-shaped recording medium, and the burden on the user can be reduced.

請求項3記載の発明によれば、中空部押圧部材の存在により、ロール状記録媒体を仮置き部に置くだけでロール状記録媒体を確実に支持することができるので、ユーザ負担を軽減できる。 According to the third aspect of the present invention, since the roll-shaped recording medium can be reliably supported only by placing the roll-shaped recording medium on the temporary placement section due to the presence of the hollow portion pressing member, the burden on the user can be reduced.

請求項4、10記載の発明によれば、支持手段の駆動制御により、ロール状記録媒体を仮置き部に置くだけでロール状記録媒体を自動的に支持することができるので、ユーザ負担を軽減できる。 According to the fourth and tenth aspects of the present invention, since the roll-shaped recording medium can be automatically supported by simply placing the roll-shaped recording medium on the temporary placement portion by driving control of the support means, the burden on the user is reduced. it can.

請求項5、11記載の発明によれば、固定手段がブレーキ機能を果たし、ロール状記録媒体のセットを固定し、固定手段を解除しない限りロール状記録媒体は外すことができないようにしており、ロール状記録媒体を確実にセットできる。

According to the inventions of

請求項6、7、12記載の発明によれば、ロール状記録媒体と仮置き部が接触することによる傷を最小限にして、プリント品質の劣化を防止できる。 According to the sixth, seventh, and twelfth aspects of the present invention, it is possible to minimize the damage caused by the contact between the roll-shaped recording medium and the temporary storage portion, and to prevent the print quality from deteriorating.

以下、図面に基づいて本発明の実施の形態について詳細に説明する。 Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

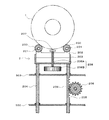

図1は本発明に係るロール状記録媒体の支持装置及び支持方法を実現する装置の一実施形態を示す斜視図である。同図はロール状記録媒体の両側にある支持装置の片側を示しているが、逆側についても同様の装置が設けられている。 FIG. 1 is a perspective view showing an embodiment of a roll recording medium supporting apparatus and apparatus for realizing the supporting method according to the present invention. Although the figure shows one side of the support device on both sides of the roll-shaped recording medium, a similar device is provided on the opposite side.

1はロール状記録媒体であり、図示の例では、該ロール状記録媒体1が仮置き部2に載置されている。かかる仮置き部2の存在により、従来のようにロール状記録媒体1を手で支える必要がなくなり、ユーザ負担を軽減できる。

仮置き部2の好ましい一例を図2及び図3に基づいて説明する。図2は仮置き部の一態様を示す正面図、図3は図2の側面図である。

A preferred example of the

図2、3において、200、200はロール状記録媒体1に接触して支持する1対の支持部であり、該支持部200、200は柔軟性あるいは弾性を有する部材(例えば、ゴム、ビニル樹脂等)によりロール状に形成され、回転軸201に軸支される。回転軸201は支持杆202に回動可能に固定され、該支持杆202の支持筐体203の内面に固定されている。

2 and 3,

支持筐体203は支持脚204により所定高さに支持されている。支持脚204の一部にはラック205が形成され、所定位置に設けられたピニオン206が螺合し、ピニオンラック機構により、仮置き部2全体が上下動する機構となっている。ピニオン206には仮置き駆動モータ206A(例えばサーボモータなど)が接続されている。なお上下動させる機構はピニオンラック機構に限定されるわけではない。

The

207は、前記ロール状記録媒体1の外径によって検出位置を検出する機構を備えた検知手段である。検出センサーとしては接触式センサー、受発光素子を用いた光学式センサーなどのいずれでもよい。検出した結果は信号変換され、図示しない制御部に送られる。

該検知手段207は、前記ロール状記録媒体の外径によって検出位置を調整する検知手段調整部208を有することが、ロール状記録媒体の太さが種々変化しても対応できるので好ましいことである。検知手段調整部208は支持杆202に形成された図示しないネジ部に螺合されたネジ棒208Aの上端に検知手段207を備え、下端に握持部208Bを備え、握持部208Bの回動によってネジ棒208Aが上下動するように構成されている。なお、握持部208Bは手動によって回動してもよいし、あるいは制御信号によって自動的に回動する構成を採用することも好ましい。

It is preferable that the detection means 207 has a detection means

次に、図1において、3は前記ロール状記録媒体1のロール中空部100に嵌め込んで回転自在にロール状記録媒体1を支持する支持手段である。

Next, in FIG. 1,

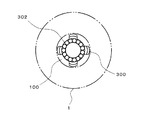

支持手段3及びその周辺の構造について、図4及び図5に基づいて説明する。図4は支持手段の一例を示す正面図、図5はロール中空部に支持手段が嵌め込まれた状態を示す要部断面図である。 The support means 3 and the surrounding structure will be described with reference to FIGS. FIG. 4 is a front view showing an example of the support means, and FIG. 5 is a cross-sectional view of a main part showing a state in which the support means is fitted into the roll hollow portion.

図4、5に示すように、支持手段3は前記ロール中空部100を押圧支持可能な中空部押圧部材300を備えている。該中空部押圧部材300は、4枚から8枚程度の羽状部材によって構成され、押圧軸301の先端周囲に固定されている。羽状部材はロール中空部100に嵌め込んで支持するために挿入しやすく抜けにくい形状が好ましい。そのために押圧軸の外周から離れる方向に弾性が働くような板バネ機能を有することが好ましい。中空部押圧部材の存在により、ロール状記録媒体を仮置き部に置くだけでロール状記録媒体を確実に支持することができるので、ユーザ負担を軽減できる。

As shown in FIGS. 4 and 5, the support means 3 includes a hollow

該中空部押圧部材300は前記ロール状記録媒体1が巻き出す方向の略垂直方向(図面上、水平方向)に往復動可能に構成され、そのために前記押圧軸301を介して押圧駆動手段4に接続される。

The hollow

押圧駆動手段4は駆動軸400を備え、該駆動軸400は押圧部材軸受302を介して前記押圧軸301と連結されている。駆動軸400にはラック401が形成され、所定位置に設けられたピニオン402が螺合し、ピニオンラック機構により、押圧駆動手段4全体が図面上水平方向移動する機構となっている。ピニオン402には回転駆動力を供給する押圧駆動モータ403が接続されている。なお、移動機構はピニオンラック機構に限定されるわけではない。

The

このように支持手段3の駆動制御を行うと、ロール状記録媒体1を仮置き部2に置くだけでロール状記録媒体1を自動的に支持することができるので、ユーザ負担を軽減できる。

When the drive control of the support means 3 is performed in this way, the roll-shaped

図1において、5はL字状の取付板であり、該取付板5の表面には2枚の支持板500、501が固定されており、該支持板500、501は駆動軸400を回動可能に所定高さに支持している。また該取付板5の表面には前記仮置き部2を上下動可能に支持する支持板502、503が設けられている。

In FIG. 1,

6は取付板5の背面及び側面に設けられる固定手段であり、前記押圧駆動手段4による前記中空部押圧部材300の水平方向の移動を所定位置で固定する。この固定手段はブレーキ機能を果たし、ロール状記録媒体のセットを固定し、固定手段を解除しない限りロール状記録媒体は外すことができないようにしており、ロール状記録媒体を確実にセットできる。

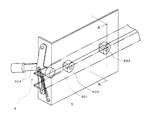

固定手段6について、図6〜図8に基づいて説明する。図6は固定手段の一例を示す要部斜視図であり、図7は図6のA−A線断面図、図8は固定手段の作動を示す説明図である。 The fixing means 6 will be described with reference to FIGS. 6 is a perspective view of the main part showing an example of the fixing means, FIG. 7 is a sectional view taken along line AA of FIG. 6, and FIG. 8 is an explanatory view showing the operation of the fixing means.

図6において、600は取付板5の背面に水平方向(図面上)に設けられたスライド溝部材であり、該スライド溝部材600は所定高さに固定されている。

In FIG. 6, reference numeral 600 denotes a slide groove member provided in the horizontal direction (on the drawing) on the back surface of the mounting

該スライド溝部材600の溝601には、図7に示すように、取付板5に固定された軸602先端に設けられたスライドコロ603、603が装着されている。該スライド溝601をスライドコロ603、603が転がることにより、ロール状記録媒体1の幅方向(図面上、水平方向)にスライドし、それに伴って中空部押圧部材3の水平移動を可能にする。

As shown in FIG. 7,

固定手段6は、取付板5の側面に設けられており、その構造の一例を図8に基づいて説明する。図8に示すように、スライド停止クランプ604を備えており、アンクランプ時は図8(A)のように開放状態にしておき、クランプ時には図8(B)に示すようにクランプ先端を該スライド溝601内面に押圧させ、摩擦力により中空部押圧部材3の水平移動を停止する。スライド停止クランプ604によって停止することで、多様な幅のロール状記録媒体を支持することが可能になる。

The fixing means 6 is provided on the side surface of the mounting

固定手段6は、前記ロール中空部100に中空部押圧部材3を嵌め込んだ状態で固定する機構を有することが好ましい。この場合、中空部押圧部材3を嵌め込んだ状態は、押圧駆動手段を駆動した時間を図示しないタイマで計数することや、図示しない光学式又は接触式による押圧軸の位置を検出することや、電気的なひずみ計測による中空部押圧部材のたわみを検出することによって確認できる。

The fixing means 6 preferably has a mechanism for fixing the roll

次に、本発明の装置に用いる制御システムを説明する。 Next, a control system used for the apparatus of the present invention will be described.

図9は本発明の装置に用いる制御システムの機能ブロック図であり、図10はロール状記録媒体の仮置きと支持開始時の処理フローを示す図であり、図11はロール状記録媒体の取外し時の処理フローを示す図である。図12〜図17は本発明の原理を説明する図である。 FIG. 9 is a functional block diagram of a control system used in the apparatus of the present invention, FIG. 10 is a diagram showing a processing flow at the time of temporarily placing and supporting a roll-shaped recording medium, and FIG. 11 is a removal of the roll-shaped recording medium. It is a figure which shows the processing flow at the time. 12 to 17 are diagrams for explaining the principle of the present invention.

制御システムは、図9に示すように、主としてコントロールパネル7、制御部8、仮置き駆動モータ206A、押圧駆動モータ403によって構成されている。

The control system, as shown in FIG. 9, is constituted mainly by co

先ず、図10に基づいてロール状記録媒体の仮置き開始から押圧状態に至る処理フローを説明する。 First, a processing flow from the temporary placement start of the roll-shaped recording medium to the pressed state will be described based on FIG.

図12に示すように、仮置き部2にロール状記録媒体1が置かれていない状態で、図13に示すように、ロール状記録媒体1を仮置き部2に置くと、仮置き部2に設けてある検知手段207がロール状記録媒体1を検知する(S1)。

As shown in FIG. 12, when the roll-shaped

検知手段が検知すると、制御部8により押圧駆動モータ403を駆動し、ピニオン402が回動する。ピニオン402と噛み合っているラック401を有する駆動軸400により、軸受302、押圧軸301、中空部押圧部材300が図1の矢印blの方向に移動する(S2)。

When the detection means detects, the

中空部押圧部材300は図14の状態から図15の状態に至り、ロール状記録媒体1の中空部100に押圧部材300が挿入、圧着され、ロール状記録媒体1を押圧しつつ支持する。

The hollow

さらに、制御部8により仮置き駆動モータ206Aが駆動し、ピニオン206が回動し、ピニオン206と噛み合っているラック205を備えた仮置き部2が矢印alの方向に下降し(S3)、仮置き部2がロール状記録媒体1より離間する。離間した状態が図16、図17に示されている。

Furthermore,

次に図11に基づいて、ロール状記録媒体の取外し時の処理フローを説明する。 Next, a processing flow at the time of removing the roll-shaped recording medium will be described with reference to FIG.

ロール状記録媒体1を取外す場合は、ユーザがコントロールパネル7からロール状記録媒体1の取外しを指令し、制御部8により仮置き駆動モータ206A、押圧駆動モータ403を作動させる。

When removing the roll-shaped

まず、仮置き駆動モータ206Aを作動させ、仮置き部2を矢印a2の方向に上昇させる(S4)。

First, by operating the

検知手段207がロール状記録媒体1と接触してロール状記録媒体1を検知したとき(S5)、制御部8により仮置き駆動モータ206Aの作動を停止させ、ロール状記録媒体1を仮置き部2で支持する。

When the detection means 207 contacts the roll-shaped

次に、制御部8により押圧駆動モータ403を駆動させ、中空部押圧部材3を矢印b2の方向に移動し(S6)、ロール状記録媒体1の押圧を解除して、ユーザがロール状記録媒体を持って取外せるようにする。

Then, by driving the

以上、本発明の好ましい実施態様について説明したが、本発明の実施態様は上記に限定されず、ロール状に巻き取る装置において、巻き取り完了したロールに仮置き部を接触させてロールを支持する手段を離間するもので、いわば図10の逆手順の態様などを採用することもできる。 The preferred embodiments of the present invention have been described above. However, the embodiments of the present invention are not limited to the above, and in the apparatus for winding in a roll shape, the roll is completed by contacting the temporarily placed portion with the roll that has been wound. For example, the reverse procedure shown in FIG. 10 can be adopted.

1:ロール状記録媒体

100:ロール中空部

2:仮置き部

200:支持部

201:回転軸

202:支持杆

203:支持筐体

204:支持脚

205:ラック

206:ピニオン

206A:仮置き駆動モータ

207:検知手段

208:検知手段調整部

208A:ネジ棒

208B:握持部

3:支持手段

300:中空部押圧部材

301:押圧軸

302:押圧部材軸受

4:押圧駆動手段

400:駆動軸

401:ラック

402:ピニオン

403:押圧駆動モータ

5:取付板

500、501:支持板

502、503:支持板

6:固定手段

600:スイライド溝部材

601:溝

602:軸

603:スライドコロ

604:スライド停止クランプ

7:コトロールパネル

8:制御部

1: Roll-shaped recording medium 100: Roll hollow portion 2: Temporary placement portion 200: Support portion 201: Rotating shaft 202: Support rod 203: Support housing 204: Support leg 205: Rack 206:

Claims (12)

前記ロール状記録媒体を所定位置に置くための仮置き部と、該仮置き部に所定の太さの前記ロール状記録媒体が置かれたことを検知する検知手段を備え、該検知手段の検知結果を入力した制御部が前記支持手段を所定時間だけ駆動することで前記ロール状記録媒体を支持することを特徴とするロール状記録媒体支持装置。 In a roll-shaped recording medium support device provided with a support means that is fitted into a roll hollow portion of a roll-shaped recording medium and supports the roll-shaped recording medium,

A temporary placement unit for placing the roll-shaped recording medium at a predetermined position; and a detection unit configured to detect that the roll-shaped recording medium having a predetermined thickness is placed on the temporary storage unit. A roll-shaped recording medium support device, wherein the control unit that inputs the result supports the roll-shaped recording medium by driving the support means for a predetermined time.

前記検知手段は、前記1対の支持部の間に設けられ、該1対の支持部に置かれた前記ロール状記録媒体が所定の太さであることを検出するセンサからなる検出部と、該検出部を上下動することにより、前記検出部の前記1対の支持部に対する高さ位置を調整する検知位置調整部を有することを特徴とする請求項1記載のロール状記録媒体支持装置。 The temporary placement part has a pair of support parts for supporting the roll-shaped recording medium,

The detection means is provided between the pair of support parts , and a detection part comprising a sensor for detecting that the roll-shaped recording medium placed on the pair of support parts has a predetermined thickness ; 2. The roll-shaped recording medium support device according to claim 1 , further comprising a detection position adjustment unit that adjusts a height position of the detection unit with respect to the pair of support units by moving the detection unit up and down .

前記ロール状記録媒体を所定位置に置く仮置き工程と、

仮置き工程で所定の太さの前記ロール状記録媒体が置かれたことを検知する検知工程と、

該検知結果に基づき前記支持手段を所定時間だけ駆動することで前記ロール状記録媒体を支持する工程を有することを特徴とするロール状記録媒体の支持方法。 In a method of supporting a roll-shaped recording medium using a supporting means that is fitted into a roll hollow portion of the roll-shaped recording medium and supports the roll-shaped recording medium,

Temporarily placing the roll-shaped recording medium in a predetermined position;

A detection step of detecting that the roll-shaped recording medium having a predetermined thickness is placed in the temporary placement step;

A method for supporting a roll-shaped recording medium, comprising: supporting the roll-shaped recording medium by driving the support means for a predetermined time based on the detection result.

前記検知工程は、前記1対の支持部に仮置かれた前記ロール状記録媒体が所定の太さであることを、該1対の支持部の間に設けられたセンサからなる検出部によって検出する検出位置検知工程と、前記検出部を上下動することにより、前記検出部の前記1対の支持部に対する高さ位置を調整する検知位置調整工程を有することを特徴とする請求項8記載のロール状記録媒体の支持方法。 The temporary placing step supports the roll-shaped recording medium by a pair of support portions,

The detecting step detects that the roll-shaped recording medium temporarily placed on the pair of support parts has a predetermined thickness by a detection unit including a sensor provided between the pair of support parts. The detection position detection step of performing and a detection position adjustment step of adjusting the height position of the detection unit with respect to the pair of support units by moving the detection unit up and down . A method for supporting a roll-shaped recording medium.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005111452A JP4581803B2 (en) | 2005-04-07 | 2005-04-07 | Rolled recording medium support device and support method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005111452A JP4581803B2 (en) | 2005-04-07 | 2005-04-07 | Rolled recording medium support device and support method |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006289696A JP2006289696A (en) | 2006-10-26 |

| JP2006289696A5 JP2006289696A5 (en) | 2008-05-08 |

| JP4581803B2 true JP4581803B2 (en) | 2010-11-17 |

Family

ID=37410814

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005111452A Expired - Fee Related JP4581803B2 (en) | 2005-04-07 | 2005-04-07 | Rolled recording medium support device and support method |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4581803B2 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5411217B2 (en) * | 2011-08-05 | 2014-02-12 | 東芝テック株式会社 | Printer |

| JP5821760B2 (en) | 2012-04-11 | 2015-11-24 | セイコーエプソン株式会社 | Medium loading apparatus and recording apparatus |

| JP6024173B2 (en) | 2012-04-16 | 2016-11-09 | セイコーエプソン株式会社 | Medium loading apparatus and recording apparatus |

| JP7430541B2 (en) * | 2020-02-18 | 2024-02-13 | 株式会社ヒラノテクシード | Winding core rotation device |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0572851U (en) * | 1992-03-09 | 1993-10-05 | 三洋電機株式会社 | Facsimile paper storage device |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60106753A (en) * | 1983-11-16 | 1985-06-12 | Fujitsu Ltd | Roll paper fixing device |

| JP2917747B2 (en) * | 1993-05-31 | 1999-07-12 | 株式会社ダイフク | Roll mounting device |

-

2005

- 2005-04-07 JP JP2005111452A patent/JP4581803B2/en not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0572851U (en) * | 1992-03-09 | 1993-10-05 | 三洋電機株式会社 | Facsimile paper storage device |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006289696A (en) | 2006-10-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4581803B2 (en) | Rolled recording medium support device and support method | |

| KR101069832B1 (en) | Removing apparatus for release film of polarizer transfer and removing method using the same | |

| JP2013006234A (en) | Cutting device for adhesive tape roll | |

| EP3603985A1 (en) | Lifting mechanism and recording apparatus | |

| TW201927672A (en) | Coiling unit including a coiling portion, a rotating mechanism, and an advancing-retracting device | |

| JP2992725B2 (en) | Tension mechanism of roll paper feeder | |

| JP2007125652A (en) | Rolled material cutter device | |

| BR0304855B1 (en) | shape sensing apparatus for controlling a tension in a laminated sheet. | |

| JP4486931B2 (en) | Laminate paper transfer assist device | |

| CN110371416B (en) | Dustproof label peeling device | |

| JPS5822245A (en) | Roll paper setting device | |

| JP4609204B2 (en) | Fast cassette cassette for X-ray fluoroscopic equipment | |

| JPH05338867A (en) | Paper feeding unit for long size exclusively of sheet recording device | |

| US6284076B1 (en) | Signage masking tool and method | |

| JP2006199405A (en) | Horizontal movement type surface/center dual winder | |

| JPH0746530Y2 (en) | Marking machine | |

| JP2876177B2 (en) | Roll object reversing device | |

| JPH04138231A (en) | Advancing device for transfer film | |

| JPH072511Y2 (en) | Sheet winding device | |

| JP2004004537A (en) | Recording plate or film-loading device | |

| JPS61270751A (en) | Cartridge provided with device for controlling axial direction of roll film | |

| JP3694334B2 (en) | Media processing device | |

| JP2577334Y2 (en) | Paper folding device | |

| JP2519152Y2 (en) | Continuous paper cutting unit device | |

| JPH10329990A (en) | Core support device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080319 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080319 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100225 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100309 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100510 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100803 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100816 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130910 Year of fee payment: 3 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |