JP4410615B2 - Shielding blade and optical path opening / closing device using the same - Google Patents

Shielding blade and optical path opening / closing device using the same Download PDFInfo

- Publication number

- JP4410615B2 JP4410615B2 JP2004179916A JP2004179916A JP4410615B2 JP 4410615 B2 JP4410615 B2 JP 4410615B2 JP 2004179916 A JP2004179916 A JP 2004179916A JP 2004179916 A JP2004179916 A JP 2004179916A JP 4410615 B2 JP4410615 B2 JP 4410615B2

- Authority

- JP

- Japan

- Prior art keywords

- light

- liquid crystal

- film

- crystal polymer

- shielding blade

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000003287 optical effect Effects 0.000 title claims description 25

- 229920000106 Liquid crystal polymer Polymers 0.000 claims description 113

- 239000004977 Liquid-crystal polymers (LCPs) Substances 0.000 claims description 113

- 239000010410 layer Substances 0.000 claims description 56

- 239000013078 crystal Substances 0.000 claims description 45

- 229920005992 thermoplastic resin Polymers 0.000 claims description 38

- 239000003795 chemical substances by application Substances 0.000 claims description 12

- 239000002346 layers by function Substances 0.000 claims description 7

- 229920001225 polyester resin Polymers 0.000 claims description 4

- 239000004645 polyester resin Substances 0.000 claims description 4

- 230000001050 lubricating effect Effects 0.000 claims description 2

- 210000003746 feather Anatomy 0.000 claims 1

- 229920002799 BoPET Polymers 0.000 description 22

- 239000006229 carbon black Substances 0.000 description 14

- 238000005452 bending Methods 0.000 description 11

- 230000000052 comparative effect Effects 0.000 description 11

- 239000003973 paint Substances 0.000 description 11

- 238000000034 method Methods 0.000 description 9

- 239000004918 carbon fiber reinforced polymer Substances 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 8

- 229920000139 polyethylene terephthalate Polymers 0.000 description 7

- 239000005020 polyethylene terephthalate Substances 0.000 description 7

- 239000000463 material Substances 0.000 description 6

- 229920005989 resin Polymers 0.000 description 6

- 239000011347 resin Substances 0.000 description 6

- 238000003466 welding Methods 0.000 description 6

- 238000007731 hot pressing Methods 0.000 description 5

- 238000004898 kneading Methods 0.000 description 5

- 238000002156 mixing Methods 0.000 description 5

- 230000005540 biological transmission Effects 0.000 description 4

- 229920006332 epoxy adhesive Polymers 0.000 description 4

- 238000001125 extrusion Methods 0.000 description 4

- 238000010030 laminating Methods 0.000 description 4

- 239000002994 raw material Substances 0.000 description 4

- 229920000049 Carbon (fiber) Polymers 0.000 description 3

- 239000004917 carbon fiber Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 3

- 239000000049 pigment Substances 0.000 description 3

- -1 polyethylene terephthalate Polymers 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 229920001187 thermosetting polymer Polymers 0.000 description 3

- 229910000838 Al alloy Inorganic materials 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- 238000003475 lamination Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 230000000704 physical effect Effects 0.000 description 2

- 239000002985 plastic film Substances 0.000 description 2

- 229920006255 plastic film Polymers 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 229920001169 thermoplastic Polymers 0.000 description 2

- 239000004416 thermosoftening plastic Substances 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- 229920006351 engineering plastic Polymers 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000006224 matting agent Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920006122 polyamide resin Polymers 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 229920006267 polyester film Polymers 0.000 description 1

- 239000011112 polyethylene naphthalate Substances 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 238000003908 quality control method Methods 0.000 description 1

- 238000007788 roughening Methods 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 230000008961 swelling Effects 0.000 description 1

Images

Landscapes

- Surface Treatment Of Optical Elements (AREA)

- Shutters For Cameras (AREA)

Description

本発明は、カメラなどの光学機器などにおける光路を開閉するための遮光羽根およびこの遮光羽根を用いた光路開閉装置に関する。 The present invention relates to a light shielding blade for opening and closing an optical path in an optical apparatus such as a camera and an optical path opening and closing device using the light shielding blade.

カメラなどの光学機器の光路を開閉するシャッタや絞りなどの光路開閉装置において、シャッタ羽根や絞り羽根を構成する遮光羽根は、極めて短時間の間に光路を横切るように移動およびその停止を行う必要があり、駆動源の負荷を軽減するために軽量かつ高剛性であることが望まれる。また、これらの遮光羽根はフィルムやCCDなどの感光体に対して光を遮る必要があることから、遮光性を有すると同時に表面の反射率が低く、しかもある程度の平面性が要求される。さらに、光路開閉装置においては複数枚の遮光羽根を重ね合わせて作動させる構成となっているものが多く、相互に重なり合う接触部分の潤滑性や帯電防止性が必要となる。上述した遮光羽根の表面の平面性は、その作動時において隣り合う遮光羽根との衝突による破損を防止する上でも重要となる。 In an optical path opening / closing device such as a shutter or diaphragm that opens and closes the optical path of an optical device such as a camera, the light shielding blades constituting the shutter blades and diaphragm blades must move and stop so as to cross the optical path in a very short time. In order to reduce the load on the drive source, it is desired to be lightweight and highly rigid. In addition, these light-shielding blades need to shield light from a photoconductor such as a film or a CCD. Therefore, the light-shielding blade is required to have a light-shielding property, a low surface reflectance, and a certain level of flatness. Furthermore, many optical path opening and closing devices are configured to operate with a plurality of light shielding blades being overlapped, and lubricity and antistatic properties of contact portions that overlap each other are required. The flatness of the surface of the light shielding blade described above is important in preventing damage due to collision with the adjacent light shielding blade during the operation.

このような遮光羽根に要求される特性を満たすため、従来から種々の素材を用いたものが提案されている。例えば、特許文献1には、複数のポリエステルなどの結晶性高分子化合物のフィルム層間に、少なくとも一層の金属層を挟んで遮光手段としたカメラ用シャッタが開示されている。また、プラスチックフィルム層の間に、一層以上の黒色塗料などの塗膜層を挟んで遮光手段とすることを教示している。加えて、プラスチックフィルムの少なくとも一層に、黒色顔料あるいは黒色染料を含有させることが開示されている。特許文献2には、フィルム厚が100μm程度以下、好ましくは70μm以下で10程度以上の光学濃度が得られるような組成からなる二軸延伸ポリエステルフィルムに、熱硬化性の艶消し塗料をコーティングし、さらに帯電防止材を付着させた光学機器用プラスチック製羽根が開示されている。特許文献3には、基材フィルムに熱可塑性樹脂を主成分とするフィルムを用い、その両面にカーボンブラック,滑材および艶消し剤を含む熱硬化性樹脂からなる層を設けて遮光性フィルムを構成することが開示されている。特許文献4にはアルミニウム合金を素材にしたカメラ用の遮光羽根が開示され、特許文献5には、炭素繊維強化熱硬化性樹脂薄板(以下、CFRPと記述する)をシャッタ羽根に適用すること、およびそのマトリックス樹脂にカーボンブラックなどを含む黒色顔料を混入することで遮光性を得ることが開示されている。さらに、特許文献6には反りの少ないCFRPが開示され、特許文献7には、CFRPが軽量,高強度,高弾性,耐衝撃性および振動減衰性を備えていることが開示されている。 In order to satisfy the characteristics required for such light shielding blades, those using various materials have been proposed. For example, Patent Document 1 discloses a camera shutter that uses at least one metal layer between film layers of a crystalline polymer compound such as a plurality of polyesters as a light shielding unit. Further, it teaches that a light shielding means is provided by sandwiching one or more coating layers of black paint or the like between plastic film layers. In addition, it is disclosed that at least one layer of the plastic film contains a black pigment or a black dye. In Patent Document 2, a thermosetting matte paint is coated on a biaxially stretched polyester film having a composition with a film thickness of about 100 μm or less, preferably 70 μm or less and an optical density of about 10 or more. Furthermore, a plastic blade for an optical device to which an antistatic material is attached is disclosed. Patent Document 3 uses a film mainly composed of a thermoplastic resin as a base film, and is provided with a light-shielding film by providing layers made of a thermosetting resin containing carbon black, a lubricant, and a matting agent on both sides. Configuration is disclosed. Patent Document 4 discloses a light shielding blade for a camera made of an aluminum alloy material, and Patent Document 5 applies a carbon fiber reinforced thermosetting resin thin plate (hereinafter referred to as CFRP) to the shutter blade. In addition, it is disclosed that light shielding properties can be obtained by mixing a black pigment containing carbon black or the like into the matrix resin. Further, Patent Document 6 discloses CFRP with less warping, and Patent Document 7 discloses that CFRP has light weight, high strength, high elasticity, impact resistance, and vibration damping.

ポリエチレンテレフタレート(以下、PETと記述する)を素材にした遮光羽根は、製造コストが低く、比重も軽いため、低価格領域のカメラなどで広く使用されている。しかしながら、PETは引張弾性率などの機械的強度が弱いため、走行中もしくは制動時に発生する振動や衝撃などで遮光羽根が撓んでしまい、遮光羽根相互の衝突やこれによる破損が発生しやすく、高速で走行するフォーカルプレーンシャッタなどで用いることができない。 A light-shielding blade made of polyethylene terephthalate (hereinafter referred to as PET) is widely used in low-price cameras and the like because of its low manufacturing cost and low specific gravity. However, since PET has low mechanical strength such as tensile elastic modulus, the light shielding blades bend due to vibrations or shocks that occur during running or braking. It cannot be used with a focal plane shutter that travels at

また、アルミニウム合金などの金属を素材にした遮光羽根は、機械的強度も高く、高速のシャッタ装置に組み込むことが可能であるが、材料自体の比重が大きいことから遮光羽根自体の重量が嵩み、大きなチャージエネルギーを必要とする。さらに、走行中および制動時に発生する振動、いわゆる波打ちが非常に大きく、この波打ち状態がなかなか収まらないため、上述したPETと同様に遮光羽根相互の衝突ならびに破損の発生という問題がある。 In addition, a light-shielding blade made of a metal such as an aluminum alloy has high mechanical strength and can be incorporated into a high-speed shutter device, but the weight of the light-shielding blade itself is increased due to the large specific gravity of the material itself. , Requires large charge energy. Furthermore, vibrations that occur during running and braking, so-called undulations, are very large, and this undulation state is not easily settled.

一方、CFRPを素材とした遮光羽根は、軽量で弾性率も高く、シャッタ速度が高速であっても走行中および制動中の波打ちが非常に少なく、仮に波打ちが発生したとしても迅速に減衰してしまう特性を有する。従って、遮光羽根相互の衝突やこれによる破損の可能性がなく、非常に高い耐久性を実現することが可能である。しかしながら、CFRPはその材料自体が高価である上、その製造時の前駆体であるプリプレグシートを複数枚積層し、この積層物をプレスしたまま加熱するという非常に手間のかかる工程で製造する必要がある。また、これによって得られたシートも、炭素繊維のばらつきによる目開きなどの不良が発生しやすく、強度のばらつきや反りなどによる不良品の発生率が高い欠点を有するため、品質管理の手間が掛かることと相俟って製造コストも非常に高いものとなってしまう。 On the other hand, the light-shielding blade made of CFRP is lightweight and has a high elastic modulus, and even when the shutter speed is high, there is very little undulation during running and braking, and even if undulation occurs, it quickly decays. It has the characteristic to end. Accordingly, there is no possibility of collision between the light shielding blades and damage due to this, and extremely high durability can be realized. However, CFRP is expensive in material itself and needs to be manufactured in a very laborious process in which a plurality of prepreg sheets, which are precursors at the time of manufacture, are laminated and heated while being pressed. is there. In addition, the sheet thus obtained is also likely to have defects such as openings due to variations in carbon fiber, and has a high defect generation rate due to variations in strength and warpage, which takes time for quality control. In combination with this, the manufacturing cost becomes very high.

ところで、エンジニアリングプラスチックとして知られ、一般の高分子物質と同様な低密度を有する液晶ポリマー(以下、LCPと記述する場合がある)を押出し成形によりフィルム状に成形した場合、各ドメイン(ポリマー鎖)毎にランダムな方向を向いていた各分子が押出し方向に沿って向きを揃え、配向性を示すこととなる。これにより、LCPは一般の高分子物質に見られない高強度および高弾性を示す。つまり、LCPにおける高弾性の発現機構は、ドメインの成形方向への配向に依存しているため、その弾性率は異方性を示し、成形方向に沿っては高弾性率を有するものの、これと直交する方向の弾性率が著しく低い場合がほとんどである。この結果、成形方向に沿って簡単に裂けるようなLCPフィルムができてしまうことが多かった。構造材料としてLCPの使用を考慮した場合、上述したような弾性率の著しい異方性は、信頼性の欠如をもたらすと共にその実用化を困難なものとしている。 By the way, when a liquid crystal polymer (hereinafter sometimes referred to as LCP), which is known as an engineering plastic and has a low density similar to that of general polymer substances, is formed into a film by extrusion molding, each domain (polymer chain) Each molecule oriented in a random direction is aligned along the extrusion direction and exhibits orientation. Thereby, LCP exhibits high strength and high elasticity not found in general polymer materials. In other words, since the mechanism of high elasticity in LCP depends on the orientation of domains in the molding direction, the elastic modulus shows anisotropy and has a high elastic modulus along the molding direction. In most cases, the elastic modulus in the orthogonal direction is extremely low. As a result, an LCP film that can be easily split along the forming direction is often produced. Considering the use of LCP as a structural material, the remarkable anisotropy of the elastic modulus as described above causes a lack of reliability and makes its practical use difficult.

本発明は、高強度かつ安定した品質の安価な遮光羽根およびこれを用いた光路開閉装置を提供することを目的とする。 An object of the present invention is to provide an inexpensive light-shielding blade having high strength and stable quality, and an optical path switching device using the same.

この目的を達成する本発明の遮光羽根は、液晶ポリマー以外の熱可塑性樹脂フィルムと、この熱可塑性樹脂フィルムを挟んで対称に積層される複数層の液晶ポリマーフィルムとを具え、前記熱可塑性樹脂フィルムを基準として対称な積層位置にある対の前記液晶ポリマーフィルムの結晶配向方向が相互に平行または相互に交差していることを特徴とする。

また、本発明の光路開閉装置は、前記遮光羽根を用いた光路開閉装置であって、対をなす液晶ポリマーフィルムの結晶配向方向が前記遮光羽根の移動方向に対して幾何学的に対称に交差しているか、あるいは最外層に位置する対の液晶ポリマーフィルムの結晶配向方向が前記遮光羽根の移動方向に対してほぼ直交していることを特徴とする。

The light-shielding blade of the present invention that achieves this object comprises a thermoplastic resin film other than a liquid crystal polymer, and a plurality of liquid crystal polymer films that are symmetrically laminated with the thermoplastic resin film interposed therebetween, and the thermoplastic resin film The crystal orientation directions of the pair of liquid crystal polymer films at symmetrical positions with respect to each other are parallel to each other or cross each other.

The optical path switching device of the present invention is an optical path switching device using the light shielding blade, wherein the crystal orientation directions of the liquid crystal polymer film forming a pair intersect geometrically symmetrically with respect to the moving direction of the light shielding blade. Or the crystal orientation direction of the pair of liquid crystal polymer films located in the outermost layer is substantially orthogonal to the moving direction of the light shielding blade.

本発明の遮光羽根によると、高強度かつ高弾性を有する安定した品質の安価な遮光羽根を実現することができる。 According to the light-shielding blade of the present invention, it is possible to realize an inexpensive light-shielding blade having high strength and high elasticity and having stable quality.

本発明の光路開閉装置によると、本発明による遮光羽根を用い、対をなす液晶ポリマーフィルムの結晶配向方向を遮光羽根の移動方向に対して幾何学的に対称に交差させるか、あるいは最外層に位置する対の液晶ポリマーフィルムの結晶配向方向を遮光羽根の移動方向に対してほぼ直交させることにより、製造が容易であって高強度かつ高弾性を有し、反りの少ない軽量な遮光羽根を用いた光路開閉装置を実現することができる。 According to the optical path switching device of the present invention, the light shielding blade according to the present invention is used, and the crystal orientation direction of the liquid crystal polymer film forming a pair is crossed geometrically symmetrically with respect to the moving direction of the light shielding blade, or the outermost layer is formed on the outermost layer. By making the crystal orientation direction of the paired liquid crystal polymer film almost orthogonal to the moving direction of the light shielding blade, it is easy to manufacture, has high strength and high elasticity, and uses a light shielding blade with little warpage It is possible to realize the optical path switching device.

本発明の第1の形態は、液晶ポリマー以外の熱可塑性樹脂フィルムと、この熱可塑性樹脂フィルムを挟んで対称に積層される複数層の液晶ポリマーフィルムとを具え、前記熱可塑性樹脂フィルムを基準として対称な積層位置にある対の前記液晶ポリマーフィルムの結晶配向方向が相互に平行または相互に交差していることを特徴とする遮光羽根にある。 A first aspect of the present invention comprises a thermoplastic resin film other than a liquid crystal polymer, and a plurality of liquid crystal polymer films laminated symmetrically across the thermoplastic resin film, with the thermoplastic resin film as a reference The light-shielding blade is characterized in that crystal orientation directions of the pair of liquid crystal polymer films in a symmetrical lamination position are parallel to each other or cross each other.

具体的には、2枚のLCPフィルムを用いて3層構造の遮光羽根を構成する場合、熱可塑性樹脂フィルム(以降、熱可塑性樹脂という記載がある場合、これは意図的にLCPを含まないものであることに注意されたい)を挟んで2枚のLCPフィルムの結晶配向方向の交差角が0°、つまり平行か、例えば60°または90°となるように積層させることができる。また、4枚のLCPフィルムを用いて5層構造の遮光羽根を構成する場合、LCPフィルムの結晶配向方向が積層方向一端側のLPCフィルムの結晶配向方向を基準(0°)として順に例えば0°/45°/熱可塑性樹脂フィルム/135°/0°という具合に交差させたり、0°/60°/熱可塑性樹脂フィルム/120°/0°という具合に交差させて積層することができる。 Specifically, when a light shielding blade having a three-layer structure is formed using two LCP films, a thermoplastic resin film (hereinafter referred to as a thermoplastic resin, this is intentionally free of LCP). The two LCP films can be laminated so that the crossing angle in the crystal orientation direction is 0 °, that is, parallel, for example, 60 ° or 90 °. Further, when a light shielding blade having a five-layer structure is configured by using four LCP films, the crystal orientation direction of the LCP film is, for example, 0 ° in order based on the crystal orientation direction of the LPC film on one side in the stacking direction (0 °). It is possible to laminate the film by crossing such as / 45 ° / thermoplastic resin film / 135 ° / 0 ° or crossing such as 0 ° / 60 ° / thermoplastic resin film / 120 ° / 0 °.

本発明にて用いられるLPCは、機械的強度の観点から全芳香族系LPCを採用することが好ましく、特にポリエステル樹脂の一種であるサーモトロピックLPCが有効である。 The LPC used in the present invention is preferably a wholly aromatic LPC from the viewpoint of mechanical strength, and thermotropic LPC which is a kind of polyester resin is particularly effective.

かかるLCPをフィルム化する方法としては、周知の方法を用いることができるが、工業的見地から溶融状態で混練・押出しする方法が好ましい。例えば、1軸または2軸の押出機を用い、Tダイから溶融樹脂を押出して一軸延伸・二軸延伸後に巻き取るTダイ法や、環状ダイスから溶融樹脂を円筒状に押出し、冷却して巻き取るインフレーション成膜法を挙げることができる。本発明においては、このような押出しによって成形されたフィルムの中でも、フィルムの押出し方向(以下、MD方向と記述する)と、このMD方向に対してフィルム面内で直交する方向(以下、TD方向と記述する)との機械的強度の異方性が大きいものが好ましい。特に、MD方向の曲げ弾性率とTD方向の曲げ弾性率との比、つまり曲げ弾性率の異方性(以下、これをMD/TDと表記する)が3〜40の範囲にあるフィルムが好ましい。 As a method for forming such an LCP into a film, a known method can be used, but a method of kneading and extruding in a molten state is preferable from an industrial viewpoint. For example, using a uniaxial or biaxial extruder, the molten resin is extruded from a T die and wound after uniaxial stretching or biaxial stretching, or the molten resin is extruded cylindrically from an annular die, cooled and wound The inflation film-forming method to take can be mentioned. In the present invention, among the films formed by such extrusion, the film extrusion direction (hereinafter referred to as MD direction) and the direction perpendicular to the MD direction in the film plane (hereinafter referred to as TD direction). And those having a large anisotropy in mechanical strength. In particular, a film having a ratio of a bending elastic modulus in the MD direction to a bending elastic modulus in the TD direction, that is, anisotropy of the bending elastic modulus (hereinafter referred to as MD / TD) is preferably in the range of 3 to 40. .

また、MD方向の曲げ弾性率が高いという理由のため、分子配向度(SOR:Segment Orientation Ratio)が1.1〜1.6のLCPフィルムが好ましい。この分子配向度(以下、SORと記述する)は、分子を構成するセグメントについての分子配向の度合いを与える指標であり、従来のMOR(Molecular Orientation Ratio)とは異なり、試料の厚さに無関係な値である。このSORは、以下のように算出される。すなわち、まず周知のマイクロ波分子配向度測定機において、マイクロ波の進行方向に対して試料であるLPCフィルムの表面が垂直になるようにこれをマイクロ波共振導波管中に挿入し、試料を透過したマイクロ波の電場強度、つまりマイクロ波透過強度を測定する。そして、この測定値に基づき、以下の式1により屈折率mを算出する。

m=(Z0/Δz)×(1−νmax/ν0) (式1)

式1において、Z0は装置の定数、Δzは試料の平均膜厚、νmaxはマイクロ波の振動数を変化させた時の最大マイクロ波透過強度を与える振動数、ν0は平均膜厚が0の時、つまり試料がない場合の最大マイクロ波透過強度を与える振動数である。

Also, an LCP film having a molecular orientation ratio (SOR: Segment Orientation Ratio) of 1.1 to 1.6 is preferable because of its high bending elastic modulus in the MD direction. This degree of molecular orientation (hereinafter referred to as SOR) is an index that gives the degree of molecular orientation of the segments constituting the molecule, and is different from the conventional MOR (Molecular Orientation Ratio) and is not related to the thickness of the sample. Value. This SOR is calculated as follows. That is, first, in a known microwave molecular orientation measuring instrument, this is inserted into a microwave resonant waveguide so that the surface of the LPC film as a sample is perpendicular to the traveling direction of the microwave. The electric field intensity of the transmitted microwave, that is, the microwave transmission intensity is measured. And based on this measured value, the refractive index m is calculated by the following formula 1.

m = (Z 0 / Δz) × (1−ν max / ν 0 ) (Formula 1)

In Equation 1, Z 0 is a constant of the apparatus, Δz is the average film thickness of the sample, ν max is the frequency that gives the maximum microwave transmission intensity when the microwave frequency is changed, and ν 0 is the average film thickness. This is the frequency that gives the maximum microwave transmission intensity when 0, that is, when there is no sample.

マイクロ波の振動方向に対する試料の回転角が0°の時、つまりマイクロ波の振動方向と、試料の分子が最もよく配向されている方向であって最小マイクロ波透過強度を与える方向とが合致している時の屈折率mをm0、試料の回転角が90°の場合の屈折率mをm90とした場合、SORはm0/m90で表される。 When the rotation angle of the sample with respect to the microwave vibration direction is 0 °, that is, the vibration direction of the microwave matches the direction in which the sample molecules are best oriented and give the minimum microwave transmission intensity. the refractive index m of the time and m 0, if the rotation angle of the sample was an index of refraction m when the 90 ° and m 90, SOR is represented by m 0 / m 90.

曲げ弾性率の異方性を示すMD/TDが3未満またはSORが1.1未満の場合、曲げ弾性率の異方性に基づく機械的強度の差は小さくなり、フィルム面内において結晶配向方向が等方性に近くなるものの、機械的強度が小さくなってしまい、例えば高速動作のシャッタ羽根に要求される高強度・高弾性を満たすことができない。また、MD/TDが40を越えたりSORが1.6を越えると、TD方向のフィルムの強度が弱すぎてしまい、簡単に成形方向に裂けるような事故が頻発する。 When MD / TD showing the anisotropy of the flexural modulus is less than 3 or SOR is less than 1.1, the difference in mechanical strength based on the anisotropy of the flexural modulus becomes small, and the crystal orientation direction in the film plane However, the mechanical strength becomes small, and for example, the high strength and high elasticity required for a shutter blade operating at high speed cannot be satisfied. Further, when MD / TD exceeds 40 or SOR exceeds 1.6, the strength of the film in the TD direction is too weak, and accidents that easily tear in the forming direction frequently occur.

ところで、結晶配向方向が相互に異なるLCPフィルムの積層枚数が多くなると、曲げ弾性率の異方性が緩和されて等方性に近づくため、本発明の顕著な効果を得るための障害となる。しかも、積層枚数が多いと、その製造のための工数が多くなって生産性も悪化してしまうため、熱可塑性フィルムも含めて全体で3〜9層、好ましくは3〜5層、つまり2枚または4枚のLCPフィルムを1枚の熱可塑性フィルムを挟むように積層することが最適である。 By the way, if the number of laminated LCP films having different crystal orientation directions increases, the anisotropy of the flexural modulus is relaxed and approaches isotropic, which is an obstacle to obtaining the remarkable effect of the present invention. In addition, if the number of laminated layers is large, the man-hours for the production increase and the productivity also deteriorates. Therefore, 3 to 9 layers in total including the thermoplastic film, preferably 3 to 5 layers, that is, 2 sheets Or it is optimal to laminate | stack four LCP films so that one thermoplastic film may be pinched | interposed.

本発明の第1の形態による遮光羽根において、最外層に位置する対の液晶ポリマーフィルムの結晶配向方向が上述した例のように相互に平行であってよい。 In the light-shielding blade according to the first aspect of the present invention, the crystal orientation directions of the pair of liquid crystal polymer films located in the outermost layer may be parallel to each other as in the above-described example.

最外層に位置する一対の液晶ポリマーフィルムの結晶配向方向を相互に平行にした場合、例えば熱可塑性樹脂フィルムとして2軸延伸したPETフィルムを用い、このPETフィルムを挟んで2枚のLCPフィルムの結晶配向方向を平行にして積層した場合、最外層を構成するLCPフィルムのMD方向の曲げ弾性率をE1,その厚さをT1とし、積層方向中央に位置するPETフィルムの曲げ弾性率をE2,その厚さをT2とすると、積層された遮光羽根の厚さHは2T1+T2であるので、この遮光羽根の全体的な曲げ弾性率Eは以下の式2にて算出される。

E=[E2T2 3+E1{(2T1+T2)3−T2 3}]/H3 (式2)

T1=T2=T,H=3Tと仮定すると、上の式2は

E=(E2+26E1)/27 (式3)

となる。つまり、最外層に位置するLCPフィルムのMD方向の曲げ弾性率は、積層方向中央に位置するPETフィルムの曲げ弾性率に比べて26倍も遮光羽根全体の曲げ弾性率に寄与することとなる。換言すれば、遮光羽根の機械的強度に関しては、最外層に位置するLCPフィルムの物性が大きく影響するので、最外層に位置するLCPフィルムの結晶配向方向が使用形態における遮光羽根の移動方向に対して直交させることが極めて有効である。ただし、遮光羽根の物理的バランスを得るために遮光羽根の移動方向に対して直交する方向を基準として、各LCPフィルムの結晶配向方向が幾何学的に対称となっていることが好ましい。

When the crystal orientation directions of a pair of liquid crystal polymer films located in the outermost layer are parallel to each other, for example, a biaxially stretched PET film is used as a thermoplastic resin film, and the crystals of two LCP films are sandwiched between the PET films. When laminated with the orientation directions parallel, the bending elastic modulus in the MD direction of the LCP film constituting the outermost layer is E 1 , the thickness is T 1, and the bending elastic modulus of the PET film located at the center of the laminating direction is E 2 , where the thickness is T 2 , the thickness H of the laminated light shielding blades is 2T 1 + T 2 , so the overall bending elastic modulus E of the light shielding blades is calculated by the following equation 2. .

E = [E 2 T 2 3 + E 1 {(2T 1 + T 2 ) 3 −T 2 3 }] / H 3 (Formula 2)

Assuming T 1 = T 2 = T and H = 3T, the above equation 2 is E = (E 2 + 26E 1 ) / 27 (Equation 3)

It becomes. That is, the bending elastic modulus in the MD direction of the LCP film located in the outermost layer contributes 26 times to the bending elastic modulus of the entire light shielding blade as compared with the bending elastic modulus of the PET film located in the center in the laminating direction. In other words, with respect to the mechanical strength of the light shielding blade, the physical properties of the LCP film located in the outermost layer greatly affect the crystal orientation direction of the LCP film located in the outermost layer with respect to the moving direction of the light shielding blade in the usage form. It is extremely effective to make them orthogonal. However, in order to obtain a physical balance of the light shielding blades, it is preferable that the crystal orientation directions of the respective LCP films are geometrically symmetrical with respect to a direction orthogonal to the moving direction of the light shielding blades.

最外層に位置する対の液晶ポリマーフィルムの結晶配向方向を相互に平行にした場合、最外層よりも内側に位置する対の液晶ポリマーフィルムの結晶配向方向は、上述した5層構造の例のように最外層に位置する対の液晶ポリマーフィルムの結晶配向方向に対して幾何学的に対称に交差していることが好ましい。 When the crystal orientation directions of the pair of liquid crystal polymer films located on the outermost layer are parallel to each other, the crystal orientation directions of the pair of liquid crystal polymer films located on the inner side of the outermost layer are as in the example of the five-layer structure described above. It is preferable to cross geometrically symmetrically with respect to the crystal orientation direction of the pair of liquid crystal polymer films located in the outermost layer.

熱可塑性樹脂は、ポリエステル,ポリオレフィン,ポリアミドなどの周知の樹脂を採用し得るが、特にPET,ポリブチレンンテレフタレート,ポリエチレンナフタレートなどのポリエステル樹脂が好ましい。 As the thermoplastic resin, well-known resins such as polyester, polyolefin, and polyamide can be adopted, and polyester resins such as PET, polybutylene terephthalate, and polyethylene naphthalate are particularly preferable.

遮光羽根全体の厚さに対する熱可塑性樹脂フィルムの厚さの割合は、20〜80%程度が好ましい。熱可塑性樹脂の割合が20%以下になると、LCPフィルムと熱可塑性樹脂フィルムとの積層時、特に熱溶着または超音波溶着を行った場合に溶着不良が発生しやすく、しかも最外層に位置するLCPフィルムの結晶配向方向に対して直交する方向の遮光羽根の強度が弱くなってしまう。このため、最外層に位置するLCPフィルムの結晶配向方向に沿って遮光羽根が簡単に裂けてしまうこととなる。逆に、熱可塑性樹脂の割合が80%を越えると、最外層に位置するLCPフィルムの結晶配向方向に沿った遮光羽根の強度が半分程度となってしまい、液晶ポリマーの特徴である高弾性が失われてしまう結果を招く。しかも、現状では遮光羽根の厚さの10%程度が1枚のLCPフィルムの厚さの限界である。 The ratio of the thickness of the thermoplastic resin film to the thickness of the entire light shielding blade is preferably about 20 to 80%. When the ratio of the thermoplastic resin is 20% or less, a LCP film and a thermoplastic resin film are easily laminated, particularly when heat welding or ultrasonic welding is performed, and the LCP located in the outermost layer. The intensity | strength of the light-shielding blade of the direction orthogonal to the crystal orientation direction of a film will become weak. For this reason, a light-shielding blade will tear easily along the crystal orientation direction of the LCP film located in the outermost layer. Conversely, if the ratio of the thermoplastic resin exceeds 80%, the strength of the light shielding blade along the crystal orientation direction of the LCP film located in the outermost layer becomes about half, and the high elasticity characteristic of the liquid crystal polymer is reduced. The result is lost. Moreover, at present, about 10% of the thickness of the light shielding blade is the limit of the thickness of one LCP film.

ちなみに、熱可塑性樹脂フィルムの厚さが遮光羽根の厚さの20%の場合、遮光羽根の弾性率Eは、T2=T,T1=2T,H=5Tとなるので、式2より

E=(E2+124E1)/125 (式4)

となる。また、熱可塑性樹脂フィルムの厚さが遮光羽根の厚さの80%の場合、遮光羽根の弾性率Eは、T1=T,T2=8T,H=10Tであるので、式2より

E=(512E2+488E1)/1000 (式5)

となる。

Incidentally, when the thickness of the thermoplastic resin film is 20% of the thickness of the light shielding blade, the elastic modulus E of the light shielding blade is T 2 = T, T 1 = 2T, and H = 5T. = (E 2 + 124E 1 ) / 125 (Formula 4)

It becomes. When the thickness of the thermoplastic resin film is 80% of the thickness of the light shielding blade, the elastic modulus E of the light shielding blade is T 1 = T, T 2 = 8T, and H = 10T. = (512E 2 + 488E 1 ) / 1000 (Formula 5)

It becomes.

相互に重なり合う熱可塑性樹脂フィルムと液晶ポリマーフィルムとの間または2層の液晶ポリマーフィルムの間に遮光剤を含む遮光性改善層を形成することができ、この遮光性改善層としてエポキシ樹脂などの接着剤を採用することが可能である。この場合、熱可塑性樹脂フィルムとLCPフィルムとの間または2層のLCPフィルムの間にカーボンブラックなどの黒色顔料が混合された接着剤を塗布してこれらを重ね合わせ、加熱などによりLCPフィルムを一体化させることができる。熱可塑性樹脂フィルムおよびLCPフィルムの一体化を熱溶着や超音波溶着などで行うことにより、生産性の向上と製造コストの低減およびリサイクル性の大幅な改善が可能となる。特に、ホットプレスによる熱溶着が好ましい。この場合、熱可塑性樹脂フィルムの表面をマット処理などで粗面化することにより、さらに接着および溶着の信頼性および強度を上げることができる。 A light-shielding improvement layer containing a light-shielding agent can be formed between the thermoplastic resin film and the liquid crystal polymer film that overlap each other or between the two liquid crystal polymer films. It is possible to employ an agent. In this case, an adhesive in which a black pigment such as carbon black is mixed is applied between the thermoplastic resin film and the LCP film or between the two layers of LCP film, and these are overlapped, and the LCP film is integrated by heating or the like. It can be made. By integrating the thermoplastic resin film and the LCP film by heat welding or ultrasonic welding, it becomes possible to improve productivity, reduce manufacturing costs, and greatly improve recyclability. In particular, heat welding by hot pressing is preferable. In this case, the reliability and strength of adhesion and welding can be further increased by roughening the surface of the thermoplastic resin film by mat processing or the like.

熱可塑性樹脂フィルムおよび少なくとも1層の液晶ポリマーフィルムに遮光剤を添加することができる。遮光剤を熱可塑性樹脂フィルムおよびLCPフィルム中に分散させる場合、周知の方法を用いることができるが、工業的見地から溶融状態で各成分を混練する方法が好ましい。この溶融混練には一般に用いられている一軸または二軸の押出し機や、各種ニーダーなどの混練装置を用いることができるが、特に二軸の高混練機が好ましい。混練に際しては、各成分を予めタンブラーまたはヘンシェルミキサーの如き装置にて均一に混合してもよいし、場合によってはこれらの混合を省き、混練装置にそれぞれ別個に定量供給する方法を採用することも可能である。 A light-shielding agent can be added to the thermoplastic resin film and at least one liquid crystal polymer film. In the case of dispersing the light-shielding agent in the thermoplastic resin film and the LCP film, a known method can be used, but a method of kneading each component in a molten state from an industrial viewpoint is preferable. For this melt-kneading, generally used single-screw or twin-screw extruders and various kneaders such as kneaders can be used, but a twin-screw high-kneader is particularly preferable. In kneading, the respective components may be mixed uniformly in advance with an apparatus such as a tumbler or a Henschel mixer. In some cases, the mixing may be omitted, and a method of separately supplying each of the components separately to the kneading apparatus may be adopted. Is possible.

最外層に位置する液晶ポリマーフィルムの表面に遮光性,潤滑性および帯電防止性のうちの少なくとも1つの機能を有する機能層を形成することができる。 A functional layer having at least one of a light shielding property, a lubricating property, and an antistatic property can be formed on the surface of the liquid crystal polymer film located in the outermost layer.

本発明の遮光羽根によると、液晶ポリマー以外の熱可塑性樹脂フィルムと、この熱可塑性樹脂フィルムを挟んで対称に積層される複数層の液晶ポリマーフィルムとを具え、熱可塑性樹脂フィルムを基準として対称な積層位置にある対の液晶ポリマーフィルムの結晶配向方向を相互に平行または相互に交差させたので、同じ厚さの場合にPETを2軸延伸したフィルム以上の強度を持つ軽量な遮光羽根を得ることができる。また、遮光羽根としての物性的バランスが改善され、反りなどの発生が非常に少ない遮光羽根を得ることが可能となる。さらに、光学濃度がほぼ0のPETなどと比較して材料自体が不透明で遮光性に優れており、25μmの膜厚のLCPフィルムで0.5程度の光学濃度を持っているため、これを3枚以上積層することで光学濃度を1.5〜2程度に高めることができ、遮光性の点でさらに有利である。 According to the light-shielding blade of the present invention, it comprises a thermoplastic resin film other than the liquid crystal polymer and a plurality of layers of liquid crystal polymer films laminated symmetrically with the thermoplastic resin film interposed therebetween, and is symmetrical with respect to the thermoplastic resin film. Since the crystal orientation directions of the pair of liquid crystal polymer films at the lamination position are parallel to each other or cross each other, a light-shielding blade having a strength higher than that of a biaxially stretched PET film is obtained when the thickness is the same. Can do. Further, the physical balance as the light shielding blade is improved, and it is possible to obtain a light shielding blade with very little occurrence of warpage. Furthermore, the material itself is opaque and excellent in light-shielding properties compared to PET having an optical density of almost 0, and an LCP film having a film thickness of 25 μm has an optical density of about 0.5. By laminating one or more sheets, the optical density can be increased to about 1.5 to 2, which is further advantageous in terms of light shielding properties.

最外層に位置する対の液晶ポリマーフィルムの結晶配向方向を相互に平行にした場合、遮光羽根としての大きな機械的強度を発現させることができ、特にこれら最外層に位置する一対の液晶ポリマーフィルムの結晶配向方向を遮光羽根の移動方向に対して直交させることにより、遮光羽根に求められる機械的強度を有効に働かせることが可能となる。特に、最外層よりも内側に位置する対の液晶ポリマーフィルムの結晶配向方向を、最外層に位置する対の液晶ポリマーフィルムの結晶配向方向に対して幾何学的に対称に交差させた場合、遮光羽根としての物性的バランスをさらに向上させることができ、反りなどの発生を確実に防ぐことができる。 When the crystal orientation directions of the pair of liquid crystal polymer films located in the outermost layer are parallel to each other, a large mechanical strength as a light-shielding blade can be expressed, and in particular, the pair of liquid crystal polymer films located in the outermost layer By making the crystal orientation direction orthogonal to the moving direction of the light shielding blade, the mechanical strength required for the light shielding blade can be effectively exerted. In particular, when the crystal orientation direction of the pair of liquid crystal polymer films located on the inner side of the outermost layer is crossed geometrically symmetrically with respect to the crystal orientation direction of the pair of liquid crystal polymer films located on the outermost layer, light shielding The physical property balance as a blade can be further improved, and the occurrence of warpage can be reliably prevented.

熱可塑性樹脂がポリエステル樹脂の場合、その他の熱可塑性樹脂に比べ、液晶ポリマーとの分子構造が近く、熱溶着性や反りなどの点で有利である。また、ポリアミド樹脂の場合、吸湿による膨潤等の問題があって好ましいとは言えない。 When the thermoplastic resin is a polyester resin, the molecular structure is close to that of the liquid crystal polymer compared to other thermoplastic resins, which is advantageous in terms of thermal weldability and warpage. Moreover, in the case of a polyamide resin, it cannot be said that there is a problem such as swelling due to moisture absorption.

相互に重なり合う熱可塑性樹脂フィルムと液晶ポリマーフィルムとの間または2層の液晶ポリマーフィルムの間に遮光剤を含む遮光性改善層を形成した場合、得られる遮光羽根の遮光性を向上させることができる上、この遮光性改善層を接着剤を主体に形成することにより、相互に重なり合うフィルムの接合力を確実に向上させることができる。 When a light-shielding improvement layer containing a light-shielding agent is formed between a thermoplastic resin film and a liquid crystal polymer film that overlap each other or between two liquid crystal polymer films, the light-shielding property of the resulting light-shielding blade can be improved. In addition, by forming the light-shielding improvement layer mainly using an adhesive, it is possible to reliably improve the bonding strength of the films that overlap each other.

熱可塑性樹脂フィルムおよび少なくとも1層の液晶ポリマーフィルムに遮光剤を添加した場合、遮光剤が添加されたCFRPのように複雑な手間を全く必要とせず、LCPフィルムの成形時にカーボンブラックなどの遮光剤を分散および練り混むことができるので、より多量の遮光剤を均一に混入させることが可能であり、遮光特性をさらに向上させることができる。 When a light-shielding agent is added to the thermoplastic resin film and at least one liquid crystal polymer film, there is no need for complicated work as in CFRP to which a light-shielding agent is added, and a light-shielding agent such as carbon black is used when forming an LCP film. Can be dispersed and kneaded, so that a larger amount of the light-shielding agent can be mixed uniformly, and the light-shielding characteristics can be further improved.

最外層に位置する液晶ポリマーフィルムの表面に、遮光性,潤滑性および帯電防止性のうちの少なくとも1つの機能を有する機能層を形成した場合、遮光羽根としての機能をさらに向上させることができる。 In the case where a functional layer having at least one of light shielding properties, lubricity, and antistatic properties is formed on the surface of the liquid crystal polymer film located in the outermost layer, the function as a light shielding blade can be further improved.

本発明の第2の形態は、本発明の第1の形態による遮光羽根を用いた光路開閉装置であって、対をなす液晶ポリマーフィルムの結晶配向方向が遮光羽根の移動方向に対して幾何学的に対称に交差しているか、あるいは最外層に位置する対の液晶ポリマーフィルムの結晶配向方向が遮光羽根の移動方向に対してほぼ直交していることを特徴とするものである。 According to a second aspect of the present invention, there is provided an optical path opening / closing device using the light shielding blade according to the first aspect of the present invention, wherein the crystal orientation direction of the liquid crystal polymer film forming a pair is geometric with respect to the moving direction of the light shielding blade. The crystal orientation directions of the pair of liquid crystal polymer films located on the outermost layer are substantially orthogonal to the moving direction of the light shielding blades.

遮光羽根の厚さは、50〜200μmの範囲にあることが好ましく、特に70〜120μmの範囲となるようにすることが有効である。遮光羽根の厚さが50μm未満の場合、遮光羽根としての機械的強度が不足する上に遮光性も不足してしまう可能性がある。逆に、厚さが200μmを超えると、機械的強度は増加するものの、遮光羽根自体の重量増に伴う慣性質量の増大により、駆動系などに負担がかかってしまう。特に、フォーカルプレーンシャッタに採用した場合、先膜と後膜との距離が離れてしまい、シャッタ効率が落ちてしまうこととなる。 The thickness of the light shielding blade is preferably in the range of 50 to 200 μm, and particularly effective in the range of 70 to 120 μm. When the thickness of the light shielding blade is less than 50 μm, the mechanical strength as the light shielding blade is insufficient and the light shielding property may be insufficient. On the other hand, when the thickness exceeds 200 μm, the mechanical strength increases, but the inertial mass increases with the increase in the weight of the light shielding blade itself, which places a burden on the drive system and the like. In particular, when employed in a focal plane shutter, the distance between the front film and the rear film is increased, and the shutter efficiency is reduced.

本発明の光路開閉装置によると、本発明による遮光羽根を用い、対をなす液晶ポリマーフィルムの結晶配向方向を遮光羽根の移動方向に対して幾何学的に対称に交差させるか、あるいは最外層に位置する対の液晶ポリマーフィルムの結晶配向方向を遮光羽根の移動方向に対してほぼ直交させることにより、製造が容易であって高強度かつ高弾性を有し、反りの少ない軽量な遮光羽根を用いた光路開閉装置を実現することができる。 According to the optical path switching device of the present invention, the light shielding blade according to the present invention is used, and the crystal orientation direction of the liquid crystal polymer film forming a pair is crossed geometrically symmetrically with respect to the moving direction of the light shielding blade, or the outermost layer is formed on the outermost layer. By making the crystal orientation direction of the paired liquid crystal polymer film almost orthogonal to the moving direction of the light shielding blade, it is easy to manufacture, has high strength and high elasticity, and uses a light shielding blade with little warpage It is possible to realize the optical path switching device.

本発明による遮光羽根をフォーカルプレーンシャッタに応用した一実施形態について、図1〜図4を参照しながら詳細に説明するが、本発明はこのような実施形態のみに限らず、特許請求の範囲に記載された本発明の概念に包含されるあらゆる変更や修正が可能であり、従って本発明の精神に帰属する他の技術にも当然応用することができる。 An embodiment in which the light-shielding blade according to the present invention is applied to a focal plane shutter will be described in detail with reference to FIGS. 1 to 4, but the present invention is not limited to such an embodiment, and is within the scope of the claims. All changes and modifications encompassed by the described inventive concept are possible and can of course be applied to other techniques belonging to the spirit of the invention.

本実施形態によるフォーカルプレーンシャッタユニットの正面形状を図1に示し、そのII−II矢視断面構造を図2に示す。すなわち、このフォーカルプレーンシャッタユニット10は、いわゆる縦走りタイプと呼称されているものであり、先膜11および後膜12として、相互に重なり合う複数枚(図示例ではそれぞれ5枚および4枚)の遮光羽根13,14,15,16,17,18,19,20,21を用いている。このようなフォーカルプレーンシャッタユニット10自体の具体的構成は、特開平10−186448号公報,特開2002−229097号公報,特開2003−280065号公報などで周知の通りである。

The front shape of the focal plane shutter unit according to the present embodiment is shown in FIG. 1, and the sectional structure taken along the line II-II is shown in FIG. In other words, this focal

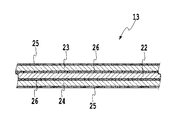

本実施形態における遮光羽根13〜21のうちの1枚の遮光羽根(以下、便宜的にこれらを代表して13で示す)の分解状態を図3に示し、その断面構造を図4に示す。すなわち、本実施形態の遮光羽根13は、1枚のPETフィルム22と、これを挟むように2枚のLCPフィルム23,24とを積層してなり、最外層に位置する2枚のLCPフィルム23,24の結晶配向方向が相互に平行に設定されている。この遮光羽根13の表裏両面には、その遮光性を改善するための黒色塗料が塗布され、本発明における機能層25を構成している。また、相互に重なり合うPETフィルム22とLCPフィルム23,24との間には、遮光性改善層26がそれぞれ形成されている。図1中、上下方向に走行する本実施形態における遮光羽根13は、それぞれ細長い矩形の板状をなし、最外層に位置する2枚のLCPフィルム23,24の配向方向がこの遮光羽根13の長手方向と平行に延在するように切り出されている。さらに、PETフィルム22およびLCPフィルム23,24にはカーボンブラックが均一に分散混入され、その遮光性を向上させている。同様に、遮光性改善層26にもカーボンブラックが均一に分布している。

FIG. 3 shows an exploded state of one of the

次に、本発明による遮光羽根の具体的な製造方法を実施例1〜実施例5として比較参考のための比較例1〜3と共に以下に示すが、これらは何れも表裏両面に5μmの膜厚の黒色塗料を機能層として塗布し、乾燥させたものである。LCPフィルムを積層した遮光羽根の場合、相互に重なり合うLCPフィルムの結晶配向方向の角度は、遮光羽根の長手方向を基準(0°)として表している。 Next, although the specific manufacturing method of the light-shielding blade by this invention is shown below with Comparative Examples 1-3 for comparative reference as Example 1-Example 5, all of these are film thickness of 5 micrometers on both front and back. The black paint was applied as a functional layer and dried. In the case of the light shielding blades on which the LCP films are laminated, the angle of the crystal orientation directions of the LCP films overlapping each other is expressed with the longitudinal direction of the light shielding blades as a reference (0 °).

(実施例1)

上野製薬製 Ueno LCP8000 にカーボンブラックを2重量%混入した原料を用意した。そして、テクノベル製 KZW15-30MG2 を使用し、シリンダー設定温度を250℃,ダイ設定温度を270℃として円筒ダイから溶融原料を上方へ押し出し、これによって形成される筒状フィルムの中空部分に乾燥空気を圧送して筒状フィルムを膨張させ、次にこれを冷却してニップロールに通し、巻き取った。これにより、厚さが25μm,SORが1.28の黒色LCPフィルムを得た。

Example 1

A raw material prepared by mixing 2% by weight of carbon black in Ueno LCP8000 manufactured by Ueno Pharmaceutical was prepared. Then, using Technovel KZW15-30MG2, the cylinder set temperature is 250 ° C, the die set temperature is 270 ° C, the molten raw material is extruded upward from the cylindrical die, and dry air is blown into the hollow portion of the cylindrical film formed thereby. The tubular film was expanded by pumping, then it was cooled, passed through a nip roll and wound up. As a result, a black LCP film having a thickness of 25 μm and an SOR of 1.28 was obtained.

一方、表面がマット処理された25μmの厚さのユニチカ製2軸延伸黒色PETフィルムを用意し、これを先の黒色LCPフィルムで挟み、これら一対の黒色LCPフィルムの結晶配向方向をそれぞれ0°に設定した。さらに、PETフィルムとLCPフィルムとの間にカーボンブラックが33重量%混入されたエポキシ接着剤を約5μmの膜厚でそれぞれ塗布しておき、熱プレスを用いてまずプレス圧を加えずに120℃にて10分間予備加熱した後、加工温度を130℃に保ったまま5kg/cm2の圧力で120分間熱プレスを行い、これらを一体化させてその表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根を製造した。 On the other hand, a 25 μm thick biaxially stretched black PET film with a matte surface was prepared and sandwiched between the black LCP films, and the crystal orientation directions of these pair of black LCP films were set to 0 °, respectively. Set. Further, an epoxy adhesive mixed with 33% by weight of carbon black is applied between the PET film and the LCP film in a film thickness of about 5 μm, and the temperature is set to 120 ° C. without first applying a press pressure using a hot press. After preheating for 10 minutes, heat pressing is performed at a pressure of 5 kg / cm 2 for 120 minutes while maintaining the processing temperature at 130 ° C., and these are integrated and a black paint is applied to both the front and back surfaces. The shading blade was manufactured by cutting into a shape.

(実施例2)

実施例1と同じ方法にて厚さが25μmの黒色LCPフィルムを得る一方、表面がマット処理された25μmの厚さのユニチカ製2軸延伸黒色PETフィルムを用意した。そして、黒色PETフィルムを黒色LCPフィルムで挟み、これら一対の黒色LCPフィルムの結晶配向方向をそれぞれ30°,150°に設定した。さらに、PETフィルムとLCPフィルムとの間にカーボンブラックが33重量%混入されたエポキシ接着剤を約5μmの膜厚でそれぞれ塗布しておき、実施例1と同じ条件にて熱プレスを行い、これらを一体化させてその表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根を製造した。

(Example 2)

A black LCP film having a thickness of 25 μm was obtained in the same manner as in Example 1, while a 25 μm-thick biaxially stretched black PET film with a thickness of 25 μm was prepared. Then, the black PET film was sandwiched between the black LCP films, and the crystal orientation directions of the pair of black LCP films were set to 30 ° and 150 °, respectively. Further, an epoxy adhesive mixed with 33% by weight of carbon black was applied between the PET film and the LCP film in a film thickness of about 5 μm, and hot pressing was performed under the same conditions as in Example 1. Were integrated and black paint was applied to both the front and back surfaces, and then cut into a predetermined shape to produce a light shielding blade.

(実施例3)

実施例1と同じ方法にて厚さが25μmの黒色LCPフィルムを得る一方、表面がマット処理された25μmの厚さのユニチカ製2軸延伸黒色PETフィルムを用意した。そして、黒色PETフィルムを黒色LCPフィルムで挟み、これら一対の黒色LCPフィルムの結晶配向方向をそれぞれ45°,135°に設定した。さらに、PETフィルムとLCPフィルムとの間にカーボンブラックが33重量%混入されたエポキシ接着剤を約5μmの膜厚でそれぞれ塗布しておき、実施例1と同じ条件にて熱プレスを行い、これらを一体化させてその表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根を製造した。

(Example 3)

A black LCP film having a thickness of 25 μm was obtained in the same manner as in Example 1, while a 25 μm thick biaxially stretched black PET film with a thickness of 25 μm was prepared. Then, the black PET film was sandwiched between the black LCP films, and the crystal orientation directions of the pair of black LCP films were set to 45 ° and 135 °, respectively. Further, an epoxy adhesive mixed with 33% by weight of carbon black was applied between the PET film and the LCP film in a film thickness of about 5 μm, and hot pressing was performed under the same conditions as in Example 1. Were integrated and black paint was applied to both the front and back surfaces, and then cut into a predetermined shape to produce a light shielding blade.

(実施例4)

実施例1と同じ方法にて厚さが25μmの黒色LCPフィルムを得る一方、表面がマット処理された25μmの厚さのユニチカ製2軸延伸黒色PETフィルムを用意した。そして、黒色PETフィルムを黒色LCPフィルムで挟み、これら一対の黒色LCPフィルムの結晶配向方向をそれぞれ0°に設定し、熱プレスを用いてまずプレス圧を加えずに180℃にて10分間予備加熱した後、180℃の温度を保ったまま5kg/cm2の圧力で5分間熱プレスを行い、これらを一体化させてその表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根を製造した。

Example 4

A black LCP film having a thickness of 25 μm was obtained in the same manner as in Example 1, while a 25 μm-thick biaxially stretched black PET film with a thickness of 25 μm was prepared. Then, the black PET film is sandwiched between the black LCP films, the crystal orientation directions of the pair of black LCP films are set to 0 °, respectively, and preheating is performed at 180 ° C. for 10 minutes without applying press pressure first using a hot press. After that, heat-press for 5 minutes at a pressure of 5 kg / cm 2 while maintaining the temperature of 180 ° C., and after integrating them and applying black paint on both the front and back sides, cut out into a predetermined shape and shield the light-shielding blade Manufactured.

(実施例5)

上野製薬製 Ueno LCP8000 にカーボンブラックを2重量%混入した原料を用意した。そして、テクノベル製 KZW15-30MG2 を使用し、シリンダー設定温度を250℃,ダイ設定温度を270℃としてダイギャップが0.3mm,ダイ幅が120mmのTダイから溶融原料を下方へ押し出し、厚さが25μm,SORが1.46の黒色LCPフィルムを得た。

(Example 5)

A raw material prepared by mixing 2% by weight of carbon black in Ueno LCP8000 manufactured by Ueno Pharmaceutical was prepared. Then, using Technovel KZW15-30MG2, the cylinder set temperature is 250 ° C, the die set temperature is 270 ° C, the die gap is 0.3mm, the die width is pushed out from the T die with a die width of 120mm. A black LCP film having a thickness of 25 μm and an SOR of 1.46 was obtained.

一方、表面がマット処理された25μmの厚さのユニチカ製2軸延伸黒色PETフィルムを用意し、これを先の黒色LCPフィルムで挟み、これら一対の黒色LCPフィルムの結晶配向方向をそれぞれ0°に設定した。さらに、PETフィルムとLCPフィルムとの間にカーボンブラックが33重量%混入されたエポキシ接着剤を約5μmの膜厚でそれぞれ塗布しておき、実施例1と同じ条件にて熱プレスを行い、これらを一体化させてその表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根を製造した。 On the other hand, a 25 μm thick biaxially stretched black PET film with a matte surface was prepared and sandwiched between the black LCP films, and the crystal orientation directions of these pair of black LCP films were set to 0 °, respectively. Set. Further, an epoxy adhesive mixed with 33% by weight of carbon black was applied between the PET film and the LCP film in a film thickness of about 5 μm, and hot pressing was performed under the same conditions as in Example 1. Were integrated and black paint was applied to both the front and back surfaces, and then cut into a predetermined shape to produce a light shielding blade.

(比較例1)

上野製薬製 Ueno LCP8000 にカーボンブラックを2重量%混入した原料を用意した。そして、テクノベル製 KZW15-30MG2 を使用し、シリンダー設定温度を250℃,ダイ設定温度を270℃としてダイギャップが0.5mm,ダイ幅が120mmのTダイから溶融原料を下方へ押し出し、厚さが75μm,SORが1.45の黒色LCPフィルムを得た。そして、その表裏両面に黒色塗料を塗布し、所定形状に切り出して遮光羽根とした。

(Comparative Example 1)

A raw material prepared by mixing 2% by weight of carbon black in Ueno LCP8000 manufactured by Ueno Pharmaceutical was prepared. Then, using Technobell KZW15-30MG2, the cylinder set temperature is 250 ° C, the die set temperature is 270 ° C, the die gap is 0.5mm, the die width is pushed out from the T die with 120mm width, A black LCP film with 75 μm and SOR of 1.45 was obtained. And black paint was apply | coated to the front and back both surfaces, it cut out to the predetermined shape, and it was set as the light-shielding blade.

(比較例2)

従来の遮光羽根として用いられている25μmの厚さを持つCFRPのプリプレグ(遮光剤の添加なし)をその炭素繊維の方向が0°/90°/0°となるように重ね合わせ、熱プレスを用いてまずプレス圧を加えずに120℃にて10分間予備加熱を行った後、130℃に加熱して5kg/cm2の圧力にて120分間熱プレスを行い、積層されたCFRPの表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根を製造した。

(Comparative Example 2)

A CFRP prepreg with a thickness of 25 μm used as a conventional light-shielding blade (without the addition of a light-shielding agent) is superposed so that the direction of the carbon fiber is 0 ° / 90 ° / 0 °, and a hot press is performed. First of all, pre-heating at 120 ° C. for 10 minutes without applying pressing pressure, then heating to 130 ° C. and hot pressing at a pressure of 5 kg / cm 2 for 120 minutes, both sides of the laminated CFRP A black paint was applied to the substrate, and then cut into a predetermined shape to produce a light shielding blade.

(比較例3)

PETにカーボンブラックを3重量%練り込み、2軸押出機で押し出した後、これを2軸延伸して厚さが75μmの黒色PETフィルムを得た。そして、その表裏両面に黒色塗料を塗布した後、所定形状に切り出して遮光羽根とした。

(Comparative Example 3)

Carbon black was kneaded with 3% by weight of PET and extruded with a biaxial extruder, and then biaxially stretched to obtain a black PET film having a thickness of 75 μm. And after apply | coating black coating material to the front and back both surfaces, it cut out to the predetermined shape and was set as the light-shielding blade.

このようにして実施例1〜4および比較例1〜3にて得られた遮光羽根は、最外層に位置するLCPフィルムのMD方向に沿って50mm,TD方向に沿って10mmの短冊状に切り出し、これを試料としてその膜厚および重量ならびに曲げ弾性率を測定した。なお、曲げ弾性率は、この試料の両端部を30mm隔てて支持し、その中央部に4mmの変位を加えた時の荷重から求めている。 Thus, the light-shielding blades obtained in Examples 1 to 4 and Comparative Examples 1 to 3 were cut into strips of 50 mm along the MD direction and 10 mm along the TD direction of the LCP film located in the outermost layer. Using this as a sample, the film thickness and weight and the flexural modulus were measured. The bending elastic modulus is obtained from the load when both ends of the sample are supported 30 mm apart and a displacement of 4 mm is applied to the center.

また、実施例1〜5および比較例1〜3にて得られた遮光羽根を図1,図2に示すフォーカルプレーンシャッタユニット10の先膜11および後膜12として組み込み、光源から2万ルクスの明るさの光を照射した場合の光線漏れの評価を行った。さらに、常温常湿にて1/8000秒のシャッタ速度にて15万回の開閉試験を行い、その耐久性も併せて調べた。これらの結果を表1に示す。

Further, the light-shielding blades obtained in Examples 1 to 5 and Comparative Examples 1 to 3 are incorporated as the

光線漏れにおいて、「なし」というのは光線漏れがほとんど起こらないことを示し、比較例2の場合の「あり」というのは光線漏れが度々起こったことを示している。本発明の遮光羽根は、各LCPフィルム自体ならびにこれらの間の遮光性改善層および表裏両面の機能層により充分な遮光性を有していることが確認された。 In light leakage, “None” indicates that light leakage hardly occurs, and “Yes” in Comparative Example 2 indicates that light leakage frequently occurs. It was confirmed that the light-shielding blade of the present invention has sufficient light-shielding properties due to each LCP film itself, the light-shielding improvement layer between them and the functional layers on both the front and back sides.

また、耐久性において、比較例1の場合の「破損」というのは5万回で遮光羽根の最外層に位置するLCPフィルムのMD方向に沿って亀裂が入ったことを示し、比較例2の場合の「破損」というのは4万回で遮光羽根が破損したことを示している。この耐久性に関しては、比較例1および比較例3のPET単層以外の試料は15万回の開閉試験に対して問題なく、本発明の遮光羽根は、従来品と同等以上の性能を有することが確認された。 Moreover, in terms of durability, “breakage” in the case of Comparative Example 1 indicates that cracks occurred along the MD direction of the LCP film located in the outermost layer of the light shielding blade at 50,000 times. The “breakage” in the case indicates that the light-shielding blade was damaged after 40,000 times. Regarding this durability, the samples other than the PET single layer of Comparative Example 1 and Comparative Example 3 have no problem with respect to 150,000 open / close tests, and the light-shielding blade of the present invention has a performance equal to or higher than that of the conventional product. Was confirmed.

10 フォーカルプレーンシャッタユニット

11 先膜

12 後膜

13〜21 遮光羽根

22 PETフィルム

23,24 LCPフィルム

25 機能層

26 遮光性改善層

DESCRIPTION OF

Claims (8)

Shielding blade root according to any one of claims 1 to 3, wherein the thermoplastic resin is characterized in that it is a polyester resin.

8. An optical path opening / closing device using the light shielding blade according to claim 1, wherein a crystal orientation direction of a pair of liquid crystal polymer films is geometrically symmetric with respect to a moving direction of the light shielding blade. An optical path switching device characterized in that the crystal orientation direction of the pair of liquid crystal polymer films located at the outermost layer is substantially orthogonal to the moving direction of the light shielding blade.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004179916A JP4410615B2 (en) | 2004-06-17 | 2004-06-17 | Shielding blade and optical path opening / closing device using the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004179916A JP4410615B2 (en) | 2004-06-17 | 2004-06-17 | Shielding blade and optical path opening / closing device using the same |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006003632A JP2006003632A (en) | 2006-01-05 |

| JP2006003632A5 JP2006003632A5 (en) | 2009-12-03 |

| JP4410615B2 true JP4410615B2 (en) | 2010-02-03 |

Family

ID=35772068

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004179916A Expired - Fee Related JP4410615B2 (en) | 2004-06-17 | 2004-06-17 | Shielding blade and optical path opening / closing device using the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4410615B2 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007187892A (en) * | 2006-01-13 | 2007-07-26 | Canon Electronics Inc | Light shielding blade and optical path opening/closing device |

| JP5298423B2 (en) * | 2006-12-01 | 2013-09-25 | 東レ株式会社 | Shading polyester film |

| JP5633595B2 (en) * | 2013-04-03 | 2014-12-03 | 東レ株式会社 | Shading polyester film |

-

2004

- 2004-06-17 JP JP2004179916A patent/JP4410615B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006003632A (en) | 2006-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4816419B2 (en) | Laminated film | |

| JP5867203B2 (en) | Multilayer laminated film, window member using the same, and laminated glass | |

| TWI440904B (en) | Method of manufacturing phase difference plate | |

| JP2006517608A5 (en) | ||

| JP6568960B2 (en) | FIBER-REINFORCED LAMINATE, SHUTTER DEVICE AND OPTICAL DEVICE | |

| KR20160137578A (en) | Reflective polarizing film for liquid-crystal-display polarizer, liquid-crystal-display polarizer comprising same, liquid-crystal-display optical element, and liquid-crystal display | |

| JP3215815B2 (en) | Light shielding blades for optical equipment | |

| KR20210058787A (en) | Polyester protective film for flexible display device | |

| JP4410615B2 (en) | Shielding blade and optical path opening / closing device using the same | |

| JP6225495B2 (en) | Multilayer laminated film and glass window member using the same | |

| JP2011141408A (en) | Polarizing reflector | |

| KR102032316B1 (en) | Optical multilayer film, optical component and display device comprising same | |

| WO2014030698A1 (en) | Optical laminate and method for manufacturing optical laminate | |

| JP4571827B2 (en) | Optical path switch | |

| KR102539936B1 (en) | Polyester film and flexible display apparatus comprising same | |

| WO2013133102A1 (en) | Retarder manufacturing method | |

| KR102540897B1 (en) | Polyester film and flexible display apparatus comprising same | |

| JP2007147880A (en) | Light cutoff vane and light path open/close unit using it | |

| JP2003149705A (en) | Light shielding blade vane material for optical apparatus | |

| JP6853500B2 (en) | Film winding layer | |

| JP2007007880A (en) | Film and shading blade using it | |

| JP2007187892A (en) | Light shielding blade and optical path opening/closing device | |

| JP2023094097A (en) | Fiber-reinforced resin laminate, shutter device and optical device | |

| JP2023142603A (en) | Multilayer laminate film | |

| JPS62109032A (en) | Sheet material for light shielding vane and its production |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070613 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070613 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091016 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20091106 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091110 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20091113 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 4410615 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121120 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131120 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |