JP4123314B2 - refrigerator - Google Patents

refrigerator Download PDFInfo

- Publication number

- JP4123314B2 JP4123314B2 JP484499A JP484499A JP4123314B2 JP 4123314 B2 JP4123314 B2 JP 4123314B2 JP 484499 A JP484499 A JP 484499A JP 484499 A JP484499 A JP 484499A JP 4123314 B2 JP4123314 B2 JP 4123314B2

- Authority

- JP

- Japan

- Prior art keywords

- vegetable

- cold air

- cooling

- heat insulating

- storage case

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/061—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation through special compartments

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D2317/00—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass

- F25D2317/06—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation

- F25D2317/066—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the air supply

- F25D2317/0665—Details or arrangements for circulating cooling fluids; Details or arrangements for circulating gas, e.g. air, within refrigerated spaces, not provided for in other groups of this subclass with forced air circulation characterised by the air supply from the top

Abstract

Description

【0001】

【発明の属する技術分野】

この発明は貯蔵性能等の優れた冷蔵庫に関するものである。

【0002】

【従来の技術】

図9は従来の冷蔵庫の側断面図である。図において、1は野菜室で、一般的には冷蔵庫の中段または下段に設けられている。2、3は仕切りで、別の温度帯との間を区画するように設けられている。4は野菜室引出扉で、野菜室1の側壁に設けたレールやローラー等の部品からなる横行移動機構に支えられており、庫内の奥行方向に引き出し可能になっている。5は野菜収納ケースで、野菜室引出扉4と一体的に支えられている。6はフルーツ収納ケースで、果物等の野菜と区別して保存したい食品専用になっており、野菜収納ケース5内の上部を製品奥行方向にスライドすることができる。7は前記野菜収納ケース5とフルーツ収納ケース6を密閉している野菜室蓋で、仕切り2から吹き出る冷気が野菜や果物に直接当り、水分が蒸散するのを防止できる。また、仕切り2と野菜室蓋7との間は冷気が循環し野菜室1を冷却するための風路の役割も果たしている。

【0003】

【発明が解決しようとする課題】

上記のように従来の冷蔵庫の形態では、野菜収納ケース5およびフルーツ収納ケース6内の野菜や果物の水分の蒸散を防止すために、冷気を直接野菜や果物の等の食品に当てないように野菜収納ケース5およびフルーツ収納ケース6を密閉する別ピースの野菜室蓋7が必要であった。また、断熱されていない仕切り2と野菜室蓋7の上に冷気を循環させて野菜室1を冷却しているので、仕切り2や野菜室蓋7に結露し、その水滴が野菜収納ケース5およびフルーツ収納ケース6内の野菜や果物に落下するなどして見栄えも悪く不衛生に感じるなどの問題があった。

【0004】

この発明はかかる問題点を解決するためになされたもので、冷気が直接野菜ケースやフルーツ収納ケース内の野菜や果物等の貯蔵物に当たらず、野菜や果物等の貯蔵物からの水分蒸散を防ぐことができ、また、結露が発生しない貯蔵性能等の優れた冷蔵庫を提供することを目的とする。

【0005】

【課題を解決するための手段】

この発明に係る冷蔵庫は、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、前記断熱壁の下面周縁部から冷気が吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したものである。

【0006】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止リブを野菜室の側壁と所望間隔を有するように前記断熱壁から垂下させて野菜収納ケースおよびまたはフルーツ収納ケースの横側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止リブの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したものである。

【0007】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止パッキンを野菜室の側壁と所望間隔を有するように前記断熱壁から垂下するように取り付けて野菜収納ケースおよびまたはフルーツ収納ケースの横側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止パッキンの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したものである。

【0008】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止リブを野菜室の側壁と所望間隔を有するように野菜ケースの横側に垂設して野菜収納ケースおよびまたはフルーツ収納ケースの両側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止リブの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したものである。

【0009】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止パッキンを野菜室の側壁と所望間隔を有するように前記野菜ケースの横側に立ち上がるように取り付けて野菜収納ケースまたはおよびフルーツ収納ケースの両側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止パッキンの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したものである。

【0010】

また、前記冷気流入防止リブを前記野菜室の天面または野菜収納ケースと同一材料で一体成形して備えたものである。

【0011】

【発明の実施の形態】

実施の形態1.

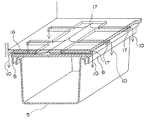

図1〜図4はこの発明に係る冷蔵庫の実施の形態1を示す野菜室を透視した断熱壁の斜視説明図、Z−Z矢視断面斜視図、正面図および風路構成の説明図である。図において、1は野菜室で、冷蔵食品として特に野菜を対象としており、一般的には冷蔵庫の中段または下段に設けられる。5は野菜収納ケースで、野菜室1の側壁に設けたレールやローラー等の部品からなる横行移動機構に支えられている野菜室引出扉4(図9参照)と一体的に支えられている。6はフルーツ収納ケースで、野菜収納ケース5内の上部に跨った状態で製品奥行方向にスライドすることができる。8は冷気流込防止リブで、野菜室1の天面の両側から側壁と所望の間隔を有し、野菜収納ケース5およびフルーツ収納ケース6を挟む状態で所望高さの隔壁を形成するように垂下している。10は冷気で、所望温度に調整され、野菜室1に流入する。16は断熱壁で、野菜室1の天面を構成する。17は野菜室冷却用風路で、野菜室1の天面を構成する断熱壁16の内部に設けられ、断熱壁16の下面の両側部では冷気流込防止リブ8の外側に開口して冷気10を吹き出すようにしている。

【0012】

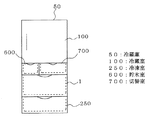

上記のように構成された実施の形態1の野菜室1は、図3に示す冷蔵庫50の中段に備えるものである。前記冷蔵庫50は、最上段が冷蔵室100、次段が引出しドアを備えた貯氷室600、および貯氷室600とは断熱壁で天井面、側面、背面の何れも完全に仕切られている切替室700になっており、最下段が冷凍室になっている。前記切替室700は、引出ドアを備えた冷凍温度帯(ー18℃)から冷蔵、野菜、チルドの温度帯に切り替えることができる。なお、野菜室1と冷凍室250とは、それぞれ5℃と−18℃の異なる温度帯なので、断熱壁で仕切られている。

【0013】

上記冷蔵庫50の冷気の循環系統を示した図4で明らかなように、野菜室1を冷却する冷気は、冷蔵室100に送られた冷気を戻すための冷蔵室用帰還風路13を野菜室1に連通させて設け、冷蔵室100から吸い込み口12bを介して帰還する途中のものである。冷蔵室100の冷却は、切替室用送風路11を通る冷気の一部を冷蔵室用送風路12に供給し、冷蔵室用ダンパ12aにより調節して行われる。冷蔵室100から送られて吹出し口14aより野菜室1に供給され、野菜室1を冷却した後の冷気は、吸込み口14bを介して野菜室用帰還風路14を通り、戻り口14cより冷却器15へ戻される。

【0014】

冷蔵室100から送られて吹出し口14aより野菜室1に供給する冷気10は、断熱壁16の中間部に設けられた野菜室冷却用風路17に取り入れ、冷気流込防止リブ8の外側に吹き出して野菜室1内を冷却するようになっている。

この結果、野菜収納ケース5およびフルーツ収納ケース6内は間接冷却されるため、冷気10が収蔵した食品に直接当たることなく食品の乾燥を防止できる。また、野菜室冷却用風路17は断熱されているので、キャベツやレタスなどを取り出し、使用後に再度収納することが行われるため、開閉頻度が他の部屋より多く、使用頻度も高い野菜室1でも、天面に結露することがなく、水滴が野菜収納ケース5およびフルーツ収納ケース6内の食品に垂れることがない。

【0015】

また、ファン18は、冷却器15で冷却された所望温度の冷気を冷蔵庫50内に循環させる。冷蔵庫50内を循環させる冷気は、貯氷室用風路19を通り、吹出し口19aより貯氷室600に供給される。同様に冷凍室用送風路20を通り、吹出し口20aより冷凍室250に供給される。貯氷室600に吹き出された冷気は、吸い込み口19bより貯氷室帰還路21を介して戻り口19cより冷却器15に戻される。冷凍室250も同様に吸い込み口20bより戻される。

【0016】

なお、野菜室冷却用風路17から野菜室1への冷気10は、冷気流込防止リブ8の外側へのみ吹き出すようにする、または冷気流込防止リブ8の外側、前面側から吹き出すようにしてもよい。さらに、冷気10は背面側からも吹き出すようにしてもよく、その際、背面側に冷気流込防止リブ8を設けてもよいものである。

【0017】

実施の形態2.

上記実施の形態1においては、冷気流込防止リブ8を断熱壁16から垂下させたが、この実施の形態2では、図5および図6に示すように野菜室1の上部の天面の断熱壁16に冷気流込防止パッキン9が取り付けられて野菜収納ケース5およびフルーツ収納ケース6を挟む状態で所望高さの隔壁を形成するように垂下し、断熱壁16の内部に設けた野菜室冷却用風路17から吹き出す冷気10を野菜収納ケース5の外側に導く構造として、冷気10が野菜収納ケース5およびフルーツ収納ケース6に冷気10が直接流入しないようになっている。この冷気流込防止パッキン9は、その長さが異なるものとすることによって、野菜収納ケース5およびフルーツ収納ケース6の外側に吹出された冷気10を野菜収納ケース5およびフルーツ収納ケース6内により一層入り難くすることができ、間接冷却の効果をより一層上げ、野菜収納ケース5およびフルーツ収納ケース6内の乾燥をさらに防ぐことができる。

【0018】

実施の形態3.

上記実施の形態1および2においては、冷気流込防止リブ8を断熱壁16から垂下したが、この実施の形態3では、図7に示すように野菜収納ケース5の上部横側に冷気流入防止リブ8を鉛直方向に備え野菜室1上部の断熱壁16の内部に設けた野菜室冷却用風路17から吹き出す冷気10を野菜収納ケース5およびフルーツ収納ケース6の外側に導く構造をとり、野菜収納ケース5およびフルーツ収納ケース6内に直接冷気10が入り込むのを防止するもので、食品の乾燥を効果的に防ぐことができる。

【0019】

実施の形態4.

上記実施の形態3においては、冷気流込防止リブ8を野菜収納ケース5の上部横側へ鉛直方向に備えたが、この実施の形態4では、図8に示すように野菜収納ケース5の上部の両側に、冷気流込防止パッキン9を断熱壁16に向かって立ち上がるように取り付けて、野菜室冷却用風路17から吹き出す冷気10を野菜収納ケース5の外側に導く構造としている。野菜収納ケース5およびフルーツ収納ケース6内に直接冷気10が入り込むのを防止する冷気流込防止パッキン9は、その長さが異なるものとすることによって、野菜収納ケース5およびフルーツ収納ケース6の外側に吹出された冷気を野菜収納ケース5およびフルーツ収納ケース6内により一層入り難くすることができ、間接冷却の効果をより一層上げ、野菜収納ケース5およびフルーツ収納ケース6内の貯蔵品の乾燥をさらに効果的に防ぐことができる。

【0020】

実施の形態5.

上記実施の形態1および3において、断熱壁16もしくは野菜収納ケース5に設けた冷気流入防止リブ8を、オレフィン系樹脂の同一材料で一体成形することによってリサイクルに有効なものとすることができる。

【0021】

【発明の効果】

この発明は、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、前記断熱壁の下面周縁部から冷気が吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したので、冷気が収蔵した食品に向かって流れるこがなく食品の乾燥を防止できる。野菜室は天面に結露することなく、野菜収納ケースおよびフルーツ収納ケースに別ピースの蓋を廃止しても、水滴が収蔵中の食品に垂れることがないので、カビの発生、腐敗等を防止でき良好な衛生状態が維持される。別ピースの蓋を廃止することにより、廃却時の分別廃却の手間を省くことができ、生産性、経済性の向上が図れる。

【0022】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止リブを野菜室の側壁と所望間隔を有するように前記断熱壁から垂下させて野菜収納ケースおよびまたはフルーツ収納ケースの横側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止リブの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したので、野菜収納ケースおよびフルーツ収納ケース内は間接冷却されるため冷気が収蔵した食品に直接当たらず、蓋で密閉することなく食品の乾燥防止等の上記のような効果がさらに向上する。

【0023】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止パッキンを野菜室の側壁と所望間隔を有するように前記断熱壁から垂下するように取り付けて野菜収納ケースおよびまたはフルーツ収納ケースの横側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止パッキンの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したので、上記のような効果が得られるとともに、設計変更への対応度を高めること等が図れる。

【0024】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止リブを野菜室の側壁と所望間隔を有するように野菜ケースの横側に垂設して野菜収納ケースおよびまたはフルーツ収納ケースの両側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止リブの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したので、野菜室の構造がシンプルになり、上記と同様な効果が得られるとともに、生産コストの低減等が図れる。

【0025】

また、野菜室の天面を断熱壁で形成するとともに、前記断熱壁の内部に野菜室冷却用風路を設け、冷気流込防止パッキンを野菜室の側壁と所望間隔を有するように前記野菜ケースの横側に立ち上がるように取り付けて野菜収納ケースまたはおよびフルーツ収納ケースの両側に所望高さの隔壁を形成し、冷気が側壁と冷気流込防止パッキンの間から吹き出す構成として、前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したので、上記と同様な効果が得られる。

【0026】

また、前記冷気流入防止リブを前記野菜室天面または野菜収納ケースと同一材料で一体成形して備えたので、上記と同様な効果が得られるとともに、リサイクルに有効なものとすることができる。

【図面の簡単な説明】

【図1】 この発明に係る冷蔵庫の実施の形態1を示す野菜室を透視した断熱壁の斜視説明図である。

【図2】 図1のZ−Z矢視断面斜視図である。

【図3】 この発明に係る冷蔵庫の実施の形態1を示す正面図である。

【図4】 この発明に係る冷蔵庫の実施の形態1を示す風路構成の説明図である。

【図5】 この発明に係る冷蔵庫の実施の形態2の野菜室を透視して示す断熱壁の斜視説明図である。

【図6】 図5のY−Y矢視を示す断面斜視図である。

【図7】 この発明に係る冷蔵庫の実施の形態3を示す野菜室の断面説明図である。

【図8】 この発明に係る冷蔵庫の実施の形態4を示す野菜室の断面説明図である。

【図9】 従来の冷蔵庫の実施の形態を示す野菜室の側面断面図である。

【符号の説明】

1 野菜室、2,3 仕切り、4 野菜室引出扉、5 野菜収納ケース、6 フルーツ収納ケース、7 野菜室蓋、8 冷気流込防止リブ、9 冷気流込防止パッキン、10 冷気、11 切替室用送風路、11a 切替室用ダンパ、11b 吸込み口、11c 吹出し口、12 冷蔵室用送風路、12a 冷蔵室用ダンパ、12b 吸込み口、13 冷蔵室用帰還風路、14 野菜室用帰還風路、14a 吹出し口、14b吸込み口、14c 戻り口、15 冷却器、16 断熱壁、17 野菜室冷却用風路、18 ファン、19 貯氷室用風路、19a 吹出し口、19b 吸込み口、19c 吹出し口、20 冷凍室用風路、20a吹出し口、20b 吸込み口、21 貯氷室用帰還風路、22 切替室用帰還風路、50 冷蔵庫、100 冷蔵室、250 冷凍室、600 貯氷室、700 切替室。[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a refrigerator having excellent storage performance and the like.

[0002]

[Prior art]

FIG. 9 is a side sectional view of a conventional refrigerator. In the figure,

[0003]

[Problems to be solved by the invention]

As described above, in the form of the conventional refrigerator, in order to prevent the moisture of the vegetables and fruits in the

[0004]

The present invention has been made to solve such a problem, and the cold air does not directly hit the storage of vegetables and fruits in the vegetable case and the fruit storage case. An object of the present invention is to provide a refrigerator that can be prevented and has excellent storage performance and the like that do not cause condensation.

[0005]

[Means for Solving the Problems]

Refrigerator according to the present invention, to form a top surface of the vegetable compartment in the heat insulating wall, the interior of the heat insulating wall provided vegetable compartment cooling air path, as cool air blown out configuration from the lower surface peripheral edge portion of the insulation wall, said The vegetable room is indirectly cooled without being directly exposed to the cold air, and the air passage for cooling the vegetable room is thermally insulated to form a cool air air path insulated on the top surface of the vegetable room .

[0006]

In addition, the top surface of the vegetable room is formed with a heat insulating wall , and the air passage for cooling the vegetable room is provided inside the heat insulating wall, and the heat insulating wall is provided so that the cold air entrainment prevention rib has a desired distance from the side wall of the vegetable room. is suspended from forming a partition wall of a desired height on the side of the vegetable storage case and or fruit storage case, cold air and configured to blow out from between the side wall and the cold air flow-preventing ribs, cold air directly hits the crisper Indirect cooling is performed, and the air passage for cooling the vegetable compartment is insulated to form a cold air passage insulated on the top surface of the vegetable compartment .

[0007]

In addition, the top surface of the vegetable room is formed by a heat insulating wall, the vegetable room cooling air passage is provided inside the heat insulating wall, and the heat insulating wall is provided so that the cold air entrainment prevention packing has a desired distance from the side wall of the vegetable room. mounted so as to depend from the lateral side of the vegetable storage case and or fruit storage case to form a partition wall of the desired height, and configured to cool air blown out from between the side walls, cold flow-preventing gasket, cold air into the vegetable compartment Indirect cooling without direct hitting, and the air passage for cooling the vegetable compartment is insulated to form a cold air passage insulated on the top surface of the vegetable compartment .

[0008]

In addition, the top of the vegetable room is formed with a heat insulating wall, a vegetable room cooling air passage is provided inside the heat insulating wall , and a cold air entrainment prevention rib is formed on the vegetable case so as to have a desired distance from the side wall of the vegetable room. It was suspended from the lateral side to form a partition wall of the vegetable storage case and or both sides to the desired height of the fruit storage case, and a configuration in which cold air is blown out from between the side walls, cold flow-preventing ribs, cold air into the vegetable compartment is In addition to indirect cooling without direct contact, the vegetable room cooling air path is thermally insulated to form a cold air path thermally insulated on the top of the vegetable room .

[0009]

In addition, the vegetable case is formed so that the top surface of the vegetable room is formed of a heat insulating wall, and the air passage for cooling the vegetable room is provided inside the heat insulating wall , and the cold air entrainment prevention packing has a desired distance from the side wall of the vegetable room. mounting to rise on the side in both sides of the vegetable storage case or and fruits storage case to form a partition wall of the desired height, and configured to cool air blown out from between the side walls, cold flow-preventing gasket, the vegetable compartment of In addition to indirect cooling without direct contact with cold air, the air passage for cooling the vegetable compartment is insulated to form a cold air passage insulated on the top surface of the vegetable compartment .

[0010]

The cold air inflow prevention rib is integrally formed of the same material as the top of the vegetable compartment or the vegetable storage case.

[0011]

DETAILED DESCRIPTION OF THE INVENTION

1 to 4 are a perspective explanatory view of a heat insulating wall seen through a vegetable

[0012]

The

[0013]

As is apparent from FIG. 4 showing the cold air circulation system of the

[0014]

The

As a result, since the inside of the

[0015]

Further, the

[0016]

The

[0017]

In the first embodiment, the cold air

[0018]

In the first and second embodiments, the cold air

[0019]

In the said

[0020]

In the first and third embodiments, the cold air

[0021]

【The invention's effect】

This invention is to form a top surface of the vegetable compartment in the heat insulating wall, the interior of the heat insulating wall provided vegetable compartment cooling air path, a structure in which cold air is blown from the lower surface peripheral edge portion of the insulation wall, the vegetable compartment The cold air is not directly hit but indirectly cooled , and the vegetable room cooling air path is insulated to form a cold air path insulated on the top of the vegetable room, so that the cold air is stored in the food. This prevents the food from drying out. The vegetable room does not condense on the top surface, and even if the lid of the vegetable storage case and fruit storage case is abolished, water drops do not drip on the food being stored, preventing mold generation, decay, etc. And good hygiene is maintained. By eliminating the lid of the separate piece, it is possible to save time and labor for separation and disposal, and to improve productivity and economy.

[0022]

In addition, the top surface of the vegetable room is formed with a heat insulating wall , and the air passage for cooling the vegetable room is provided inside the heat insulating wall, and the heat insulating wall is provided so that the cold air entrainment prevention rib has a desired distance from the side wall of the vegetable room. is suspended from forming a partition wall of a desired height on the side of the vegetable storage case and or fruit storage case, cold air and configured to blow out from between the side wall and the cold air flow-preventing ribs, cold air directly hits the crisper Without indirect cooling, and because the air passage for cooling the vegetable compartment is insulated to form a cold air passage insulated on the top of the vegetable compartment, the inside of the vegetable storage case and the fruit storage case is Since it is indirectly cooled, the above-mentioned effects such as prevention of drying of the food can be further improved without directly hitting the food stored in the cold and without sealing with a lid.

[0023]

In addition, the top surface of the vegetable room is formed by a heat insulating wall, the vegetable room cooling air passage is provided inside the heat insulating wall, and the heat insulating wall is provided so that the cold air entrainment prevention packing has a desired distance from the side wall of the vegetable room. mounted so as to depend from the lateral side of the vegetable storage case and or fruit storage case to form a partition wall of the desired height, and configured to cool air blown out from between the side walls, cold flow-preventing gasket, cold air into the vegetable compartment Indirect cooling without direct hitting, and by forming a cold air passage insulated on the top of the vegetable compartment by insulating the air passage for cooling the vegetable compartment, the effects as described above As a result, the degree of response to design changes can be increased.

[0024]

In addition, the top of the vegetable room is formed with a heat insulating wall, a vegetable room cooling air passage is provided inside the heat insulating wall , and a cold air entrainment prevention rib is formed on the vegetable case so as to have a desired distance from the side wall of the vegetable room. and vertically on the side to form a partition wall of the vegetable storage case and or both sides to the desired height of the fruit storage case, and a configuration in which cold air is blown out from between the side walls, cold flow-preventing ribs, cold air into the vegetable compartment is In addition to indirect cooling without direct contact, the vegetable room cooling air path is insulated to form a cold air path insulated on the top of the vegetable room, so the structure of the vegetable room is simple Thus, the same effects as described above can be obtained, and the production cost can be reduced.

[0025]

In addition, the vegetable case is formed so that the top surface of the vegetable room is formed of a heat insulating wall, and the air passage for cooling the vegetable room is provided inside the heat insulating wall , and the cold air entrainment prevention packing has a desired distance from the side wall of the vegetable room. mounting to rise on the side in both sides of the vegetable storage case or and fruit storage case to form a partition wall of the desired height, and configured to cool air blown out from between the side walls, cold flow-preventing gasket, the vegetable compartment of Since cold air is not directly applied but indirectly cooled and the vegetable room cooling air path is insulated to form a cold air path insulated on the top of the vegetable room, the same effect as above Is obtained.

[0026]

In addition, since the cold air inflow prevention rib is integrally formed of the same material as the vegetable room top surface or the vegetable storage case, the same effect as described above can be obtained, and it can be effective for recycling.

[Brief description of the drawings]

FIG. 1 is a perspective explanatory view of a heat insulating wall seen through a vegetable compartment showing a refrigerator according to a first embodiment of the present invention.

FIG. 2 is a cross-sectional perspective view taken along the line ZZ in FIG.

FIG. 3 is a front

FIG. 4 is an explanatory diagram of an air passage

FIG. 5 is a perspective explanatory view of a heat insulating wall seen through a vegetable compartment in a refrigerator according to a second embodiment of the present invention.

6 is a cross-sectional perspective view taken along the arrow YY in FIG.

FIG. 7 is a cross-sectional explanatory view of a vegetable

FIG. 8 is a cross sectional view of a vegetable

FIG. 9 is a side sectional view of a vegetable room showing an embodiment of a conventional refrigerator.

[Explanation of symbols]

1 vegetable compartment, 2, 3 partitions, 4 vegetable compartment drawer door, 5 vegetable storage case, 6 fruit storage case, 7 vegetable compartment lid, 8 cold air entrainment prevention rib, 9 cold air entrainment prevention packing, 10 cold air, 11 switching room Blower, 11a Switching room damper, 11b Suction port, 11c Outlet, 12 Refrigerator room, 12a Chiller damper, 12b Suction port, 13 Refrigerator return air path, 14 Vegetable room return air path , 14a Air outlet, 14b Air inlet, 14c Return port, 15 Cooler, 16 Heat insulation wall, 17 Vegetable room cooling air passage, 18 Fan, 19 Ice storage air passage, 19a Air outlet, 19b Air inlet, 19c Air outlet , 20 Freezer compartment air channel, 20a outlet, 20b Suction port, 21 Ice storage chamber return air channel, 22 Switch room return air channel, 50 Refrigerator, 100 Refrigeration room, 250 Freezer room, 600 Ice storage room, 7 0 switching room.

Claims (6)

前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、

前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したことを特徴とする冷蔵庫。While forming the top surface of the vegetable room with a heat insulating wall, providing a vegetable room cooling air passage inside the heat insulating wall, as a configuration in which cold air blows out from the lower peripheral edge of the heat insulating wall ,

Indirect cooling without direct air hitting the vegetable compartment ,

A refrigerator characterized in that a cold air passage insulated from the top of the vegetable compartment is formed by insulating the air passage for cooling the vegetable compartment .

前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、

前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したことを特徴とする冷蔵庫。The top surface of the vegetable room is formed with a heat insulating wall , and the air passage for cooling the vegetable room is provided inside the heat insulating wall , and the cold air entrainment prevention rib is suspended from the heat insulating wall so as to have a desired distance from the side wall of the vegetable room. by forming a desired height of the partition wall on the side of the vegetable storage case and or fruit storage case, and a configuration in which cold air is blown out from between the side walls, cold flow-prevention rib,

Indirect cooling without direct air hitting the vegetable compartment,

A refrigerator characterized in that a cold air passage insulated from the top of the vegetable compartment is formed by insulating the air passage for cooling the vegetable compartment .

前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、

前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したことを特徴とする冷蔵庫。The top surface of the vegetable room is formed with a heat insulating wall , and an air passage for cooling the vegetable room is provided inside the heat insulating wall, and the cooling air entrainment prevention packing is suspended from the heat insulating wall so as to have a desired distance from the side wall of the vegetable room. mounted for forming a partition wall of a desired height on the side of the vegetable storage case and or fruit storage case, and a configuration in which cold air is blown out from between the side walls, cold flow-preventing gasket,

Indirect cooling without direct air hitting the vegetable compartment,

A refrigerator characterized in that a cold air passage insulated from the top of the vegetable compartment is formed by insulating the air passage for cooling the vegetable compartment .

前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、

前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したことを特徴とする冷蔵庫。The vegetable room top is formed with a heat insulating wall, the vegetable room cooling air passage is provided inside the heat insulating wall , and the cold air entrainment prevention rib is placed on the side of the vegetable case so as to have a desired distance from the vegetable room side wall. and vertically on both sides of vegetable storage case and or fruit storage case to form a partition wall of the desired height, and configured to cool air blown out from between the side walls, cold flow-prevention rib,

Indirect cooling without direct air hitting the vegetable compartment,

A refrigerator characterized in that a cold air passage insulated from the top of the vegetable compartment is formed by insulating the air passage for cooling the vegetable compartment .

前記野菜室に冷気が直接当たることなく間接冷却するようにするとともに、

前記野菜室冷却用風路を断熱することにより前記野菜室の天面に断熱された冷気風路を形成したことを特徴とする冷蔵庫。The top surface of the vegetable room is formed with a heat insulating wall, a vegetable room cooling air passage is provided inside the heat insulating wall , and a cold air entrainment prevention packing is placed beside the vegetable case so as to have a desired distance from the side wall of the vegetable room. mounted so as to rise to the side to form a partition wall of a desired height on both sides of the vegetable storage case or and fruit storage case, cold air and configured to blow out from between the side wall and the cold air flow-preventing gasket,

Indirect cooling without direct air hitting the vegetable compartment,

A refrigerator characterized in that a cold air passage insulated from the top of the vegetable compartment is formed by insulating the air passage for cooling the vegetable compartment .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP484499A JP4123314B2 (en) | 1999-01-12 | 1999-01-12 | refrigerator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP484499A JP4123314B2 (en) | 1999-01-12 | 1999-01-12 | refrigerator |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2000205732A JP2000205732A (en) | 2000-07-28 |

| JP2000205732A5 JP2000205732A5 (en) | 2005-10-27 |

| JP4123314B2 true JP4123314B2 (en) | 2008-07-23 |

Family

ID=11595003

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP484499A Expired - Fee Related JP4123314B2 (en) | 1999-01-12 | 1999-01-12 | refrigerator |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4123314B2 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007105902A1 (en) * | 2006-03-13 | 2007-09-20 | Lg Electronics Inc. | A cool air supply structure of storage receptacle for refrigerator |

| JP4799288B2 (en) * | 2006-06-23 | 2011-10-26 | シャープ株式会社 | refrigerator |

| JP5573014B2 (en) * | 2008-06-19 | 2014-08-20 | パナソニック株式会社 | refrigerator |

| JP5985936B2 (en) * | 2012-09-06 | 2016-09-06 | シャープ株式会社 | refrigerator |

| JP6543131B2 (en) * | 2015-08-07 | 2019-07-10 | 日立グローバルライフソリューションズ株式会社 | refrigerator |

| CN107782040B (en) * | 2017-10-30 | 2020-03-31 | 青岛海尔股份有限公司 | Fresh-keeping chamber and refrigerator thereof |

| CN107940862B (en) * | 2017-10-30 | 2020-06-30 | 青岛海尔股份有限公司 | Fresh-keeping control method |

| WO2020170386A1 (en) * | 2019-02-21 | 2020-08-27 | 三菱電機株式会社 | Refrigerator |

| CN114659336B (en) * | 2020-12-23 | 2023-11-03 | 合肥华凌股份有限公司 | Drawer assembly and refrigeration equipment |

-

1999

- 1999-01-12 JP JP484499A patent/JP4123314B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2000205732A (en) | 2000-07-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3814537B2 (en) | refrigerator | |

| JP2008256349A (en) | Refrigerator | |

| JP4123314B2 (en) | refrigerator | |

| JPH07218088A (en) | Refrigerator | |

| JP2007120942A (en) | Refrigerator | |

| JP2002357385A (en) | Constitution of vegetable chamber of refrigerator | |

| JP2017116121A (en) | refrigerator | |

| JP4079960B2 (en) | refrigerator | |

| JP2000304435A (en) | Refrigerator | |

| JP6793457B2 (en) | refrigerator | |

| JP6592274B2 (en) | refrigerator | |

| JP2983824B2 (en) | Horizontal refrigerator | |

| JP2001280795A (en) | Refrigerator | |

| JP2002295947A (en) | Freezer/refrigerator | |

| JP2001116425A (en) | Refrigerator | |

| JPH0755321A (en) | Freezer/refrigerator | |

| JP2004340449A (en) | Refrigerator | |

| JP2007271243A (en) | Storage | |

| JP2002295953A (en) | Refrigerator | |

| JP2023095342A (en) | refrigerator | |

| JP2023132900A (en) | refrigerator | |

| JPH09126628A (en) | Storeroom with high humidity and low temperature | |

| JP2001280796A (en) | Cooling box | |

| JP2017161129A (en) | refrigerator | |

| JPH04174273A (en) | Freezing refrigerator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050720 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050720 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20071126 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071204 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080109 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080415 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080422 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110516 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110516 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120516 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120516 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130516 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140516 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |