JP4092089B2 - Foamed synthetic resin packaging container - Google Patents

Foamed synthetic resin packaging container Download PDFInfo

- Publication number

- JP4092089B2 JP4092089B2 JP2001171520A JP2001171520A JP4092089B2 JP 4092089 B2 JP4092089 B2 JP 4092089B2 JP 2001171520 A JP2001171520 A JP 2001171520A JP 2001171520 A JP2001171520 A JP 2001171520A JP 4092089 B2 JP4092089 B2 JP 4092089B2

- Authority

- JP

- Japan

- Prior art keywords

- synthetic resin

- packaging container

- groove

- box

- foamed synthetic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Description

【0001】

【発明の属する技術分野】

本発明は、合成樹脂製包装容器に関し、更に詳しくは、断熱性、保冷性に優れ、長時間にわたって保冷することが可能な発泡合成樹脂製の包装容器に関する。

【0002】

【従来の技術】

近年、発泡合成樹脂製容器は、軽量で、衛生的で、断熱性に優れていることから冷凍、あるいは冷蔵を必要とする魚介類等の生鮮食品の包装容器として広く使用されている。

【0003】

発泡合成樹脂製包装容器は、発泡スチレン等の発泡合成樹脂が箱状に成形され、強度あるいは断熱性を確保するために肉厚の壁体の容器とされ、生鮮食品を氷等の冷却材と共に収容して、輸送、保存に使用されている。

【0004】

かかる発泡合成樹脂製包装容器は、熱伝導性が低く優れた保冷容器であるが、発泡体を形成する合成樹脂は通常透明であり、発泡した場合には見掛け上は白色不透明になるが熱輻射線の透過は大きく、外部から熱が入り、保冷性を阻害する問題があった。

【0005】

かかる問題を解決することを目的として、輻射線による熱の移動を遮断して断熱性を向上するために着色した内袋に保冷物を入れて包んだ上で、これを発泡合成樹脂製包装容器に収容する技術が提案された(特開平11−245974)。

【0006】

これらの内袋11は、図5に示すように、製函業者によって函体2内に装着され、内袋11の上部を函体2の外方に折り返して函体2の外部を覆うようにして一体化されて出荷されている。しかし、内袋11の上部を函体2の外方に折り返して函体2を覆う場合には、函体の輸送、保冷物の充填等において、函体2をコンベアーで移動させる際、内袋11が周囲の固定物に触れて引っ掛かり、函体2が落下するおそれがあった。

【0007】

このため、周囲に引っ掛かることがなく、また、見た目にも美麗にまとめられた内袋付き発泡合成樹脂製包装容器が要請されている。

【0008】

【発明が解決しようとする課題】

本発明は、コンベアーによる移動中にも内袋が周囲に引っ掛かるようなことがなく、また、断熱性、保冷性に優れ、長期に保冷可能な発泡合成樹脂製の包装容器を提供するものである。

【0009】

【課題を解決するための手段】

本発明は、かかる目的を達成するため鋭意検討をした結果なされたもので、発泡合成樹脂で形成された函体の少なくとも相対向する2つの側壁の上面に、該函体内に装着される合成樹脂製内袋の上部を差込んで保持するための溝が該側壁の長さ方向に沿って形成されており、前記溝の少なくとも一端は、前記側壁の上面から前記函体の側方にかけて開放していることを特徴とする発泡合成樹脂製包装容器を提供するものである。

【0010】

また、本発明は、側壁の上面の溝が、側壁の一部又は長さ方向の全長に亘って穿設されてなる上記の発泡合成樹脂製包装容器、溝の両端が、溝に挿入された内袋を弾力的に保持するように、溝の中央部より狭隘とされてなる上記の発泡合成樹脂製包装容器、側壁の上面の溝が、側壁の全周に亘って穿設されてなる上記の発泡合成樹脂製包装容器を提供するものである。

【0011】

さらに、本発明は、函体が発泡ポリスチレンからなる上記の合成樹脂製包装容器を提供するものである。

【0012】

【発明の実施の形態】

本発明の発泡合成樹脂製包装容器1は、肉厚の合成樹脂発泡体で形成される。発泡合成樹脂製包装容器を形成する合成樹脂としては発泡ポリスチレン、発泡ポリエチレン、発泡ポリプロピレン、硬質発泡ウレタン樹脂等を用いることができる。中でも発泡ポリスチレンが好ましい。

【0013】

包装容器1は、図1に示すように、肉厚の側壁3および底板4によって箱状に形成された函体2と、函体2に結合する形状に形成された蓋体5とが組み合わされ、通常は蓋体5と組合されて使用される。

【0014】

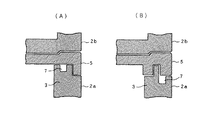

蓋体5は、函体2に結合するように嵌め合い構造とすることが望ましく、包装容器1を上下に積み重ねて移送する際に横ずれを防止して安定にするために、図4(A)、(B)に示すように、函体2の側壁3の上縁と蓋体5、蓋体5と上側函体2bの底板4の裏面がそれぞれ嵌め合い構造となるように形成することが好ましい。

【0015】

本発明発泡合成樹脂製包装容器1は、函体2の側壁3の上面6に溝7が形成されるところに特徴を有する。溝7は、後述の内袋の上部を差込んで保持させるためのもので、少なくとも相対向する2つの側壁3a、3bの上面6a、6bに、側壁3a、3bの長さ方向に穿設される。溝7は、函体2の全周、すなわち4辺全てに設けることもできる。

【0016】

この場合、溝7は側壁3a、3bの全長に亘って形成されるのが一般的であるが、目的に応じては側壁3a、3bの両端部に部分的に形成したものであってもよい。

【0017】

溝7を側壁3a、3bの全長に亘って形成する場合には、溝7の両端部7c、7dを溝7の中央部7eより若干狭くして狭隘とすることによって、内袋を弾力的に保持して抜き出し難くすることができ、また、内袋の差込みが容易となる。

【0018】

包装容器1内部には内袋11が装着される。内袋11は可撓性の合成樹脂で構成され、高圧法低密度ポリエチレン、線状低密度ポリエチレン、エチレン・酢酸ビニル共重合体、ポリプロピレン等のポリオレフィンフィルム、あるいは、塩化ビニル、ポリエステル、ポリアミド等のフィルムを用いて形成することができる。

【0019】

内袋11には、輻射線の透過を遮断する処理を行なうことが望ましく、輻射線の透過を遮断する処理としては、輻射線、特に、赤外線、近赤外線を反射する輻射線反射性物質の粉末を合成樹脂に混練することによって行なうことができる。輻射線反射性物質の粉末としては、アルミニウム、鉄、銅等の金属粉、酸化チタン、酸化亜鉛等の金属の酸化物粉体を用いることができる。

【0020】

輻射線反射性物質の添加量は目的に応じて任意に選定することができるが、一般には、1〜30重量%、好ましくは3〜20重量%程度である。

【0021】

また、合成樹脂からなるフィルムにアルミニウム等の輻射線反射性物質を積層した複合フィルムを用いることができ、輻射線反射性物質を積層する方法としては、金属箔に合成樹脂のフィルムを貼付する方法、あるいは、真空蒸着、スパッタリングによって蒸着することによって行なうことができる。中でも合成樹脂フィルムにアルミニウムを蒸着したものが好ましい。

【0022】

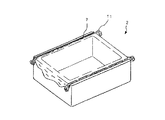

内袋11は、保冷物12を収容して函体2の内部に装填されるもので、図2に示すように、内袋11に保冷物12を収容した後、内袋11の上部を畳んで保冷物12を覆うようにして使用される。従って、内袋11は可撓性を有するように形成されると共に函体2の深さ以上の深さ、好ましくは函体2の深さの1.5〜3倍程度の深さを持つ袋が使用される。

【0023】

本発明の発泡合成樹脂製包装容器1を出荷するときは、函体2の内部に内袋11を装填して、内袋11の下部を函体2の内壁に沿わせた後、内袋11の上部を折り曲げて上下方向を束ねると共に、側壁3の長さのところを持って横方向に引張った状態で内袋11の束ねた部分を溝7に差込むことによって、図3に示すように、内袋11は弾性的に溝7に保持され、結果、内袋11が函体2の外側にはみ出すことがなく、コンベアーによる移動中に周囲のものに引っ掛かるようなおそれをなくすことができる。

【0024】

本発明の発泡合成樹脂製包装容器1は、魚介類、野菜等の生鮮食料品等の保冷を要する物品の保存、移送に使用することができ、特に鰯、秋刀魚、鯖、鯵等冷却のむらが忌避される魚類の保存、移送に適する。

【0025】

本発明の発泡合成樹脂製包装容器1を使用するときは、内袋11内に氷と共に保冷物12を入れた後、内袋11の上部を折り畳んで保冷物を覆い、その上に蓋体5を被せることによって包装を行なうことができる。

【0026】

【発明の効果】

本発明によれば、発泡合成樹脂製の函体あるいは蓋体を透過した輻射線は、内袋によって遮断されるから、保冷性に優れ、長期の保冷を行なうことができ、また、内袋は側壁で保持されているから取扱い易く、また、コンベアーによる移動中に周囲のものに引っ掛かるようなおそれがない実用的な発泡合成樹脂製包装容器が得られる。

【図面の簡単な説明】

【図1】本発明発泡合成樹脂製包装容器の函体の実施例を示す斜視図

【図2】発泡合成樹脂製包装容器の使用例を示す縦断面図

【図3】函体に内袋を取り付けた状態を示す斜視図

【図4】函体と蓋体の嵌め合い構造を示す縦断面図

【図5】従来の内袋の取り付けを示す斜視図

【符号の説明】

1:発泡合成樹脂製包装容器

2:函体

3:側壁

4:底板

5:蓋体

6:上面

7:溝

11:内袋

12:保冷物[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a synthetic resin packaging container, and more particularly to a foamed synthetic resin packaging container that is excellent in heat insulation and cold insulation and can be kept cold for a long time.

[0002]

[Prior art]

In recent years, foamed synthetic resin containers are widely used as packaging containers for fresh foods such as seafood that require freezing or refrigeration because they are lightweight, hygienic, and excellent in heat insulation.

[0003]

The foamed synthetic resin packaging container is made of foamed synthetic resin such as foamed styrene in a box shape and is a thick walled container to ensure strength or heat insulation. Housed and used for transportation and storage.

[0004]

Such a foamed synthetic resin packaging container is an excellent cold storage container having low thermal conductivity. However, the synthetic resin forming the foam is usually transparent. There was a problem that the transmission of the wire was large and heat entered from the outside, impairing the cold insulation.

[0005]

For the purpose of solving such problems, a heat-insulated material is wrapped in a colored inner bag so as to improve heat insulation by blocking the movement of heat due to radiation, and this is then wrapped in a synthetic resin packaging container. Has been proposed (Japanese Patent Laid-Open No. 11-245974).

[0006]

As shown in FIG. 5, these

[0007]

For this reason, there is a demand for a foamed synthetic resin packaging container with an inner bag that does not get caught in the surroundings and is beautifully organized.

[0008]

[Problems to be solved by the invention]

The present invention provides a packaging container made of a foamed synthetic resin that does not cause the inner bag to be caught around during movement by a conveyor, is excellent in heat insulation and cold insulation, and can be kept cold for a long period of time. .

[0009]

[Means for Solving the Problems]

The present invention has been made as a result of intensive studies to achieve such an object, and is a synthetic resin mounted on the upper surface of at least two opposing side walls of the box formed of foamed synthetic resin. A groove for inserting and holding the upper part of the inner bag is formed along the length direction of the side wall, and at least one end of the groove opens from the upper surface of the side wall to the side of the box. it is intended to provide a foamed synthetic resin packaging containers, characterized in that.

[0010]

Further, according to the present invention, the above-mentioned foamed synthetic resin packaging container, in which the groove on the upper surface of the side wall is perforated over a part of the side wall or the entire length in the length direction , both ends of the groove are inserted into the groove. The above-mentioned foamed synthetic resin packaging container, which is narrower than the central part of the groove so as to hold the inner bag elastically, the groove on the upper surface of the side wall is perforated over the entire circumference of the side wall A foamed synthetic resin packaging container is provided.

[0011]

Furthermore, the present invention provides the above-mentioned synthetic resin packaging container whose box is made of expanded polystyrene .

[0012]

DETAILED DESCRIPTION OF THE INVENTION

The foamed synthetic

[0013]

As shown in FIG. 1, the

[0014]

It is desirable that the lid 5 has a fitting structure so as to be coupled to the

[0015]

The foamed synthetic

[0016]

In this case, the

[0017]

When the

[0018]

An

[0019]

The

[0020]

The addition amount of the radiation reflecting substance can be arbitrarily selected according to the purpose, but is generally about 1 to 30% by weight, preferably about 3 to 20% by weight.

[0021]

In addition, a composite film in which a radiation reflecting material such as aluminum is laminated on a film made of a synthetic resin can be used. As a method of laminating the radiation reflecting material, a method of sticking a synthetic resin film on a metal foil Alternatively, it can be performed by vapor deposition by vacuum vapor deposition or sputtering. Among these, a synthetic resin film obtained by evaporating aluminum is preferable.

[0022]

The

[0023]

When shipping the foamed synthetic

[0024]

The

[0025]

When the foamed synthetic

[0026]

【The invention's effect】

According to the present invention, since the radiation transmitted through the box or lid made of the synthetic foam resin is blocked by the inner bag, it is excellent in cold insulation and can be kept for a long period of time. Since it is held by the side wall, it is easy to handle, and a practical foamed synthetic resin packaging container that does not get caught by surrounding objects during movement by the conveyor can be obtained.

[Brief description of the drawings]

FIG. 1 is a perspective view showing an embodiment of a case of a foamed synthetic resin packaging container according to the present invention. FIG. 2 is a longitudinal sectional view showing an example of use of a foamed synthetic resin packaging container. FIG. 4 is a longitudinal sectional view showing a fitting structure of a box and a lid. FIG. 5 is a perspective view showing attachment of a conventional inner bag.

1: foamed synthetic resin packaging container 2: box 3: side wall 4: bottom plate 5: lid body 6: upper surface 7: groove 11: inner bag 12: cold insulation

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001171520A JP4092089B2 (en) | 2001-06-06 | 2001-06-06 | Foamed synthetic resin packaging container |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001171520A JP4092089B2 (en) | 2001-06-06 | 2001-06-06 | Foamed synthetic resin packaging container |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002362630A JP2002362630A (en) | 2002-12-18 |

| JP2002362630A5 JP2002362630A5 (en) | 2005-08-04 |

| JP4092089B2 true JP4092089B2 (en) | 2008-05-28 |

Family

ID=19013279

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001171520A Expired - Fee Related JP4092089B2 (en) | 2001-06-06 | 2001-06-06 | Foamed synthetic resin packaging container |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4092089B2 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006027664A (en) * | 2004-07-16 | 2006-02-02 | Hane:Kk | Container made of foamed synthetic resin |

| JP4749034B2 (en) * | 2005-05-24 | 2011-08-17 | 株式会社羽根 | Foamed synthetic resin container |

| JP2007238110A (en) * | 2006-03-07 | 2007-09-20 | Toho Kogyo Kk | Packaging container and assembling tool therefor |

| JP4893508B2 (en) * | 2007-07-05 | 2012-03-07 | 株式会社ダイフク | Box body to which a bag is attached and a bag attachment device for attaching the bag to the box body |

| JP5281299B2 (en) * | 2008-02-21 | 2013-09-04 | 株式会社カネカ | Foamed synthetic resin container |

| KR101050712B1 (en) * | 2008-11-24 | 2011-07-20 | 지피에스코리아(주) | Packing box with cold insulation function |

| JP6060493B2 (en) * | 2011-04-08 | 2017-01-18 | 株式会社カネカ | Heat insulating laminated thin film covering the upper surface of the container in the transport container |

| JP7349771B2 (en) * | 2016-12-27 | 2023-09-25 | 大日本印刷株式会社 | Cool containers and transportation methods for perishables |

| NO346467B1 (en) * | 2020-12-22 | 2022-08-29 | Smartfoodpack As | A packaging device, system and method |

-

2001

- 2001-06-06 JP JP2001171520A patent/JP4092089B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002362630A (en) | 2002-12-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6037829B2 (en) | Foldable insulated container | |

| EP1238922B1 (en) | Portable insulated container for transporting refrigerated or frozen goods | |

| CN101754898B (en) | Insulated shipping bags | |

| US20120137637A1 (en) | Cool bags systems | |

| JP4092089B2 (en) | Foamed synthetic resin packaging container | |

| WO2001032519A1 (en) | Insulated water-tight container | |

| JP3568342B2 (en) | refrigerator | |

| WO1998031608A1 (en) | Insulated transport container | |

| US20220000235A1 (en) | Lunch box container usable on induction cooktop | |

| JPS6382968A (en) | Combination packaging capable of being heated by microwave and service vessel | |

| JPS644512Y2 (en) | ||

| JPS644513Y2 (en) | ||

| JP2003205939A (en) | Foldable heat-insulating container | |

| JPS5914369Y2 (en) | Cold storage packaging bag | |

| JP2003160173A (en) | Cold-reserving packaging container, cold-reserving container, refrigerant storage container, and cold and warm control partition, and transportation method | |

| JPH05178380A (en) | Insulating bag and method for its use | |

| JP4019485B2 (en) | Refrigerated box and method of transporting and transporting fresh food using the same | |

| CN218086964U (en) | Give birth to bright transport box | |

| JP4326911B2 (en) | Packaging bag | |

| KR200240740Y1 (en) | Structure of hot and cool insulation box | |

| JPH0340777Y2 (en) | ||

| AU720164B2 (en) | Insulated transport container | |

| JP4252851B2 (en) | Cold insulation container and inner bag for cold insulation container | |

| WO2000063082A1 (en) | Fresh food container | |

| JP4749034B2 (en) | Foamed synthetic resin container |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20041227 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050307 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20071121 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071211 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080115 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080212 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080303 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4092089 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110307 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110307 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120307 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120307 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120307 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120307 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130307 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130307 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140307 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |