JP3767897B2 - Gas supply integrated unit - Google Patents

Gas supply integrated unit Download PDFInfo

- Publication number

- JP3767897B2 JP3767897B2 JP2004056286A JP2004056286A JP3767897B2 JP 3767897 B2 JP3767897 B2 JP 3767897B2 JP 2004056286 A JP2004056286 A JP 2004056286A JP 2004056286 A JP2004056286 A JP 2004056286A JP 3767897 B2 JP3767897 B2 JP 3767897B2

- Authority

- JP

- Japan

- Prior art keywords

- flow path

- manual valve

- process gas

- common flow

- gas common

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C7/00—Methods or apparatus for discharging liquefied, solidified, or compressed gases from pressure vessels, not covered by another subclass

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C13/00—Details of vessels or of the filling or discharging of vessels

- F17C13/04—Arrangement or mounting of valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D1/00—Pipe-line systems

- F17D1/02—Pipe-line systems for gases or vapours

- F17D1/04—Pipe-line systems for gases or vapours for distribution of gas

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2205/00—Vessel construction, in particular mounting arrangements, attachments or identifications means

- F17C2205/01—Mounting arrangements

- F17C2205/0123—Mounting arrangements characterised by number of vessels

- F17C2205/013—Two or more vessels

- F17C2205/0134—Two or more vessels characterised by the presence of fluid connection between vessels

- F17C2205/0146—Two or more vessels characterised by the presence of fluid connection between vessels with details of the manifold

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2205/00—Vessel construction, in particular mounting arrangements, attachments or identifications means

- F17C2205/03—Fluid connections, filters, valves, closure means or other attachments

- F17C2205/0302—Fittings, valves, filters, or components in connection with the gas storage device

- F17C2205/0323—Valves

- F17C2205/0329—Valves manually actuated

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2205/00—Vessel construction, in particular mounting arrangements, attachments or identifications means

- F17C2205/03—Fluid connections, filters, valves, closure means or other attachments

- F17C2205/0302—Fittings, valves, filters, or components in connection with the gas storage device

- F17C2205/0382—Constructional details of valves, regulators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2223/00—Handled fluid before transfer, i.e. state of fluid when stored in the vessel or before transfer from the vessel

- F17C2223/01—Handled fluid before transfer, i.e. state of fluid when stored in the vessel or before transfer from the vessel characterised by the phase

- F17C2223/0107—Single phase

- F17C2223/0123—Single phase gaseous, e.g. CNG, GNC

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2227/00—Transfer of fluids, i.e. method or means for transferring the fluid; Heat exchange with the fluid

- F17C2227/04—Methods for emptying or filling

- F17C2227/044—Methods for emptying or filling by purging

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2250/00—Accessories; Control means; Indicating, measuring or monitoring of parameters

- F17C2250/04—Indicating or measuring of parameters as input values

- F17C2250/0404—Parameters indicated or measured

- F17C2250/043—Pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2250/00—Accessories; Control means; Indicating, measuring or monitoring of parameters

- F17C2250/06—Controlling or regulating of parameters as output values

- F17C2250/0605—Parameters

- F17C2250/0636—Flow or movement of content

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2260/00—Purposes of gas storage and gas handling

- F17C2260/02—Improving properties related to fluid or fluid transfer

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17C—VESSELS FOR CONTAINING OR STORING COMPRESSED, LIQUEFIED OR SOLIDIFIED GASES; FIXED-CAPACITY GAS-HOLDERS; FILLING VESSELS WITH, OR DISCHARGING FROM VESSELS, COMPRESSED, LIQUEFIED, OR SOLIDIFIED GASES

- F17C2270/00—Applications

- F17C2270/05—Applications for industrial use

- F17C2270/0518—Semiconductors

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Valve Housings (AREA)

- Pipeline Systems (AREA)

- Filling Or Discharging Of Gas Storage Vessels (AREA)

Description

本発明は、半導体工程にプロセスガスを供給するため、プロセスガスを分岐して供給するガス供給集積ユニットに関するものである。 The present invention relates to a gas supply integrated unit that branches and supplies a process gas to supply a process gas to a semiconductor process.

半導体製造工場においては、プロセスガスはタンクに収納されクリーンルームの外に配置されている。そして、タンクから同じプロセスガスをクリーンルーム内の複数箇所に供給するために、プロセスガスを分岐して供給するガス供給装置が使用されている。その様なガス供給装置においては、プロセスガスを新たに必要とする箇所が生じた場合には、1ライン増設する作業を行う必要がある。

図16に、3ラインの供給を行っているプロセスガス供給装置の回路図を示し、図17に、その回路を具体化した空圧機器の設置状態を平面図で示す。プロセスガスエアオペレート弁107が、プロセスガス供給口108を介して図示しないプロセスガスタンクと接続している。プロセスガスエアオペレート弁107は、プロセスガス共通流路105を介して、第2手動弁103A,103B,103Cに接続している。

In a semiconductor manufacturing factory, process gas is stored in a tank and disposed outside a clean room. In order to supply the same process gas from the tank to a plurality of locations in the clean room, a gas supply device that branches and supplies the process gas is used. In such a gas supply apparatus, when a location where a process gas is newly required arises, it is necessary to perform an operation of adding one line.

FIG. 16 shows a circuit diagram of a process gas supply apparatus that supplies three lines, and FIG. 17 shows a plan view of an installation state of pneumatic equipment embodying the circuit. A process gas air operated

第2手動弁103A,103B,103Cは、第1手動弁101A,101B,101Cに接続している。第1手動弁101A,101B,101Cの出口は、プロセスガス出口100A,100B,100Cと連通されている。第2手動弁103A,103B,103Cと、第1手動弁101A,101B,101Cとの間の流路には、圧力計102A,102B,102Cが連通されている。

また、パージガス手動弁110が、パージガス供給口111を介して図示しないパージガスタンクと接続している。パージガス手動弁111は、逆止弁109、パージガス共通流路106を介して、第3手動弁104A,104B,104Cに接続している。第3手動弁104A,104B,104Cは、第1手動弁101A,101B,101Cに接続している。

プロセスガス共通流路105の端部105aは止め栓により封止されている。パージガス共通流路106の端部106aは、止め栓により封止されている。

The second

A purge gas

An

次に、図16の3ラインの回路に1ライン増設する場合について説明する。図16には、第4ラインDを右側に記載している。図18に、増設後の回路図を示し、図19に、その回路を具体化した空圧機器の配置状態を平面図で示す。

第4ラインを増設する工事手順を説明する。この工事中は、プロセスガスは供給できず、半導体製造工程も停止している必要がある。

始めに、プロセスガスエアオペレート弁107を閉弁状態とし、第3手動弁104A,104B,104Cを開弁状態とし、第1手動弁101A,101B,101Cを開弁状態とする。その状態で、パージガス手動弁111を開弁する。これにより、プロセスガスエアオペレート弁107から第1手動弁101A,101B,101C内に残っているプロセスガスを窒素ガスであるパージガスと置換する。十分な時間をかけてガス置換を行った後、パージガス手動弁110を閉弁する。

Next, a case where one line is added to the three-line circuit of FIG. 16 will be described. In FIG. 16, the fourth line D is shown on the right side. FIG. 18 shows a circuit diagram after expansion, and FIG. 19 shows a plan view of the arrangement state of pneumatic equipment embodying the circuit.

The construction procedure for adding the fourth line will be explained. During this construction, process gas cannot be supplied and the semiconductor manufacturing process must be stopped.

First, the process gas air operated

次に、パージガス共通流路106の端部106aを封止している止め栓を外して、第4ラインのパージガス共通流路の入口端部106bと、配管112により接続する。また、プロセスガス共通流路105の端部105aを封止している止め栓を外して、第4ラインのプロセスガス共通流路の入口端部105bと、配管113により接続する。

第4ラインの機器の構成は第1から第3ラインの構成と同じなので説明を省略する。第4ラインのパージガス共通流路106の新たな端部106cは、止め栓により封止されて

いる。また、プロセスガス共通流路105の新たな端部105cは止め栓により封止されている。

次に、プロセスガス出口100Dを図示しない必要な箇所と接続する。

これにより、第4ラインの増設が終了する。

Next, the stopper plug that seals the

Since the configuration of the equipment on the fourth line is the same as the configuration of the first to third lines, description thereof is omitted. The new end portion 106c of the purge gas

Next, the

Thereby, the expansion of the fourth line is completed.

しかしながら、従来のガス供給集積ユニットには、以下の問題があった。

(1)新たなガスラインの増設工事を行う場合、既存のガスラインを停止しなければならないため、半導体製造工程が停止するときにしか増設工事を行うことができなかった。

また、増設工事を終了した後においても、プロセスガス共通流路105、及びパージガス共通流路106の図18に大気暴露部として斜線で示す部分が、大気に暴露されるため、大気中の水分が流路の内壁に付着する問題があった。即ち、プロセスガスに水分が混入すると、プロセスガスの機能が不完全となる場合があり、第4ラインを増設した後、パージガス共通流路よりパージガスを長時間流して、空気暴露した流路の水分を除去する必要があったからである。実際に、数時間から数十時間のパージが行われていた。

However, the conventional gas supply integrated unit has the following problems.

(1) When an expansion work for a new gas line is performed, the existing gas line must be stopped. Therefore, the expansion work can only be performed when the semiconductor manufacturing process is stopped.

In addition, even after the completion of the expansion work, the portions indicated by hatching in FIG. 18 of the process gas

(2)余分な配管112,113を必要とするため、ガス供給集積ユニットが横方向に大きくなり、集積化による小型化の要請に反していた。また、第4ラインは、ボルトにより、ベースプレート120に取り付けられているが、その位置あわせを配管112,113により調整する必要があり、配管工事に無駄な時間がかかる問題があった。

(2) Since

上記課題を解決するために特願2003―382139を提案した。しかしながら、本特願発明には、以下の問題があった。

増設工事を終了した後のガスラインにおいて、大気暴露された部分は回路43、回路44であり、図11に斜線で示す。この大気暴露された部分の水分を除去するため、パージガス共通流路16より、第3ガスユニット内にパージガスを流し、第3ガスユニット内の水分の除去を行う。このパージにおけるパージガスの流れとパージガスから遮断された大気残留部を図12の構成を示す平面図、図13の機器を取り除いた下部の流路ブロックを示す平面図、及び図14のプロセスガス共通流路端部手動弁22、24と下部の流路ブロックの断面図、及び図15の機器を取り除いた下部の流路ブロックを示す斜視図で示す。これらの図からわかるように、回路44にはパージガスが流れるが、回路43はパージガスから遮断され、大気が残留するという問題があった。そのため、パージが不完全となり、プロセスガスに水分が混入し、プロセスガスの機能が不完全となる場合があった。

そこで、本発明は、上記課題を解決するためになされたものであり、ラインを増設してパージを行う際、パージが確実にできるガス供給集積ユニットを提供することを目的とする。

In order to solve the above problems, Japanese Patent Application No. 2003-382139 has been proposed. However, the present invention has the following problems.

In the gas line after the completion of the expansion work, the portions exposed to the atmosphere are the circuit 43 and the

Accordingly, the present invention has been made to solve the above-described problems, and an object of the present invention is to provide a gas supply integrated unit capable of reliably purging when a line is added and purging is performed.

本発明に係るガス供給集積ユニットは、次のような構成を有している。

(1)出口流路に設けられた第1手動弁と、該第1手動弁とプロセスガス共通流路とを連通する位置に設けられた第2手動弁と、前記第1手動弁とパージガス共通流路とを連通する位置に設けられた第3手動弁とが流路ブロックにより一体に連結されているガスユニットを複数備えるガス供給集積ユニットにおいて、前記プロセスガス共通流路の端部と連通するプロセスガス共通流路端部手動弁と、前記パージガス共通流路の端部と連通するパージガス共通流路端部手動弁と、前記プロセスガス共通流路端部手動弁と連通する別のプロセスガス共通流路端部手動弁と前記パージガス共通流路端部手動弁と連通する別のパージガス共通流路端部手動弁と前記プロセスガス共通流路端部手動弁と連通する別の第2手動弁を備える増設するガスユニットと、前記別のパージガス共通流路端部手動弁の出口流路と前記別のプロセスガス共通流路端部手動弁の出口流路とを連通させる第1連通路と、前記別のプロセスガス共通流路端部手動弁の入口流路と前記プロセスガス共通流路端部手動弁の出口流路とを連通させる第2連通路と、前記プロセスガス共通流路端部手動弁の出口流路と前記別の第2手動弁の入口流路とを連通させる第3連通路とを有することを特徴とする

The gas supply integrated unit according to the present invention has the following configuration.

(1) A first manual valve provided in the outlet channel, a second manual valve provided in a position where the first manual valve and the process gas common channel communicate with each other, and the first manual valve and the purge gas in common In a gas supply integrated unit including a plurality of gas units integrally connected by a flow path block to a third manual valve provided at a position communicating with the flow path, the gas supply integrated unit communicates with an end of the process gas common flow path. Common process gas common flow path end manual valve, purge gas common flow path end manual valve communicating with the end of the purge gas common flow path, and another process gas common communicating with the process gas common flow path end manual valve Another purge gas common flow path end manual valve communicating with the flow path end manual valve and the purge gas common flow path end manual valve and another second manual valve communicating with the process gas common flow path end manual valve Additional gas uni A first communication passage that communicates the outlet flow path of the other purge gas common flow path end manual valve with the outlet flow path of the another process gas common flow path end manual valve, and the different process gas A second communication path for communicating an inlet flow path of the common flow path end manual valve and an outlet flow path of the process gas common flow path end manual valve; and an outlet flow path of the process gas common flow path end manual valve And a third communication passage that communicates with the inlet flow path of the other second manual valve.

(2)(1)に記載するガス供給集積ユニットにおいて、前記プロセスガス共通流路端部手動弁の内部に弁座に連通するように形成された出口流路を二つに分岐させ、前記増設するガスユニットの前記別のプロセスガス共通流路端部手動弁の内部に弁座に連通するように形成された出口流路を二つに分岐させていることを特徴とする。

(3)(2)に記載するガス供給集積ユニットにおいて、前記第1連通路を前記別のパージガス共通流路端部手動弁の出口流路と前記別のプロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の両方に連通させ、前記第2連通路を前記別のプロセスガス共通流路端部手動弁の入口流路と前記プロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の一方に連通させ、前期第3連通路を前記プロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の他方と前記別の第2手動弁の入口流路に連通させるように設けられていることを特徴とする。

(4)(1)に記載するガス供給集積ユニットにおいて、前記第3流路が、前記プロセスガス共通流路端部手動弁の出口流路と前記別の第2手動弁の入口流路とを連通させるように流路ブロックに形成されたU字流路であり、前記U字流路が前記第2連通路につながれていることを特徴とする。

(2) In the gas supply integrated unit described in (1), an outlet flow channel formed to communicate with a valve seat is branched into two inside the process gas common flow channel end manual valve, and the extension An outlet channel formed to communicate with the valve seat is branched into two inside the other process gas common channel end manual valve of the gas unit.

(3) In the gas supply integrated unit described in (2), the first communication path is connected to an outlet flow path of the other purge gas common flow path end manual valve and the other process gas common flow path end manual valve. The second branch passage is communicated with both of the two branched outlet passages, and the second communication passage is connected to the inlet passage of the other process gas common passage end manual valve and the process gas common passage end manual valve. One of the outlet channels branched into two is communicated, and the other third manual valve is connected to the other of the two branched outlet channels of the process gas common channel end manual valve in the previous third communication channel. It is provided so that it may be connected to the inlet flow path.

(4) In the gas supply integrated unit described in (1), the third flow path includes an outlet flow path of the process gas common flow path end manual valve and an inlet flow path of the second second manual valve. A U-shaped flow path formed in the flow path block so as to communicate with each other, wherein the U-shaped flow path is connected to the second communication path.

続いて、上記構成を有する発明の作用効果について説明する。

通常、プロセスガス共通流路の端部と連通するプロセスガス共通流路端部手動弁、及びパージガス共通流路の端部と連通するパージガス共通流路端部手動弁とは、閉弁状態にある。新しいラインを増設する場合、増設するガスユニットを、ガスの流れと直角方向に交差して複数配置されたレールに取付け、レール上を移動させて、次のように回路を接続する。

まず、既設ラインのプロセスガス共通流路端部手動弁の出口流路と増設ラインの第2手動弁の入口流路とを流路ブロック内の連通路により連通させ、第3連通路を設ける。既設ラインのパージガス共通流路端部手動弁の出口流路と増設ラインの第3手動弁の入口流路とを流路ブロック内の連通路により連通させる。既設ラインのプロセスガス共通流路端部手動弁の出口流路と増設ラインのプロセスガス共通流路端部手動弁の入口流路とをパイプにより接続し、第2連通路を設ける。尚、増設工事の前に増設ラインのプロセスガス共通流路端部手動弁の出口流路と増設ラインのパージガス共通流路端部手動弁の出口流路とは、パイプの第1連通路で接続されている。以上のように回路を接続した後、接続ボルト、増設するガスユニットの固定ボルトを締める。

Subsequently, functions and effects of the invention having the above-described configuration will be described.

Normally, the process gas common flow path end manual valve communicating with the end of the process gas common flow path and the purge gas common flow path end manual valve communicating with the end of the purge gas common flow path are in a closed state. . When a new line is added, the gas unit to be added is attached to a plurality of rails that intersect perpendicularly to the gas flow and moved on the rails, and the circuit is connected as follows.

First, the outlet flow path of the existing process gas common flow path end manual valve in the existing line and the inlet flow path of the second manual valve in the extension line are communicated by a communication path in the flow path block to provide a third communication path. The outlet flow path of the purge gas common flow path end manual valve in the existing line and the inlet flow path of the third manual valve in the extension line are communicated with each other through a communication path in the flow path block. The outlet flow path of the process gas common flow path end manual valve in the existing line and the inlet flow path of the process gas common flow path end manual valve in the extension line are connected by a pipe to provide a second communication path. Before the expansion work, connect the outlet flow path of the process gas common flow path end manual valve on the expansion line and the outlet flow path of the purge gas common flow path end manual valve on the expansion line through the first communication path of the pipe. Has been. After connecting the circuit as above, tighten the connection bolt and the fixing bolt of the gas unit to be added.

このように、増設ラインを既設ラインに接続した後、増設ラインのプロセスガス共通流路端部手動弁、パージガス共通流路端部手動弁、第1手動弁、第2手動弁及び第3手動弁を開弁状態として、既設ラインのパージガス共通流路端部手動弁を開弁する。

次に既設ラインのパージガス手動弁を開弁して、増設ライン内にパージガスが一方は第3手動弁、第1手動弁からプロセスガス出口へと流される。また、パージガスの他方はパージガス共通流路端部手動弁、プロセスガス共通流路端部手動弁、第2手動弁、第1手動弁からプロセスガス出口へと流される。こうして、特願2003―382139の発明で、パージガスが流れない回路にもパージガスを満たすことができる。パージガスが滞留する部分が一部発生するが、必要な時間パージをすれば、増設ライン内の水分の除去をほぼ完全に行うことができる。水分が除去でき、半導体製造装置側の準備が整ったら、増設ラインのプロセスガス共通流路端部手動弁、パージガス共通流路端部手動弁、及び第3手動弁を閉じ、既設ラインのプロセスガス共通流路端部手動弁を開くことにより、増設ラインにプロセスガスを供給することができる。

Thus, after connecting the extension line to the existing line, the process gas common flow path end manual valve, the purge gas common flow path end manual valve, the first manual valve, the second manual valve, and the third manual valve of the extension line Is opened, and the purge gas common flow path end manual valve of the existing line is opened.

Next, the purge gas manual valve on the existing line is opened, and one of the purge gas flows in the extension line from the third manual valve and the first manual valve to the process gas outlet. The other of the purge gas flows from the purge gas common flow path end manual valve, the process gas common flow path end manual valve, the second manual valve, and the first manual valve to the process gas outlet. Thus, according to the invention of Japanese Patent Application No. 2003-382139, the purge gas can be filled in the circuit in which the purge gas does not flow. A portion where the purge gas stays is partially generated, but if the purge is performed for a necessary time, the moisture in the extension line can be removed almost completely. When the moisture can be removed and the semiconductor manufacturing equipment is ready, close the process gas common flow path end manual valve, purge gas common flow path end manual valve, and third manual valve of the extension line, and process gas in the existing line The process gas can be supplied to the extension line by opening the common flow path end manual valve.

また、既設ラインのプロセスガス共通流路端部手動弁、及び増設ラインのプロセスガス共通流路端部手動弁にそれぞれ内部で二つに分岐した出口流路を形成することにより、パージガスを既設ラインのプロセスガス共通流路端部手動弁、及び増設ラインのプロセスガス共通流路端部手動弁のそれぞれ内部にも流すことができ、パージガスの滞留部が僅かになる。従って、増設ライン内の水分の除去をほぼ完全に行うことができる。

以上説明したように、本発明のガス供給集積ユニットは、出口流路に設けられた第1手動弁と、該第1手動弁とプロセスガス共通流路とを連通する位置に設けられた第2手動弁と、該第1手動弁とパージガス共通流路とを連通する位置に設けられた第3手動弁とが流路ブロックにより一体に連結されているガスユニットを複数備えるガス供給集積ユニットにおいて、前記プロセスガス共通流路の端部と連通するプロセスガス共通流路端部手動弁と、前記パージガス共通流路の端部と連通するパージガス共通流路端部手動弁と、前記プロセスガス共通流路端部手動弁と連通する別のプロセスガス共通流路端部手動弁と、前記パージガス共通流路端部手動弁と連通する別のパージガス共通流路端部手動弁と、前記プロセスガス共通流路端部手動弁と連通する別の第2手動弁を備える増設するガスユニットと、前記別のパージガス共通流路端部手動弁の出口流路と前記別のプロセスガス共通流路端部手動弁の出口流路とを連通させる第1連通路と、前記別のプロセスガス共通流路端部手動弁の入口流路と前記プロセスガス共通流路端部手動弁の出口流路とを連通させる第2連通路と、前記プロセスガス共通流路端部手動弁の出口流路と前記別の第2手動弁の入口流路とを連通させる第3連通路とを有するので、ラインを増設して増設ラインのパージを行う際、すべての回路にパージガスを満たすことができ、必要な時間パージを行って、増設するガスユニット内の水分をほぼ完全に除去できる。

In addition, the purge gas can be supplied to the existing line by forming an outlet flow passage that is branched into two in the process gas common flow path end manual valve in the existing line and the process gas common flow path end manual valve in the extension line. The process gas common flow path end manual valve and the process gas common flow path end manual valve of the extension line can also be flown inside, respectively, and the purge gas retention portion becomes small. Therefore, the water in the extension line can be removed almost completely.

As described above, the gas supply integrated unit according to the present invention includes the first manual valve provided in the outlet flow path, and the second manual valve provided in a position where the first manual valve and the process gas common flow path communicate with each other. In a gas supply integrated unit comprising a plurality of gas units in which a manual valve and a third manual valve provided at a position communicating with the first manual valve and the purge gas common flow path are integrally connected by a flow path block, Process gas common flow path end manual valve communicating with the end of the process gas common flow path, Purge gas common flow path end manual valve communicating with the end of the purge gas common flow path, and the process gas common flow path Another process gas common flow path end manual valve communicating with the end manual valve, another purge gas common flow path end manual valve communicating with the purge gas common flow path end manual valve, and the process gas common flow path End manual valve An additional gas unit including another second manual valve in communication; an outlet channel of the other purge gas common channel end manual valve; and an outlet channel of the other process gas common channel end manual valve A first communication path that communicates; a second communication path that communicates an inlet flow path of the other process gas common flow path end manual valve and an outlet flow path of the process gas common flow path end manual valve; Since the process gas common flow path end manual valve outlet flow path and the third flow path for communicating the second second manual valve flow path are communicated, when the line is expanded and the additional line is purged All the circuits can be filled with the purge gas, and the purge can be performed for a necessary time, so that the moisture in the additional gas unit can be removed almost completely.

さらに、本発明のガス供給集積ユニットは、前記プロセスガス共通流路端部手動弁の内部で二つに分岐した出口流路が形成され、前記増設するガスユニットの前記別のプロセスガス共通流路端部手動弁の内部で二つに分岐した出口流路が形成されているので、ラインを増設して増設ラインのパージを行う際、既存ラインのプロセスガス共通流路端部手動弁及び増設ラインのプロセスガス共通流路端部手動弁のそれぞれ内部までパージガスを流すことができ、時間をかけることなく、増設するガスユニット内の水分をほぼ完全に除去できる。 Further, in the gas supply integrated unit of the present invention, the process gas common flow path end manual valve has a bifurcated outlet flow path formed therein, and the additional process gas common flow path of the additional gas unit is formed. Since the outlet flow path branched into two inside the end manual valve is formed, when expanding the line and purging the extension line, the process gas common flow path end manual valve and the extension line of the existing line The purge gas can flow to the inside of each of the process gas common flow path end manual valves, and moisture in the added gas unit can be almost completely removed without taking time.

さらに、本発明のガス供給集積ユニットは、前記第1連通路を前記別のパージガス共通流路端部手動弁の出口流路と前記別のプロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の両方に連通させ、前記第2連通路を前記別のプロセスガス共通流路端部手動弁の入口流路と前記プロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の一方に連通させ、前期第3連通路を前記プロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の他方と前記別の第2手動弁の入口流路に連通させるように設けられているので、既存ラインのプロセスガス共通流路端部手動弁及び増設ラインのプロセスガス共通流路端部手動弁のそれぞれの内部まで、且つすべての流路にパージガスを流すことができる。従って、パージに時間をかけることなく、増設するガスユニット内の水分をほぼ完全に除去できる。 Furthermore, the gas supply integrated unit of the present invention is configured such that the first communication path is connected to the two outlets of the other purge gas common flow path end manual valve and the other process gas common flow path end manual valve. The second communication path is branched into the two of the other process gas common flow path end manual valve and the process gas common flow path end manual valve. The other end of the outlet flow path branched into the two of the process gas common flow path end manual valves and the second flow path of the second manual valve are communicated with one of the outlet flow paths. The purge gas is supplied to the interior of each process gas common flow path end manual valve of the existing line and the process gas common flow path end manual valve of the extension line, and to all the flow paths. It can flow. Therefore, it is possible to almost completely remove the moisture in the additional gas unit without spending time for purging.

次に、本発明に係るガス供給集積ユニットの第1実施例について、図面を参照して説明する。図1に、既設のラインへプロセスガスの供給を行っているガスユニットAからなるガス供給集積ユニットの回路図、及びそれに増設するための第2ガスユニットBの回路図を示す。

プロセスガスエアオペレート弁17は、プロセスガス供給口18を介して図示しないプ

ロセスガスタンクと接続している。プロセスガスエアオペレート弁17は、プロセスガス共通流路15を介して、第2手動弁13Aの一方のポートに接続している。 第2手動弁13Aの他ポートは、第1手動弁11Aに接続している。第1手動弁11Aの出口ポートは、プロセスガス出口10Aと連通している。第2手動弁13Aと、第1手動弁11Aとを連通させている流路に、圧力計12Aが連通されている。

また、パージガス手動弁20が、パージガス供給口21を介して図示しないパージガスタンクと接続している。パージガス手動弁20は、逆止弁19、パージガス共通流路16を介して、第3手動弁14Aの一方のポートに接続している。第3手動弁14Aの他のポートは、第1手動弁11Aに接続している。 プロセスガス共通流路15の端部は、プロセスガス共通流路端部手動弁22により封止されている。また、パージガス共通流路16の端部は、パージガス共通流路端部手動弁23により封止されている。

Next, a first embodiment of the gas supply integrated unit according to the present invention will be described with reference to the drawings. FIG. 1 shows a circuit diagram of a gas supply integrated unit composed of a gas unit A that supplies process gas to an existing line, and a circuit diagram of a second gas unit B to be added thereto.

The process gas air operated

The purge

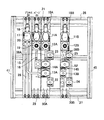

図2に、その回路を具体化した空圧機器の設置状態を平面図で示す。2本のレール26,27が、両端をレール固定棒41,45により平行に固定されている。レール26,27に沿って、ユニット固定板28,29,30Aが横方向に平行移動可能に取り付けられている。プロセスガス用ユニット固定板28には、プロセスガスエアオペレート弁17が固定されている。パージガス用ユニット固定板29には、パージガス手動弁20と逆止弁19が固定されている。

FIG. 2 is a plan view showing an installation state of a pneumatic device that embodies the circuit. Two

第1ガスユニット固定板30Aには、上から第1手動弁11A、圧力計12A、そしてパイプ38Aにつながれて、第3手動弁14A、第2手動弁13A、そして少し右側にずれた位置に既設プロセスガス共通流路端部手動弁22が固定されている。また、パイプ38Aを避けて少し右側にずれた位置に既設のパージガス共通流路端部手動弁23が固定されている。

既設ガスユニットから少し離れて、増設する第2ガスユニットが第2ガスユニット固定板30B上に固定されている。即ち、第2ガスユニット固定板30Bには、上から第1手動弁11B、圧力計12B、パイプ38Bにつながれて、第3手動弁14B、第2手動弁13B、そして少し右側にずれた位置に増設のプロセスガス共通流路端部手動弁24が固定されている。また、パイプ38Bを避けて少し右側にずれた位置にパージガス共通流路端部手動弁25が固定され、プロセスガス共通流路端部手動弁24とパージガス共通流路端部手動弁25とがパイプの第1連通路52でつながれる。

The first gas

The second gas unit to be added is fixed on the second gas

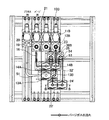

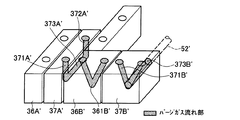

以上のように、既設ガスユニットから少し離れて、増設する第2ガスユニットが配置されている状態から、次のように第2ガスユニットの取付け工事を行う。まず、第2ガスユニットの固定板30Bを第1ガスユニットの固定板30Aに近づけて、図5及び図6で示すように、プロセスガス共通流路端部手動弁22の出口流路22bと第2ガスユニットの第2手動弁13Bの入口流路51(図3参照)とを流路ブロック37Aで連通させる。即ち、プロセスガス共通流路端部手動弁22の出口流路22bは、流路ブロック37A内で、U字流路の流路371A、流路373Aから流路372Aに連通させ、流路372Aは第2手動弁13Bの入口流路51と連通させる。同様に、図3及び図4で示すように、パージガス共通流路端部手動弁23の図示しない出口流路と第2ガスユニットの第3手動弁14Bの図示しない入口流路とを流路ブロック58の流路56、流路55及び流路57で連通させる。次に、図5及び図6で示すように、プロセスガス共通流路端部手動弁22の出口流路22bと連通する流路371Aと第2ガスユニットのプロセスガス共通流路端部手動弁24の入口流路24aと連通する流路361Bとがパイプの第2連通路59でつながれる。なお、第2ガスユニットの取付け工事の前に、プロセスガス共通流路端部手動弁24の出口流路24bは、流路ブロック37B内で出口流路24bと連通する流路371B、水平方向の流路373Bと連通し、流路373Bからパイプの第1連通路52につながれている。同様に、図3及び図4で示すパージガス共通流路端部手動弁25の出口流路54は、流路ブロック47内の流路53からパイプ52につながれている。

As described above, the installation of the second gas unit is performed as follows from the state where the second gas unit to be added is disposed a little away from the existing gas unit. First, the fixing

以上により第2ガスユニットの取付け工事は終了する。次に、第2ガスユニットの新たなプロセスガス共通流路端部手動弁24、パージガス共通流路端部手動弁25、第2手動弁13B、第1手動弁11B及び第3手動弁14Bを開弁状態として、既設ガスユニットのパージガス共通流路端部手動弁23及びパージガス手動弁20を開弁する。

これにより、第2ガスユニット内にパージガスを流して、第2ガスユニット内の水分の除去を行う。パージガスの流れとパージガスの滞留部を次の図面で示す。即ち、図3の構成を示す平面図、図4の機器を取り除いた下部の流路ブロックを示す平面図、図5のプロセスガス共通流路端部手動弁22、24と流路ブロック36,37の断面図及び図6の機器を取り除いた下部の流路ブロックを示す斜視図で示す。

This completes the installation work of the second gas unit. Next, the new process gas common flow path end

As a result, purge gas is caused to flow into the second gas unit to remove moisture in the second gas unit. The flow of purge gas and purge gas retention are shown in the following drawings. That is, a plan view showing the configuration of FIG. 3, a plan view showing the lower flow path block with the equipment of FIG. 4 removed, the process gas common flow path end

以下にパージガスの流れを説明する。パージガス手動弁20を開弁して、第2ガスユニット内にパージガスを流すと、図示しないパージガスタンクからパージガス供給口21、パージガス手動弁20、逆止弁19、パージガス共通流路16を介して、パージガス共通流路端部手動弁23から、第3手動弁14Bとパージガス共通流路端部手動弁25とに分岐して流れる。第3手動弁14Bに流れたパージガスは、第1手動弁11Bから、プロセスガス出口10Bに流れる。

また、パージガス共通流路端部手動弁25に流れたパージガスは、パイプの第1連通路52、プロセスガス共通流路端部手動弁24、パイプの第2連通路59、流路ブロック37A内のU字流路の水平方向の第3連通路373A、及び垂直方向の流路372Aに流れる。流路372Aに流れたパージガスは、第2手動弁13Bの入口流路51、第2手動弁13B、第1手動弁11Bを介して、プロセスガス出口10Bに流れる。

The purge gas flow will be described below. When the purge

Further, the purge gas that has flowed to the purge gas common flow path end

このように第2ガスユニット内にパージガスを流すと、図5及び図6で示すように、一部の流路にパージガスの滞留部が発生する。しかし、パージガスが滞留しても、パージガスの流れと連通しているので、必要な時間パージガスを流せば、第2ガスユニット内の水分の除去を行うことが出来る。水分が十分除去でき、半導体製造装置側の準備が整ったら、プロセスガス共通流路端部手動弁24、パージガス共通流路端部手動弁25及び第3手動弁14Bを閉じ、プロセスガス共通流路端部手動弁22を開くことにより、第2ガスラインにプロセスガスを供給することができる。

When the purge gas is caused to flow into the second gas unit in this way, as shown in FIGS. 5 and 6, a purge gas retention portion is generated in a part of the flow paths. However, even if the purge gas stays, it is in communication with the flow of the purge gas, so that the moisture in the second gas unit can be removed if the purge gas is allowed to flow for a necessary time. When the moisture can be sufficiently removed and the semiconductor manufacturing apparatus is ready, the process gas common flow path end

以上、詳細に説明したように第1実施例のガス供給集積ユニットによれば、出口流路に設けられた第1手動弁11と、第1手動弁11とプロセスガス共通流路15とを連通する位置に設けられた第2手動弁13と、第1手動弁11とパージガス共通流路16とを連通する位置に設けられた第3手動弁14とが流路ブロックにより一体に連結されているガスユニットを複数備えるガス供給集積ユニットにおいて、プロセスガス共通流路15の端部と連通するプロセスガス共通流路端部手動弁22と、パージガス共通流路16の端部と連通するパージガス共通流路端部手動弁23と、プロセスガス共通流路端部手動弁22と連通する別のプロセスガス共通流路端部手動弁24とパージガス共通流路端部手動弁23と連通する別のパージガス共通流路端部手動弁25とプロセスガス共通流路端部手動弁22と連通する別の第2手動弁13Bを備える増設するガスユニットと、別のパージガス共通流路端部手動弁25の出口流路54と別のプロセスガス共通流路端部手動弁24の出口流路24bとを連通させる第1連通路52と、別のプロセスガス共通流路端部手動弁24の入口流路24aとプロセスガス共通流路端部手動弁22の出口流路22bとを連通させる第2連通路59と、プロセスガス共通流路端部手動弁22の出口流路22bと別の第2手動弁13Bの入口流路51とを連通させる第3連通路373Aとを有するので、ラインを増設して増設ラインのパージを行う際、増設するガスユニット内のすべての流路にパージガスを満たすことができる。パージガスの流れのない滞留部が一部発生するが、滞留部はパージガスの流れと連通しているので、必要な時間パージガスを流せば、第2ガスユニット内の水分をほぼ完全に除去することができる。

As described above in detail, according to the gas supply integrated unit of the first embodiment, the first manual valve 11 provided in the outlet flow path, the first manual valve 11 and the process gas

次に、本発明の第2の実施例を説明する。第2実施例のガス供給集積ユニットの構成及び作用効果は、第1実施例とほぼ同じなので、相違する点のみ説明して、他を割愛する。相違点は既設ラインのプロセスガス共通流路端部手動弁から、増設ラインの第2連通路、プロセスガス共通流路端部手動弁、及び第1連通路につなぐ間の流路構造である。

第2ガスユニットを既設ガスユニットに取付ける工事は、第1実施例と同様に実施される。第2ガスユニットが取付けられたガス供給集積ユニットを次の図面で示す。図3に対応する図面を図7、図4に対応する図面を図8、図5に対応する図面を図9及び図6に対応する図面を図10にそれぞれ示す。図9及び図10で示すように、プロセスガス共通流路端部手動弁22’の出口流路を下方に向かって二つに分岐させ、一方の流路222bと第2ガスユニットの第2手動弁13Bの入口流路51とを流路ブロック37A’のU字形の流路で連通させる。即ち、プロセスガス共通流路端部手動弁22’の出口流路222bを、流路ブロック37A’内で、垂直方向の流路371A’、水平方向の第3連通路373A’、及び垂直方向の流路372A’と連通させ、流路372A’を第2手動弁13Bの入口流路51と連通させる。

Next, a second embodiment of the present invention will be described. Since the configuration and operational effects of the gas supply integrated unit of the second embodiment are almost the same as those of the first embodiment, only the differences will be described and the others will be omitted. The difference is the flow path structure between the process gas common flow path end manual valve of the existing line and the second communication path, the process gas common flow path end manual valve of the extension line, and the first communication path.

The work for attaching the second gas unit to the existing gas unit is performed in the same manner as in the first embodiment. The gas supply integrated unit with the second gas unit attached is shown in the following drawing. FIG. 7 shows a drawing corresponding to FIG. 3, FIG. 8 shows a drawing corresponding to FIG. 4, FIG. 10 shows a drawing corresponding to FIG. 9 and FIG. As shown in FIGS. 9 and 10, the outlet flow path of the process gas common flow path end

次に、プロセスガス共通流路端部手動弁22’の出口流路の他方の流路221bと第2ガスユニットのプロセスガス共通流路端部手動弁24’の入口流路24a’を流路ブロック36B’のV字流路の第2連通路361B’により連通させる。プロセスガス共通流路端部手動弁24’の出口流路をプロセスガス共通流路端部手動弁22’と同様に、下方に向かって二つに分岐させ、一方の流路241b及び他方の流路242bを流路ブロック37B’のV字流路371B’の左のポート375及び右のポート376とそれぞれ連通させる。流路ブロック37B’内のV字流路371B’をV字の最下点で流路373B’と連通させ、流路373B’をパイプの第1連通路52’と連通させる。

このように設けられた第2実施例の作動及びその作用効果について説明する。第2ガスユニット内にパージガスを流して、第2ガスユニット内の水分の除去を行う。パージガスの流れとパージガスの滞留部を図7、図8、図9及び図10で示す。

Next, the

The operation and effects of the second embodiment thus provided will be described. Purge gas is allowed to flow through the second gas unit to remove moisture in the second gas unit. The purge gas flow and the purge gas retention portion are shown in FIGS. 7, 8, 9, and 10. FIG.

以下にパージガスの流れを説明する。第1実施例とは、パージガス共通流路端部手動弁25からパイプの第1連通路52’に流れるところまでは同様で、第1連通路52’から第3連通路373A’までの流れが異なり、この間の流れを説明する。パイプの第1連通路52’ に流れたパージガスは、流路ブロック37B’の流路373B’から、V字流路371B’のV字の最下点に流れ、V字の一方の流路から左のポート375を介して、プロセスガス共通流路端部手動弁24’の出口流路の一方の流路241bに、またV字の他方の流路から右のポート376を介して、プロセスガス共通流路端部手動弁24’の出口流路の他方の流路242bに流れる。流路241bおよび流路242bからプロセスガス共通流路端部手動弁24’に流れたパージガスは、入口流路24a’、 流路ブロック36B’のV字流路の第2連通路361B’、プロセスガス共通流路端部手動弁22’ の出口流路の他方の流路221bから一方の出口流路222bに流れる。プロセスガス共通流路端部手動弁22’ の一方の出口流路222bに流れたパージガスは、流路ブロック37A’内のU字流路の流路371A’、第3連通路の流路373A’から流路372A’に流れる。流路372A’に流れたパージガスは、第2手動弁13Bの入口流路51に流れ、それ以降は第1実施例と同様である。

The purge gas flow will be described below. The first embodiment is the same as the flow from the purge gas common flow path end

このように第2ガスユニット内にパージガスを流すと、図9及び図10で示すように、プロセスガス共通流路端部手動弁22’ の出口流路の一部にパージガスの流れのない滞留部が発生する。しかし、滞留部はパージガスの流れが鋭角に変化する変曲点近傍にあるので、見かけ上のみであり、実際は流れに巻き込まれてほとんど滞留せず、且つ体積も極めて少ないので、時間をかけることなく、第2ガスユニット内の水分の除去をほぼ完全に行うことが出来る。

水分が十分除去でき、半導体製造装置側の準備が整ったら、プロセスガス共通流路端部手動弁24’、パージガス共通流路端部手動弁25及び第3手動弁14Bを閉じ、プロセスガス共通流路端部手動弁22’を開くことにより、第2ガスラインにプロセスガスを供給することができる。

When the purge gas is caused to flow into the second gas unit in this way, as shown in FIGS. 9 and 10, as shown in FIG. 9 and FIG. Will occur. However, the staying part is in the vicinity of the inflection point where the flow of the purge gas changes at an acute angle, so it is only apparent. In fact, the staying part is almost trapped in the flow and the volume is very small. The moisture in the second gas unit can be removed almost completely.

When the moisture can be sufficiently removed and the semiconductor manufacturing apparatus is ready, the process gas common flow path end

以上、詳細に説明したように第2実施例のガス供給集積ユニットによれば、プロセスガス共通流路端部手動弁22’の内部で二つに分岐した出口流路221b、出口流路222bが形成され、増設するガスユニットの別のプロセスガス共通流路端部手動弁24’の内部で二つに分岐した出口流路241b、出口流路242bが形成されているので、ラインを増設して増設ラインのパージを行う際、プロセスガス共通流路端部手動弁22’、 別のプロセスガス共通流路端部手動弁24’のそれぞれ内部までパージガスを流すことができ、時間をかけることなく、増設するガスユニット内の水分をほぼ完全に除去できる。

As described above in detail, according to the gas supply integrated unit of the second embodiment, the

また、第2実施例のガス供給集積ユニットによれば、第1連通路52’を別のパージガス共通流路端部手動弁25の出口流路54と別のプロセスガス共通流路端部手動弁24’の二つに分岐した出口流路241b及び242bの両方に連通させ、第2連通路361B’を別のプロセスガス共通流路端部手動弁24’の入口流路24a’とプロセスガス共通流路端部手動弁22’の二つに分岐した出口流路の一方221bに連通させ、第3連通路373A’をプロセスガス共通流路端部手動弁22’の二つに分岐した出口流路の他方222bと別の第2手動弁の入口流路51に連通させるように設けられているので、ラインを増設して増設ラインのパージを行う際、プロセスガス共通流路端部手動弁22’、 別のプロセスガス共通流路端部手動弁24’のそれぞれ内部まで、且つすべての流路にパージガスを流すことができる。従って、パージに時間をかけることなく、増設するガスユニット内の水分をほぼ完全に除去できる。

なお、本発明の実施の形態について説明したが、本発明は、上記実施の形態に限定されることなく、色々な応用が可能である。

Further, according to the gas supply integrated unit of the second embodiment, the

Although the embodiments of the present invention have been described, the present invention is not limited to the above-described embodiments, and various applications are possible.

11 第1手動弁

13 第2手動弁

14 第3手動弁

15 プロセスガス共通流路

16 パージガス共通流路

17 プロセスガスエアオペレート弁

20 パージガス手動弁

22,24 プロセスガス共通流路端部手動弁

23,25 パージガス共通流路端部手動弁

22b 出口流路

24a 入口流路

24b 出口流路

51 入口流路

52 第1連通路

54 出口流路

59 第2連通路

373A 第3連通路

221b、222b 出口流路

241b、242b 出口流路

361B’ 第2連通路

11 First manual valve 13 Second manual valve 14 Third

Claims (4)

前記プロセスガス共通流路の端部と連通するプロセスガス共通流路端部手動弁と、

前記パージガス共通流路の端部と連通するパージガス共通流路端部手動弁と、

前記プロセスガス共通流路端部手動弁と連通する別のプロセスガス共通流路端部手動弁と前記パージガス共通流路端部手動弁と連通する別のパージガス共通流路端部手動弁と前記プロセスガス共通流路端部手動弁と連通する別の第2手動弁を備える増設するガスユニットと、

前記別のパージガス共通流路端部手動弁の出口流路と前記別のプロセスガス共通流路端部手動弁の出口流路とを連通させる第1連通路と、

前記別のプロセスガス共通流路端部手動弁の入口流路と前記プロセスガス共通流路端部手動弁の出口流路とを連通させる第2連通路と、

前記プロセスガス共通流路端部手動弁の出口流路と前記別の第2手動弁の入口流路とを連通させる第3連通路とを有することを特徴とするガス供給集積ユニット。 A first manual valve provided in the outlet flow path; a second manual valve provided at a position communicating the first manual valve and the process gas common flow path; the first manual valve and the purge gas common flow path; In a gas supply integrated unit comprising a plurality of gas units integrally connected by a flow path block with a third manual valve provided at a position communicating with

A process gas common flow path end manual valve communicating with an end of the process gas common flow path;

A purge gas common flow path end manual valve communicating with an end of the purge gas common flow path;

Another process gas common flow path end manual valve communicating with the process gas common flow path end manual valve, another purge gas common flow path end manual valve communicating with the purge gas common flow path end manual valve, and the process An additional gas unit with another second manual valve communicating with the gas common flow path end manual valve;

A first communication path that communicates an outlet flow path of the other purge gas common flow path end manual valve and an outlet flow path of the another process gas common flow path end manual valve;

A second communication path that communicates an inlet flow path of the another process gas common flow path end manual valve and an outlet flow path of the process gas common flow path end manual valve;

A gas supply integrated unit, comprising: a third communication passage that communicates an outlet flow path of the process gas common flow path end manual valve and an inlet flow path of the second manual valve.

前記プロセスガス共通流路端部手動弁の内部に弁座に連通するように形成された出口流路を二つに分岐させ、前記増設するガスユニットの前記別のプロセスガス共通流路端部手動弁の内部に弁座に連通するように形成された出口流路を二つに分岐させていることを特徴とするガス供給集積ユニット。 In the gas supply integrated unit according to claim 1,

The process gas common flow path end manual valve is branched into two outlet flow paths formed so as to communicate with the valve seat, and the additional process gas common flow path end manual operation of the additional gas unit A gas supply integrated unit characterized in that an outlet flow passage formed to communicate with a valve seat is branched into two inside the valve .

前記第1連通路を前記別のパージガス共通流路端部手動弁の出口流路と前記別のプロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の両方に連通させ、

前記第2連通路を前記別のプロセスガス共通流路端部手動弁の入口流路と前記プロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の一方に連通させ、

前記第3連通路を前記プロセスガス共通流路端部手動弁の前記二つに分岐した出口流路の他方と前記別の第2手動弁の入口流路に連通させるように設けられることを特徴とするガス供給集積ユニット。 In the gas supply integrated unit according to claim 2,

The first communication path is connected to both the outlet flow path of the other purge gas common flow path end manual valve and the two branched flow paths of the other process gas common flow path end manual valve;

The second communication path communicates with one of an inlet flow path of the other process gas common flow path end manual valve and one of the two branched flow paths of the process gas common flow path end manual valve;

In that it is provided with a pre-Symbol third communication passage so as to communicate with the inlet passage of the other and the further second manual valve of the outlet flow path which is branched into the two of the process gas common flow passage end part manual valve Characteristic gas supply integrated unit.

前記第3流路が、前記プロセスガス共通流路端部手動弁の出口流路と前記別の第2手動弁の入口流路とを連通させるように流路ブロックに形成されたU字流路であり、前記U字流路が前記第2連通路につながれていることを特徴とするガス供給集積ユニット。A U-shaped channel formed in the channel block so that the third channel communicates the outlet channel of the process gas common channel end manual valve and the inlet channel of the second second manual valve. And the U-shaped flow path is connected to the second communication path.

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004056286A JP3767897B2 (en) | 2004-03-01 | 2004-03-01 | Gas supply integrated unit |

| PCT/JP2005/000656 WO2005083754A1 (en) | 2004-03-01 | 2005-01-20 | Gas supply integration unit |

| KR1020067020398A KR100825050B1 (en) | 2004-03-01 | 2005-01-20 | Gas supply integration unit |

| CN2005800067744A CN101073141B (en) | 2004-03-01 | 2005-01-20 | Gas supply integration unit |

| TW094102114A TWI411742B (en) | 2004-03-01 | 2005-01-25 | Gas supply collection unit |

| TW100130883A TWI416029B (en) | 2004-03-01 | 2005-01-25 | Gas supply collection unit |

| TW099130142A TWI486535B (en) | 2004-03-01 | 2005-01-25 | Gas supply collection unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004056286A JP3767897B2 (en) | 2004-03-01 | 2004-03-01 | Gas supply integrated unit |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005251790A JP2005251790A (en) | 2005-09-15 |

| JP2005251790A5 JP2005251790A5 (en) | 2005-11-17 |

| JP3767897B2 true JP3767897B2 (en) | 2006-04-19 |

Family

ID=34908905

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004056286A Expired - Fee Related JP3767897B2 (en) | 2004-03-01 | 2004-03-01 | Gas supply integrated unit |

Country Status (5)

| Country | Link |

|---|---|

| JP (1) | JP3767897B2 (en) |

| KR (1) | KR100825050B1 (en) |

| CN (1) | CN101073141B (en) |

| TW (3) | TWI416029B (en) |

| WO (1) | WO2005083754A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10982782B2 (en) | 2018-11-09 | 2021-04-20 | Samsung Electronics Co., Ltd. | Valve apparatus |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4567370B2 (en) * | 2004-05-10 | 2010-10-20 | シーケーディ株式会社 | Gas supply integrated unit |

| WO2005114016A1 (en) * | 2004-05-20 | 2005-12-01 | Ckd Corporation | Gas supply integrated unit and method of adding gas unit |

| EP1917244A2 (en) | 2005-08-24 | 2008-05-07 | Abbott GmbH & Co. KG | Hetaryl-substituted guanidine compounds and use thereof as binding partners for 5-ht5-receptors |

| KR101194104B1 (en) | 2011-01-27 | 2012-10-24 | 주식회사 바이코 | Gas supply system with mini block |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100242982B1 (en) * | 1996-10-17 | 2000-02-01 | 김영환 | Gas supply apparatus of semiconductor device |

| JP3586075B2 (en) * | 1997-08-15 | 2004-11-10 | 忠弘 大見 | Pressure type flow controller |

| JPH11212653A (en) * | 1998-01-21 | 1999-08-06 | Fujikin Inc | Fluid supplier |

| JP3607950B2 (en) * | 1998-04-10 | 2005-01-05 | 大陽日酸株式会社 | Gas supply equipment |

| JP4238453B2 (en) * | 2000-03-10 | 2009-03-18 | 株式会社東芝 | Fluid control device |

| JP4554853B2 (en) * | 2001-09-17 | 2010-09-29 | シーケーディ株式会社 | Gas supply integrated valve |

-

2004

- 2004-03-01 JP JP2004056286A patent/JP3767897B2/en not_active Expired - Fee Related

-

2005

- 2005-01-20 KR KR1020067020398A patent/KR100825050B1/en active IP Right Grant

- 2005-01-20 CN CN2005800067744A patent/CN101073141B/en not_active Expired - Fee Related

- 2005-01-20 WO PCT/JP2005/000656 patent/WO2005083754A1/en active Application Filing

- 2005-01-25 TW TW100130883A patent/TWI416029B/en not_active IP Right Cessation

- 2005-01-25 TW TW099130142A patent/TWI486535B/en not_active IP Right Cessation

- 2005-01-25 TW TW094102114A patent/TWI411742B/en not_active IP Right Cessation

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10982782B2 (en) | 2018-11-09 | 2021-04-20 | Samsung Electronics Co., Ltd. | Valve apparatus |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201043828A (en) | 2010-12-16 |

| TWI411742B (en) | 2013-10-11 |

| WO2005083754A1 (en) | 2005-09-09 |

| TWI416029B (en) | 2013-11-21 |

| KR20060122973A (en) | 2006-11-30 |

| CN101073141B (en) | 2012-06-27 |

| CN101073141A (en) | 2007-11-14 |

| JP2005251790A (en) | 2005-09-15 |

| KR100825050B1 (en) | 2008-04-24 |

| TWI486535B (en) | 2015-06-01 |

| TW200530532A (en) | 2005-09-16 |

| TW201200778A (en) | 2012-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4780555B2 (en) | Fluid control device | |

| KR100714755B1 (en) | Fluid control apparatus | |

| US6039360A (en) | Couplings for fluid controllers | |

| US6615871B2 (en) | Fluid control apparatus | |

| US20020033195A1 (en) | Fluid control apparatus and gas treatment system comprising same | |

| KR101560962B1 (en) | Purge line change block joint and fluid control device | |

| JP4832428B2 (en) | Fluid control device | |

| JP3767897B2 (en) | Gas supply integrated unit | |

| JP7061808B2 (en) | Fittings and fluid controls | |

| JP2008298180A (en) | Fluid control device | |

| KR20080111443A (en) | Fluid equipment unit structure | |

| JP4504368B2 (en) | Gas supply integrated unit and gas unit expansion method | |

| KR20010083047A (en) | Modular chemical delivery blocks | |

| JPWO2007017937A1 (en) | Fluid control device | |

| JP4238453B2 (en) | Fluid control device | |

| JP3809162B2 (en) | Gas supply integrated unit | |

| JP6630496B2 (en) | Manifold block and fluid control device | |

| JP2005150191A5 (en) | ||

| KR100203781B1 (en) | Supplying system of developing solution in semiconductor photolithographic processing. | |

| JP6486035B2 (en) | Manifold valve and fluid control device | |

| JP2005180527A (en) | Leak valve | |

| JP2002213680A (en) | Gas shutoff method | |

| JP3115789U (en) | Pipe joint device | |

| JP2004247740A (en) | Gas supply unit | |

| JP2006024776A (en) | Chemical solution supplying unit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050715 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050928 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20050928 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20051109 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060124 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060130 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3767897 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20090210 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100210 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110210 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110210 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120210 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120210 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130210 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130210 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140210 Year of fee payment: 8 |

|

| LAPS | Cancellation because of no payment of annual fees |