JP3604013B2 - Drainage culvert facility - Google Patents

Drainage culvert facility Download PDFInfo

- Publication number

- JP3604013B2 JP3604013B2 JP2001301929A JP2001301929A JP3604013B2 JP 3604013 B2 JP3604013 B2 JP 3604013B2 JP 2001301929 A JP2001301929 A JP 2001301929A JP 2001301929 A JP2001301929 A JP 2001301929A JP 3604013 B2 JP3604013 B2 JP 3604013B2

- Authority

- JP

- Japan

- Prior art keywords

- water

- drainage culvert

- culvert

- pipe

- washing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Sewage (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、地中に埋設され、農業用水、上水道用水、工業用水等の各種用水を取水する、集水埋渠設備に関するものである。詳しくは、本発明は、集水埋渠の洗浄に関する。

【0002】

【従来の技術】

集水埋渠設備は、伏流水又は自由水面を持つ地下水(自由地下水)の存在する地中、すなわち河床や旧河床に埋設され、複数の集水孔を介して上記伏流水又は自由地下水をその内部に取水する集水埋渠を備えている。また、集水埋渠設備は、集水埋渠内に取水された水を吸入し、農業用水、上水道用水、工業用水等として利用する水路や設備(供給側)に吐出する揚水ポンプとを備えている。

【0003】

【発明が解決しようとする課題】

集水埋渠の底部には、土砂、ごみ等の沈殿物や堆積物(以下、「沈殿堆積物」という。)が溜まる。この沈殿堆積物の増加は、取水効率の低下や水質低下等の原因となる。従って、集水埋渠はある程度の期間毎に洗浄し、沈殿堆積物を除去することが望ましい。

【0004】

しかし、従来、集水埋渠の洗浄の際には、集水埋渠の周囲の土砂を重機と人手で除去した後、すなわち集水埋渠を掘り出した後、集水埋渠内の沈殿堆積物を人手で除去していた。また、洗浄後には埋め戻しが必要であった。従って、従来の集水埋渠の洗浄作業は、大規模な作業にならざるを得ず、多大な時間、労力、及び費用を要していた。特に、集水埋渠が河床に埋設されている場合には、河川を堰き止める必要があり、洗浄作業は一層大規模なものとなっていた。

【0005】

そこで、本発明は、集水埋渠内を簡単に洗浄して沈殿堆積物を除去可能とするすることを課題としている。

【0006】

【課題を解決するための手段】

上記課題を解決するため、本発明は、伏流水の存在する河川の河床に埋設され、かつ一方の河岸から他方の河岸に向けて延びる集水埋渠と、上記一方の河岸に設けられた取水槽と、上記集水埋渠の基端側と上記取水槽を接続する上記一方の河岸に埋設された取水路と、上記集水埋渠内に取水されて上記取水路を介して上記取水槽に流入した水を吸入し、供給側に吐出する揚水ポンプとを備え、上記集水埋渠の開口部は上記伏流水を取水するための複数の集水孔を設けたグレーチング板により閉鎖され、かつこのグレーチング板の上方に洗堀防止のための防護体が配設されている集水埋渠設備において、上記集水埋渠に沿って上記河床に埋設され、かつ両端が閉鎖された洗浄水供給管と、それぞれ上記洗浄水供給管から分岐して上記集水埋渠の内部まで延びる複数の分岐管と、それぞれ上記分岐管の先端に設けられ、上記集水埋渠の底部に配置され、かつ上記集水埋渠の基端側を向いている複数の洗浄ノズルと、上記洗浄水供給管と上記揚水ポンプを接続する管路と、上記揚水ポンプを、上記供給側と上記管路のいずれか一方に切り換える切換手段と、上記取水路と上記集水埋渠の接続部分に設けられた沈殿堆積物溜まりと、この沈殿堆積物溜まりに収容され、かつその吐出管の先端の吐出口が上記河川の水面上に位置している除去ポンプを備え、上記集水埋渠の底部は、その延在方向と直交する方向の断面形状が両側から中央に向けて傾斜し、上記集水埋渠の洗浄時には、上記切換手段を上記管路側に切り換えて上記揚水ポンプから上記管路を介して上記洗浄水供給管に洗浄水を供給し、上記分岐管に設けた上記洗浄ノズルから上記一方の河岸側に向けて上記集水埋渠内で水流を噴射させ、上記洗浄ノズルが噴射した洗浄水により上記集水埋渠から運ばれた沈殿堆積物を上記沈殿堆積物溜まりに収集し、上記沈殿堆積物溜まりの沈殿堆積物を除去ポンプにより吸い上げて上記河川に廃棄するようにしていることを特徴とする集水埋渠設備を提供する。

【0007】

本発明では、洗浄水供給管及び分岐管を介して供給された洗浄水が洗浄ノズルによって集水埋渠内で噴射される。そして、洗浄ノズルが噴射した洗浄水により運ばれた沈殿堆積物は、沈殿堆積物溜まりで除去ポンプにより排出される。従って、本発明では、地中に埋設された集水埋渠を、その周囲から土砂等を除去することなく洗浄することができる。

【0009】

上記揚水ポンプを、上記供給側と上記洗浄水供給管のいずれか一方に切り換える切換手段を備え、上記集水埋渠の洗浄時には、上記切換手段を上記洗浄水供給管側に切り換えて、揚水ポンプから上記洗浄水供給管に洗浄水を供給する。よって、集水埋渠内の水を洗浄水として使用するため、洗浄水の供給源を別途設ける必要がない。従って、集水埋渠の構造が複雑化せず、設備の製造及び管理に要する費用が低減される。

【0011】

上記集水埋渠の底部は、その延在方向と直交する方向の断面形状が両側から中央に向けて傾斜し、かつ上記洗浄ノズルは上記集水埋渠の底部の中央付近に配置されている。集水埋渠の底部をこのような断面形状とすることにより、集水埋渠内の沈殿堆積物が、上記集水埋渠の底部中央付近に集る。従って、沈殿堆積物は、底部の中央付近に配置された洗浄ノズルから噴射される洗浄水により、確実に沈殿堆積物溜まりに集められる。

【0012】

【発明の実施の形態】

次に、図面に示す実施形態に基づいて、本発明を詳細に説明する。図1から図5は、本発明の実施形態に係る集水埋渠設備1を示している。

図1及び図2に示すように、集水埋渠設備1は、一方の河岸2aから他方の河岸(図示せず)に向けて延びるように河床2bに埋設された集水埋渠3を備えている。この集水埋渠3は、ほぼ直線状に延びる鉄筋コンクリート製の構造物であり、上方が開口部3aである溝3bを備えている。

【0013】

図3に示すように、集水埋渠3の開口部3aは、グレーチング板4により閉鎖されている。このグレーチング板4は多数の集水孔4aが設けられた金属又は樹脂製の板であり、これらの集水孔4aを介して河床に存在する伏流水が集水埋渠3の内部に取水される。また、グレーチング板4の上方には洗掘を防止するための防護体(ふとんかご)6が配設されている。この防護体6は、針金を編成してなる袋6aと、この袋6aに充填された多数の石6bとを備えている。

【0014】

図4に示すように、上記集水埋渠3の溝3bの先端側は端部壁3cにより閉鎖されている。一方、集水埋渠3の基端側は、河岸2aに埋設された水平方向に延びる取水路7を介して、取水槽8に接続されている。取水路7は鉄筋コンクリート製である両端開口の管状構造物である。また、取水路7と集水埋渠3の接続部分には後述する沈殿堆積物槽(沈殿堆積物溜まり)9が設けられている。一方、取水槽8は、河岸2aに埋設された鉄筋コンクリート製の水槽であり、地表に位置している上部開口は蓋体8aにより閉鎖されている。地上に設置された揚水ポンプ11の吸入管11aがこの蓋体8aを貫通して取水槽8内に延びている。吸入口を備える吸入管11aの先端は、取水槽8の底部近傍に位置している。一方、吸入管11aの基端は揚水ポンプ11の本体に接続されている。揚水ポンプ11の本体には主吐出弁12を介して主吐出管11bの一端が接続されている。この主吐出管11bの他端側は、集水埋渠設備1により取水した水を農業用水、上水道用水、工業用水等として利用する水路や設備(供給側)に接続されている。なお、取水槽8及び揚水ポンプ11は地上建造物14内に収容されている。

【0015】

上記防護体6の石6bの隙間及びグレーチング板4の集水孔4aを介して集水埋渠3の溝3b内に水が取水される。溝3b内の水は沈殿堆積物槽9及び取水路7を介して取水槽8に流入し、取水槽8内に蓄積される。揚水ポンプ11は取水槽8内の水を吸入管11aから吸入し、開弁状態にある主吐出弁12及び主吐出管11bを介して供給側に吐出する。

【0016】

次に、この集水埋渠設備1が備える集水埋渠3の洗浄装置について説明する。まず、集水埋渠3の下側に、金属又は樹脂製の直管である洗浄水供給管16が埋設されている。図1及び図3に示すように、洗浄水供給管16は集水埋渠3の溝3bの底部3dの幅方向中央に配置され、かつ集水埋渠3に対して平行に延びている。図1及び図4に示すように、洗浄水供給管16の基端は河岸2a付近に位置しており、先端は集水埋渠3の端部壁3c付近に位置している。また、洗浄水供給管16の先端及び基端は突合わせ溶接式のキャップ17a,17bにより閉鎖されている。さらに、図3に示すように、洗浄水供給管16は、集水埋渠3の下側に設けられたコンクリート製の保護構造体18内に収容されている。

【0017】

洗浄水供給管16から複数の分岐管19が分岐している。本実施形態では、これらの分岐管19は集水埋渠3の長手方向に一定間隔をあけて設けられている。各分岐管19は、基端が洗浄水供給管16に接続され、保護構造体18を貫通して集水埋渠3の内部に延びており、先端が溝3bの底部3dより僅かに突出している。この分岐管19の先端には洗浄ノズル21が取り付けられている。図4及び図5に示すように、この洗浄ノズル21向きは、集水埋渠3の先端から基端に向けて水流を噴射するように設定されている。

【0018】

洗浄水供給管16の長手方向中央よりも基端側には、揚水ポンプ11と洗浄水供給管16を接続するための金属又は樹脂製の管路(洗浄水供給管)22が継手23により接続されている。図1及び図2を参照してこの管路22の配管構造を説明すると、管路22は上記洗浄水供給管16に接続された一端から平面視で洗浄水供給管16に対して斜めに延びる。また、河岸2aの傾斜に沿って平面視で洗浄水供給管16に対し平行に延び、揚水ポンプ11の補助吐出管11cに接続されている。補助吐出管11cは補助吐出弁24を介して揚水ポンプ11の本体に接続されている。ただし、管路22の配管構造は特に限定されず、洗浄水供給管16と揚水ポンプ11が補助吐出弁24を介して接続されていればよい。

【0019】

上記集水埋渠3と取水路7の接続部分に設けられた沈殿堆積物槽9は、上部に開口9aを備え、河岸2aの傾斜面に埋設されている。地表に位置している開口9aは蓋体9bによって閉鎖されている。また、沈殿堆積物槽9は、上記集水埋渠3の溝3bに接続された第1の連通口9cと、上記取水路7に接続された第2の連通口9dとを備えている。さらに、沈殿堆積物槽9には除去ポンプ26が収容されている。除去ポンプ26の吐出管26aは、上記蓋体9bを貫通して沈殿堆積物槽9の外部まで延び、吐出管26aの先端の吐出口は河川の水面30上に位置している。

【0020】

次に、集水埋渠3の洗浄作業について説明する。なお、洗浄開始時には集水埋渠3の溝3b、沈殿堆積物槽9、取水路7、及び取水槽8には、取水された水がある程度の水位まで存在している。

【0021】

まず、揚水ポンプ11を運転したままで、主吐出弁12を閉弁して供給側への用水の吐出を停止する一方、補助吐出弁24を開弁する。また、除去ポンプ26の運転を開始する。主吐出弁12及び補助吐出弁24の開閉を上記のように設定すると、吸入管11aから吸入された取水槽8内の水は、補助吐出弁24、補助吐出管11c、管路22、洗浄水供給管16、及び個々の分岐管19を介して個々の洗浄ノズル21に供給される。そして、図において矢印Fで示すように、個々の洗浄ノズル21から集水埋渠3の河岸2a側に向けて、すなわち沈殿堆積物槽9に向けて、水流が噴射される。この洗浄ノズル21から噴射される水流により、集水埋渠3の溝3bの底部3dから沈殿堆積物が吹き上げられ、沈殿堆積物を含む濁った水が集水埋渠3の溝3bを沈殿堆積物槽9に向けて流れる。従って、沈殿堆積物は洗浄ノズル21から噴射された水により沈殿堆積物槽9に運ばれる。

【0022】

図3に示すように、集水埋渠3の溝3bの底部3dは、集水埋渠3の延在方向と直交する方向の断面形状において、両側部3e,3fが平坦な中央部3gに向かって傾斜しており、沈殿堆積物は主として底部3dの中央部3gに存在している。従って、この中央部3gの幅方向のほぼ中央に配設された洗浄ノズル21から噴射される水流により沈殿堆積物が確実に吹き上げられる。

【0023】

上記沈殿堆積物槽9に収集された沈殿堆積物は洗浄ノズル21から噴射された水と共に除去ポンプ26により吸い上げられ、その吐出管26aを介して河川に廃棄される。洗浄終了時には、補助吐出弁24を閉弁し、主吐出弁12を開弁すると共に、除去ポンプ26を停止する。

【0024】

このように洗浄ノズル21が噴射した洗浄水により運ばれた沈殿堆積物は、沈殿堆積物槽9から除去ポンプ26により排出される。従って、本実施形態の集水埋渠設備1では、地中に埋設された集水埋渠3を、その周囲から土砂等を除去して掘り出すことなく洗浄することができる。

【0025】

また、集水埋渠3の洗浄時には、主吐出弁12及び補助吐出弁24(切換手段)の開閉の設定により、取水槽8内の水を洗浄水として揚水ポンプ11から洗浄水供給管16に供給するため、洗浄水の供給源を別途設ける必要がない。従って、集水埋渠設備1の構造が複雑化せず、設備の製造及び管理に要する費用が低減される。

【0027】

本発明は、上記実施形態に限定されず、種々の変形が可能である。

例えば、図6に示すように、集水埋渠3の側方に洗浄水供給管16を配置してもよい。さらに、図7に示すように、複数本(図7では2本)の洗浄水供給管16を設け、個々の洗浄水供給管16から分岐する分岐管19に洗浄ノズル21を設けてもよい。さらにまた、図8で示すように、集水埋渠3の側壁に洗浄ノズル21を配置してもよい。

【0028】

上記実施形態では、すべての洗浄ノズル21は集水埋渠3の基端(沈殿堆積物槽9側)を向いているが、これらのうち1個又は複数個の洗浄ノズル21の向きを図9に示すように上向に設定してもよい。この上向の洗浄ノズル21から噴射される水流により、グレーチング板4の集水孔4aを閉塞している砂等の異物や、防護体6の石6bの間に存在する異物が河川の水流中に吹き上げられる。従って、この向きの洗浄ノズル21を設けることにより、集水埋渠3の洗浄と同時に、グレーチング板4及び防護体6の洗浄を併せて行うことができる。

【0030】

【発明の効果】

以上の説明から明らかなように、本発明の集水埋渠では、洗浄水供給管及び分岐管を介して供給された洗浄水が洗浄ノズルによって集水埋渠内で噴射される。そして、洗浄ノズルが噴射した洗浄水により運ばれた沈殿堆積物は、沈殿堆積物溜まりで除去ポンプにより排出される。従って、本発明の集水埋渠では、地中に埋設された集水埋渠を、その周囲から土砂等を除去することなく洗浄することができる。よって、集水埋渠の洗浄作業に要する時間が大幅に短縮され、設備の管理に要する労力及び費用が大幅に低減される。また、複数の洗浄ノズルから洗浄水が噴射されるため、比較的少量の洗浄水であっても集水埋渠内を洗浄することができる。さらに、集水埋渠の長さが長い場合でも、それに応じて洗浄ノズルの数を増やすことにより、確実に集水埋渠内を洗浄することができる。

【図面の簡単な説明】

【図1】本発明の実施形態に係る集水埋渠を示す平面図である。

【図2】本発明の実施形態に係る集水埋渠を示す縦断面図である。

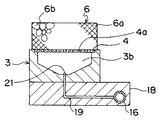

【図3】図1のIII-III線での断面図である。

【図4】図2の部分 IVの部分拡大図である。

【図5】図2の部分Vの部分拡大図である。

【図6】本発明の第1の変形例を示す断面図である。

【図7】本発明の第2の変形例を示す断面図である。

【図8】本発明の第3の変形例を示す断面図である。

【図9】本発明の第4の変形例を示す断面図である。

【符号の説明】

1 集水埋渠設備

2a 河岸

2b 河床

3 集水埋渠

3a 開口部

3b 溝

3c 端部壁

3d 底部

3e,3f 側部

3g 中央部

4 グレーチング板

4a 集水孔

6 防護体

6a 袋

6b 石

7 取水路

8 取水槽

8a 蓋体

9 沈殿堆積物槽

9a 開口

9b 蓋体

9c,9d 連通口

11 揚水ポンプ

11a 吸入管

11b 主吐出管

11c 補助吐出管

12 主吐出弁

14 地上建造物

16 洗浄水供給管

17a,17b キャップ

18 保護構造体

19 分岐管

21 洗浄ノズル

22 管路

23 継手

24 補助吐出弁

26 除去ポンプ

26a 吐出管

30 水面[0001]

TECHNICAL FIELD OF THE INVENTION

BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates to a drainage culvert facility that is buried in the ground to collect various types of water such as agricultural water, water supply water, and industrial water. More specifically, the present invention relates to cleaning a drainage culvert.

[0002]

[Prior art]

The underground drainage system is buried in the ground where underground water or underground water with free water surface (free underground water) exists, that is, in the riverbed or old riverbed, and the underground water or free underground water is discharged through a plurality of water collection holes. There is a drainage culvert for taking water inside. In addition, the drainage culvert facility is provided with a water pump that sucks water taken into the drainage culvert and discharges it to waterways and facilities (supply side) that are used as agricultural water, water supply water, industrial water, etc. ing.

[0003]

[Problems to be solved by the invention]

Sediment and sediment (hereinafter, referred to as “sediment sediment”) such as earth and sand and refuse accumulate at the bottom of the drainage culvert. This increase in precipitate deposit ing the causes of degradation and water quality such as reduction in water intake efficiency. Therefore, it is desirable to clean the drainage culvert every certain period to remove the sediment.

[0004]

However, conventionally, when cleaning the drainage culvert, the sediment around the drainage culvert is removed by heavy equipment and humans, that is, after the drainage culvert is dug out, the sedimentation in the drainage culvert is removed. Things were removed manually. Also, backfilling was required after washing. Therefore, the conventional operation of cleaning the drainage culvert has to be a large-scale operation, and requires a great deal of time, labor, and cost. In particular, when the drainage culvert is buried in the riverbed, it is necessary to block the river, and the cleaning work has been much larger.

[0005]

Therefore, an object of the present invention is to make it possible to easily clean the inside of a drainage culvert and remove sediment.

[0006]

[Means for Solving the Problems]

In order to solve the above-mentioned problems, the present invention provides a drainage culvert buried in the riverbed of a river where underflow water exists and extending from one shore to the other shore, and a drain provided on the one shore. A water tank, a water intake channel buried on the one bank connecting the base end side of the water collection culvert and the water intake tub, and the water intake tub that is drawn into the water collection culvert and is passed through the water intake channel A suction pump that sucks in water that flows into the supply side and discharges the water to the supply side, and the opening of the collecting culvert is closed by a grating plate provided with a plurality of collecting holes for collecting the underflow water. And in a drainage culvert facility in which a protective body for preventing scouring is provided above the grating plate, the washing water buried in the riverbed along the drainage culvert and both ends of which are closed. A supply pipe and a branch from the washing water supply pipe, A plurality of branch pipes extending to parts, respectively provided at the front end of the branch pipe, located at the bottom of the catchment Umamizo, and a plurality of cleaning nozzles facing the base end side of the catchment Umamizo, A pipe connecting the washing water supply pipe and the pump; a switching means for switching the pump to one of the supply side and the pipe ; and a connecting portion between the water intake and the collection culvert. A sediment deposit reservoir provided in the sediment deposit reservoir, and a removal pump whose discharge port at the tip of the discharge pipe is located above the water surface of the river; The bottom portion has a cross-sectional shape in a direction orthogonal to the extending direction thereof is inclined from both sides toward the center, and at the time of cleaning the drainage culvert, the switching means is switched to the pipeline side to switch the pipeline from the pump to the pipeline. Supply the washing water to the washing water supply pipe via Then, a water flow is jetted from the washing nozzle provided in the branch pipe toward the one bank side in the drainage culvert, and the washing water jetted by the washing nozzle is carried from the drainage culvert. the precipitate deposited was collected in the collecting the precipitate deposits provide infiltration gallery equipment which is characterized in that so as to discard to the river sucked up by removal pump precipitate deposits accumulate the precipitate deposit .

[0007]

In the present invention, the washing water supplied through the washing water supply pipe and the branch pipe is jetted by the washing nozzle in the drainage culvert. The sediment carried by the washing water sprayed from the washing nozzle is discharged by a removal pump in a sediment accumulation. Therefore, in the present invention, the drainage buried underground can be washed without removing soil and the like from the surroundings.

[0009]

Switching means for switching the pump to one of the supply side and the washing water supply pipe; and, when washing the collection culvert, switching the switching means to the washing water supply pipe side to provide a pump. To supply the washing water to the washing water supply pipe. Therefore, since the water in the drainage culvert is used as washing water, there is no need to separately provide a supply source of washing water. Therefore, the structure of the drainage culvert does not become complicated, and the cost required for manufacturing and managing the equipment is reduced.

[0011]

The bottom of the catchment levee has a cross-sectional shape in a direction orthogonal to the extending direction thereof is inclined from both sides toward the center, and the washing nozzle is disposed near the center of the bottom of the catchment cultivation. . By forming the bottom of the catchment culvert with such a cross-sectional shape, the sediment deposited in the catchment culvert collects near the bottom center of the catchment culvert. Therefore, the sediment is reliably collected in the sediment pool by the cleaning water jetted from the cleaning nozzle disposed near the center of the bottom.

[0012]

BEST MODE FOR CARRYING OUT THE INVENTION

Next, the present invention will be described in detail based on embodiments shown in the drawings. 1 to 5 show a drainage culvert facility 1 according to an embodiment of the present invention.

As shown in FIGS. 1 and 2, the drainage culvert facility 1 includes a

[0013]

As shown in FIG. 3, the opening 3 a of the

[0014]

As shown in FIG. 4, the front end side of the

[0015]

Water is taken into the

[0016]

Next, a description will be given of a cleaning device for the

[0017]

A plurality of

[0018]

A metal or resin pipe (washing water supply pipe) 22 for connecting the pumping pump 11 and the washing

[0019]

The sediment sediment tank 9 provided at the connection between the

[0020]

Next, a cleaning operation of the

[0021]

First, with the pump 11 running, the

[0022]

As shown in FIG. 3, the bottom 3 d of the

[0023]

The sediment collected in the sediment sediment tank 9 is sucked up by the

[0024]

The sediment carried by the washing water sprayed from the

[0025]

In addition, when the

[0027]

The present invention is not limited to the above embodiment, and various modifications are possible.

For example, as shown in FIG. 6, the washing

[0028]

In the above embodiment, all the

[0030]

【The invention's effect】

As is apparent from the above description, in the water collection culvert of the present invention, the cleaning water supplied through the cleaning water supply pipe and the branch pipe is jetted in the water collection burial by the cleaning nozzle. Then, the sediment carried by the washing water sprayed from the washing nozzle is discharged by the removal pump in the sediment accumulation. Therefore, in the drainage culvert of the present invention, the drainage buried underground can be washed without removing soil and the like from its surroundings. Therefore, the time required for cleaning the drainage culvert is significantly reduced, and the labor and cost required for facility management are significantly reduced. Further, since the washing water is jetted from the plurality of washing nozzles, the inside of the drainage culvert can be washed even with a relatively small amount of washing water. Furthermore, even when the length of the drainage culvert is long, the inside of the drainage culvert can be reliably washed by increasing the number of washing nozzles accordingly.

[Brief description of the drawings]

FIG. 1 is a plan view showing a drainage culvert according to an embodiment of the present invention.

FIG. 2 is a longitudinal sectional view showing a drainage culvert according to the embodiment of the present invention.

FIG. 3 is a sectional view taken along line III-III in FIG. 1;

4 is a partially enlarged view of the part amount I V of FIG.

FIG. 5 is a partially enlarged view of a portion V in FIG. 2;

FIG. 6 is a sectional view showing a first modification of the present invention.

FIG. 7 is a sectional view showing a second modification of the present invention.

FIG. 8 is a sectional view showing a third modification of the present invention.

FIG. 9 is a sectional view showing a fourth modification of the present invention .

[Explanation of symbols]

DESCRIPTION OF SYMBOLS 1 Water collecting burial equipment

Claims (1)

上記集水埋渠に沿って上記河床に埋設され、かつ両端が閉鎖された洗浄水供給管と、

それぞれ上記洗浄水供給管から分岐して上記集水埋渠の内部まで延びる複数の分岐管と、

それぞれ上記分岐管の先端に設けられ、上記集水埋渠の底部に配置され、かつ上記集水埋渠の基端側を向いている複数の洗浄ノズルと、

上記洗浄水供給管と上記揚水ポンプを接続する管路と、

上記揚水ポンプを、上記供給側と上記管路のいずれか一方に切り換える切換手段と、

上記取水路と上記集水埋渠の接続部分に設けられた沈殿堆積物溜まりと、

この沈殿堆積物溜まりに収容され、かつその吐出管の先端の吐出口が上記河川の水面上に位置している除去ポンプを備え、

上記集水埋渠の底部は、その延在方向と直交する方向の断面形状が両側から中央に向けて傾斜し、

上記集水埋渠の洗浄時には、上記切換手段を上記管路側に切り換えて上記揚水ポンプから上記管路を介して上記洗浄水供給管に洗浄水を供給し、上記分岐管に設けた上記洗浄ノズルから上記一方の河岸側に向けて上記集水埋渠内で水流を噴射させ、上記洗浄ノズルが噴射した洗浄水により上記集水埋渠から運ばれた沈殿堆積物を上記沈殿堆積物溜まりに収集し、上記沈殿堆積物溜まりの沈殿堆積物を除去ポンプにより吸い上げて上記河川に廃棄するようにしていることを特徴とする集水埋渠設備。A catchment buried buried in the riverbed of underground water and extending from one shore to the other shore, a water intake tank provided on the one shore, and a base end of the catchment grave And an intake channel buried on the one bank that connects the intake tank to the intake side, and sucks water that has been taken into the catchment culvert and that has flowed into the intake tank via the intake channel, to the supply side. A pump for discharging the water, the opening of the drainage culvert is closed by a grating plate provided with a plurality of water collecting holes for collecting the underflow water, and a scouring prevention is provided above the grating plate. In a drainage culvert facility where a protective body for

A flush water supply pipe buried in the riverbed along the catchment culvert and closed at both ends ;

A plurality of branch pipes each branching from the washing water supply pipe and extending to the inside of the drainage culvert,

A plurality of washing nozzles respectively provided at the distal end of the branch pipe , arranged at the bottom of the drainage culvert, and facing the base end side of the drainage culvert ,

A pipe connecting the washing water supply pipe and the pump;

Switching means for switching the water pump to one of the supply side and the pipeline;

Sediment deposits provided at the connection between the intake channel and the drainage culvert ,

A discharge pump that is housed in the sediment deposits and has a discharge port at the tip of the discharge pipe positioned above the surface of the river;

The bottom part of the drainage culvert has a cross-sectional shape in a direction orthogonal to the extending direction thereof is inclined from both sides toward the center,

At the time of washing the drainage culvert, the switching means is switched to the pipe side to supply wash water to the wash water supply pipe from the pump through the pipe, and the washing nozzle provided in the branch pipe. A jet of water is injected in the drainage culvert toward the one bank side from above, and the sediment carried from the drainage culvert is collected in the sediment reservoir by the washing water injected by the washing nozzle. and, infiltration gallery facility which is characterized in that so as to discard to the river sucked up by removal pump precipitate deposits accumulate the precipitate deposits.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001301929A JP3604013B2 (en) | 2001-09-28 | 2001-09-28 | Drainage culvert facility |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001301929A JP3604013B2 (en) | 2001-09-28 | 2001-09-28 | Drainage culvert facility |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2003105811A JP2003105811A (en) | 2003-04-09 |

| JP3604013B2 true JP3604013B2 (en) | 2004-12-22 |

Family

ID=19122264

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001301929A Expired - Fee Related JP3604013B2 (en) | 2001-09-28 | 2001-09-28 | Drainage culvert facility |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3604013B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112482533A (en) * | 2020-11-19 | 2021-03-12 | 北京市水利规划设计研究院 | Method for setting river channel rainwater drainage port and river channel rainwater drainage system |

-

2001

- 2001-09-28 JP JP2001301929A patent/JP3604013B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003105811A (en) | 2003-04-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3895505B2 (en) | Equipment for collecting and transferring sediment | |

| CN218072854U (en) | Hillside rainwater collection infiltrating irrigation device capable of improving rainwater utilization efficiency | |

| CN109183802A (en) | A kind of construction method for protecting municipal pipeline | |

| CN210049323U (en) | Water intaking pump station entry trash rack system | |

| KR100953397B1 (en) | Infiltration system with cleaning system using riverbed filtration | |

| JP3604013B2 (en) | Drainage culvert facility | |

| JP3483847B2 (en) | Intake structure of river surface water with sloped intake screen installed at floor stop | |

| CN211312481U (en) | Hydraulic engineering retaining wall drainage structures | |

| CN212316672U (en) | Hidden drainage system of municipal administration bridge | |

| CN205769209U (en) | Circulating water wash recessing | |

| KR101151090B1 (en) | Keeping treatment system for primary stage rainwater using the water-storage tank | |

| CN221895869U (en) | Canal head building for water taking and irrigation from silt-rich river channel | |

| JP4675061B2 (en) | Sediment flow transfer equipment | |

| JP3361356B2 (en) | Rainwater treatment facility | |

| CN109763556A (en) | The construction method that a kind of bilge well and sewage network change its course | |

| CN220377500U (en) | Flushing device of inverted siphon and inverted siphon device | |

| CN214459282U (en) | Firm type town road structure of mating formation that permeates water | |

| KR100450602B1 (en) | Drainage apparatus of slope for road | |

| CN220318498U (en) | Wall-penetrating type concealed pipe drainage structure | |

| CN210288617U (en) | Building roof rainwater collecting and recycling system | |

| KR100677865B1 (en) | Under water structure for river fountain and construction method thereof | |

| CN215483021U (en) | Ecological slope protection | |

| CN211973736U (en) | Town road rainwater recovery system | |

| CN212039232U (en) | Construction sewage treatment device | |

| CN212641692U (en) | A drainage device for landscape river system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20040413 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040611 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20040907 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20040922 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3604013 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20071008 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20081008 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20081008 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20091008 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20091008 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101008 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111008 Year of fee payment: 7 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111008 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121008 Year of fee payment: 8 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121008 Year of fee payment: 8 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131008 Year of fee payment: 9 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |