JP3196642U - Resealable packaging box - Google Patents

Resealable packaging box Download PDFInfo

- Publication number

- JP3196642U JP3196642U JP2015000105U JP2015000105U JP3196642U JP 3196642 U JP3196642 U JP 3196642U JP 2015000105 U JP2015000105 U JP 2015000105U JP 2015000105 U JP2015000105 U JP 2015000105U JP 3196642 U JP3196642 U JP 3196642U

- Authority

- JP

- Japan

- Prior art keywords

- piece

- lid

- side plate

- line

- opening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Cartons (AREA)

Abstract

【課題】蓋部の開封性が良く、開封した蓋部を容易かつ確実に再封することができるシールエンドカートン型の包装箱を提供する。【解決手段】箱体形成片12は、4つの側面板14,16,18,20と、側面板20の連接方向の端部に延設された補助板68と、蓋部を形成するための蓋片28,44を備える。第一の側面板16は、連接方向に対して直角方向の端辺の内側に、第一の破断線30に囲まれた開封部42を備える。補助板68は、連接方向に対して直角方向の端部であって開封部42と同じ側の端部に、第二の破断線で区切られた再封片を備える。組み立てた状態で、側面板14の連接方向の端部裏面が、補助板68の表面に糊付けされて筒体が形成される。再封片74の表面が開封部42の裏面に糊付され、蓋片28,44により筒体の開口端を塞ぐように蓋部が形成され、蓋部が再封片74と連続する。【選択図】図2The present invention provides a sealed end carton-type packaging box that has a good opening of a lid and can easily and reliably reseal the opened lid. A box-forming piece 12 forms four side plates 14, 16, 18, 20, an auxiliary plate 68 extended at the end of the side plate 20 in the connecting direction, and a lid. Lid pieces 28 and 44 are provided. The first side plate 16 includes an opening 42 that is surrounded by the first breaking line 30 on the inner side of the edge in the direction perpendicular to the connecting direction. The auxiliary plate 68 is provided with a re-sealing piece separated by a second break line at an end portion perpendicular to the connecting direction and on the same side as the opening portion 42. In the assembled state, the back surface of the end portion in the connecting direction of the side plate 14 is glued to the surface of the auxiliary plate 68 to form a cylinder. The front surface of the resealable piece 74 is glued to the back surface of the opening portion 42, a lid portion is formed so as to close the open end of the cylindrical body by the lid pieces 28 and 44, and the lid portion is continuous with the resealable piece 74. [Selection] Figure 2

Description

本考案は、開封した蓋部を簡易的に再封できるシールエンドカートン型の包装箱に関しする。 The present invention relates to a sealed end carton-type packaging box that can easily re-seal an opened lid.

従来、この種の包装箱として、例えば特許文献1に開示されている包装用箱があった。この包装用箱は、ブランクシートから一体的に打ち抜かれた箱体形成片から成り、箱体形成片の状態で、筒体を形成する第一側面板、正面板、第二側面板及び背面板が順に連接され、筒体の一方の開口端を塞ぐ外蓋片及び内蓋片が、それぞれ正面板及び背面板の一端に折罫線で区切られて延設されている。開封操作を容易にするため構成として、正面板の外蓋片側の端部に、折罫線とU字状の破断線に囲まれた開封部が設けられ、この折罫線の両端部に、開封用切込線が設けられている。また、再封可能にするための構成として、内蓋片の先端部に、再封片が折罫線で区切られて延設され、内蓋片の再封片側の端部に、折罫線とU字状の破断線に囲まれた貼付片が設けられている。

Conventionally, as this type of packaging box, for example, there has been a packaging box disclosed in

組み立てた状態で、再封片が折り曲げられて内蓋片に重なり、再封片の裏面が貼着片の裏面に糊付けされ、筒体の一方の開口端を塞ぐように内蓋片が折り曲げられ、その上に外蓋片が重なって糊付けされて蓋部が形成される。 In the assembled state, the resealable piece is folded and overlapped with the inner lid piece, the backside of the resealable piece is glued to the backside of the sticking piece, and the inner lid piece is folded so as to block one open end of the cylinder. The outer lid piece overlaps and is glued to form a lid portion.

開封するときは、指で開封部を押し込んで正面板の破断線を破断し、さらに蓋部を引き上げて開封用切込線を破断し、蓋部を開く。その後、再封する時は、再封片を内蓋片から引き離して破断線を破断し、引き起こした再封片を正面板の開封用切込線側の端部の内側に差し込んで係合させることにより、蓋部を閉じた状態に保持する構造になっている。 When opening, the opening part is pushed with a finger to break the breaking line of the front plate, and the lid part is pulled up to break the opening cutting line, and the lid part is opened. After that, when resealing, the resealing piece is pulled away from the inner lid piece to break the breaking line, and the resulting resealing piece is inserted inside the end of the opening cut line side of the front plate and engaged. Thus, the lid is held in a closed state.

しかし、特許文献1の包装用箱は、開封部を囲む破断線を最適化する設計が簡単ではない。例えば、比較的破れやすく設計すると、商品輸送時のハンドリングによって不意に破断線が破れてしまうおそれがあり、反対に、破断しにくく設計すると、開封するため開封部を押し込んだとき、破断線が破れる前に正面板が変形してしまうおそれがある。しかも、破断線の破断のしやすさは、破断線の寸法のばらつき、基材(紙など)の厚みのばらつき、吸湿の度合い、開封部が押圧される角度のばらつき等によっても変化する。したがって、常に良好な開封性が得られるようにするのは難しいものであった。

However, the packaging box of

また、この包装用箱は、開封後、開封部が外蓋片の端部に繋がって固定されずに側方に延出するので、見栄えが良くないだけでなく、再封する操作の障害になる可能性もある。 In addition, after opening the packaging box, the unsealing part is connected to the end of the outer lid piece and extends to the side without being fixed. There is also a possibility.

本考案は、上記背景技術に鑑みて成されたものであり、蓋部の開封性が良く、開封した蓋部を容易かつ確実に再封することができるシールエンドカートン型の再封可能な包装箱を提供することを目的とする。 The present invention has been made in view of the above-described background art, and has an easy-to-re-sealable end-carton-type re-sealable packaging that allows easy opening and unsealing of the lid. The purpose is to provide a box.

本考案は、一枚のブランクシートから一体的に打ち抜かれた箱体形成片から成り、この箱体形成片は、互いに平行に連接された4つの側面板と、前記4つの側面板の連接方向の一方の端部に延設された補助板と、蓋部を形成するための蓋片とを有し、前記4つの側面板の中の1つの側面板は、前記連接方向に対して直角方向の端辺の内側に、この端辺とU字状に形成された第一の破断線とで囲まれた開封部が設けられ、前記補助板は、前記連接方向に対して直角方向の端部であって前記開封部と同じ側の端部に、再封片が第二の破断線で区切られて延設され、組み立てた状態で、前記4つの側面板の連接方向の他方の端部裏面が、前記補助板の表面に糊付けされて筒体が形成され、前記再封片の表面が前記開封部の裏面に糊付され、前記蓋片により前記筒体の一方の開口端を塞ぐように蓋部が形成され、前記蓋部が前記再封片と連続し、前記開封部を押し込んで、前記第一及び第二の破断線を破断することによって前記蓋部を開封することができ、開封した後、前記再封片を前記筒体の開口端部分に係合させることによって前記蓋部を再封することができる再封可能な包装箱である。 The present invention comprises a box-forming piece integrally punched from a single blank sheet. The box-forming piece includes four side plates connected in parallel to each other and the connecting direction of the four side plates. An auxiliary plate extending at one end of the first plate and a lid piece for forming a lid portion, and one of the four side plates is perpendicular to the connecting direction. An opening portion surrounded by this end side and a first breaking line formed in a U shape is provided inside the end side of the auxiliary plate, and the auxiliary plate has an end portion in a direction perpendicular to the connecting direction. In the end portion on the same side as the opening portion, the resealing piece is divided and extended by the second breaking line, and in the assembled state, the other end portion back surface in the connecting direction of the four side plates Is glued to the surface of the auxiliary plate to form a cylinder, and the surface of the resealable piece is glued to the back surface of the opening portion, A lid portion is formed so as to close one open end of the cylindrical body, the lid portion is continuous with the resealing piece, pushes the opening portion, and breaks the first and second break lines. The re-sealable packaging box that can open the lid part and then re-seal the lid part by engaging the re-sealing piece with the open end portion of the cylindrical body It is.

前記包装箱は、前記箱体形成片の状態で、前記4つの側面板の中の1つである第一の側面板は、前記連接方向に対して直角方向の端部に、第一の蓋片が第一の折罫線で区切られて延設され、前記第一の折罫線に沿うように、前記第一の蓋片の基端部両端から内向きに第三の破断線が設けられ、前記第一の側面板の内側に、前記第三の破断線の内側両端を起点として連続する前記第一の破断線と前記第一の折罫線とで囲まれた前記開封部が設けられ、前記第一の側面板と1つ空けて隣の第二の側面板は、前記第一の蓋片と同じ側の端部に、第二の蓋片が第二の折罫線で区切られて延設され、組み立てた状態で、前記筒体の一方の開口端を塞ぐように前記第一及び第二蓋片が重ねられ互いに糊付けされて前記蓋部が形成され、前記再封片が前記開封部に糊付けされることにより、前記蓋部が、前記第一の蓋片及び前記開封部を通じて前記再封片と連続し、前記開封部を押し込んで、前記第一及び第二の破断線を破断すると共に、前記第三の破断線を破断することによって前記蓋部を開封することができる構成であることが好ましい。 The packaging box is in the state of the box-forming piece, and the first side plate, which is one of the four side plates, has a first lid at the end perpendicular to the connecting direction. The piece is extended by being divided by a first crease line, and along the first crease line, a third break line is provided inward from both ends of the base end of the first lid piece, Inside the first side plate, the opening portion surrounded by the first rupture line and the first crease line continuous from both inner ends of the third rupture line is provided, The second side plate, which is adjacent to the first side plate, extends from the end on the same side as the first cover piece with the second cover piece separated by a second crease line. In the assembled state, the first and second lid pieces are stacked and glued together so as to close one open end of the cylindrical body to form the lid portion, and the reseal piece is opened. By being glued to the part, the lid part is continuous with the reseal piece through the first lid piece and the opening part, and pushes the opening part to break the first and second break lines. In addition, it is preferable that the lid can be opened by breaking the third break line.

あるいは、前記包装箱は、箱体形成片の状態で、前記4つの側面板の中の1つである第一の側面板は、前記連接方向に対して直角方向の端辺の内側に、この端辺とU字状に形成された前記第一の破断線とで囲まれた前記開封部が設けられ、前記第一の側面板と1つ空けて隣の第二の側面板は、前記開封部と同じ側の端部に、第二の蓋片が折罫線で区切られて延設され、前記補助板は、前記連接方向に対して直角な端部であって前記開封部と同じ側の端部に、再封片が第二の破断線で区切られて延設され、前記再封片の先端部に、第一の蓋片が第一の折罫線で区切られて延設され、組み立てた状態で、前記筒体の一方の開口端を塞ぐように前記第一及び第二蓋片が重ねられ互いに糊付けされて前記蓋部が形成され、前記蓋部が、前記第一の蓋片を通じて前記再封片と連続する構成であることが好ましい。 Alternatively, the packaging box is in the form of a box body, and the first side plate, which is one of the four side plates, is disposed on the inner side of the end perpendicular to the connecting direction. The opening portion surrounded by the end side and the first breaking line formed in a U-shape is provided, and the second side plate adjacent to the first side plate is separated by the opening A second lid piece is provided on the end on the same side as the part, and is extended with a crease line, and the auxiliary plate is an end perpendicular to the connecting direction and on the same side as the opening part. At the end, the resealing piece is divided and extended by a second breaking line, and at the tip of the resealing piece, the first lid piece is extended and divided by a first crease line, and assembled. In this state, the first and second lid pieces are overlapped and glued together so as to close one open end of the cylindrical body to form the lid portion, and the lid portion is the first lid piece. It is preferably configured to continuous with the reclosure strips through.

さらに、前記補助片の内側に、表示片が第四の破断線で区切られて設けられ、前記表示片は、前記蓋部を開封した後、前記第四の破断線を破断することにより前記筒体から分離させることができる構成にしてもよい。 Further, a display piece is provided inside the auxiliary piece by a fourth break line, and the display piece is formed by breaking the fourth break line after opening the lid. You may make it the structure which can be made to isolate | separate from a body.

本考案の再封可能な包装箱は、簡単な構造で組み立て易く、包装の作業性もよいものである。また、組み立てた状態で、側面板の開封部の近傍が補助板と重なって補強されるので、良好な開封性を安定的に実現することができる。開封後は、再封片を用いて違和感なく確実に再封することができる。 The resealable packaging box of the present invention has a simple structure, is easy to assemble, and has good packaging workability. Moreover, since the vicinity of the opening part of the side plate overlaps with the auxiliary plate and is reinforced in the assembled state, it is possible to stably realize a good opening property. After opening, it can be reliably resealed using a resealable piece without a sense of incongruity.

以下、本考案の再封可能な包装箱の第一の実施形態について、図1〜図7に基づいて説明する。この実施形態の包装箱10は、図1に示すように、略直方体の箱体であり、厚紙等の一枚のブランクシートを一体的に打ち抜いた箱体形成片12を組み立てることによって形成される。

Hereinafter, 1st embodiment of the resealable packaging box of this invention is described based on FIGS. As shown in FIG. 1, the

図2は、箱体形成片12を裏面から見た展開図であり、箱体形成片12は、互いに平行に連接された4つの側面板14,16,18,20を有している。4つの側面板14,16,18,20は、連接方向と直交する幅方向の長さが同じで、連接方向の長さもほぼ同じであり、各々折罫線22,24,26で区切られている。以下、側面板16を第一の側面板16、第一の側面板16の1つ挟んで隣の側面板20を第二の側面板20と称する。

FIG. 2 is a developed view of the box-forming

第一の側面板16の、連接方向に対して直角方向の一端部には、略矩形の第一の蓋片28が延設され、第一の折罫線30で第一の側面板16と区切られている。第一の蓋片28の延出方向長さは、側面板14,18の連接方向長さとほぼ同じである。第一の側面板16の他端部には、第一の蓋片28と同形の蓋片32が延設され、折罫線34で第一の側面板16と区切られている。蓋片32は、延出方向のほぼ中央部にV字状の分解用破断線36が設けられ、基端側部分32aと先端側部分32bとに区切られている。

A substantially rectangular

さらに、第一の折罫線30に沿うように、第一の蓋片28の基端部両端から内向きに破断線38が設けられ、第一の側面板16の内側に、破断線38の内側両端を起点として連続する破断線40と第一の折罫線30とで囲まれた開封部42が設けられている。以下、破断線38を第三の破断線38、破断線40を第一の破断線40と称する。

Further, along the

第二の側面板20の、連接方向に対して直角方向の一端部(第一の蓋片28側の端部)には、先端側の幅が狭くなった台形状の第二の蓋片44が延設され、第二の折罫線46で第二の側面板20と区切られている。第二の蓋片44の延出方向長さは、側面板14,18の連接方向長さの約2/3程度である。第二の側面板20の他端部には、先端部の幅がやや狭くなった台形状の蓋片48が延設され、折罫線50で第二の側面板20と区切られている。

The

側面板14の、第一の側面板16の第一の折罫線30に連続する端部には、サイドフラップ52が延設され、折罫線54で側面板14と区切られている。側面板14の他端部には、サイドフラップ56が延設され、折罫線58で側面板14と区切られている。側面板18の、第一の側面板16の第一の折罫線30に連続する端部にも、同様のサイドフラップ60が延設され、折罫線62で側面板18と区切られている。側面板18の他端部にも同様のサイドフラップ64が延設され、折罫線66で側面板18と区切られている。

A

4つの側面板14,16,18,20が連接する第二の側面板20側の端部には、補助板68が延設され、折罫線70で第二の側面板20と区切られている。補助板68は、基端部から先端部までの途中の位置に、折罫線70と平行な折罫線72が設けられ、基端側部分68aと先端側部分68bに区切られている。基端側部分68aは、連接方向の長さが側面板14とほぼ同じであり、折罫線30から折罫線72に近づくにしたがって幅が狭くなっている。先端側部分68bは、連接方向の長さが第一の側面板16よりも僅かに短く、折罫線70から離れるにしたがって幅が狭くなっている。

An

補助板68の先端側部分68bは、連接方向に対して直角方向の端部であって、第一の側面板16の開封部42と同じ側の端部に再封片74が延設され、破断線76で先端側部分68bと区切られている。再封片74は、第一の側面板16の開封部42に対応する位置に設けられ、先端部の幅は第一の側面板16の連接方向長さとほぼ同じで、基端部の幅は両角が取れて狭くなっており、全体として開封部42を塞ぐ程度の大きさである。以下、破断線76を第二の破断線76と称する。

The

次に、表示片付き包装箱10の組み立て方法の一例を説明する。ここで、箱体形成片12の表面が凸になる折り方を正折り、そして裏面が凸になる折り方を逆折りと称する。

Next, an example of the assembly method of the

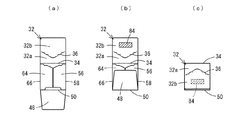

まず、図3(a)に示すように、折罫線70を正折して、補助板68の基端側部分68aを第二の側面板20に重ね、先端側部分68b及び再封片74を側面板18に重ねる。そして、基端側部分68aの表面の折罫線70に近い位置に糊78を塗布し、先端側部分68bの表面の中央部に糊80を塗布し、再封片74の表面の中央部に糊82を塗布する。

First, as shown in FIG. 3A, the

その後、図3(b)に示すように、折罫線24を正折りして、側面板14の裏面の端部を基端側部分68bの表面に糊付し、第一の側面板16の裏面の中央部を先端側部分68aの表面に糊付し、開封部42の裏面を再封片74の表面に糊付する。箱体形成片12は、この折り畳まれた状態で出荷される。

Thereafter, as shown in FIG. 3B, the

次に商品を収容して包装する工場等において、折罫線22,24,26,70,72を各々90°に正折りする。側面板14,16がそれぞれ補助板68に糊付されているので、しっかりした四角形の筒体をワンアクションで形成することができる。その後、図4(a)、(b)、(c)に順に示すように、折罫線58,66でサイドフラップ56,64を各々90°に正折りし、折罫線50で蓋片48を90°に正折りする。その後、蓋片32の先端側部分32bに糊84を塗布し、折罫線34で蓋片32を90°に正折りし、蓋片32の裏面を蓋片48の表面に糊付する。これによって、筒体の一方の端部が閉鎖され底部が形成されるので、開放している他端部から箱体の中に商品を入れる。

Next, the crease lines 22, 24, 26, 70, and 72 are each normally folded at 90 degrees in a factory or the like that stores and packs products. Since the

次に、図5(a)、(b)、(c)に順に示すように、折罫線54,62でサイドフラップ52,60を各々90°に正折りし、第二の折罫線46で第二の蓋片44を90°に正折りする。その後、第一の蓋片28の裏面に糊86を塗布し、第一の折罫線30で第一の蓋片28を90°に正折りし、第一の蓋片28の裏面を第二の蓋片44の表面に糊付する。

Next, as shown in FIGS. 5A, 5B, and 5C in order, the side flaps 52 and 60 are each normally folded at 90 ° by the crease lines 54 and 62, and the

これで商品の包装作業が終了し、図1に示す状態になる。この組み立て状態で、第一の側面板14の広い範囲が補助板68の先端側部分68bと重なり、開封部42の周辺部分が補強される。

This completes the product packaging operation and the state shown in FIG. In this assembled state, the wide range of the

次に、この包装箱10を開封及び再封する操作について説明する。開封するときは、第一の側面板16の開封部42を指で押し破る。このとき、開封部42の周縁部分が補助板68により補強されているので、第一の側面板16が変形しにくく、第一の破断線40を容易に破断させることができる。開封部42を押し破ると、第二の破断線76もほぼ同時に破断し、再封片74が補助板68から切り離される。そして、再封片74及び第一の蓋片28を摘んで引き上げると、第三の破断線38も破断し、図6(a)に示すように、蓋部で塞がれていた筒体の端部が開放し、中の商品を取り出すことができる。

Next, operations for opening and resealing the

開封後、包装箱10の中に商品を戻して再封するときは、図6(b)に示すように、再封片74をサイドフラップ52,60と第一の側面板16との隙間に差し込んで係合させることにより、筒体の端部を蓋部で閉鎖する。再封片74は、切り離された第二の破断線76側の両角が取れているので、容易に差し込むことができる。また、第一の側面板16の開封部42が除去された開口部は、再封片74によって塞がれる。開封部42は、再封片74の表面に糊付けされているので、ブラブラせずに見栄えが良く、再封する操作の障害にもならない。

When the product is returned to the

再封片74は、その幅を第一の側面板16の幅いっぱいに広く設定するのが好ましく、再封片74が第一の側面板16の内面に広い面積で当接させることによって、安定に係止することができる。

The width of the

開封後、包装箱10を廃棄するため分解するときは、図7(a)、(b)、(c)に順に示すように、底部の蓋片32の中央部を押し込んで、分解用破断線36を破断させる。すると、底部の閉鎖が簡単に解除され、包装箱10を薄く折り畳むことができるようになり、コンパクトな形で廃棄することができる。

When disassembling the

以上説明したように、包装箱10は、簡単な構造で組み立て易く、包装の作業性もよいものである。また、組み立てた状態で、開封部42の近傍が補助板68で補強されるので、良好な開封性を安定的に実現することができる。また、開封後は、再封片74を用いて違和感なく確実に再封することができ、廃棄のため分解する操作も容易である。

As described above, the

次に、本考案の再封可能な包装箱の第二の実施形態について、図8〜図12に基づいて説明する。ここで、上記実施形態と同様の構成は、同一の符号を付して説明を省略する。この実施形態の包装箱88は、図8に示すように、略直方体の箱体であり、厚紙等の一枚のブランクシートを一体的に打ち抜いた箱体形成片90を組み立てることによって形成される。

Next, 2nd embodiment of the resealable packaging box of this invention is described based on FIGS. Here, the same components as those in the above embodiment are denoted by the same reference numerals and description thereof is omitted. As shown in FIG. 8, the

図9は、箱体形成片90を裏面から見た展開図であり、全体として図2の箱体形成片12と類似しているが、特徴的なのは、補助板68の基端側部分68aの内側に表示片92が設けられている点と、側面板14の内側に補助表示部94が設けられている点と、廃棄するときに使用する分解用破断線36に代えて、第二の側面板20の端部に分解用押圧部96が設けられている点である。

FIG. 9 is a developed view of the box-forming

表示片92は、補助板68の基端側部分68aの内側に、第四の破断線98で区切られて設けられている。第四の折罫線は、補助板68における折罫線72の位置と、折罫線70より少し折罫線72側に離れた位置の2箇所に、折罫線70と平行に形成され、2つの第四の破断線98に挟まれた部分が表示片92となる。また、表示片92の、再封片74と反対側の端部に、摘み部92aが折罫線100で区切られて延設されている。折罫線100は、ほぼ側面板20の折罫線50を延長した位置に設けられている。表示片92には、あらかじめ、製品名や使用者が読むべき詳しい情報(例えば、商品の取り扱い説明、使用上の注意事項)等が印刷されている。

The

補助表示部94は、側面板14の中央部やや折罫線54寄りの位置に、略矩形の第五の破断線102で囲まれて設けられ、組み立てた状態で、表示片92の内側に重なって糊付される部分である。補助表示部94には、例えば、商品を包装する工程で、商品の製造番号や使用期限等の情報が印刷される。

The

分解用押圧部96は、折罫線50に沿うように、蓋片48の基端部両端から内向きに破断線104aを形成し、第二の側面板20の内側に、破断線104aの内側両端を起点として連続する破断線104bを形成することにより設けられ、折罫線50と破断線104bで囲まれた部分が分解用押圧部96となる。

The disassembling

次に、再封可能な包装箱88の組み立て方法の一例を説明する。ここで、箱体形成片90の表面が凸になる折り方を正折り、そして裏面が凸になる折り方を逆折りと称する。

Next, an example of a method for assembling the

まず、図10(a)に示すように、折罫線70を正折して、補助板68の基端側部分68aを第二の側面板20に重ね、先端側部分68b及び再封片74を側面板18に重ねる。そして、基端側部分68aの表面の折罫線70に近い位置(表示片92以外の部分)に糊78を塗布し、先端側部分68bの表面の中央部に糊80を塗布し、再封片74の表面の中央部に糊82を塗布する。さらに、表示片92の表面の中央部やや第二の蓋片44寄りの位置にも糊106を塗布する。

First, as shown in FIG. 10A, the

その後、図10(b)に示すように、折罫線24を正折りして、側面板14の裏面の端部を基端側部分68bの表面に糊付し、第一の側面板16の裏面の中央部を先端側部分68aの表面に糊付し、開封部42の裏面を再封片74の表面に糊付し、さらに、補助表示部94の裏面を表示片92の表面に糊付する。箱体形成片90は、この折り畳まれた状態で出荷される。

Thereafter, as shown in FIG. 10B, the

商品を収容して包装する工場等で行う工程は、上記包装箱10とほぼ同様であり、まず、折罫線22,24,26,70,72を各々90°に正折りして四角形の筒体をし、図4(a)(b)(c)に順に示すように、筒体の一方の端部を閉鎖して底部を形成する。このとき、表示片92の摘み部92aは、底部に押されて折罫線100で正折りされ、箱体の内側に収容される。次に、開放している他端部から箱体の中に商品を入れ、図5(a)(b)(c)に順に示すように、筒体の開放している端部を閉鎖して蓋部を形成する。さらに、収容した商品の製造番号や使用期限等を補助表示部94の表面に印刷する作業を行う。これで商品の包装作業が終了し、図8に示す組み立て状態になる。

The process performed in a factory for storing and packaging products is substantially the same as that of the

組み立てられた包装箱88を開封する操作及び再封する操作は、上記包装箱10と同様である。

The operation of opening and resealing the assembled

開封後、包装箱88を廃棄するため分解するときは、図11(a),(b)に順に示すように、第二の側面板20の分解用押圧部96を指で押し破り、蓋片32,48を摘んで引き上げると、破断線104aも破断し、図12(a)に示すように、底部で塞がれていた筒体の端部が開放する。

When disassembling the

底部が開放すると、表示片92の摘み部92aを指で摘まんで側面板14から引き離すと、図12(b)に示すように、2つの第四の破断線98が破断して、表示片92が側面板14から分離する。このとき、側面板14の補助表示部94が表示片92に糊付けされているため、第五の破断線102もほぼ同時に破断し、補助表示部94も側面板14から分離する。補助表示部94が一体になった表示片92には、商品の製品名や使用期限等の重要な情報が記載されているので、例えば、商品を包装箱88から取り出して保管棚等で保管する場合、商品識別用の表示カードとして使用することができる。表示片92以外の箱体部分は、底部の閉鎖が解除されて薄く折り畳むことができるようになるので、コンパクトな形で廃棄することができる。

When the bottom portion is opened, when the

以上説明したように、包装箱88は、上記の包装箱10と同様の作用効果を得ることができ、さらに、補助板68の基端側部分68aの部分を利用して、便利な表示片92を得ることができる。

As described above, the

次に、本考案の再封可能な包装箱の第三の実施形態について、図13〜図16に基づいて説明する。ここで、上記実施形態と同様の構成は、同一の符号を付して説明する。この実施形態の包装箱106は、図13に示すように、略直方体の箱体であり、厚紙等の一枚のブランクシートを一体的に打ち抜いた箱体形成片108を組み立てることによって形成される。

Next, 3rd embodiment of the resealable packaging box of this invention is described based on FIGS. Here, the same configurations as those in the above embodiment are described with the same reference numerals. As shown in FIG. 13, the

図14は、箱体形成片108を裏面から見た展開図であり、箱体形成片108は、互いに平行に連接された4つの側面板110,112,114,116を有している。4つの側面板110,112,114,116は、連接方向と直交する幅方向の長さが同じである。連接方向の長さは、側面板112,116が長くて互いにほぼ等しく、側面板110,114が短くて互いにほぼ等しく、各々折罫線118,120,122で区切られている。以下、側面板116を第一の側面板116、第一の側面板116と1つ挟んで隣の側面板112を第二の側面板112と称する。

FIG. 14 is a developed view of the box-forming

第一の側面板116の、連接方向に対して直角方向の一端部には蓋片32が延設され、折罫線34で第一の側面板116と区切られている。さらに、折罫線50に沿うように、蓋片34の基端部両端から内向きに破断線104aを形成し、第一の側面板116の内側に、破断線104aの内側両端を起点として連続する破断線104bを形成することにより、分解用押圧部96が設けられている。

A

さらに、第一の側面板116の、前記折罫線34と反対側の端辺の中央部内側に、U字状に形成された第一の破断線40に囲まれた開封部42が設けられている。

Furthermore, an

第二の側面板112の、連接方向に対して直角方向の一端部(開封部42の側の端部)には、先端側の幅がやや狭くなった台形状の第二の蓋片44が延設され、第二の折罫線46で第二の側面板112と区切られている。第二の蓋片44の延出方向長さは、側面板110,114の連接方向長さとほぼ同じである。第二の側面板112の他端部にも、同様の蓋片48が延設され、折罫線50で第二の側面板112と区切られている。

A trapezoidal

側面板110の、第二の側面板44の第二の折罫線46に連続する端部には、サイドフラップ52が延設され、折罫線54で側面板110と区切られている。側面板110の他端部には、サイドフラップ56が延設され、折罫線58で側面板110と区切られている。側面板114の、第二の側面板112の第二の折罫線46に連続する端部にも、同様のサイドフラップ60が延設され、折罫線62で側面板18と区切られている。側面板114の他端部にも同様のサイドフラップ64が延設され、折罫線66で側面板114と区切られている。

A

4つの側面板110,112,114,116が連接する側面板110側の端部には、略四角形の補助板124が延設され、折罫線70で側面板110と区切られている。補助板124の連接方向長さは、第一の側面板116よりも僅かに短い。

A substantially rectangular

補助板124は、連接方向に対して直角方向の端部であって、第一の側面板116の開封部42と同じ側の端部に再封片74が延設され、第二の破断線76で補助板124と区切られている。再封片74は、第一の側面板116の開封部42に対応する位置に設けられ、先端部の幅は第一の側面板116の連接方向長さとほぼ同じで、基端部の幅は両角が取れてやや狭くなっており、全体として開封部42を塞ぐ程度の大きさである。

The

さらに、再封片74の先端部に第一の蓋片28が延設され、第一の折罫線30で再封片74と区切られている。第一の折罫線30は、ほぼ側面板110の折罫線54を延長した位置に設けられ、第一の蓋片28の延出方向長さは、側面板110,114の連接方向長さの約4/5程度である。

Further, the

次に、再封可能な包装箱106の組み立て方法の一例を説明する。ここで、箱体形成片108の表面が凸になる折り方を正折り、そして裏面が凸になる折り方を逆折りと称する。

Next, an example of an assembly method of the

まず、図15(a)に示すように、折罫線70を正折して、補助板124を側面板110に重ねる。そして、補助板124の折罫線70に近い位置に糊78を塗布し、再封片74の表面の中央部に糊82を塗布する。

First, as shown in FIG. 15A, the

その後、図15(b)に示すように、折罫線120を正折りして、第一の側面板116の裏面の端部を補助板124の表面に糊付し、開封部42の裏面を再封片74の表面に糊付する。箱体形成片108は、この折り畳まれた状態で出荷される。

Thereafter, as shown in FIG. 15B, the

商品を収容して包装する工場等で行う工程は、上記包装箱10とほぼ同様であり、まず、折罫線118,120,122,70を各々90°に正折りして四角形の筒体をし、図4(a)、(b)、(c)に順に示す要領で筒体の一方の端部を閉鎖し、底部を形成する。ただし、この実施形態の場合は、第二の蓋片44の方が第一の蓋片28よりも大きいので、第一の蓋片28の外側に第二の蓋片44を重ねて糊付する。次に、開放している他端部から箱体の中に商品を入れ、図5(a)、(b)、(c)に順に示す要領で筒体の開放している端部を閉鎖し、蓋部を形成する。ただし、この実施形態の場合は、蓋片48の方が蓋片32よりも大きいので、蓋片32の外側に蓋片48を重ねて糊付する。これで商品の包装作業が終了し、図13に示す組み立て状態になる。

The process performed in a factory for storing and packaging products is almost the same as that of the

次に、この包装箱106を開封及び再封する操作について説明する。開封するときは、第一の側面板116の開封部42を指で押し破る。このとき、開封部42の周縁部分が補助板124により補強されているので、第一の側面板116が変形しにくく、第一の破断線40を容易に破断させることができる。開封部42を押し破ると、第二の破断線76もほぼ同時に破断し、再封片74が補助板68から切り離される。開封部42は第一の側面板116から分離するが、再封片74に糊付けされているのでゴミにはならない。そして、再封片74及び第一の蓋片28を摘んで引き上げると、図16(a)に示すように、蓋部で塞がれていた筒体の端部が開放し、中の商品を取り出すことができる。

Next, operations for opening and resealing the

開封後、包装箱106の中に商品を戻して再封するときは、図16(b)に示すように、再封片74をサイドフラップ52,60と第一の側面板116との隙間に差し込んで係合させることにより、筒体の端部を蓋部で閉鎖する。再封片74は、切り離された第二の破断線76側の両角が取れているので、容易に差し込むことができる。また、第一の側面板116の開封部42が除去された開口部は、再封片74によって塞がれる。開封部42は、再封片74の表面に糊付けされているので、ブラブラせずに見栄えが良く、再封する操作の障害にもならない。

When the product is returned to the

再封片74は、その幅を第一の側面板116の幅いっぱいに広く設定するのが好ましく、再封片74が第一の側面板116の内面に広い面積で当接させることによって、安定に係止することができる。また、第一の折罫線30の両端から一対の切り込みを設けておけば、切り込みとサイドフラップ52,60の端縁とが互いに係合するので、閉鎖状態をより確実に保持することができる。

The width of the

開封後、包装箱106を廃棄するため分解するときは、図11(a),(b)に順に示す要領で、第一の側面板116の分解用押圧部96を指で押し破り、蓋片32,48を摘んで引き上げると、破断線104aも破断し、底部の閉鎖が簡単に解除され、包装箱106を薄く折り畳むことができるようになり、コンパクトな形で廃棄することができる。

When the

以上説明したように、包装箱106は、上記の包装箱10と同様の作用効果を得ることができ、さらに、箱体形成片108のサイズが小さくなり、糊付する箇所も少なくなるので、包装箱のコストダウンを図ることができる。

As described above, the

なお、本考案の再封可能な包装箱は、上記実施形態に限定されるものではない。例えば、第一の実施形態の包装箱10の場合、第一の蓋片28及び第一の折罫線30が第一の側面板16の端部に設けられているが、第三の実施形態の包装箱106のように、これらを再封片74の先端部に設けてもよく、同様の作用効果が得られる。また、第三の実施形態の包装箱106の場合、第一の蓋片28及び第一の折罫線30が再封片74の先端部に設けられているが、第一の実施形態の包装箱10のように、これらを第一の側面板116の端部に設けてもよく、同様の作用効果が得られる。

In addition, the resealable packaging box of this invention is not limited to the said embodiment. For example, in the case of the

補助板の形態は、再封片が延設される部分が開封部を有する側面板と重なり、開封部の近傍を補強することができるものであれば、自由に変更することができる。例えば、第二の実施形態の包装箱88の補助板は、一部を切り離して表示カードとして使用できる形態であるが、その他にも、補助板の一部が箱体内部の中仕切りの働きをする形態にしてもよい。

The form of the auxiliary plate can be freely changed as long as the portion where the resealing piece is extended overlaps the side plate having the opening portion and can reinforce the vicinity of the opening portion. For example, the auxiliary plate of the

箱体の大きさ、素材、各部材の形状、破断線の形態(ミシン目、ジッパ線等)は適宜変更可能である。また、蓋部側だけでなく、底部側にも上記のような再封片及び開封部を設け、筒体の両側を開封及び再封可能な構造にしてもよい。 The size of the box, the material, the shape of each member, and the form of the break line (perforation, zipper line, etc.) can be changed as appropriate. Further, not only the lid part side but also the bottom part side may be provided with the above-mentioned resealing pieces and opening parts so that both sides of the cylindrical body can be opened and resealed.

10,88,106 再封可能な包装箱

12,90,108 箱体形成片

14,18,110,114 側面板

16,116 第一の側面板

20,112 第二の側面板

28 第一の蓋片

30 第一の折罫線

38 第三の破断線

40 第一の破断線

42 開封部

44 第二の蓋片

46 第二の折罫線

68 補助板

68a 基端側部分

68b 先端側部分

74 再封片

76 第二の破断線

78,80,82,84,86,106 糊

92 表示片

98 第四の破断線

124 補助板

10, 88, 106

Claims (4)

前記4つの側面板の中の1つの側面板は、前記連接方向に対して直角方向の端辺の内側に、この端辺とU字状に形成された第一の破断線とで囲まれた開封部が設けられ、前記補助板は、前記連接方向に対して直角方向の端部であって前記開封部と同じ側の端部に、再封片が第二の破断線で区切られて延設され、

組み立てた状態で、前記4つの側面板の連接方向の他方の端部裏面が、前記補助板の表面に糊付けされて筒体が形成され、前記再封片の表面が前記開封部の裏面に糊付され、前記蓋片により前記筒体の一方の開口端を塞ぐように蓋部が形成され、前記蓋部が前記再封片と連続し、

前記開封部を押し込んで、前記第一及び第二の破断線を破断することによって前記蓋部を開封することができ、開封した後、前記再封片を前記筒体の開口端部分に係合させることによって前記蓋部を再封することができることを特徴とする再封可能な包装箱。 It consists of a box-forming piece integrally punched from one blank sheet, and this box-forming piece has four side plates connected in parallel to each other and one end in the connecting direction of the four side plates. An auxiliary plate extending to the part, and a lid piece for forming a lid part,

One side plate of the four side plates is surrounded by an end side perpendicular to the connecting direction and a first break line formed in a U-shape. An opening portion is provided, and the auxiliary plate extends at an end portion in a direction perpendicular to the connecting direction and on the same side as the opening portion, with a reseal piece separated by a second breaking line. Established,

In the assembled state, the back surface of the other end in the connecting direction of the four side plates is glued to the surface of the auxiliary plate to form a cylinder, and the surface of the resealing piece is glued to the back surface of the opening portion. Is attached, and a lid is formed so as to close one open end of the cylindrical body by the lid piece, the lid is continuous with the reseal piece,

The lid portion can be opened by pushing the opening portion and breaking the first and second breaking lines, and after opening, the resealing piece is engaged with the opening end portion of the cylindrical body The re-sealable packaging box characterized by being able to reseal the said cover part by making it.

組み立てた状態で、前記筒体の一方の開口端を塞ぐように前記第一及び第二蓋片が重ねられ互いに糊付けされて前記蓋部が形成され、前記再封片が前記開封部に糊付けされることにより、前記蓋部が、前記第一の蓋片及び前記開封部を通じて前記再封片と連続し、

前記開封部を押し込んで、前記第一及び第二の破断線を破断すると共に、前記第三の破断線を破断することによって前記蓋部を開封することができる請求項1記載の再封可能な包装箱。 In the state of the box-forming piece, the first side plate, which is one of the four side plates, has a first lid piece at the end perpendicular to the connecting direction. A third break line is provided inwardly extending from both ends of the base end portion of the first lid piece so as to extend along the crease line and along the first crease line, and the first side Inside the face plate, the opening portion surrounded by the first break line and the first crease line continuous from both inner ends of the third break line is provided, and the first side plate And the second side plate adjacent to the first cover piece is extended at the same end as the first cover piece, with the second cover piece separated by a second crease line,

In the assembled state, the first and second lid pieces are stacked and glued together so as to block one open end of the cylindrical body to form the lid part, and the resealing piece is glued to the opening part. The lid portion is continuous with the re-sealing piece through the first lid piece and the opening portion,

2. The resealable body according to claim 1, wherein the lid portion can be opened by pushing the opening portion to break the first and second breaking lines and breaking the third breaking line. Packaging box.

組み立てた状態で、前記筒体の一方の開口端を塞ぐように前記第一及び第二蓋片が重ねられ互いに糊付けされて前記蓋部が形成され、前記蓋部が、前記第一の蓋片を通じて前記再封片と連続する請求項1記載の再封可能な包装箱。 In the state of a box-forming piece, the first side plate, which is one of the four side plates, is inside the end side perpendicular to the connecting direction, in a U-shape with this end side. The opening portion surrounded by the formed first breaking line is provided, and the second side plate adjacent to the first side plate is separated from the end portion on the same side as the opening portion. The second cover piece is divided and extended by a crease line, and the auxiliary plate is an end portion perpendicular to the connecting direction and on the same side as the opening portion, Is extended by being separated by a second break line, and the first lid piece is extended by being separated by a first crease line at the tip of the reseal piece,

In the assembled state, the first and second lid pieces are stacked and glued together so as to block one open end of the cylindrical body to form the lid portion, and the lid portion is the first lid piece. The resealable packaging box of claim 1, which is continuous with the resealable piece.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015000105U JP3196642U (en) | 2015-01-13 | 2015-01-13 | Resealable packaging box |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015000105U JP3196642U (en) | 2015-01-13 | 2015-01-13 | Resealable packaging box |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP3196642U true JP3196642U (en) | 2015-03-26 |

| JP3196642U7 JP3196642U7 (en) | 2016-08-18 |

Family

ID=52986276

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015000105U Active JP3196642U (en) | 2015-01-13 | 2015-01-13 | Resealable packaging box |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3196642U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021084668A (en) * | 2019-11-28 | 2021-06-03 | 小林製薬株式会社 | Packaging box |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5602972B1 (en) * | 2014-04-18 | 2014-10-08 | カンナル印刷株式会社 | Packaging box |

| JP3194136U (en) * | 2014-08-27 | 2014-11-06 | 富山スガキ株式会社 | Resealable packaging box |

-

2015

- 2015-01-13 JP JP2015000105U patent/JP3196642U/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5602972B1 (en) * | 2014-04-18 | 2014-10-08 | カンナル印刷株式会社 | Packaging box |

| JP3194136U (en) * | 2014-08-27 | 2014-11-06 | 富山スガキ株式会社 | Resealable packaging box |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021084668A (en) * | 2019-11-28 | 2021-06-03 | 小林製薬株式会社 | Packaging box |

| JP7421319B2 (en) | 2019-11-28 | 2024-01-24 | 小林製薬株式会社 | packaging box |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5955077B2 (en) | Packaging box | |

| JP5259754B2 (en) | Packaging box | |

| JP5836101B2 (en) | Packaging box | |

| JP4816237B2 (en) | Packaging box | |

| AU2012231785A1 (en) | A box for packaging | |

| JP4775560B2 (en) | Paper carton | |

| JP3196642U (en) | Resealable packaging box | |

| JP2010052759A (en) | Paper carton | |

| JP2017132483A (en) | Packing box | |

| JP3194136U (en) | Resealable packaging box | |

| JP4807230B2 (en) | Two stage resealable carton | |

| JP6895327B2 (en) | Packaging box | |

| JP3197969U (en) | Packaging box with information card | |

| JP3224236U (en) | Packaging box with reseal function | |

| JP6482795B2 (en) | Packaging box | |

| JP3217785U (en) | Packaging box | |

| JP3224237U (en) | Packaging box with reseal function | |

| JP2013112366A (en) | Packaging box | |

| JP2019043618A (en) | Packaging box | |

| JP2013159373A (en) | Packaging box | |

| JP7327780B2 (en) | packaging box | |

| JP3224242U (en) | Packaging box | |

| JP3224507U (en) | Packaging box with display | |

| JP6110108B2 (en) | Sheet for cardboard box, cardboard box and method for sealing confidential waste paper | |

| JP6967890B2 (en) | Packaging box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3196642 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| A623 | Registrability report |

Free format text: JAPANESE INTERMEDIATE CODE: A623 Effective date: 20151211 |

|

| R231 | Written correction (descriptions, etc.) |

Free format text: JAPANESE INTERMEDIATE CODE: R231 |

|

| R157 | Certificate of patent or utility model (correction) |

Free format text: JAPANESE INTERMEDIATE CODE: R157 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R323531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |