JP2017013722A5 - - Google Patents

Download PDFInfo

- Publication number

- JP2017013722A5 JP2017013722A5 JP2015134868A JP2015134868A JP2017013722A5 JP 2017013722 A5 JP2017013722 A5 JP 2017013722A5 JP 2015134868 A JP2015134868 A JP 2015134868A JP 2015134868 A JP2015134868 A JP 2015134868A JP 2017013722 A5 JP2017013722 A5 JP 2017013722A5

- Authority

- JP

- Japan

- Prior art keywords

- art

- prior

- present

- deformation amount

- load

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000010521 absorption reaction Methods 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 230000002787 reinforcement Effects 0.000 description 2

- 230000003111 delayed Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

Images

Description

図10はバンパリインフォースメント14の変形量に対する荷重の変化を従来技術と本実施形態とを対比して示す線図である。図10の線図において、Gは従来技術、Hは本実施形態を示す。この両者の比較線図から良く分かるように、座屈タイミングは従来技術では変形量m1の位置であったの対し、本実施形態では変形量m2の位置となり、変形量mdだけ遅れて生じる。これにより座屈が生じるピーク荷重も従来技術ではn1であったのが、本実施形態ではn2となり大幅にピーク荷重の増大も図られる。評価試験結果の数値は、従来技術Gの座屈荷重(ピーク荷重)n1が133KNで、その変形量m1が35mmであったのに対し、本実施形態では座屈荷重(ピーク荷重)n2が243KNで、その変形量m2が56.8mmである。 FIG. 10 is a diagram showing a change in load with respect to the deformation amount of the bumper reinforcement 14 in comparison with the prior art and the present embodiment. In the diagram of FIG. 10, G indicates the prior art, and H indicates the present embodiment. As can be clearly seen from the comparison diagram between the two, the buckling timing is at the position of the deformation amount m1 in the prior art, whereas in the present embodiment, it is at the position of the deformation amount m2 and is delayed by the deformation amount md. As a result, the peak load at which buckling occurs is n1 in the prior art, but becomes n2 in the present embodiment, and the peak load is significantly increased. Numerical evaluation test results in buckling load (peak load) n1 prior art G is 133KN, while the deformation amount m1 was 35 mm, in the present embodiment is buckling load (peak load) n2 in 243KN, the deformation amount m2 is 56.8mm.

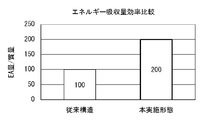

図12はエネルギー吸収量効率比較を示す。エネルギー吸収量効率とは〔エネルギー吸収(EA)量/バンパリインフォースメントの質量〕である。従来技術を100とした場合、本実施形態は200という高い値の効率を得た。なお、本説明でのエネルギー吸収(EA)量は、従来技術および本実施形態それぞれについて、図10に示す線図の変形量0mm〜150mmまでを積分して求めた値としている。

FIG. 12 shows energy absorption efficiency comparison. The energy absorption efficiency is [energy absorption (EA) amount / bumper reinforcement mass]. Assuming that the prior art is 100, this embodiment has obtained a high efficiency of 200. Note that the energy absorption (EA) amount in this description is a value obtained by integrating the

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015134868A JP2017013722A (en) | 2015-07-06 | 2015-07-06 | Bumper reinforcement |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015134868A JP2017013722A (en) | 2015-07-06 | 2015-07-06 | Bumper reinforcement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2017013722A JP2017013722A (en) | 2017-01-19 |

| JP2017013722A5 true JP2017013722A5 (en) | 2017-09-28 |

Family

ID=57827749

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015134868A Pending JP2017013722A (en) | 2015-07-06 | 2015-07-06 | Bumper reinforcement |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2017013722A (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6798457B2 (en) | 2017-09-15 | 2020-12-09 | トヨタ自動車株式会社 | Vampari Information |

| JP7264072B2 (en) * | 2020-01-24 | 2023-04-25 | トヨタ自動車株式会社 | vehicle reinforcement |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS529934U (en) * | 1975-07-10 | 1977-01-24 | ||

| CN1976832B (en) * | 2004-07-01 | 2012-03-28 | 麦格纳国际公司 | Bumper beam for a motor vehicle |

| JP2010047077A (en) * | 2008-08-20 | 2010-03-04 | Mazda Motor Corp | Vehicular bumper structure |

| JP5918092B2 (en) * | 2012-09-18 | 2016-05-18 | 富士重工業株式会社 | Bumper beam for vehicles |

-

2015

- 2015-07-06 JP JP2015134868A patent/JP2017013722A/en active Pending

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2014026273A5 (en) | ||

| MX2015009725A (en) | Impact absorbing element. | |

| JP2017534766A5 (en) | ||

| JP2013213735A5 (en) | ||

| JP2013528272A5 (en) | ||

| MX2017004767A (en) | Impact absorption member. | |

| JP2016200526A5 (en) | ||

| JP2017013722A5 (en) | ||

| JP2015201986A5 (en) | ||

| JP2015529327A5 (en) | ||

| JP2017085424A5 (en) | ||

| JP2016037909A5 (en) | ||

| JP2015525489A5 (en) | ||

| RU2015154555A (en) | METHOD FOR PRODUCING STEEL PIPE | |

| JP2012248108A5 (en) | ||

| JP2012148874A5 (en) | ||

| TH184495B (en) | Shock absorber parts | |

| TH184496B (en) | Shock absorber parts | |

| TH1401005435B (en) | Aluminum alloy sheet materials for lithium-ion batteries and methods for producing the same. | |

| JP2015103932A5 (en) | ||

| JP2016502197A5 (en) | ||

| TH59737S1 (en) | Shock absorber parts | |

| JP2018039878A5 (en) | ||

| TH176438B (en) | Load sensors and load sensor units | |

| TH51023S1 (en) | Metal cross-section |