JP2012144686A - Bored soap - Google Patents

Bored soap Download PDFInfo

- Publication number

- JP2012144686A JP2012144686A JP2011015771A JP2011015771A JP2012144686A JP 2012144686 A JP2012144686 A JP 2012144686A JP 2011015771 A JP2011015771 A JP 2011015771A JP 2011015771 A JP2011015771 A JP 2011015771A JP 2012144686 A JP2012144686 A JP 2012144686A

- Authority

- JP

- Japan

- Prior art keywords

- soap

- consumption

- new

- bored

- solid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000000344 soap Substances 0.000 title claims abstract description 66

- 239000007787 solid Substances 0.000 abstract description 9

- 238000004519 manufacturing process Methods 0.000 abstract description 3

- 239000002699 waste material Substances 0.000 abstract 1

- 238000010586 diagram Methods 0.000 description 4

- 206010011906 Death Diseases 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 208000003443 Unconsciousness Diseases 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000002537 cosmetic Substances 0.000 description 1

- 210000004907 gland Anatomy 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000036651 mood Effects 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

Images

Landscapes

- Detergent Compositions (AREA)

Abstract

Description

本出願は固形石鹸の使い終わりに近づいた、残渣石鹸を穴開き石鹸に挿入し、再利用できる目的を持つ石鹸の提唱である。以下図面に従って詳述する。 This application is a proposal of a soap that has the purpose of being able to reuse the soap that has reached the end of its use by inserting residual soap into the perforated soap. This will be described in detail with reference to the drawings.

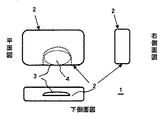

図1に一般的石鹸の模式図を三角法で示す。石鹸1の長方外周側面2に切り窪み窪み3を形成した、穴開き石鹸である。FIG. 1 shows a schematic diagram of a general soap by trigonometry. This is a perforated soap in which a cut-out depression 3 is formed on the longer outer

図2に固形石鹸の使い終わりの石鹸4を示す平面図。すり減り石鹸を新たな穴開き石鹸 1の窪み3に差込み使用の結果、新品石鹸1と共に最後まで有効消費するものである。 The top view which shows the

家庭や学校職場で消費する分野。 Fields consumed at home and school.

固形石鹸消費間際のすり減り石鹸4の完全消費は、新品石鹸に貼り付け消費が家庭レベルの節約志向の中で行われている。しかしながら、消費末期石鹸4の接合面と新品石鹸1との接合面が合わず、使うとき面倒であった。

他方消費末期石鹸が時間経過と共に乾燥し溶けなくなり、益々石鹸同士の融合性が確保できず、使用中に手の中で剥れてしまい、最終的に破棄同然となる。The complete consumption of the

On the other hand, the end-of-consumption soap is dried and does not melt with the passage of time, more and more soap cannot be secured, peels off during use, and finally becomes discarded.

学校・職場・その他施設などでメッシュ袋に詰めて消費の時、新たな石鹸を消費末期石鹸と共に挿入消費している。 At the time of consumption after packing in mesh bags at schools, workplaces and other facilities, new soap is inserted and consumed together with end-of-life soap.

消費末期石鹸4、どのように最後まで消費させるか。単独では非常に不便であり、貼り付けも確実でなく、新石鹸との一体化とその手段である。 End-of-

得に一般家庭において、高価な化粧機能石鹸のとき、消費環境と保全条件が室内でもあり、メッシュ袋詰で使用するのは甚だムード的環境が不適切であり、かような消費環境の改善。 In particular, in the general household, when using an expensive cosmetic function soap, the consumption environment and the maintenance conditions are also indoors, and the mood environment is inappropriate for use in mesh bags, which improves the consumption environment.

石鹸製造時に一つ以上の窪みを成型し、消費間際の石鹸を差込み一体化し、新石鹸1との脱落を防止する。One or more dents are molded at the time of soap production, and the soap just before consumption is inserted and integrated to prevent it from falling off with the

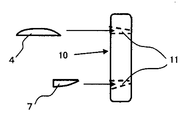

消費間際石鹸4の形状は中央が厚い円盤状である。一つ丸々挿入できる穴では側面空間が増すので半分に切り分け、切り分け面が外面になるように挿入できれば、略消費間際石鹸4で側面2を塞ぐ事が可能となる。その目的達成のために新石鹸1の左右側面2に挿入ポケットを設けた。 The shape of the

使用に耐えないほど消費した固形石鹸3を、最後まで新石鹸1と共に、簡便無意識に使い切る。The solid soap 3 consumed so much that it cannot be used is used up to the end together with the

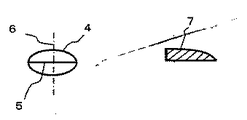

図3に、図2の磨り減った固形石鹸4の切断線5の断面図一点鎖線6の、断面図7を示す。 FIG. 3 shows a cross-sectional view 7 of a

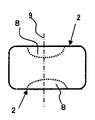

図4に新品石鹸1平面図を示し、長い両側面2に三日月状の窪み8を破線で示し、中央一点鎖線9の断面図を図5に示した。FIG. 4 shows a plan view of the

図5に中央線6の断面図7と三日月状の窪み8の関係図を示す。同図は三日月形窪み8に、三日月形断面を持つ磨り減り石鹸7が挿入される関係図で、挿入された両者の関係と環境が大きな間隙を生まないことを示す。 FIG. 5 shows a cross-sectional view of the

石鹸1の厚みに対し三日月形窪み8位置が、厚み中央線9よりも上方に位置し、その効果と意義は、石鹸1の消費が上面が下面より勝り、穴開き石鹸が再度消費完了間近じかになる前に挿入石鹸4が消費される、重大な効果現象となる。The crescent-

図6では固形石鹸1の表面に甲丸楔型貫通穴11を二つ設けた実施例図。本実施例図の側面図が図6。

本実施例の優位性は製造過程で固形石鹸の型抜きにある。側面窪み穴形成は回転刃で開ける。本実施例では二枚のプレス刃で貫通形成が特徴。

消費利用の優位性として磨り減り石鹸4挿入時接触するまで差込み装着が安定であり、はみ出し部分を切り分け他の穴に差し込む簡便性がある。先細の先端貫通突出部分は即消費され平らになる。FIG. 6 is an embodiment diagram in which two round wedge-type through

The advantage of the present embodiment is in the demolding of the soap bar in the manufacturing process. The side depression is formed with a rotary blade. This embodiment is characterized by penetration formation with two press blades.

As an advantage of consumption use, it is worn down until it is worn down and touched when

1 穴開き石鹸。

2 石鹸外周側面。

3 穴開き石鹸の窪み。

4 消費石鹸、消費末期の平面図。

5 切断腺。

6 図化用断面図化の中央線。

7 分割した消費末期石鹸の断面図。

8 穴器石実施例ずで、両脇に窪み。

9 固形石鹸の暑さに対する中心線

10 固形石鹸表面

11 半球楔形貫通穴 1 hole soap.

2 Soap outer side.

3 A dimple of soap with a hole.

4 Top view of consumed soap, end of consumption.

5 Cut glands.

6 Centerline of plotting cross section.

7 A sectional view of the divided end-of-consumption soap.

8 Dimples on both sides without hole stone example.

9 Center line against heat of

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011015771A JP2012144686A (en) | 2011-01-11 | 2011-01-11 | Bored soap |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011015771A JP2012144686A (en) | 2011-01-11 | 2011-01-11 | Bored soap |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2012144686A true JP2012144686A (en) | 2012-08-02 |

Family

ID=46788584

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011015771A Withdrawn JP2012144686A (en) | 2011-01-11 | 2011-01-11 | Bored soap |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2012144686A (en) |

-

2011

- 2011-01-11 JP JP2011015771A patent/JP2012144686A/en not_active Withdrawn

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102948997A (en) | Energy-saving toothbrush | |

| JP2012144686A (en) | Bored soap | |

| CN208918980U (en) | A kind of Furniture panel connector | |

| CN203649316U (en) | Hot and cold core box with loose piece for casting | |

| CN207593575U (en) | Nodal diamond grinding disc | |

| CN205614104U (en) | Drill | |

| CN204385055U (en) | A kind of diamond disc cutting glass | |

| CN204711844U (en) | Around limit opening bit | |

| CN206241390U (en) | Internal expansion type scraper | |

| CN202088324U (en) | Detachable granulating device | |

| CN206997929U (en) | Saw blade | |

| CN204366182U (en) | A kind of scraper for machining shaft bearing Internal Spherical Surface | |

| CN204609774U (en) | A kind of side set drill bit | |

| CN201737837U (en) | Toothed glass drill bit | |

| CN203830842U (en) | Saw blade | |

| CN203751391U (en) | Drilling template used on forming die tool | |

| CN203296349U (en) | Wall putty scraper | |

| CN204712327U (en) | A kind of round platform core rod with chamfering exhaust | |

| CN204312144U (en) | Blade damping structure and blade | |

| CN202180537U (en) | Thin-wall drill | |

| CN203923576U (en) | Little circular knitting machine | |

| CN203282530U (en) | Plastic product horizontal hole processing jig | |

| CN202168815U (en) | Novel shoe brush | |

| TWM486504U (en) | Improved detachable blade structure for milling cutter | |

| CN209845287U (en) | Binder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110305 |

|

| A300 | Withdrawal of application because of no request for examination |

Free format text: JAPANESE INTERMEDIATE CODE: A300 Effective date: 20140401 |