JP2012024223A - Bread making machine - Google Patents

Bread making machine Download PDFInfo

- Publication number

- JP2012024223A JP2012024223A JP2010164555A JP2010164555A JP2012024223A JP 2012024223 A JP2012024223 A JP 2012024223A JP 2010164555 A JP2010164555 A JP 2010164555A JP 2010164555 A JP2010164555 A JP 2010164555A JP 2012024223 A JP2012024223 A JP 2012024223A

- Authority

- JP

- Japan

- Prior art keywords

- heater

- kneading

- temperature

- motor

- control device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Abstract

Description

本発明は、一般家庭において使用されるパンに加えてあんも作れるパン製造機に関するものである。 The present invention relates to a bread maker that can make bread in addition to bread used in general households.

従来のあんを作る方法としては、特許文献1に示されるように、業務用のあん類製造方法であり、小型煮炊攪拌機に入れてあんを製造するが、これは家庭用ではなく、製パン機能がない。 As shown in Patent Document 1, as a conventional method of making ann, it is a method for producing annix for business use, and it is put into a small-sized boiled stirrer to produce ann, but this is not for home use, There is no function.

しかしながら、従来のパン製造機はパン生地を練り上げるには無負荷で毎分300回転程度の回転数が必要であるが、同じ回転数であん材料を攪拌すると数秒間回転させただけで、あん材料がパン容器の外に飛散するという問題があり、それを防ぐには可変式の減速機構を設けてゆっくりした回転に変える必要があり、コスト高になるという課題があった。 However, the conventional bread maker does not load the dough to knead the bread dough and requires about 300 revolutions per minute. When the ingredients are stirred at the same number of revolutions, the ingredients are only rotated for a few seconds. There is a problem of scattering outside the bread container, and in order to prevent this, it is necessary to provide a variable speed reduction mechanism and change to a slow rotation, which raises the problem of high costs.

本発明は、前記従来の課題を解決するもので、あん材料が飛散することなく、短時間で簡単にあんを作ることができるパン製造機を提供することを目的とする。 SUMMARY OF THE INVENTION The present invention solves the above-described conventional problems, and an object of the present invention is to provide a bread maker that can easily make bean paste in a short time without splashing bean ingredients.

前記従来の課題を解決するために、本発明のパン製造機は、スタートすると予熱工程に入り、温度検知部が110〜130℃の設定温度に達するまで、90%以上のヒータ通電率であん材料を加熱するようにしたものである。 In order to solve the above-mentioned conventional problems, the bread maker of the present invention starts with a preheating process when started, and the material has a heater current of 90% or more until the temperature detection unit reaches a set temperature of 110 to 130 ° C. Is to be heated.

これによって、従来より高い設定温度とヒータ通電率で、あん材料を素早く加熱して煮込み工程に入ることができるため、よく煮詰まったあんを短時間で作り上げることができる。 Thereby, since the bean paste can be quickly heated and put into the stew process at a higher set temperature and heater energization rate than before, well cooked bean paste can be made in a short time.

本発明のパン製造機によれば、スタートすると予熱工程に入り、温度検知部が110〜130℃の設定温度に到達するまで、90%以上のヒータ通電率であん材料を加熱することにより、あん材料を素早く加熱することができ、短時間であん材料を焦げ付かせることなく、あんを作ることができる。 According to the bread maker of the present invention, when it is started, the preheating process is started, and the material is heated at a heater energization rate of 90% or more until the temperature detector reaches a set temperature of 110 to 130 ° C. The material can be heated quickly, and can be made in a short time without burning the material.

また、あん材料の飛散、焦げ付きを防止し温度を均一にしながら、高い設定温度であん材料を素早く煮詰められるため、短時間で簡単にあんを作ることができる。 In addition, the sauce can be quickly boiled at a high set temperature while preventing the spatter and burnt of the sauce and making the temperature uniform, so that the sauce can be easily made in a short time.

第1の発明は、材料を混練または攪拌する練り羽根を有する着脱自在なパン容器とヒータと温度検知部とを具備した焼成室と、練り羽根を回転させるモータと、前記ヒータやモータ等の通電を制御する制御装置を備え、前記制御装置のプログラムには、予熱工程と煮込み工程と冷却工程とを有するあんコースを有し、前記予熱工程において温度検知部が110〜130℃の設定温度に到達するまで、90%以上のヒータ通電率であん材料を加熱するようにしたパン製造機としたものであり、従来より高い設定温度とヒータ通電率であん材料を素早く加熱するため、短時間で素材から水分を溶出させて、材料の砂糖を溶解させることができる。 The first invention is a baking chamber equipped with a removable bread container having a kneading blade for kneading or stirring materials, a heater and a temperature detection unit, a motor for rotating the kneading blade, and energization of the heater, the motor, etc. The control device program includes an annulus having a preheating step, a stew step, and a cooling step, and the temperature detector reaches a set temperature of 110 to 130 ° C. in the preheating step. Until then, it is a bread maker that heats the raw material at a heater energization rate of 90% or more, and the material is heated quickly at a higher set temperature and heater energization rate than before, so the material in a short time Moisture can be eluted from the material to dissolve the sugar of the material.

第2の発明は、材料を混練または攪拌する練り羽根を有する着脱自在な容器とヒータと温度検知部とを具備した焼成室と、練り羽根を回転させるモータと、前記ヒータやモータ等の通電を制御する制御装置を備え、前記制御装置のプログラムには、予熱工程と煮込み工程と冷却工程とを有するあんコースを有し、前記煮込み工程において設定温度を110〜130℃に設定し、温度検知部の温度が設定温度を越えると、ヒータを切って練り羽根の間欠回転によりあん材料を攪拌し、温度検知部の温度が設定温度より下がると、練り羽根を止めて80%以上のヒータ通電率で、あん材料を加熱するようにしたパン製造機としたものであり、パン容器とあん材料の温度が上がりすぎてあん材料が焦げ付く前に自動的にヒータを切って、間欠回転による攪拌により、あん材料の温度を均一にしながら、高い設定温度とヒータ通電率であん材料を素早く加熱するため、短時間で焦げ付きを防ぎながらあん材料を煮詰めることができる。 According to a second aspect of the present invention, there is provided a detachable container having a kneading blade for kneading or stirring the material, a firing chamber provided with a heater and a temperature detection unit, a motor for rotating the kneading blade, and energization of the heater and the motor. A control device for controlling, the program of the control device has an anise course having a preheating step, a stew step, and a cooling step, a set temperature is set to 110 to 130 ° C. in the stew step, and a temperature detector If the temperature exceeds the set temperature, the heater is turned off and the ingredients are stirred by intermittent rotation of the kneading blades. When the temperature of the temperature detector falls below the set temperature, the kneading blades are stopped and the heater energization rate is 80% or more. This is a bread maker that heats the bean paste, and the heater is automatically turned off to prevent intermittent rotation before the temperature of the pan container and bean paste rises too much. The stirring that, while the uniform temperature of the bean material, to heat the An materials high set temperature and heater power rate quickly, it is possible to boil a sauce material while preventing scorching in a short time.

第3の発明は、材料を混練または攪拌する練り羽根を有する着脱自在な容器とヒータと温度検知部とを具備した焼成室と、練り羽根を回転させるモータと、前記ヒータやモータ等の通電を制御する制御装置を備え、前記制御装置のプログラムには、予熱工程と煮込み工程と冷却工程とを有するあんコースを有し、前記あんコースにおいて練り羽根の回転数を0.2秒以下、停止時間を回転時間の10倍以上でかつ1秒以上に設定した間欠回転を繰り返すことにより、あん材料の攪拌を行なうパン製造機としたものであり、パン生地を練り上げる時と同じ回転速度でも、回転時間を微小時間に設定し、回転量を小さくおさえることにより、あん材料の飛散を防ぐとともに、あん材料は練り羽根の広い面の小さな動きで攪拌されるため、あん材料の温度の均一化と焦げ付き防止を図ることができ、変速機構がなくても同じ練り羽根を使ってパン生地を練り上げることもできる。 According to a third aspect of the present invention, there is provided a detachable container having a kneading blade for kneading or stirring materials, a heating chamber provided with a heater and a temperature detection unit, a motor for rotating the kneading blade, and energization of the heater, the motor and the like. A control device for controlling, and the program of the control device has an anise course having a preheating step, a stew step, and a cooling step, and the rotational speed of the kneading blades in the anise course is 0.2 seconds or less, and the stop time Is a bread maker that stirs the ingredients by repeating intermittent rotation that is set to 10 times or more of the rotation time and 1 second or more, and the rotation time is the same as when the dough is kneaded. By setting the minute time and keeping the amount of rotation small, the material is prevented from scattering and the material is stirred by a small movement of the wide surface of the kneading blade. It is possible to prevent scorching and uniformity of temperature, even without transmission mechanism can also elaborate the dough with the same dough blade.

第4の発明は、材料を混練または攪拌する練り羽根を有する着脱自在な容器とヒータと温度検知部とを具備した焼成室と、練り羽根を回転させるモータと、前記ヒータやモータ等の通電を制御する制御装置を備え、前記制御装置のプログラムには、予熱工程と煮込み工程と冷却工程とを有するあんコースを有し、前記あんコースにおいて練り羽根の回転数を段階的に変化させ、停止時間を回転時間の10倍以上でかつ1秒以上に設定した間欠回転を繰り返すことにより、あん材料の攪拌を行なうパン製造機としたものであり、パン生地を練り上げる時と同じ回転速度でも、回転時間を微小時間に設定し、回転量を小さくおさえることにより、あん材料の飛散を防ぐとともに、あん材料の状態によって練り羽根の回転数を変えることにより、より良いあんを作ることができる。 In a fourth aspect of the present invention, a removable container having a kneading blade for kneading or stirring the material, a heating chamber provided with a heater and a temperature detection unit, a motor for rotating the kneading blade, and energization of the heater, the motor, etc. A control device for controlling, the program of the control device has an annulus course having a preheating step, a stew step, and a cooling step, and the rotation speed of the kneading blades is changed stepwise in the annulus course, and the stop time Is a bread maker that stirs the ingredients by repeating intermittent rotation that is set to 10 times or more of the rotation time and 1 second or more, and the rotation time is the same as when the dough is kneaded. By setting the minute time and keeping the amount of rotation small, it is possible to prevent the scattering of the material and to change the rotation speed of the kneading blade according to the state of the material. It is possible to make a good sauce.

以下、本発明の実施の形態について、図面を参照しながら説明する。なお、この実施の形態によって本発明が限定されるものではない。 Hereinafter, embodiments of the present invention will be described with reference to the drawings. Note that the present invention is not limited to the embodiments.

(実施の形態1)

以下、本発明の第1の実施の形態のパン製造機について図面を参照しながら説明する。

(Embodiment 1)

Hereinafter, a bread maker according to a first embodiment of the present invention will be described with reference to the drawings.

図1、図2において1はシャーシで、板金で形成した本体2とモータ3と焼成室4と容器取付台5が取り付けられている。焼成室4の内部には、パン材料がセットされ着脱自在なパン容器6と、ヒータ7と、焼成室4内部の温度を検知する温度検知部8が設けられている。9はモータ3によって小プーリ10、ベルト11、大プーリ12を介して回転され、パン材料の混練やあん材料の攪拌を行うもので、パン容器6の軸13に嵌合される穴を具備したボス部14に、略L字形の平板部15を突設して形成されている。また、練り羽根9はパン生地を練り上がるのに適した回転速度、つまり無負荷で毎分300回転程度に設定され、それに合わせて小プーリ10と大プーリ12の径寸法を決めている。16は焼成室4を開閉する外蓋で、複数の排気孔17が設けられた内蓋18と、イーストをセットするイースト容器19と、イーストを投入する開閉弁20を具備している。21はイースト容器19と一体的に設けられた排気ダクトで、排気孔17の上方に配され、焼成室4内の蒸気を後方の排気口(図示せず)より外気へ排出している。22は温度検知部8により検知された温度情報に基づいてモータ3やヒータ7の通電を制御する制御装置で、パンの焼上げコース、生地コースやあんコース等のプログラムを内蔵し、パンの混練、ねかし、発酵、焼成やあんの予熱、加熱、冷却の各工程を自動的に行う。23は動作状態の表示やコース選択、調理スタート等を行う操作部材、24はレバー25を介して開閉弁20を駆動するソレノイドである。

1 and 2, reference numeral 1 denotes a chassis to which a

以上のように構成されたパン製造機について、図3を用いてその動作を工程ごとに説明する。 About the bread | baking machine comprised as mentioned above, the operation | movement is demonstrated for every process using FIG.

まず、あんの材料、例えば小豆あんであれば、煮た小豆と砂糖を、練り羽根9をセットしたパン容器6にいれて、スタート釦を押すと予熱工程に入り、ヒータ7が90%の通電率で通電されあん材料が加熱され、温度検知部8の温度が120℃を越えると、煮込み工程に移行する。するとあん材料の温度が上がるにつれて、砂糖が溶けてシロップを形成し始め、小豆がそのシロップ中に浮かんだ状態になっていく。この間、練り羽根9は間欠回転するため、あん材料が焦げ付くこともない。また、設定温度を高めの120℃としヒータ通電率を90%にすることにより、素早くあん材料を加熱して小豆をつぶしやすい状態にすることができる。なお、ここでは予熱工程の設定温度を120℃としヒータ通電率90%で行っているが、これは一実施例であり材料の種類や容量に応じて最適条件は変わり、設定温度は110〜130℃、ヒータ通電率は90%以上、工程時間は10〜20分に設定すれば、前記と同様な作用効果が得られる。

First of all, if it is red bean paste, boiled red beans and sugar are put in a

次に40分の煮込み工程に入り、予熱工程と同様に制御装置22により高温の115℃に温度調節しながら、温度検知部8の温度が設定温度の115℃を越えヒータ7が切られた時のみ、モータ3に0.08秒ON、2秒OFFのパターンで通電され練り羽根9が間欠回転する。また、前述のようにあん材料は小豆の浮かんだシロップ状になり、温度が上がるにつれて沸騰状態となって、ふきこぼれが発生する恐れがあるため、急激に温度が上がらないよう、ヒータ通電率は予熱工程より多少低い80%に設定している。この時、練り羽根9の回転時間を0.08秒と微小時間に設定することにより、パン生地を練る時と同じ無負荷で毎分300回転程度の高速回転でも、練り羽根9は90°以下の小刻みな回転速度で動き、それを温度検知部8が設定温度の120℃以下になるまで約2秒毎に繰り返すため、モータ3の通電率は約1.2%となり、あん材料の飛散を発生させることなくあん材料を攪拌することができ、あん材料の温度を均一にしながら焦げ付きも防止することができる。また、それによって煮込み温度を従来より高温の115℃に設定することが可能となるため、あん材料を効率よく煮詰めることができ、短時間で程よいあんをつくることができる。

Next, when the simmering process is started for 40 minutes and the temperature of the

なお、ここでは前記のようにふきこぼれを防止するため、ヒータ通電率を80%としているが、これは一実施例であり、材料の種類や容量によってはヒータ通電率をもっと上げ

てもふきこぼれが発生することはなく、調理時間を短縮することもでき、ヒータ通電率は80%以上に設定しておけば、前記と同様な作用効果が得られる。また、練り羽根の回転時間を0.08秒に設定したが、0.2秒以下であればあん材料が飛散することはなく、材料の種類や容量によっては、0.2秒以下の範囲内で変えて攪拌性能の向上を図っても構わない。

Here, the heater energization rate is set to 80% in order to prevent spillage as described above. However, this is an example, and depending on the type and capacity of the material, the spillage may occur even if the heater energization rate is further increased. The cooking time can be shortened, and if the heater energization rate is set to 80% or more, the same effect as described above can be obtained. In addition, the rotation time of the kneading blade was set to 0.08 seconds. However, if the rotation time is 0.2 seconds or less, the material will not scatter, and depending on the type and capacity of the material, it may be within the range of 0.2 seconds or less. However, the stirring performance may be improved.

最後に残時間が5分を表示すると、冷却工程に移行する。冷却工程に入ると、制御装置22によりヒータ7が切られ、出来上がったあんが自然冷却される。そのため、冷却工程が終わった調理完了直後に外蓋16を開いて、あんを覗き込んだり取り出したりしても、火傷の恐れはなく、安全性を確保することができる。

When the remaining time is finally displayed as 5 minutes, the process proceeds to the cooling process. When the cooling process is started, the

なお、ここでは冷却工程を5分間にしているが、5〜15分であれば焼成室4内の雰囲気温度が100〜80℃に下がるため、調理完了直後に外蓋16を開いても前記と同様に火傷の恐れはなく、安全性を確保することができる。 In addition, although the cooling process is set to 5 minutes here, if it is 5 to 15 minutes, since the atmospheric temperature in the baking chamber 4 will fall to 100 to 80 degreeC, even if it opens the outer cover 16 immediately after cooking completion, Similarly, there is no fear of burns and safety can be ensured.

また、練り羽根9を面を立てて形成することにより、パン生地を練り上げることができるとともに、変速機構がなく同じ練り羽根9を使っても、回転時間を微小時間に設定することで、練り羽根9の広い面の小さな動きによる攪拌が可能となるため、あん材料の飛散や焦げ付きを防止しながらあんを作ることができるパン製造機を安価に提供することができる。 In addition, the dough can be kneaded by forming the kneading blade 9 upright, and even if there is no speed change mechanism and the same kneading blade 9 is used, by setting the rotation time to a minute time, the kneading blade 9 Therefore, it is possible to provide an inexpensive bread maker that can make bean while preventing the material from being scattered or burnt.

(実施の形態2)

本発明の第2の実施の形態における本体の構成は実施の形態1と同じであるため、同一の箇所には同一の符号を付し、説明は省略する。

(Embodiment 2)

Since the configuration of the main body in the second embodiment of the present invention is the same as that in the first embodiment, the same portions are denoted by the same reference numerals and description thereof is omitted.

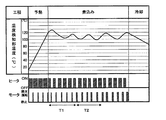

図4は、本発明の第2の実施の形態のパン製造機の温度制御特性図であり、実施の形態1のパン製造機と比較して、予熱工程および煮込み工程のモータの通電率を段階的に変化させるようにしたことが相違する。第2の実施の形態における動作について図4を中心に説明する。 FIG. 4 is a temperature control characteristic diagram of the bread maker according to the second embodiment of the present invention, and in comparison with the bread maker according to the first embodiment, the energization ratio of the motor in the preheating process and the stew process is stepped. The difference is that it was changed in a way. The operation in the second embodiment will be described with reference to FIG.

まず、あんの材料、例えば小豆あんであれば、煮た小豆と砂糖を、練り羽根9をセットしたパン容器6にいれて、スタート釦を押すと、予熱工程に入り、ヒータ7が90%の通電率で通電されてあん材料が加熱され、温度検知部8の温度が120℃を検知すると、煮込み工程に移行する。制御装置22が動作してヒータ7が切られた時のみ、モータ3に0.02秒ON、2秒OFFのパターンで通電され練り羽根9が間欠回転する。

First of all, if it is red bean paste, boiled red beans and sugar are put into a

煮込み工程に入り、予熱工程と同様に制御装置22により高温の115℃に温度調節しながら、温度検知部8の温度が設定温度の115℃を越えヒータ7が切られた時のみ、モータ3に0.04秒ON、2秒OFFのパターンである通電され、ある一定時間T1が経過すると、モータ3に0.06秒ON、2秒OFFのパターンで通電され、またある一定時間T2が経過すると、モータ3に0.08秒ON、2秒OFFのパターンで通電され練り羽根9が間欠運転する。

As in the preheating step, the temperature is adjusted to a high temperature of 115 ° C. by the

以上のように、本実施の形態のパン製造機では、あん材料の状態によって、練り羽根の回転数が段階的に変化するため、よりよいあんを作ることができる。なお、本実施例におけるT1、T2、T3の値は実施の一例であり、状況に応じて数値を設定することができる。 As described above, in the bread maker according to the present embodiment, the number of rotations of the kneading blades changes stepwise depending on the state of the bean curd, so that a better bean can be made. In addition, the value of T1, T2, and T3 in a present Example is an example of implementation, and a numerical value can be set according to a condition.

以上のように、本発明にかかるパン製造機は、あんコース選択時に、あん専用の調理シ

ーケンスで調理することが可能となるので、カレー、シチューなどのように、調理物を攪拌または混練しながら加熱調理する調理器などの用途としても適用できる。また、業務用としても適用可能である。

As described above, the bread maker according to the present invention can cook in a cooking sequence dedicated to an ann when selecting an ann course, and therefore, while stirring or kneading a food such as curry or stew. It can also be used as a cooking device for cooking by heating. It can also be applied for business use.

3 モータ

4 焼成室

6 パン容器

7 ヒータ

8 温度検知部

9 練り羽根

22 制御装置

DESCRIPTION OF

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010164555A JP2012024223A (en) | 2010-07-22 | 2010-07-22 | Bread making machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010164555A JP2012024223A (en) | 2010-07-22 | 2010-07-22 | Bread making machine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2012024223A true JP2012024223A (en) | 2012-02-09 |

| JP2012024223A5 JP2012024223A5 (en) | 2013-05-09 |

Family

ID=45777921

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010164555A Pending JP2012024223A (en) | 2010-07-22 | 2010-07-22 | Bread making machine |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2012024223A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014033866A (en) * | 2012-08-09 | 2014-02-24 | Sharp Corp | Heat cooker |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08308741A (en) * | 1995-05-16 | 1996-11-26 | Hitachi Home Tec Ltd | Automatic bread baker |

| JP2773392B2 (en) * | 1990-06-05 | 1998-07-09 | 松下電器産業株式会社 | Rotating cooker |

| JP2000116527A (en) * | 1998-10-16 | 2000-04-25 | Matsushita Electric Ind Co Ltd | Bread maker |

| JP2002000471A (en) * | 2000-06-26 | 2002-01-08 | Matsushita Electric Ind Co Ltd | Electric cooker |

| JP2003250696A (en) * | 2002-02-27 | 2003-09-09 | Shinagawa Kogyosho:Kk | Heating pot and scorch preventing device for open fire pot |

| JP2008178462A (en) * | 2007-01-23 | 2008-08-07 | Sanyo Electric Co Ltd | Cooker |

-

2010

- 2010-07-22 JP JP2010164555A patent/JP2012024223A/en active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2773392B2 (en) * | 1990-06-05 | 1998-07-09 | 松下電器産業株式会社 | Rotating cooker |

| JPH08308741A (en) * | 1995-05-16 | 1996-11-26 | Hitachi Home Tec Ltd | Automatic bread baker |

| JP2000116527A (en) * | 1998-10-16 | 2000-04-25 | Matsushita Electric Ind Co Ltd | Bread maker |

| JP2002000471A (en) * | 2000-06-26 | 2002-01-08 | Matsushita Electric Ind Co Ltd | Electric cooker |

| JP2003250696A (en) * | 2002-02-27 | 2003-09-09 | Shinagawa Kogyosho:Kk | Heating pot and scorch preventing device for open fire pot |

| JP2008178462A (en) * | 2007-01-23 | 2008-08-07 | Sanyo Electric Co Ltd | Cooker |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014033866A (en) * | 2012-08-09 | 2014-02-24 | Sharp Corp | Heat cooker |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110022733B (en) | Automated device for cooking food and corresponding method | |

| JP5260421B2 (en) | Baking machine with steaming function | |

| KR102501960B1 (en) | Cooking method for electric cooking apparatus with stirring means | |

| JP2002000471A (en) | Electric cooker | |

| JP5909677B2 (en) | Automatic bread machine | |

| JP6436334B2 (en) | Automatic bread machine | |

| JP6102240B2 (en) | Cooking device | |

| JP5269227B1 (en) | Cooker | |

| JP2012024323A (en) | Bread maker with steaming function | |

| JP2000116527A (en) | Bread maker | |

| JP2012024223A (en) | Bread making machine | |

| JP2012024223A5 (en) | ||

| JP2017000798A (en) | Cooking device and bread production method | |

| JP6331091B2 (en) | Electric cooker | |

| JP2014087388A (en) | Automatic bread baking machine | |

| JP6012488B2 (en) | Cooker | |

| JP5316323B2 (en) | Baking machine with steaming function | |

| JP2002051920A (en) | Table cooker | |

| JP5861031B2 (en) | Automatic bread machine | |

| JP2007181542A (en) | Cooker | |

| JP3303779B2 (en) | Cooking device | |

| JP2011010911A (en) | Bread maker with steaming function | |

| JP2007181542A5 (en) | ||

| JP6460177B2 (en) | Cooking device | |

| JP2578938B2 (en) | Baking machine baking program |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130322 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20130322 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20130412 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20140107 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20140115 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20140128 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20140417 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140527 |